Splicing and processing method of flat crack array antenna

A processing method and array antenna technology, applied to leaky waveguide antennas, circuits, etc., can solve problems such as narrow application range, high technical difficulty, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

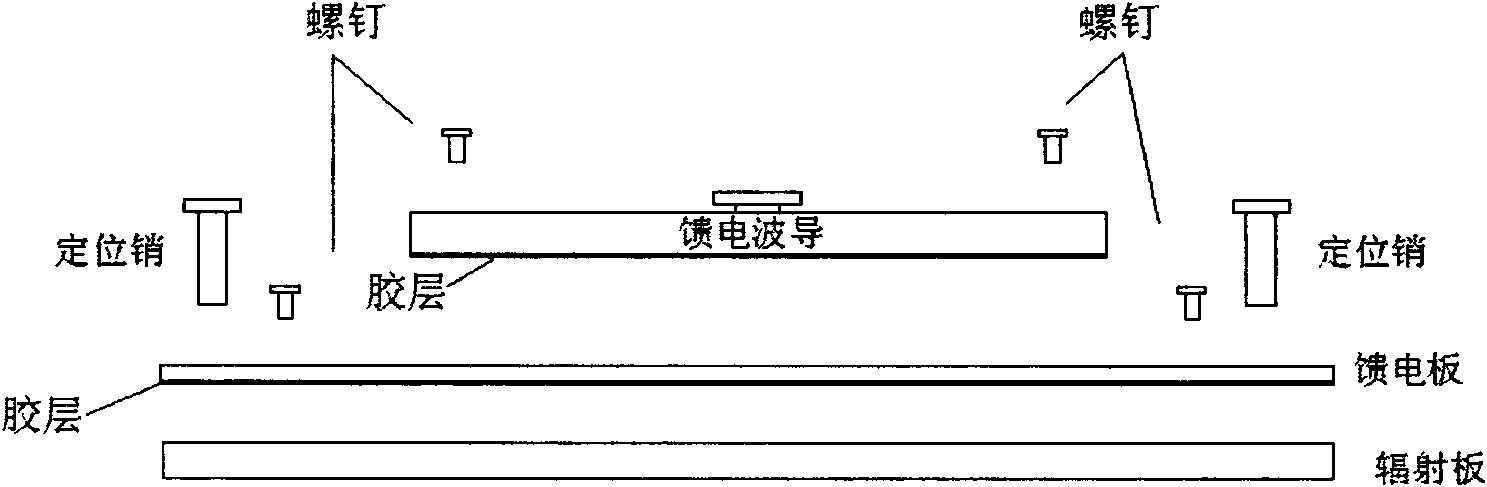

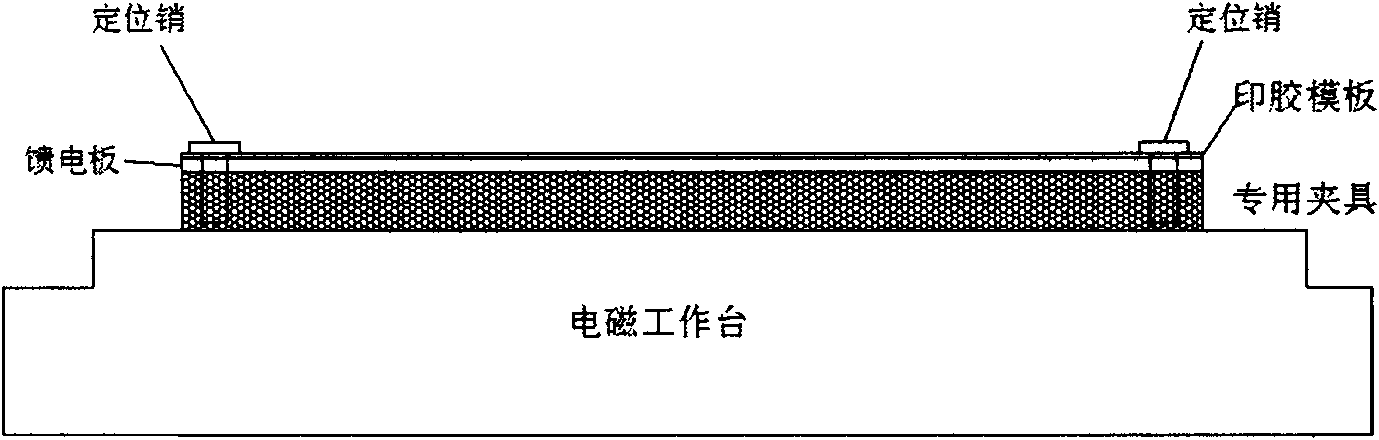

[0035] Refer to attached figure 1 , in the present invention, the planar slit array antenna is divided into radiation plate, feeder plate, feeder waveguide and other parts, between the feeder waveguide and the feeder plate, between the feeder plate and the radiation plate are respectively connected by conductive adhesive and screws, Fixing, wherein the radiating plate is formed by processing the metal aluminum plate out of grooves and cracks, and is bonded with the feed plate through conductive glue to form a waveguide cavity. The positioning pins are used for assembling the antenna and installing the printing template, etc.

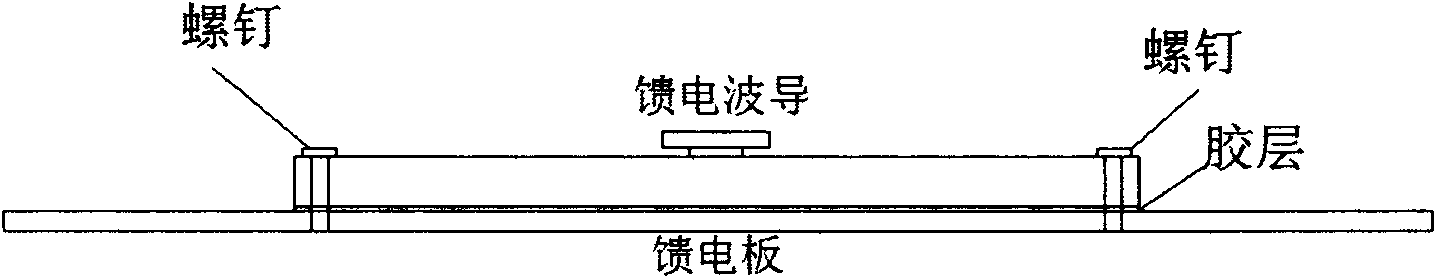

[0036] Refer to attached figure 2 , the present invention first bonds the feed waveguide and the feed plate together, the bonding process is relatively simple, can use manual glue, the glue layer is coated on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com