Mould for producing precise plastic parts

A technology of precision plastics and molds, applied in the field of molds for the production of precision plastic parts, can solve the problems of incomplete separation of products and runner plastics, fragile products, low efficiency, etc. The effect of flat cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

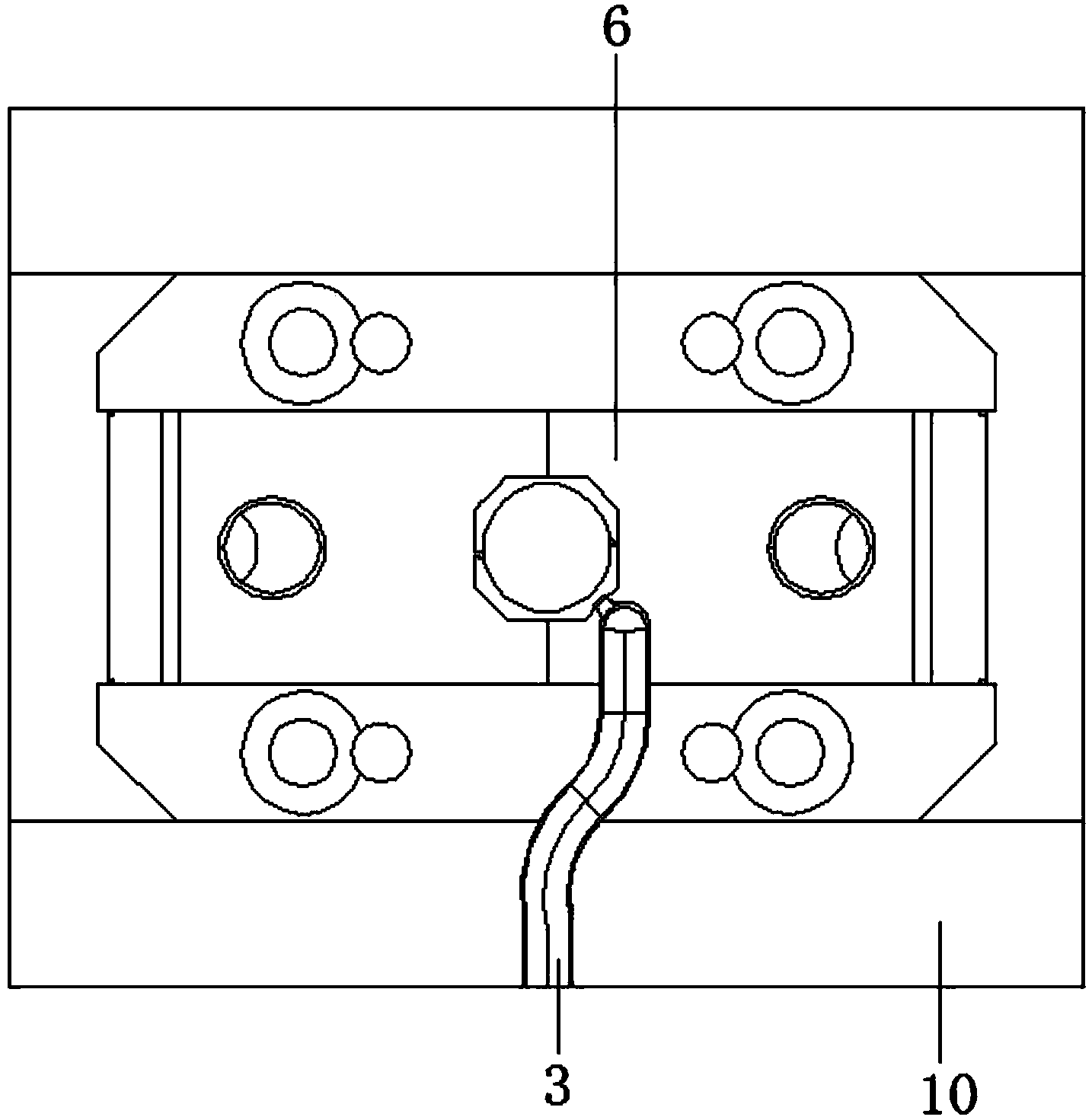

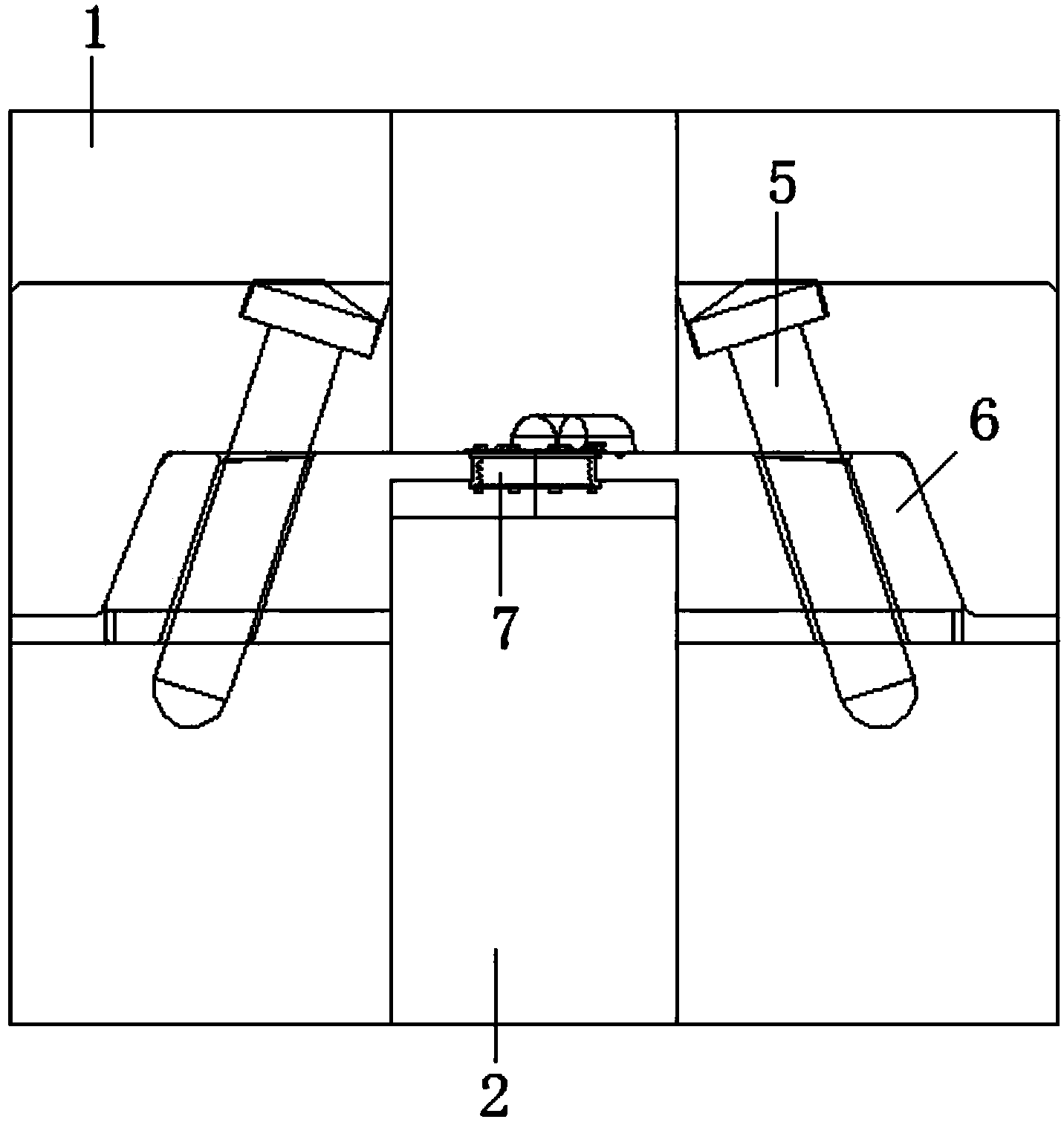

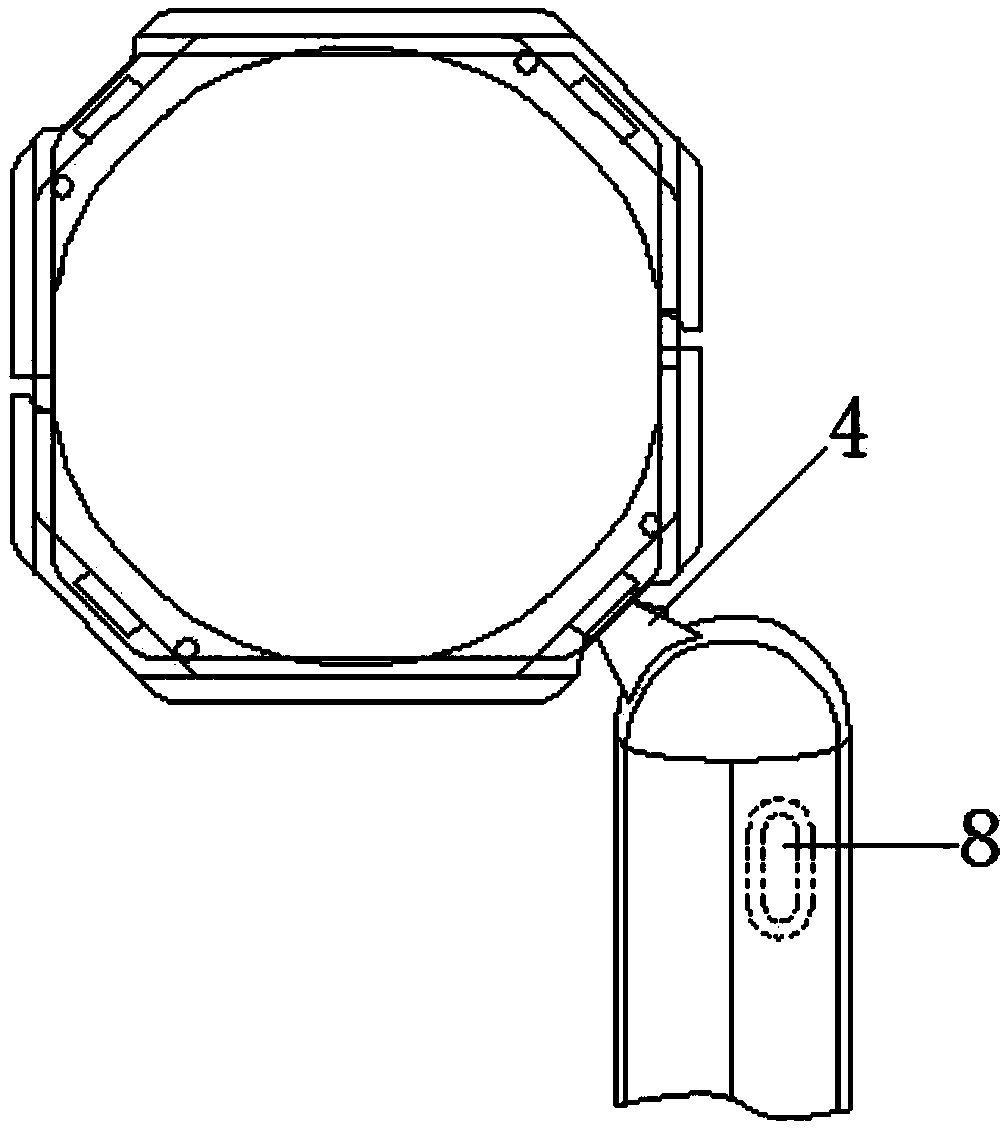

[0019] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 A mold for the production of precision plastic parts is shown, including an upper mold 1, a lower mold 2, and a mold cavity. The mold cavity is communicated with a flow channel 3, and the flow channel 3 is located above the cavity side. The runner 3 includes at least one turning section, and the runner 3 has a submerged section 4 where it contacts the mold cavity, and the uppermost and lowermost upper and lower contours of the submerged section 4 are straight lines, The difference between the angles formed by the upper contour line, the lower contour line and the horizontal plane is greater than 5 degrees, and the described dive section 4 is composed of an upper half and a lower half, and the length of the lower half is at least twice the length of the upper half , the position of the lower half is lower than the main part of the runner 3, and the upper mold 1 is provided with two opposite sliders 6, the sl...

Embodiment 2

[0021] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The shown mold for producing precision plastic parts has the same basic structure and implementation as in Example 1, except that the angle formed by the upper contour line and the horizontal plane is larger than that formed by the lower contour line and the horizontal plane. , and the angle difference is 15 to 85 degrees. The upper half includes two upper sides, and the lower half includes two lower sides. The upper side and the lower side are correspondingly overlapped to form two outer sides 9 of the diving section 4, and the two outer sides 9 are For the inclined surface inclined outwardly at the upper part, the distance between the bottoms of the two outer surfaces 9 is the smallest and is consistent with the height of the opening at the end of the flow channel 3 . The opening at the end of the runner 3 is the glue mouth, and the distance between the bottom of the outer surface 9 is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com