Landscape road floor tile and construction method thereof

A technology of floor tiles and roads, which is applied in the field of landscape road floor tiles and its construction, can solve the problems of inconvenient laying and replacement, complex structure, damaged floor tiles, etc., and achieve the effects of avoiding waste of construction waste, saving costs, and not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

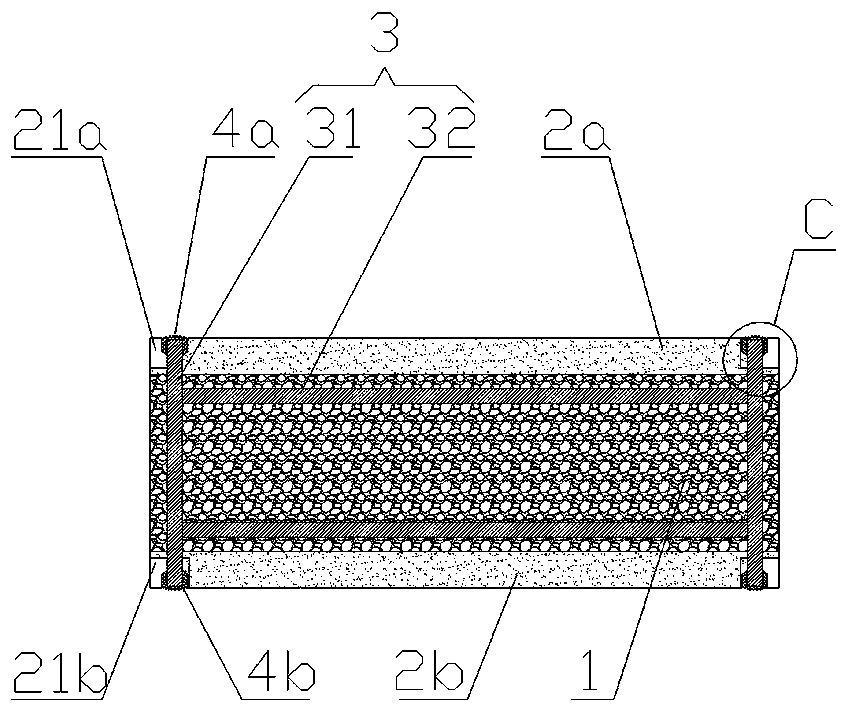

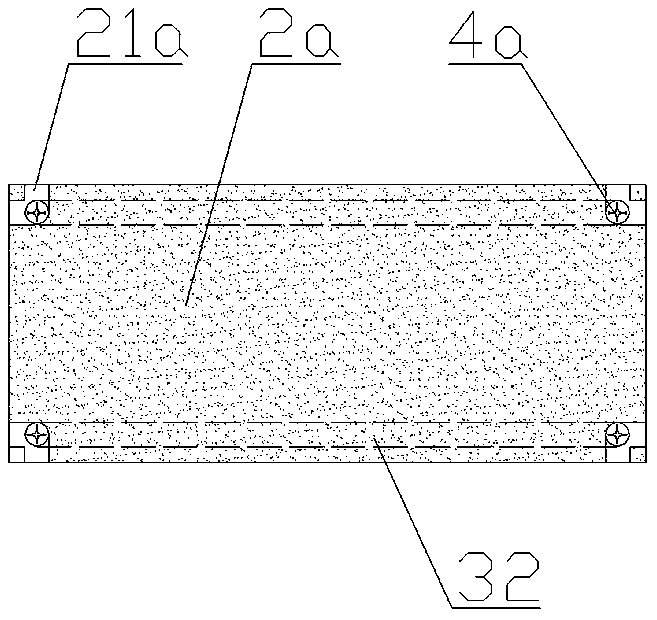

[0042] Such as Figure 1 ~ Figure 4 and Figure 7 ~ Figure 9 As shown, a landscape road floor tile includes a support layer 1, a water guide layer and a steel bracket 3 arranged in the support layer 1;

[0043] The support layer 1 is a block with gaps formed by bonding hard particles (such as construction waste, waste ceramics, or other hard material crushed uniform particles), and the upper and lower surfaces of the support layer 1 are parallel to each other; The water-conducting layer is a plate-shaped body with gaps formed by bonding elastic granular materials (such as rubber particles, plastic particles, etc.); The water-guiding layer 2a and the lower water-guiding layer 2b are respectively fixed on the upper and lower surfaces of the supporting layer 1, and the upper water-guiding layer 2a, the supporting layer 1 and the lower water-guiding layer 2b form a brick body; the floor tiles are in the shape of a cube, a cuboid, or a regular hexagonal prism Or other splicable r...

Embodiment 2

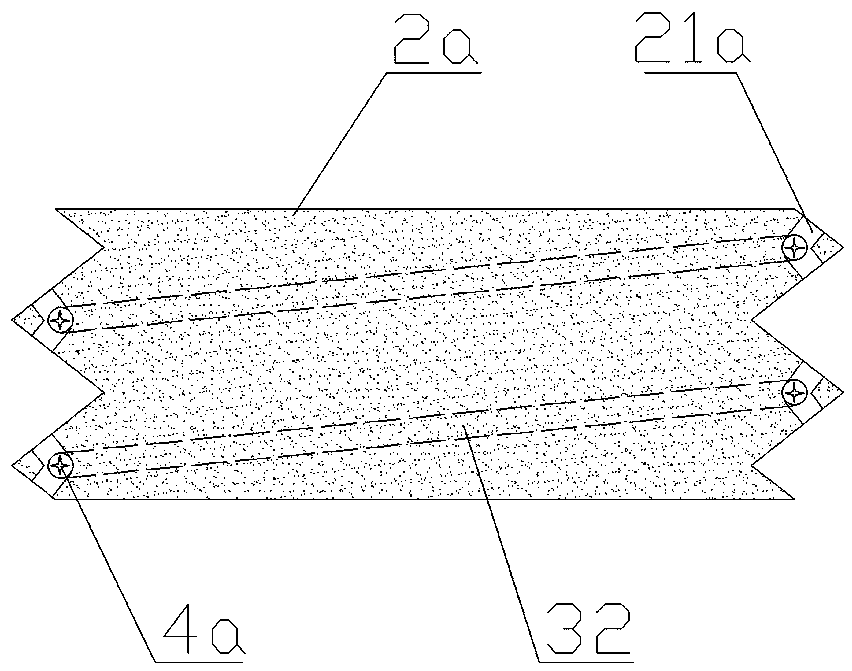

[0058] This embodiment is basically the same as Embodiment 1, the difference is that, as Figure 5 ~ Figure 6 As shown, there are more than two steel brackets 3, and the centers of the cross bars 32 of the two or more steel brackets 3 are misaligned and cross each other.

[0059] Such as Figure 5 As shown, when there are three steel brackets 3, the two cross bars 32 of the second steel bracket 3 are located between the two cross bars of the first steel bracket 3, and the two cross bars 32 of the third steel bracket 3 are located Between the two cross bars 32 of the second steel bracket 3 .

[0060] The cross bars 32 of two or more steel brackets 3 are misaligned and intersected with each other, which is mainly applied to regular polygonal columnar floor tiles, because they have no length direction during application, and each steel bracket 3 should be evenly distributed to strengthen the floor tiles as a whole.

[0061] The construction method of any one of the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com