Delivery mechanism enabling reel to be compressed

A technology of conveying mechanism and reel, applied in the directions of external support, transportation packaging, packaging, etc., can solve the problems of waste cost, unsightly packaging, skew, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

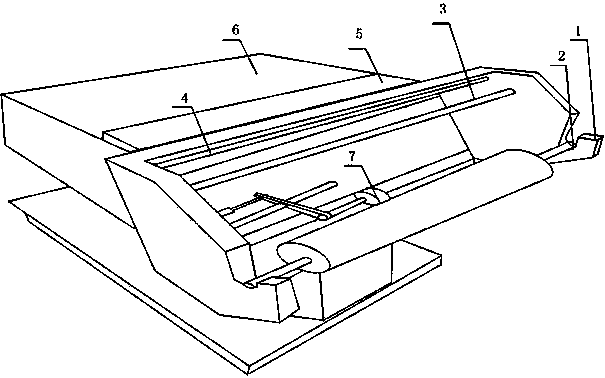

[0020] see figure 1 , the conveying mechanism that can compress the reel, comprises feeding position and workbench 6, and above-mentioned sending position comprises film reel placement position 1, and film reel placement position 1 is left and right symmetrical two, and this film reel placement position 1 is set On the symmetrical plate at both ends of the upper part of the feeding position, a U-shaped groove 2 is provided at the place 1 where the film reel is placed, and a pressing device 7 is also arranged on the symmetrical plate at one side of the upper part of the feeding part, and the pressing device 7 and A retractable device is also connected between the symmetrical plates at the upper end of the feeding position.

Embodiment 2

[0022] Similar to Embodiment 1, specifically, a roller 3 and a tension roller 4 are also included.

[0023] Above-mentioned roller 3 and tension roller 4 are arranged in parallel on the upper symmetrical plate at both ends of the feeding position, and are parallel to the connection line of the film reel placement position, and above-mentioned tension roller 4 is located above roller 3 . when thin

[0024] After the film comes out from the place where the film roll is placed below, it is pulled to the roller 3, wound from the bottom of the roller 3 to the top of it, and then passes through the tension roller 4 to further tension the film.

[0025] The workbench 6 includes a film separating part 5, which is arranged parallel to the upper end of the dispensing part, and the cross-sectional area of the above film separating part 5 is triangular. The film separating part 5 divides the film into upper and lower parts, wraps the product up and down, and sends it to the cutting par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com