Packaging film receiving device

A packaging film and film device technology, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problems of wasting packaging film, wasting raw materials, and unusable packaging film, so as to save raw materials and time, and guarantee smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it should be noted that the description of the following embodiments is schematic and does not constitute a specific limitation to the present invention.

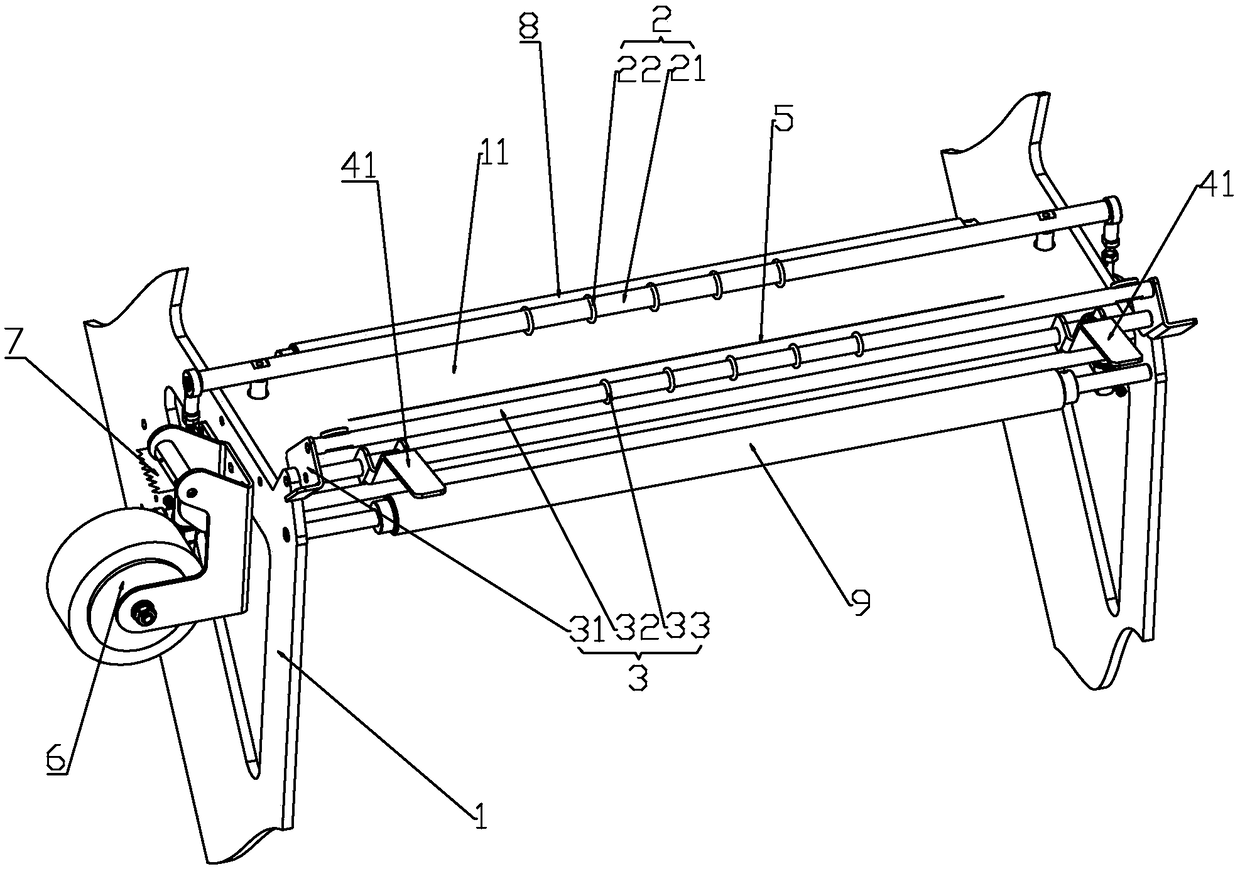

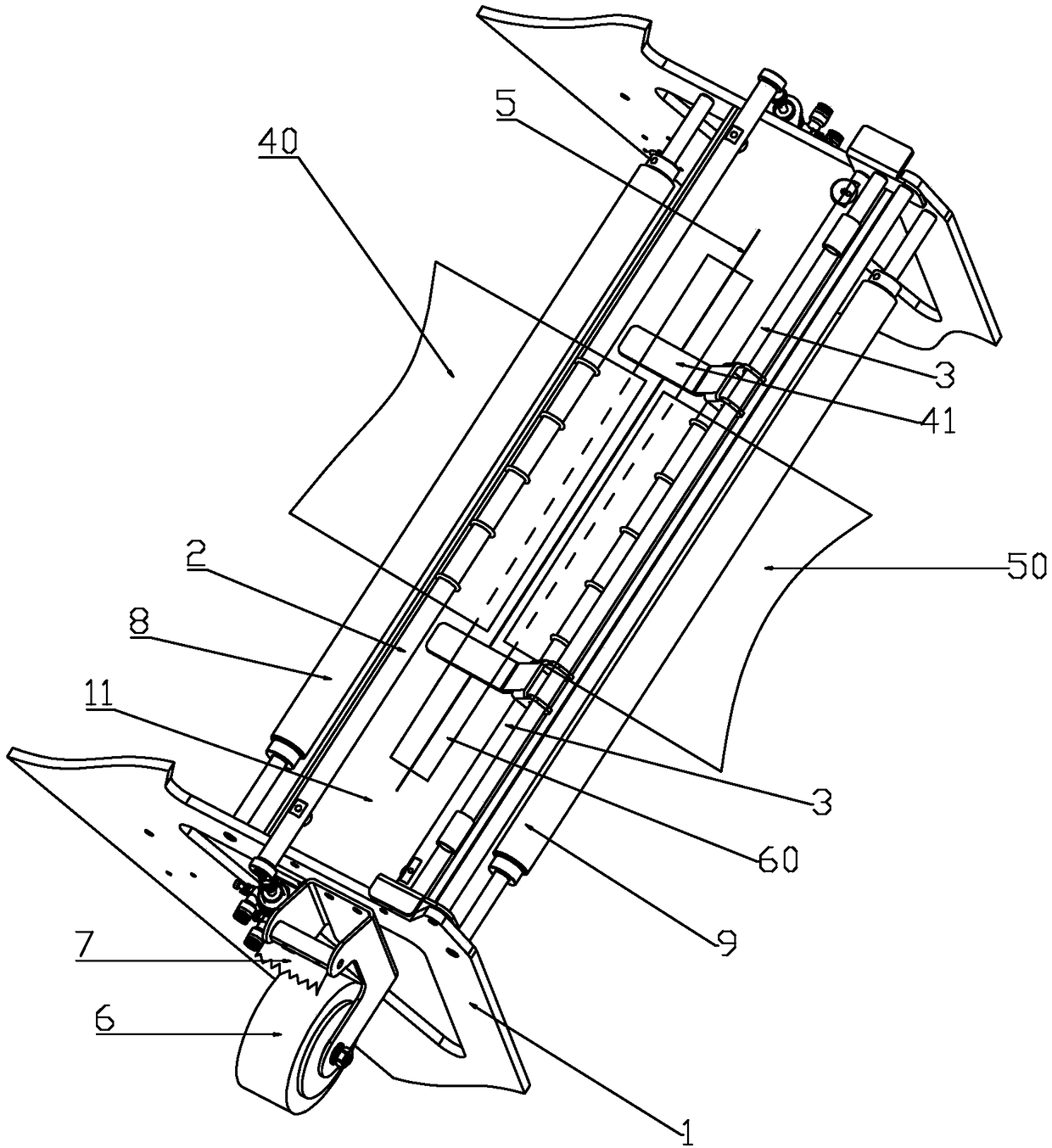

[0019] refer to figure 1 and figure 2 , a film bonding device for packaging films, comprising: a mounting frame 1, on which a worktable 11 is arranged, and the worktable 11 is provided with a film bonding area and a front area and a rear area located at the front and rear of the film bonding area; A film pressing mechanism 2, which is movably arranged on the mounting frame 1, is used to press the packaging film left on the drive roller after cutting to the front area; a second film pressing mechanism 3, which is movably arranged on the mounting frame 1 , used to compress the free end of the packaging film on the replaced roll material on the rear area; the adhesive film su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com