Instrument identifier for deep space probe

A deep space detector and marking technology, which is applied in the field of surface marking of deep space detectors, can solve the problems of difficult to prepare coatings with high adhesion, high quality of metal materials, inability to meet the requirements, and achieve good printing adaptability. , reduce resource utilization, good film quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

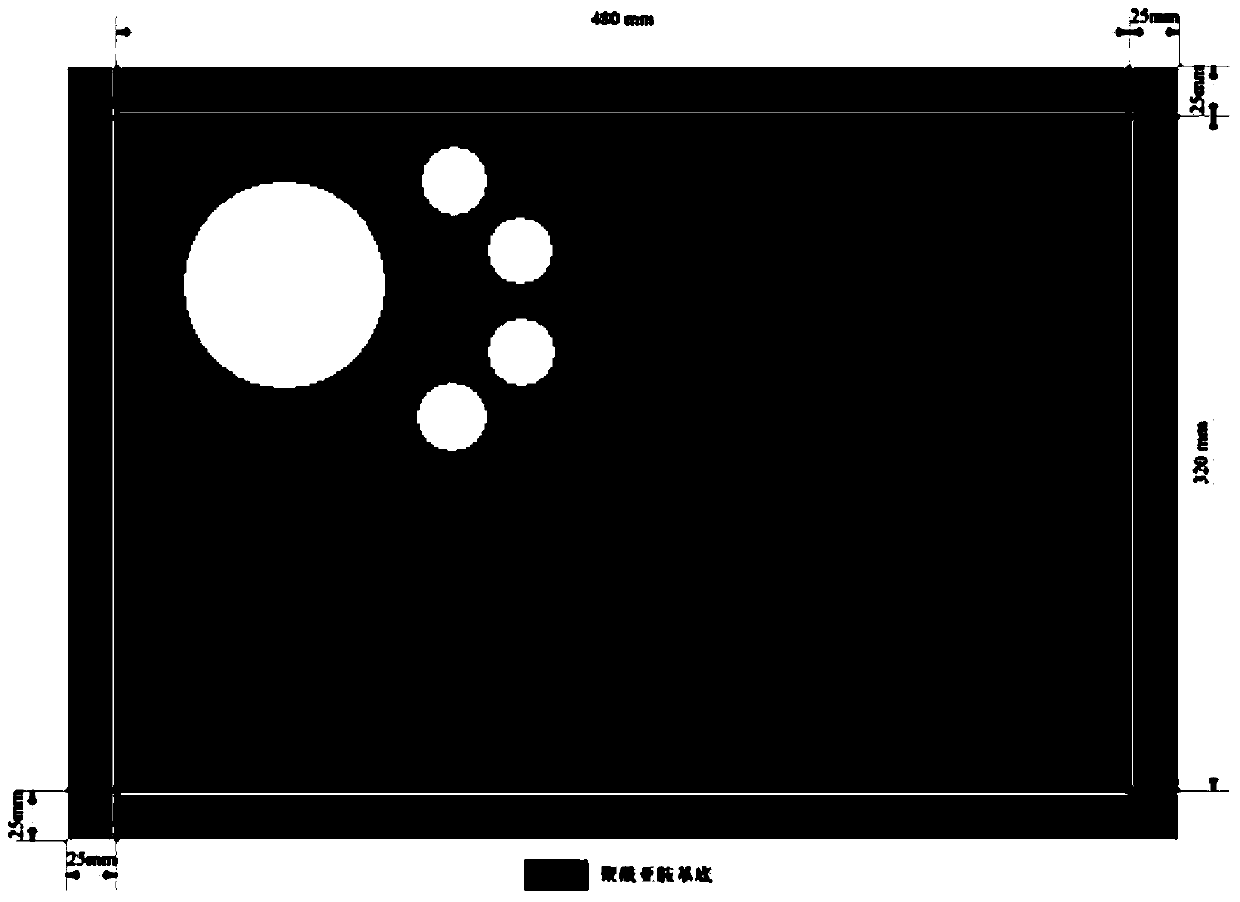

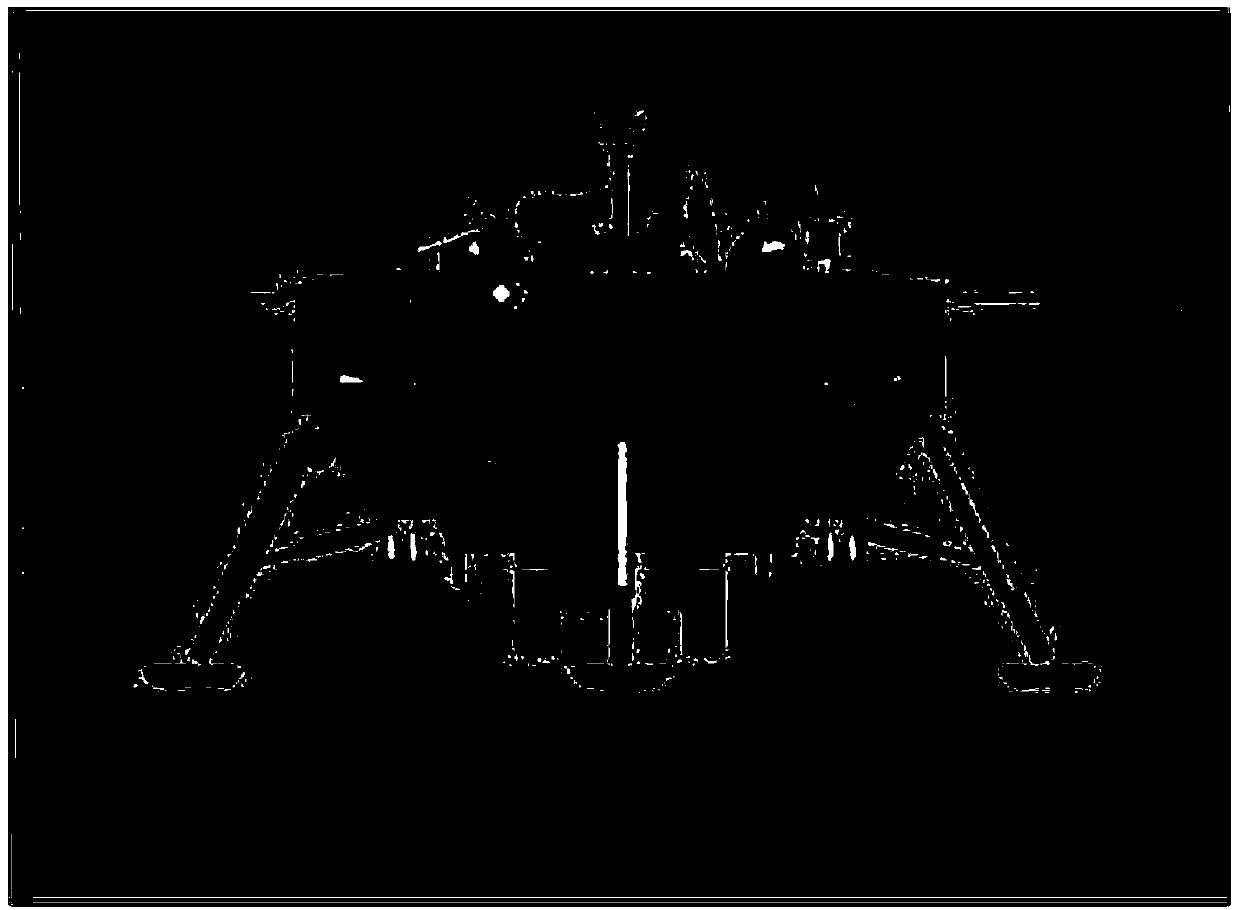

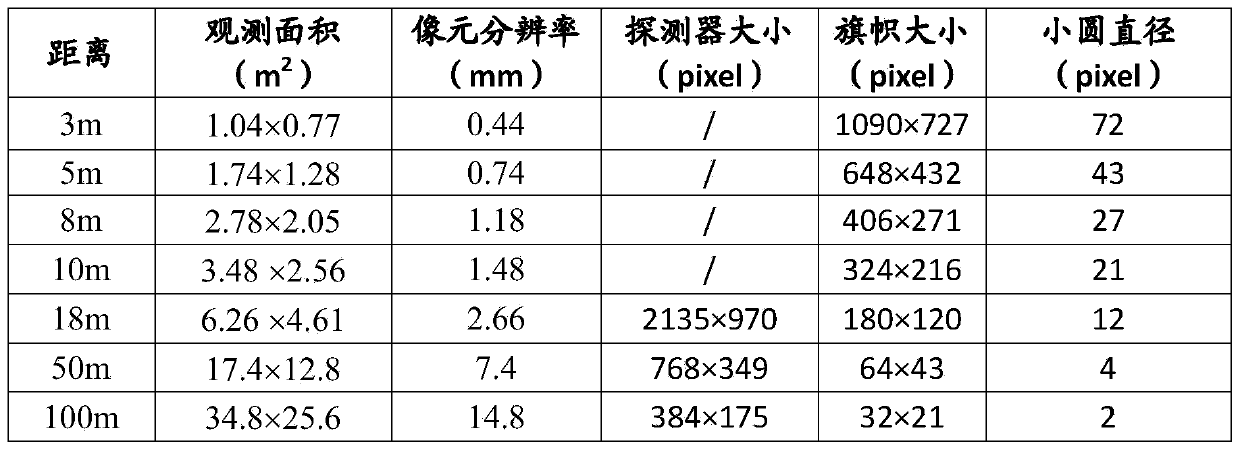

Image

Examples

Embodiment 1

[0039] In the marking synthetic paint, the proportions of the main components are as follows: silicone resin accounts for 55% (weight) of the overall synthetic paint consumption; modified resin accounts for 36% (weight) of the overall synthetic paint consumption; organic pigments account for the overall synthetic paint. 5% by weight of the amount; 4% by weight of the adjuvant.

Embodiment 2

[0041] In the marking synthetic paint, the proportions of the main components are as follows: silicone resin accounts for 65% (weight) of the total synthetic paint; modified resin accounts for 24% (weight) of the overall synthetic paint; organic pigments account for the overall synthetic paint 5% by weight of the amount; 6% by weight of the adjuvant.

Embodiment 3

[0043] In the marking synthetic paint, the proportions of the main components are as follows: silicone resin accounts for 65% (weight) of the total synthetic paint; modified resin accounts for 24% (weight) of the overall synthetic paint; organic pigments account for the overall synthetic paint 3% by weight of the amount; 8% by weight of the adjuvant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com