Patents

Literature

44results about How to "Improve output per unit time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

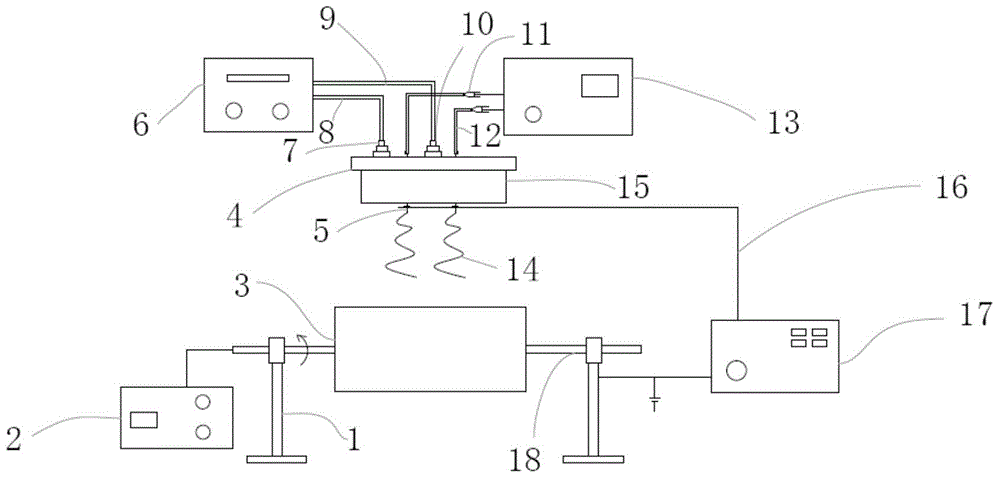

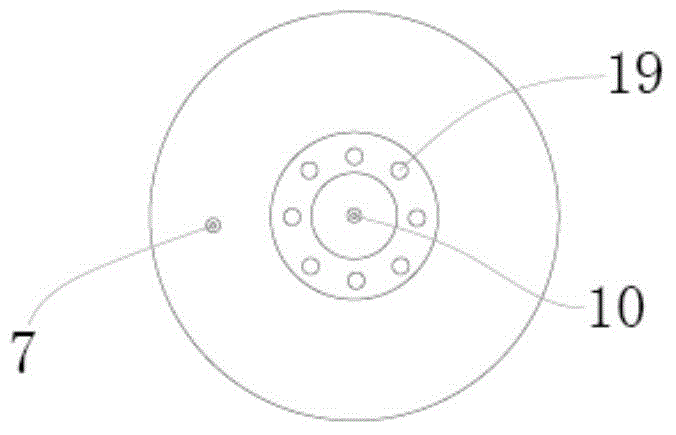

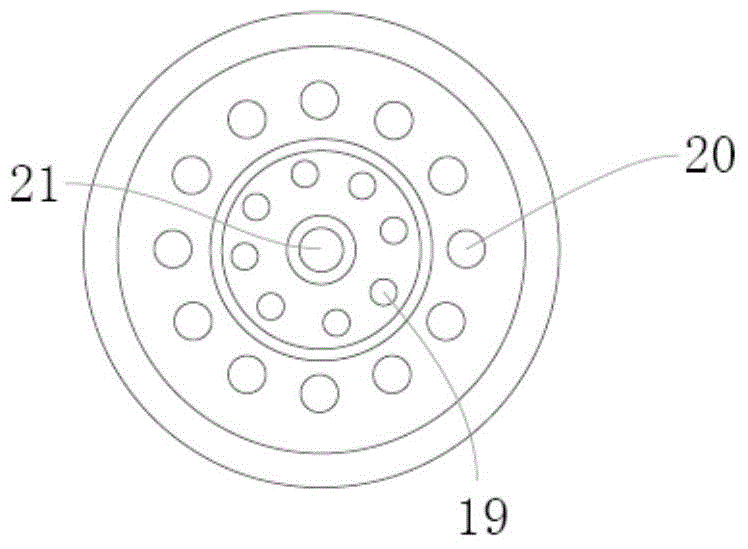

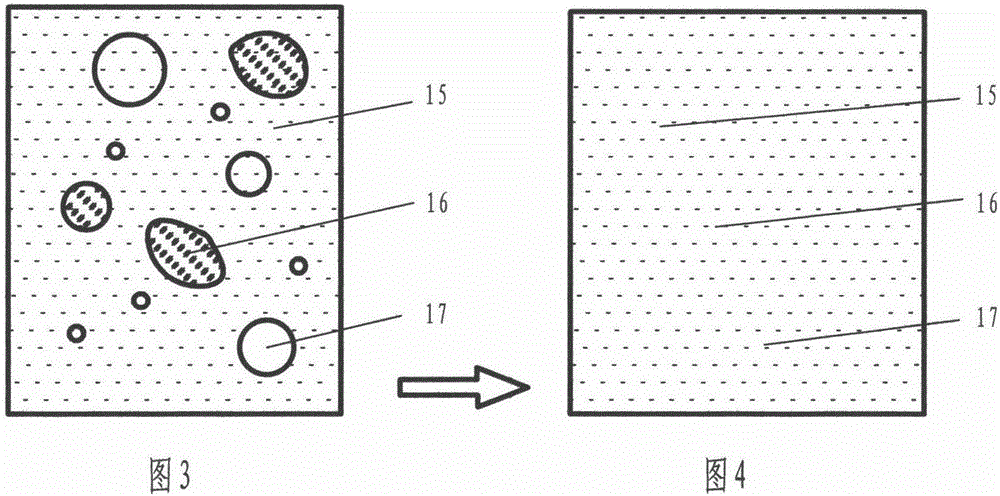

Air jet assisting multi-needle electrostatic spinning device and method for preparing nanofiber net through air jet assisting multi-needle electrostatic spinning device

InactiveCN104862788ASpeed up evaporationFaster curing and running speedFilament/thread formingNon-woven fabricsInjectorAirflow

The invention discloses an air jet assisting multi-needle electrostatic spinning device which comprises a spinneret plate with the air jet assisting function. Multiple metal needles are arranged on the spinneret plate. The head ends of all the metal needles are connected in series through a wire. The wire is connected with the positive electrode of a direct-current high-pressure generator. The tail end of each metal needle is connected with an injector through a liquid guide pipe. The injector is driven through a micro-injection pump. A receiving device is arranged below the spinneret plate and connected with the negative electrode of the direct-current high-pressure generator. By the adoption of the air jet assisting multi-needle electrostatic spinning device, the spinneret plate with the multiple needles serves as a spinning module, on the basis, the air jet assisting function is added to increase the volatilizing speed of a spinning solvent, accelerate jet flow solidification and increase the operation speed, so that the yield of unit time of nanofibers is increased, the fibers are stretched to a certain degree through jet air flow, and the nanofibers with the smaller diameter can be acquired.

Owner:XI'AN POLYTECHNIC UNIVERSITY

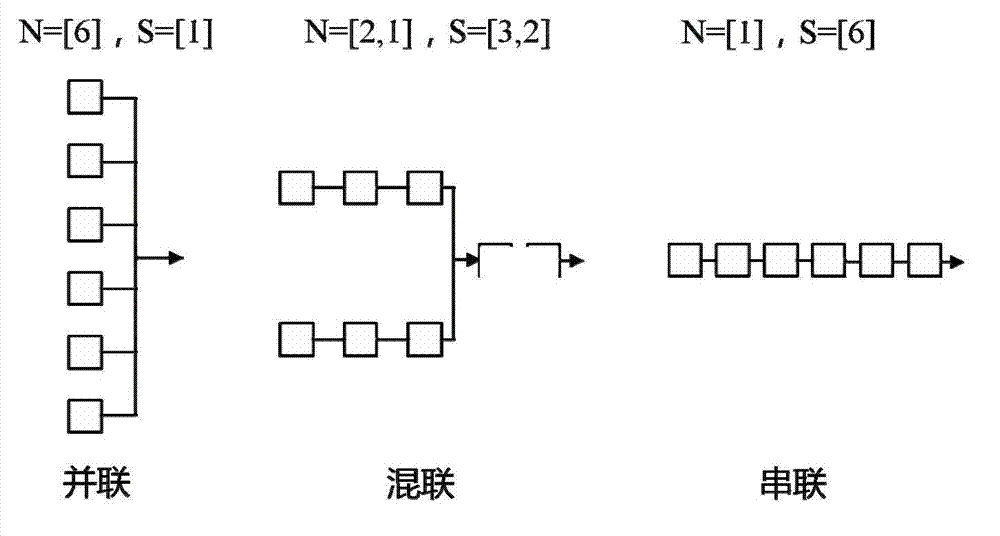

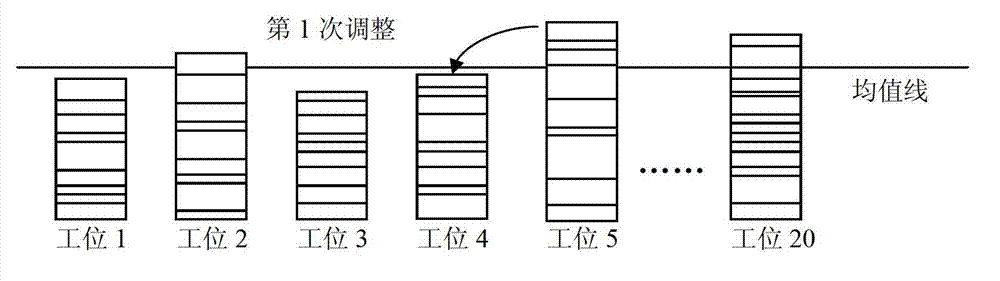

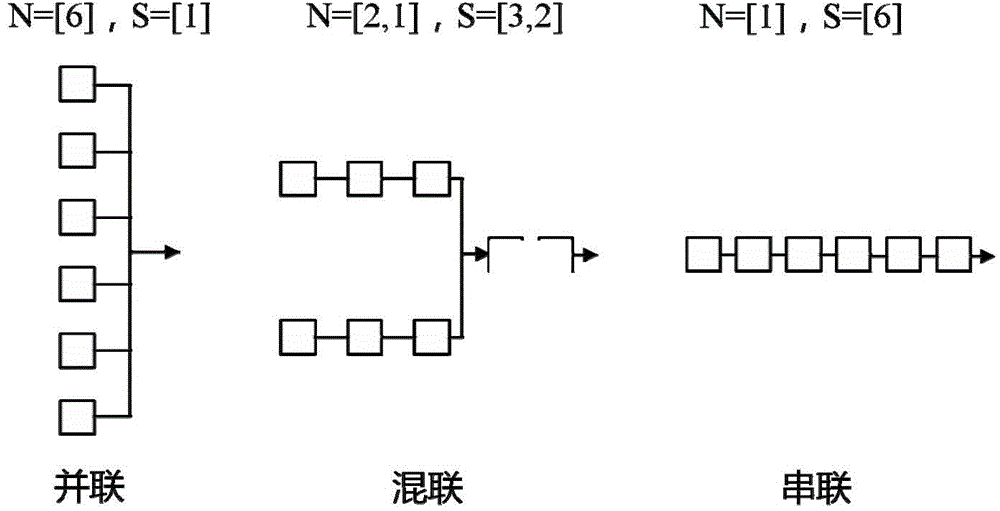

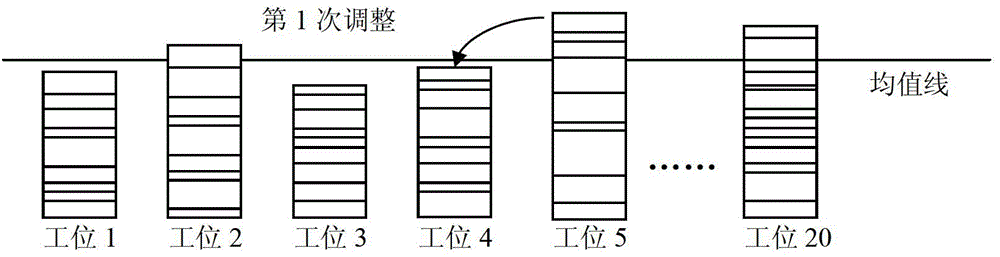

Optimal design method for production line layout

ActiveCN103049801AReduce the impact of volatilityIncrease production capacityForecastingProduction lineTotal investment

The invention relates to the field of engineering manufacture, in particular to an optimal design method for production line layout. The technical problem that the influence of production fluctuation on production efficiency cannot be reduced by the conventional method so as to reduce enterprise benefits is solved. According to the scheme, the optimal design method for new production line layout mainly comprises the following steps of: acquiring the labor house data of original sub-procedures; generating functional segments and a station number by adopting a line balancing planning method, so that the cycle time of a single line in each functional segment is shortest; when total investment C is determined, finding all N and S combinations consistent with a constraint condition by using an enumeration method; calculating the cycle time of each functional segment; calculating the overall cycle time of each [N, S] scheme; and performing calculation according to the steps, and when the total investment C is determined, determining a scheme with the shortest cycle time in all the [N, S] schemes as a target scheme. The method can be used for the design of the new production line layout and the modification of the conventional production line layout.

Owner:四川长虹智能制造技术有限公司

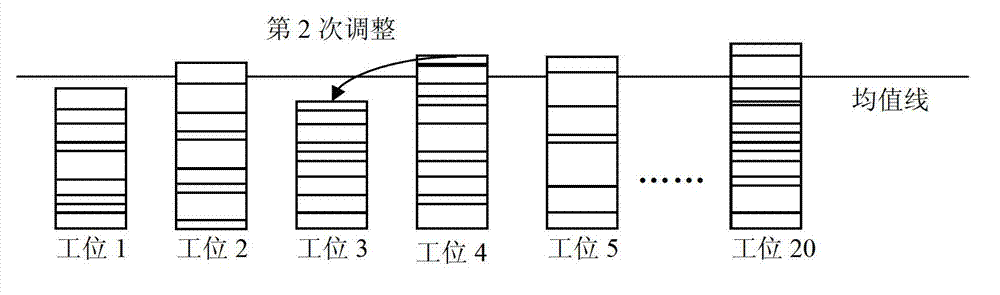

Production process of single-head spin high modulus low shrinkage polyester industrial filament

The invention relates to a production technique of a single-head spinned high modulus low-shrink industrial polyester filament. The technique includes the steps: 1. the processing of high-viscosity polyester slices: firstly pre-crystallizing is carried out for the polyester slice and then solid phase polymerization is carried out for polyester slice and then the viscosity of the polyester slice can reach 1.25 to 1.35 dl / g; 2. melt spinning: the polyester slice is transferred to a high-flow spinning screw extrusion machine with screw-diameter of 125 to 160mm, fused mass is extruded out from the spinning screw extrusion machine, then the fused mass is distributed to fused mass branch pipes through a fused mass header pipe, and the fused mass enters a spinning element through a measuring pump and then is extruded out from a spinneret plate with diameter of 220 to 240mm; the extruded filaments are heated by a slow-cooling heating ring, are cooled for forming through an annular air-blowing device and then enter spinning shafts; 3. stretch-wrap forming: the surfaces of filaments are oiled, filaments are stretched at a two-level high speed with total stretching-multiple of 1.8 to 2.2; then the filaments are loosely formed under high temperature between 230 and 260 DEG C and are wrapped with the technique speed of 5200 to 6500 meters / minute to obtain the finished product.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

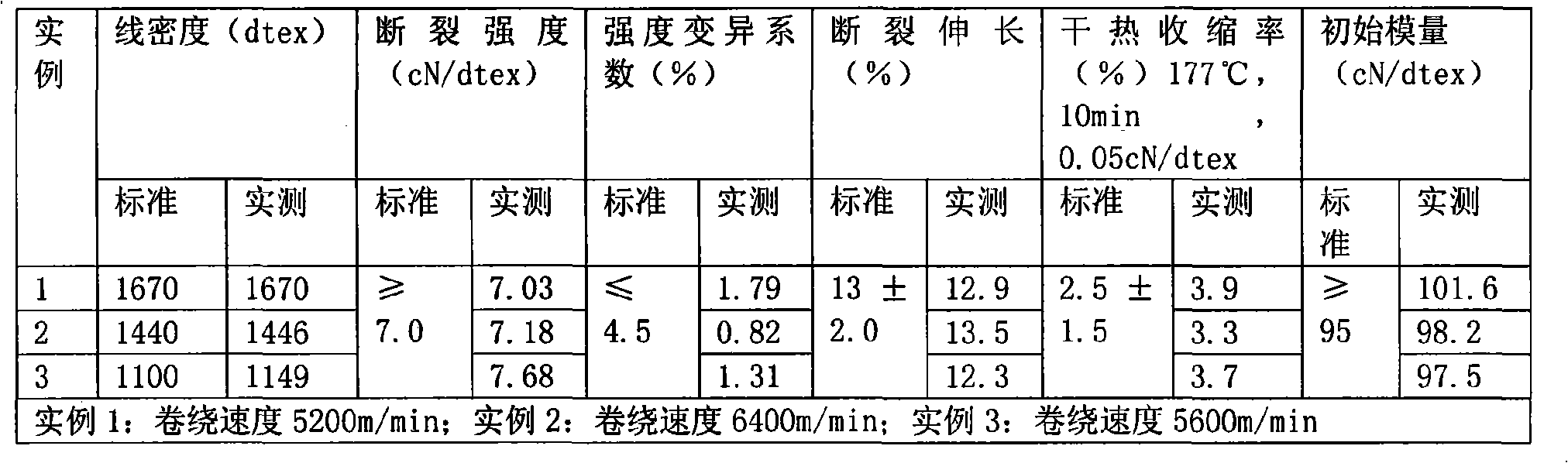

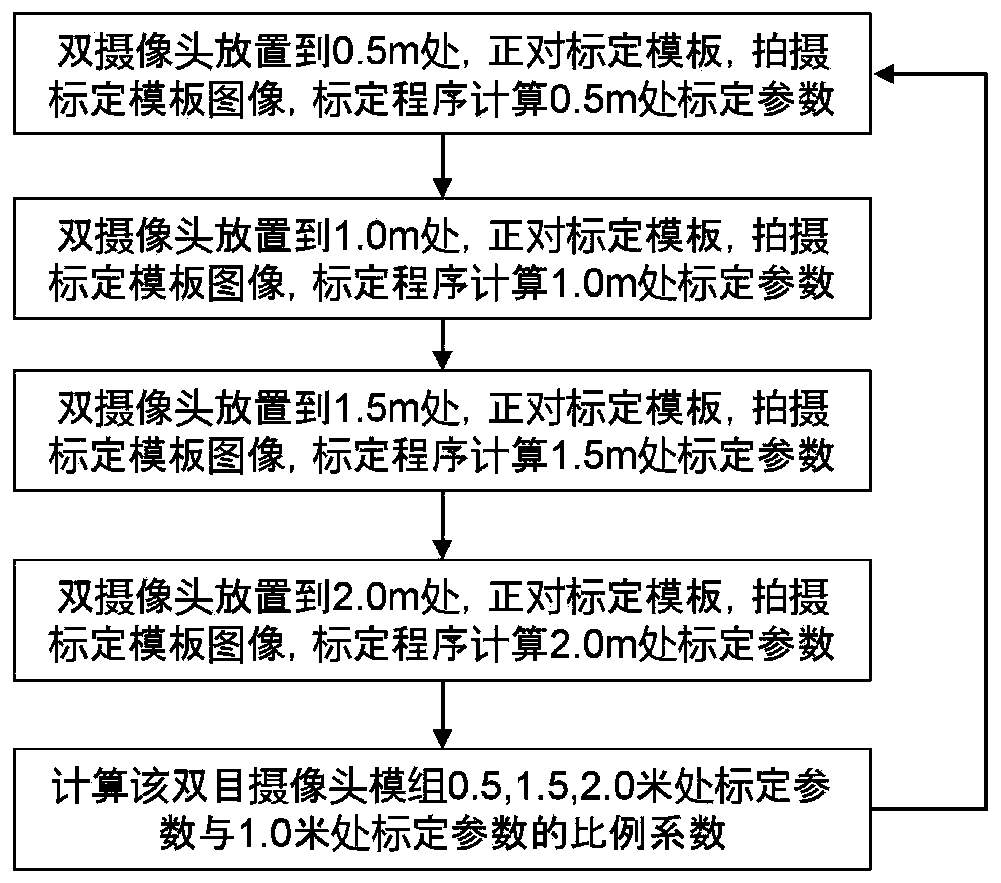

Automatic focusing binocular camera calibration and depth calculation method

PendingCN109767476AIncrease productivityShorten the calibration timeImage analysisManufacturing computing systemsPhysicsImage analysis

The invention provides an automatic focusing binocular camera calibration method. The automatic focusing binocular camera calibration method comprises the following steps: A1, obtaining a calibrationtemplate image from a standard calibration distance; A2, analyzing and processing a single calibration template image shot at the standard calibration distance, and acquiring calibration parameters ofthe binocular camera at the standard calibration distance through calculation; A3, calculating calibration parameter approximate values of the plurality of specific calibration distances according toa pre-obtained proportionality coefficient of the calibration parameters of the binocular camera module at the plurality of specific calibration distances and the calibration parameters of the standard calibration distance, wherein the calibration parameters of the binocular camera module are measured at the standard calibration distance; And A4, taking the approximate value as a production linecalibration result of the automatic focusing binocular camera. When the binocular camera is used, more accurate calibration parameters and more accurate depth values are obtained through online updating and iteration of the calibration parameters based on the currently photographed image.

Owner:像工场(深圳)科技有限公司

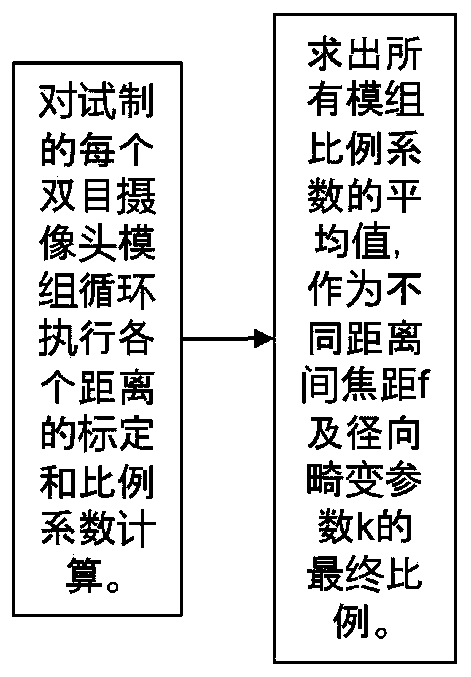

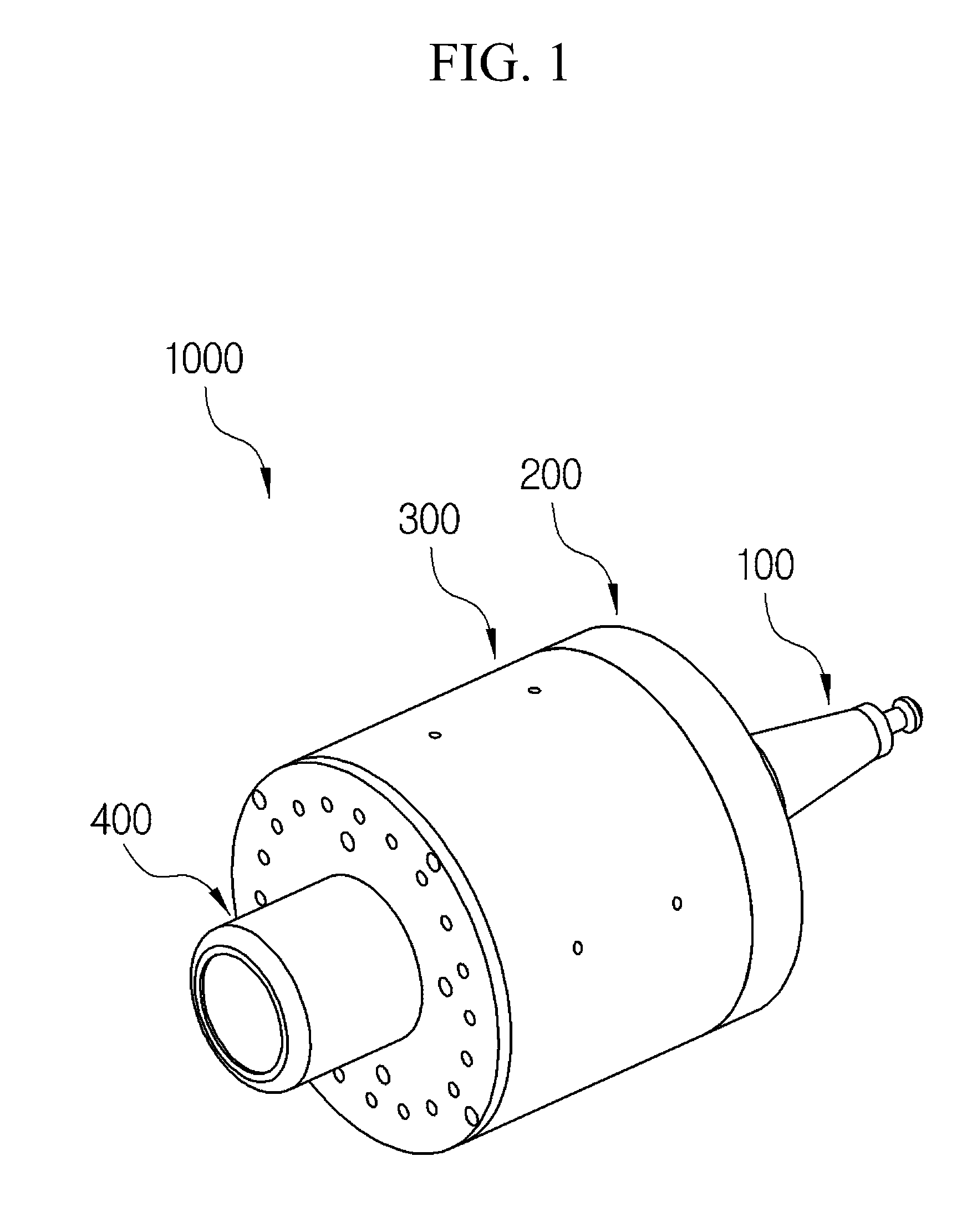

Built-in type vision based inspection tool for autonomous setting of initial origin

ActiveUS20150094844A1Reduce shapingMinimize delayAutomatic control devicesImage analysisVirtual machiningVision based

The present invention relates to a vision based inspection tool for setting of an initial origin of an automation machine tool, and more particularly, to a built-in type of vision based inspection tool for setting of an initial origin capable of improving setting precision of a current automation machine tool that depends on initial setting and increasing productivity depending on individual automatic setting by automatically sensing a machining origin in order to perform initial machining and re-machining of an existing workpiece using an automation machine tool and compensating for the machining origin to eliminate a time required for setting machining origins for various shapes in a jog mode.

Owner:KOREA INST OF MACHINERY & MATERIALS

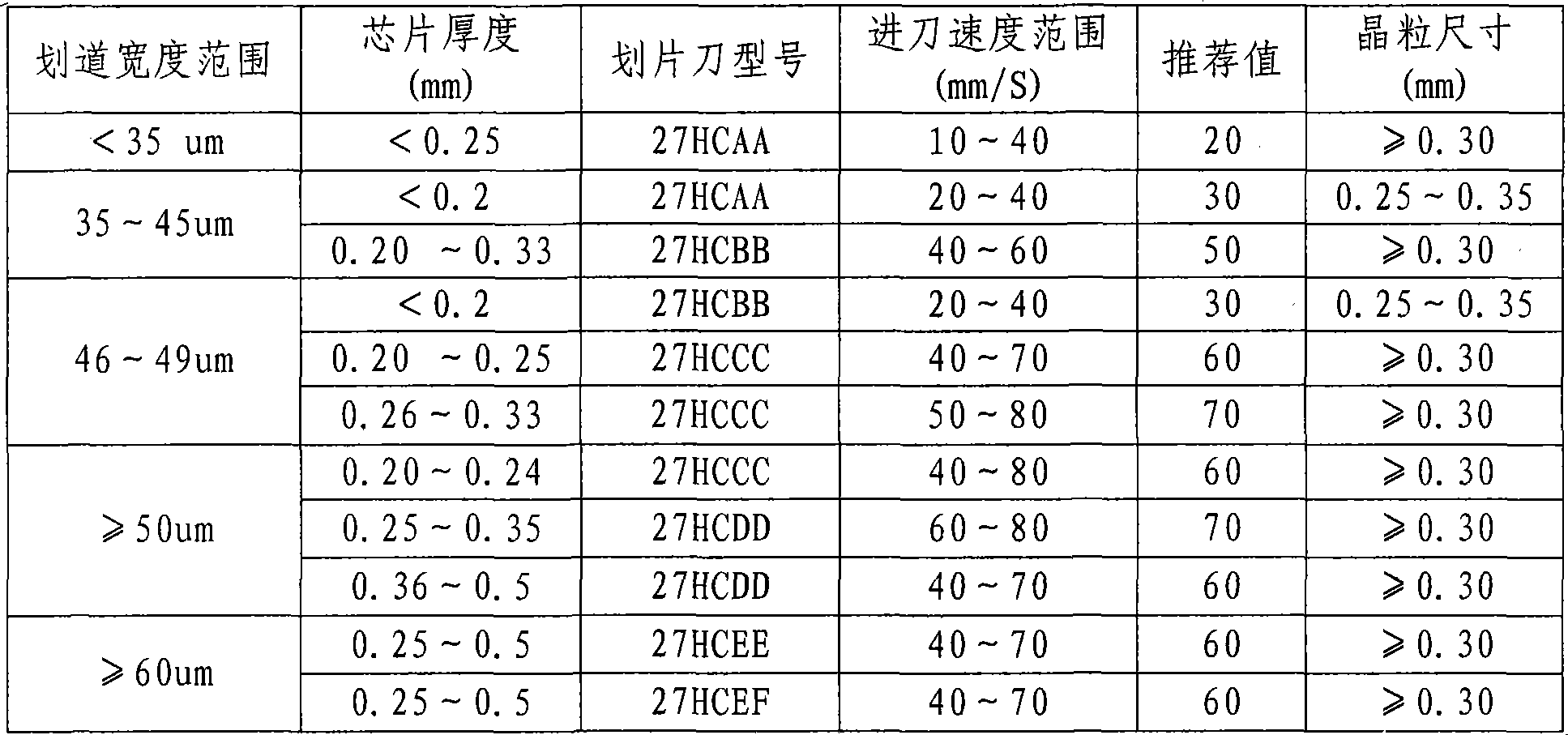

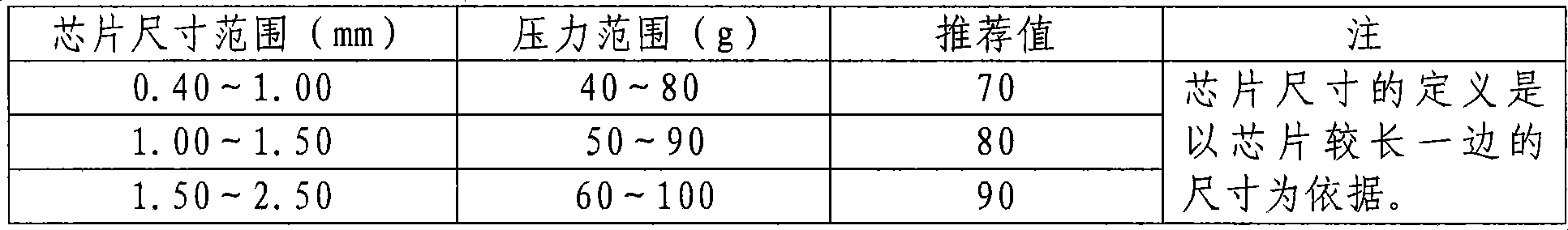

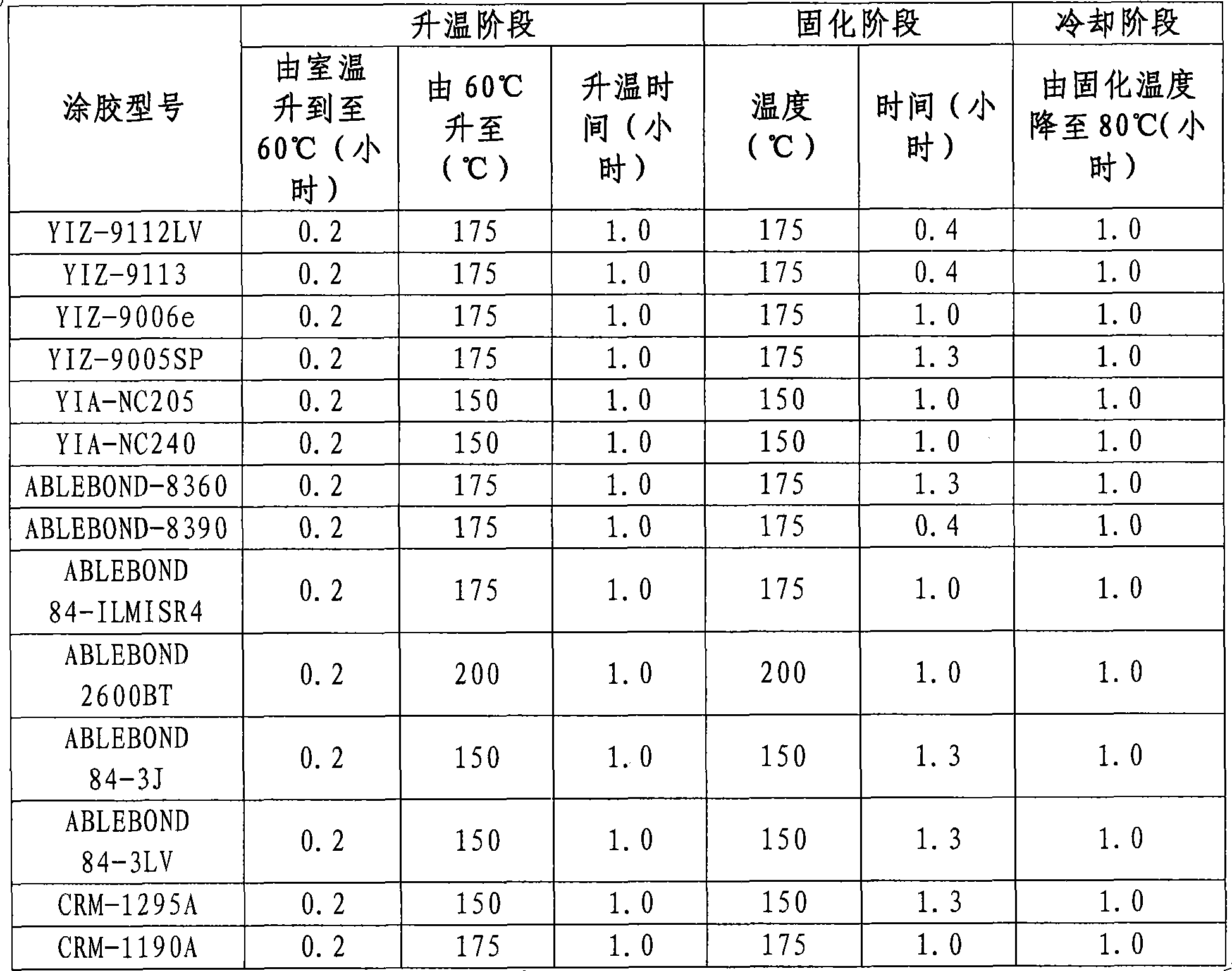

Method for preparing crystal round back electrode and crystal round

InactiveCN101350296AReduce dosageEliminate FringingSemiconductor/solid-state device manufacturingSemiconductor devicesScreen printingRound back

The invention discloses a wafer whose back side is coated with adhesive through adopting the silk screen printing and a process for preparing a back electrode of the wafer, the preparation process comprises the following five steps: preparing a wafer, and keeping the wafer flat in the subsequent steps, adopting the silk screen printing to coat the adhesive on the back side of the wafer and drying, arranging the wafer which is coated with the adhesive on a scribing blue film, separating, adhering and solidifying the separated wafer. The process eliminates the flanging phenomenon which easily occurs during the preparation of the wafer, the dosage of bonding slurry is reduced by one-third, the cost of the bonding slurry is greatly reduced by about ten percent, and the flatness of the coating surface of a back electrode of the chip is guaranteed, a scribing is easily cut, the intensity of the combination between the chip and the electrode during the eutectic welding is guaranteed, and the production time and cost are greatly saved. The wafer whose back side is coated with the adhesive of the invention can be stored for a long time, and the control to the quality of the stock is improved.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +1

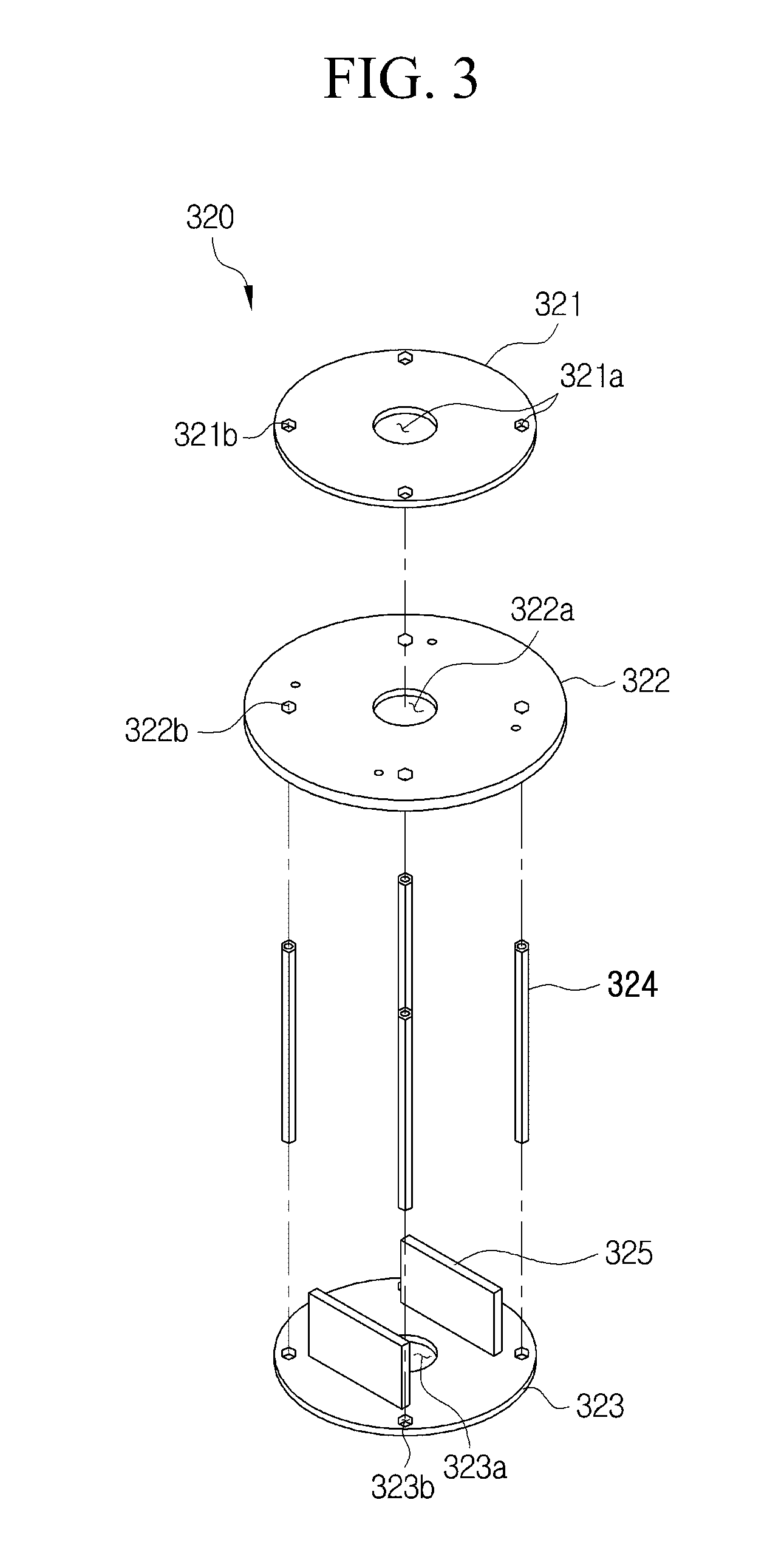

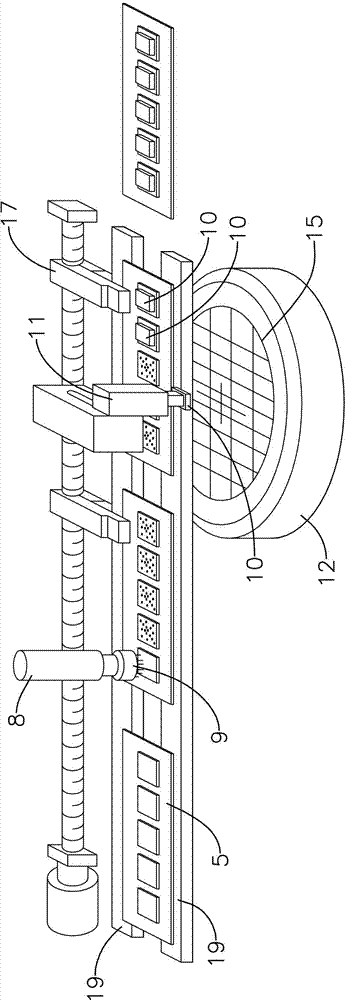

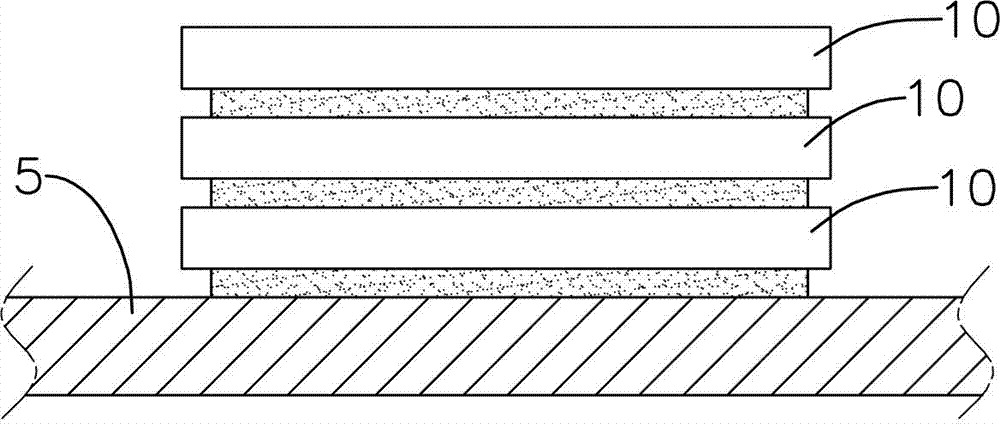

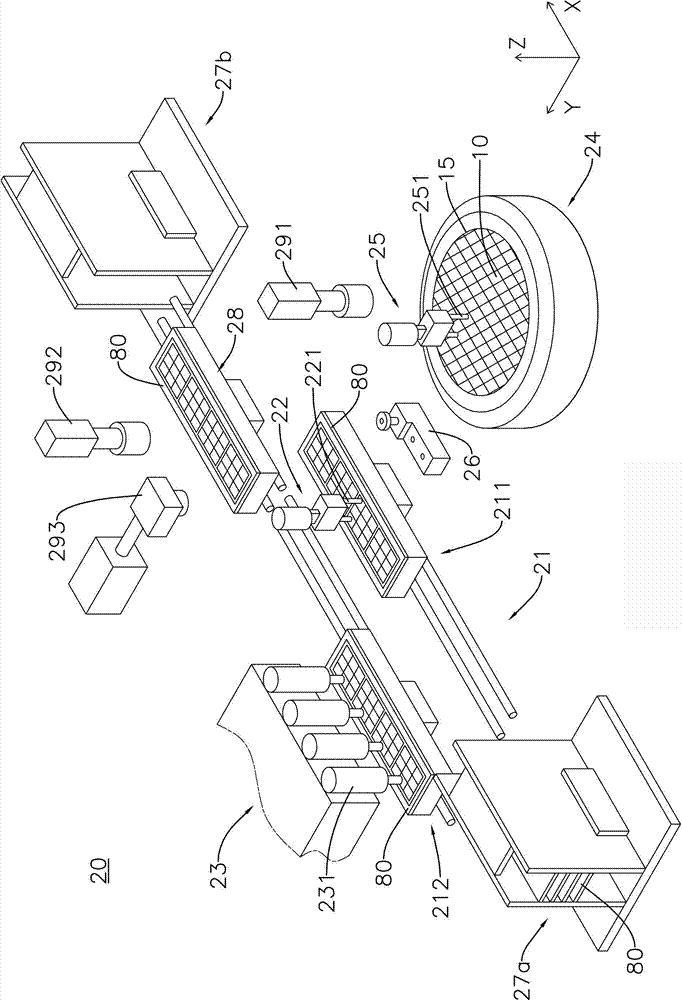

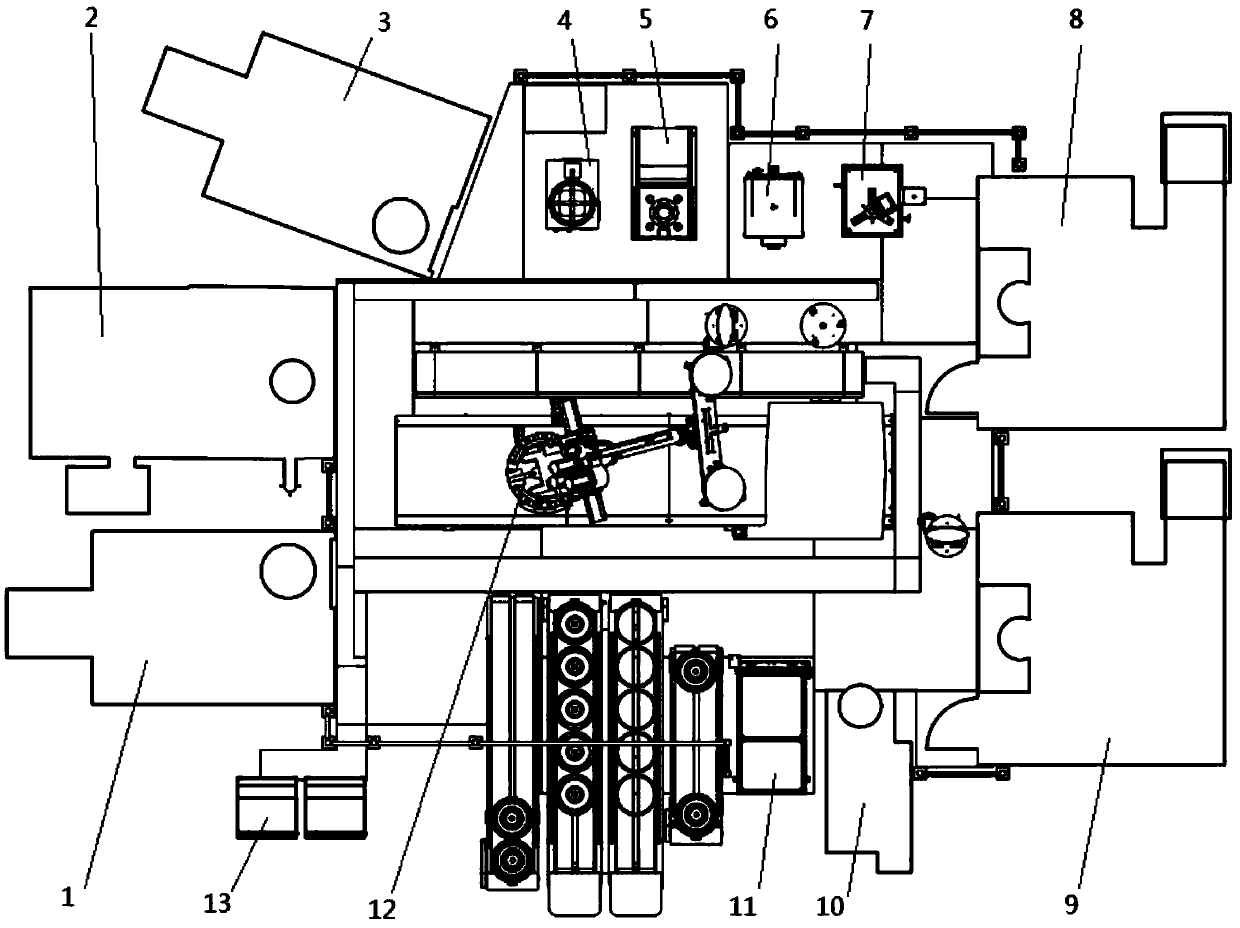

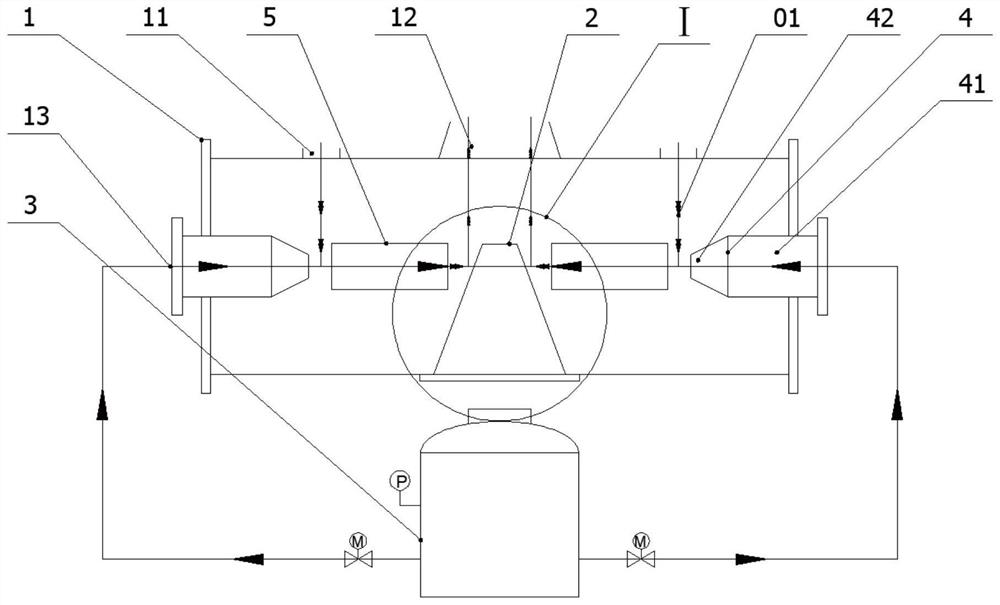

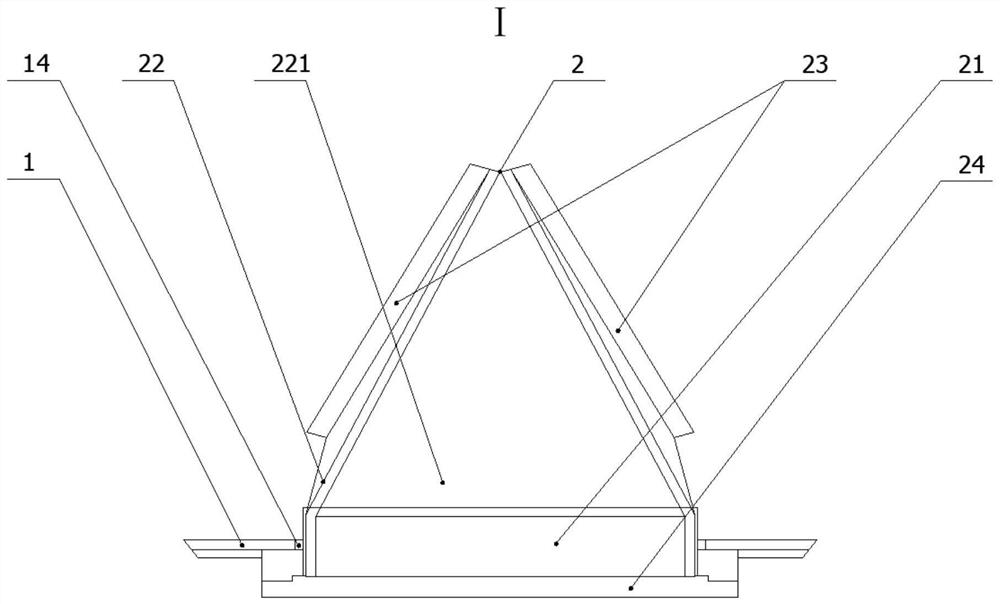

Device for bonding semiconductor chips

ActiveCN103579056AImprove output per unit timeSemiconductor/solid-state device manufacturingConveyor partsSemiconductor chip

A device for bonding semiconductor chips is a packaging mechanism which is used for bonding and fixing the chips or used for stacking multiple chips. The device comprises a first feeding conveying mechanism, a second feeding conveying mechanism, a pre-pressing module and a main pressing fit module. A packaging carrier is conveyed to a position for performing pre-pressing fit of the pre-pressing module through the first feeding conveying mechanism and the second feeding conveying mechanism respectively, and the packaging carrier which has been processed in a pre-pressing fit is conveyed to or made to remain in the position for performing main pressing fit of the main pressing fit module respectively through the first feeding conveying mechanism and the second feeding conveying mechanism respectively. The pre-pressing module can apply pressure to enable at least one chip to be in pre-pressing fit with the packaging carrier or another chip on the packaging carrier. Then, the multiple chips which have been processed in a pre-pressing fit are stressed by multiple pressing-fit heads of the main pressing fit module at the same time, and thus the multiple chips are in main pressing fit with the packaging carrier or the chip on the packaging carrier.

Owner:苏州均华精密机械有限公司

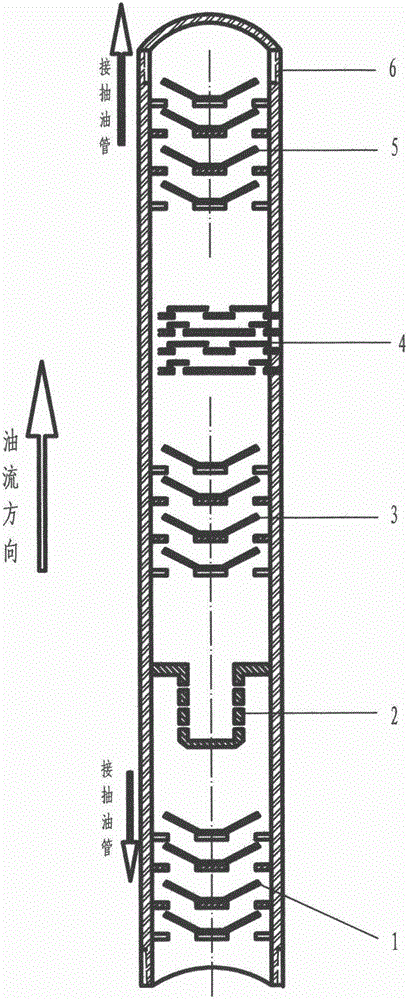

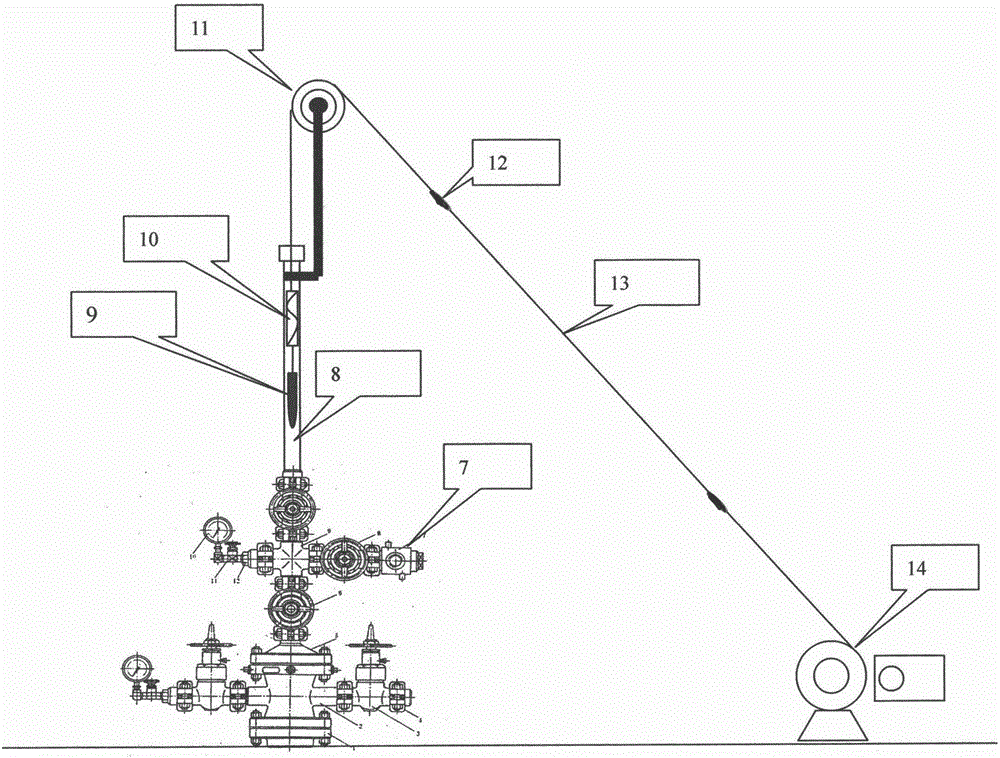

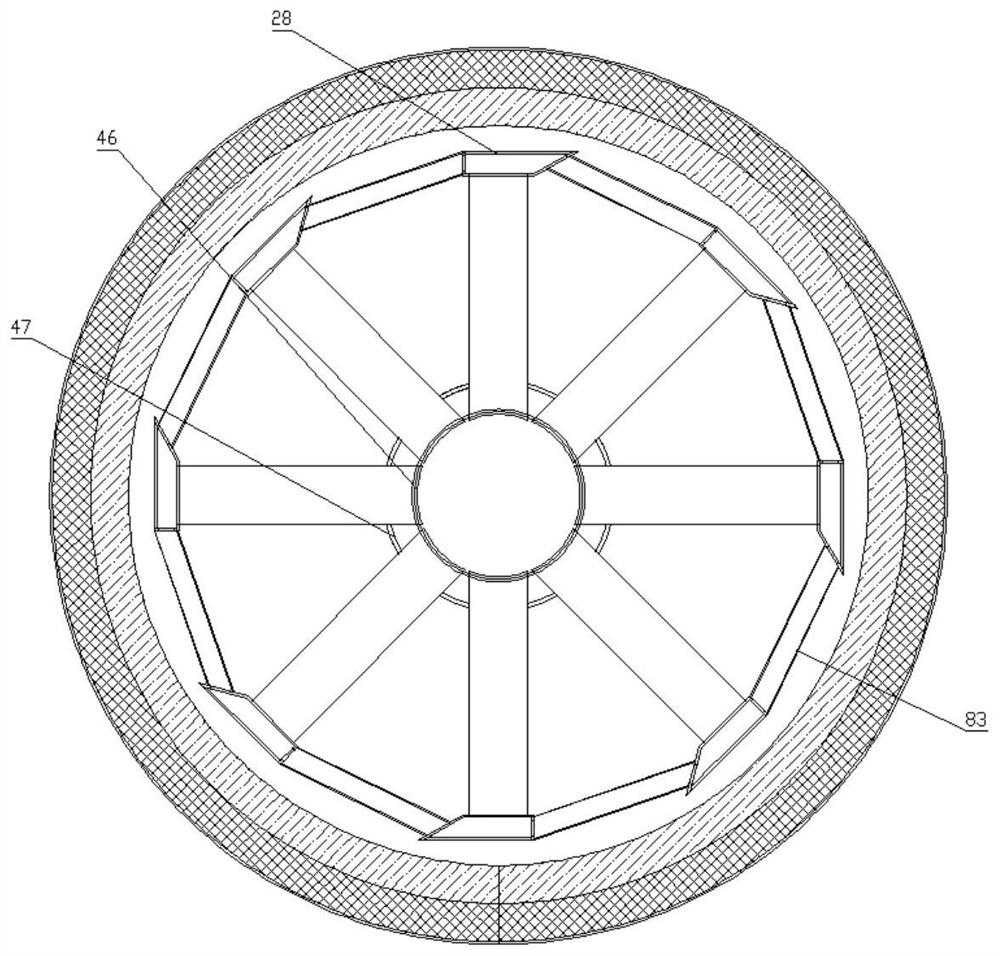

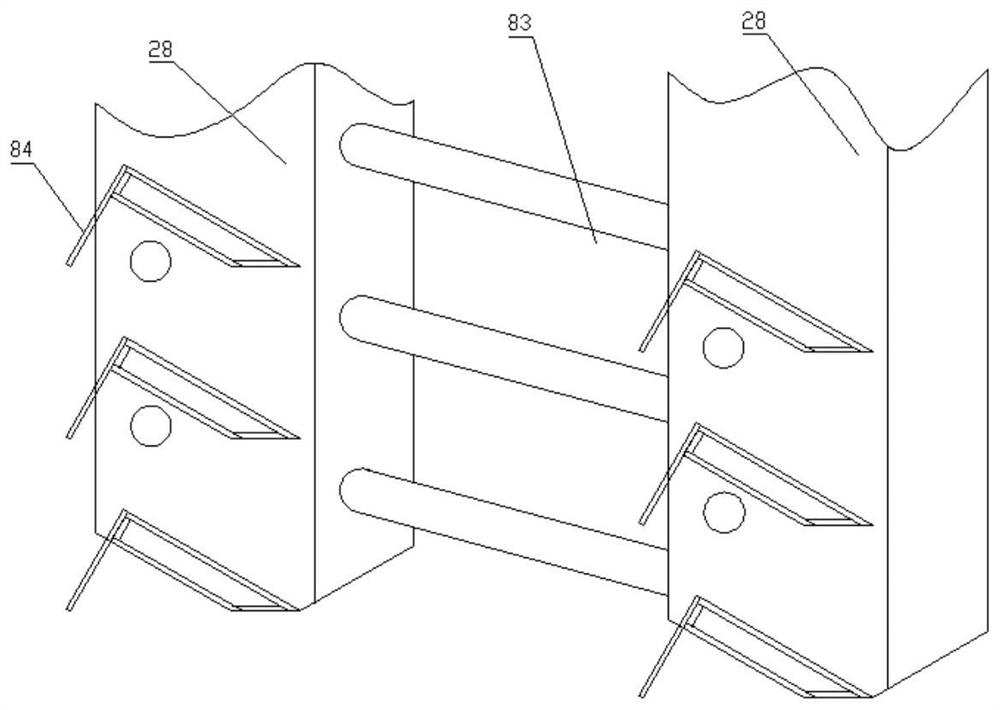

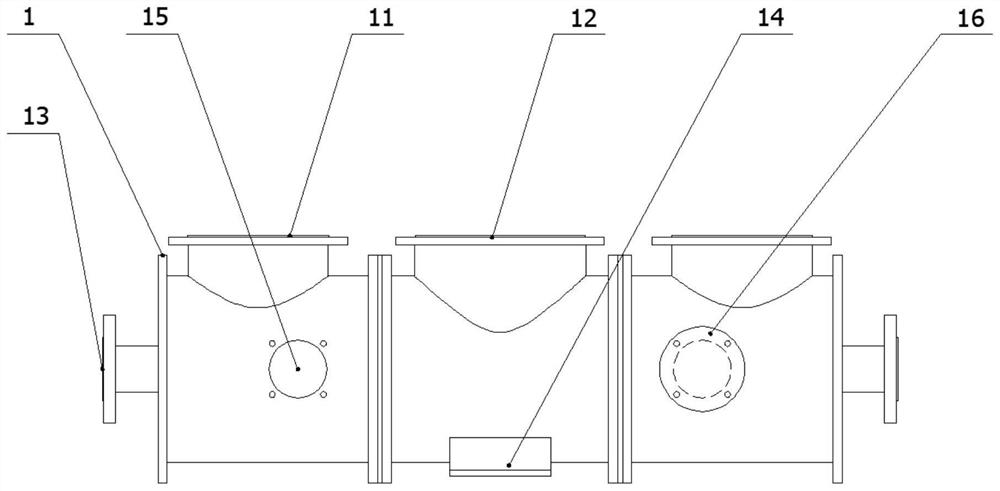

Paraffin-prevention and viscosity-reduction rectifier of oil field flowing well

PendingCN105909204AAchieve decentralizationRealize the shielding effectCleaning apparatusVibration devicesWaxPhase mixing

A paraffin-prevention and viscosity-reduction rectifier of an oil field flowing well is suitable for extracting oil from an oil field high-pressure well, and the long-standing, big and difficult problem that paraffin and scale of a flowing well are scraped and removed through manual work since the beginning of the oil exploitation history is solved. The rectifier is a tubular tool and mounted in the position about one thousand meters under a paraffin-troubled well section of the well. A first-level vortex rectifier body, an impinging stream phase mixing device, a second-level vortex rectifier body, an impact type acoustic oscillator and a third-level vortex rectifier body are mounted in the rectifier from bottom to top, a large-cluster laminar-flow condensed phase state of flowing oil, gas and water can be treated to form a fine-cluster milky eddying turbulence phase state, all heterogeneous components are made to wrap one another, refining, scattering and shielding of paraffin crystals and scale crystals are achieved, the physical state, the physical property, the flow state and the flow speed of produced liquid are optimized, and the phenomenon that the well is blocked by gathered paraffin and scale crystals on the oil tube wall is fundamentally eliminated; and meanwhile, the viscosity of the produced liquid is greatly lowered, the in-well burble procedure is effectively prolonged, manual paraffin and scale scraping and removing are omitted, workover treatment is reduced, oil extraction cost is lowered, and production and efficiency are improved.

Owner:邓海波

Continuous preparation method for phytocide 2,4-D acid

ActiveCN102659565AEasy to operateProduction safety and controllablePreparation from carboxylic acid saltsSolubilityEnergy consumption

The invention provides a continuous preparation method for phytocide 2,4-D acid, which comprises the following steps: continuously reacting 2,4-sodium dichlorphenoxyacetic acid with acid, of which a volume ratio is (1-1.5):1, in a multistage tower reactor under the temperature at 50-100 DEG C, and then introducing the materials after reacting into a cooling tower and cooling the materials to be below 50 DEG C, and lastly, filtering and cleaning the materials after being cooled, thereby obtaining the phytocide 2,4-D acid. According to the invention, the present intermittent method is replaced by the continuous preparation method for preparing the phytocide 2,4-D acid; the operation is convenient and the production is safe and controllable; the labor intensity of workers is greatly reduced, the energy consumption is reduced and the unit time output is increased; and meanwhile, according to the continuous preparation method provided by the invention, the reactive solubility is increased, the generation of byproduct is reduced and the yield of product is increased.

Owner:先正达集团股份有限公司

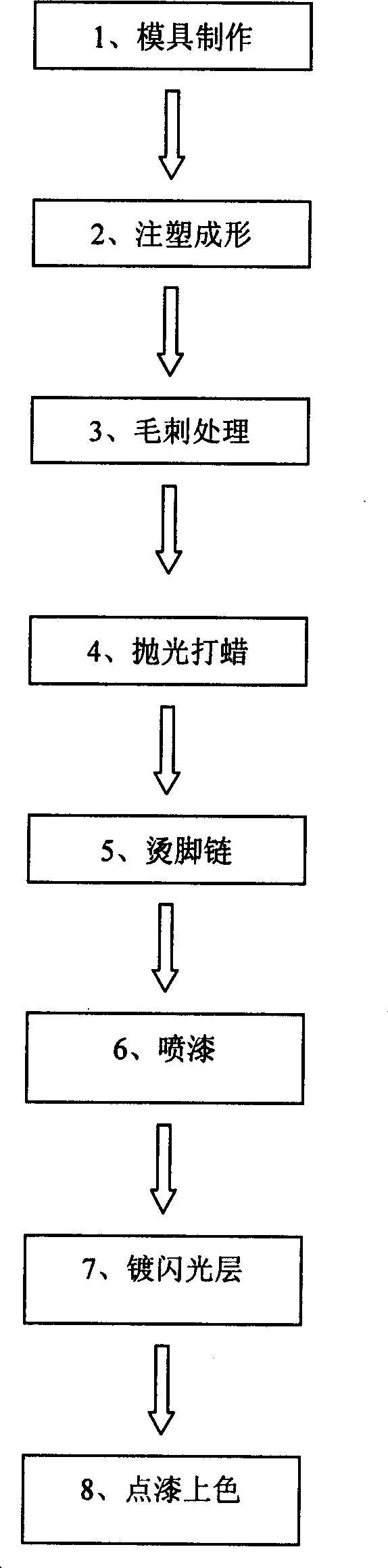

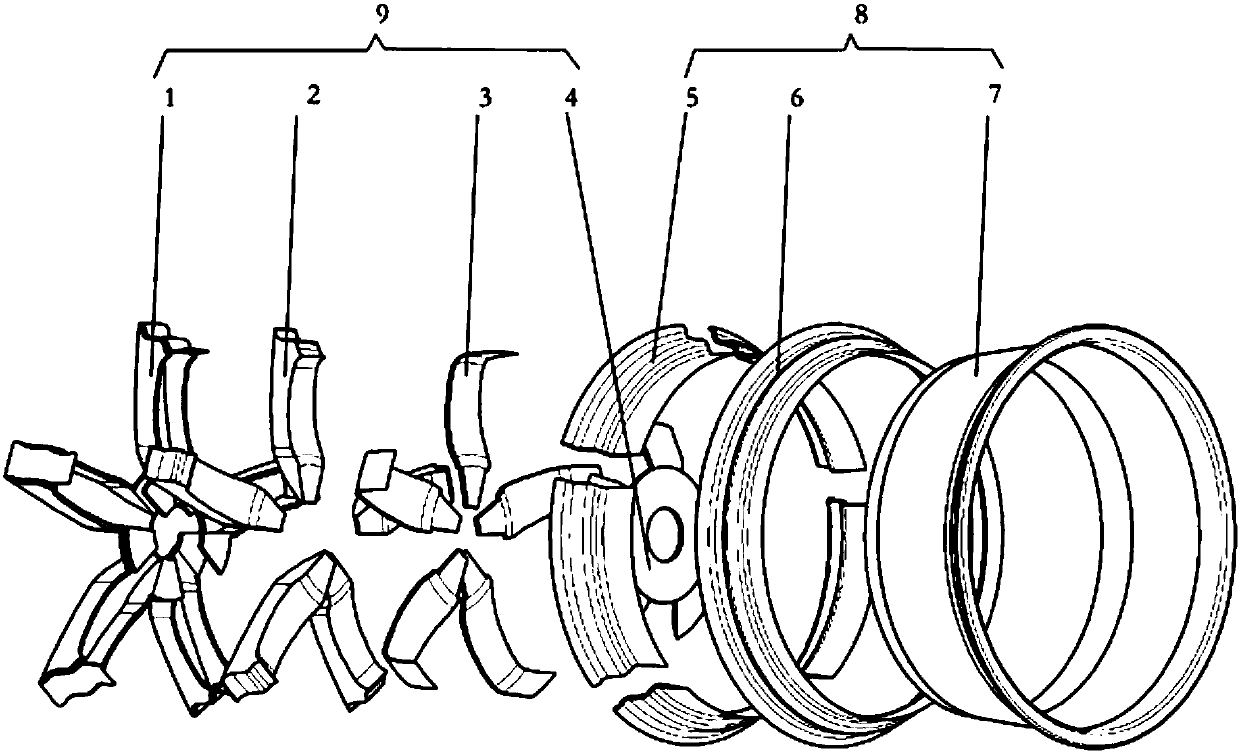

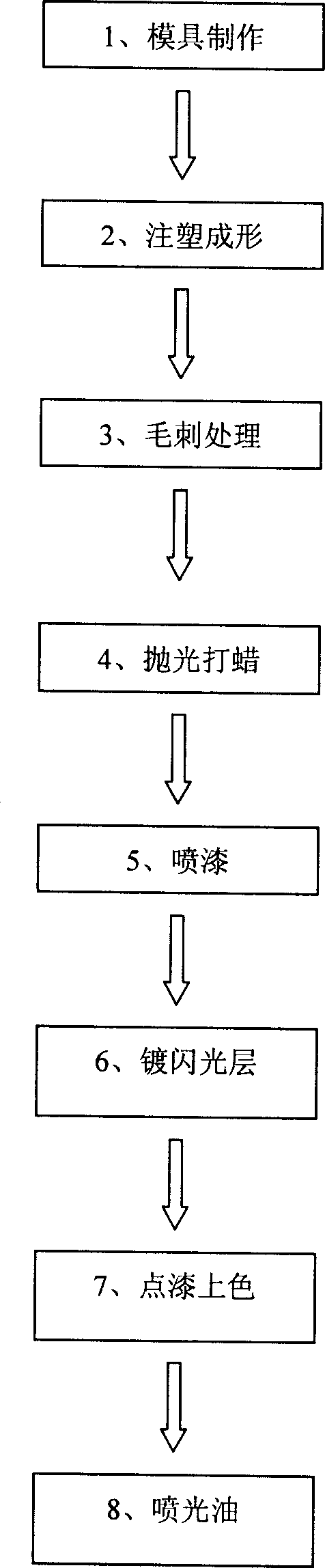

New one-step shaping process of carving and diamond-setting for plastic spectacles

InactiveCN1776480AImprove output per unit timeIncrease productivityNon-optical partsEngineeringHand operations

The technique includes steps: (1) manufacturing dies of spectacle stern frame and foot rests; motif pattern and diamond holes are designed in die cavity directly; (2) injection mold technique produces spectacle stern frame and foot rests; (3) polishing and waxing the spectacle stern frame and foot rests; (4) connecting the foot chain between spectacle stern frame and foot rests by using heating; (5) carrying out treatment of spray-paint for spectacle stern frame and foot rests integrally; (6) plating flash layer on diamond holes depressed on spectacle stern frame and foot rests. Comparing with traditional technique, the invention overcomes disadvantages of hand labor, complex production flow, and high rejection ratio.

Owner:寿加定

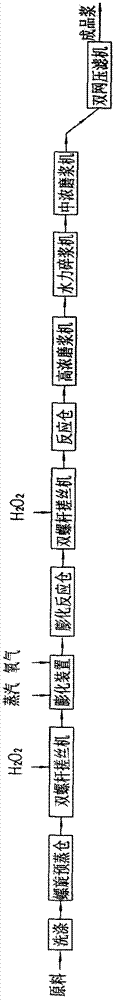

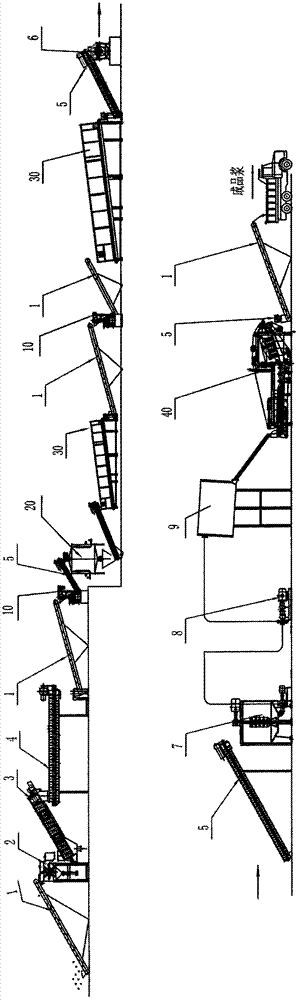

Anhydrous pulping and puffing device

The invention relates to an anhydrous pulping and puffing device, adopting the oxygen alkali puffing mode to obtain the energy-saving and water-saving clean pulping process without discharge of the waste water, waste gas and waste residue, the oxygen alkali puffing and pulping method adopts the combination mode of the oxygen alkali process and puffing process for dissociating the fiber, the weak mechanical treatment mode is adopted for guaranteeing the fiber strength, reducing the energy consumption and realizing high pulping yield; a set of puffing device is arranged behind the thread rolling machine of the existing preparation device and used for pressing the coarse sizing agent into the sealed tank, the sizing agent can be discharged during a short time and transported to the puffing reaction cabin for having reaction continuously, the fiber can be fast separated and easily lancinated by adopting the improved process and the production efficiency is raised.

Owner:BEIJING ZHONGJIN YUANLONG TECH DEV

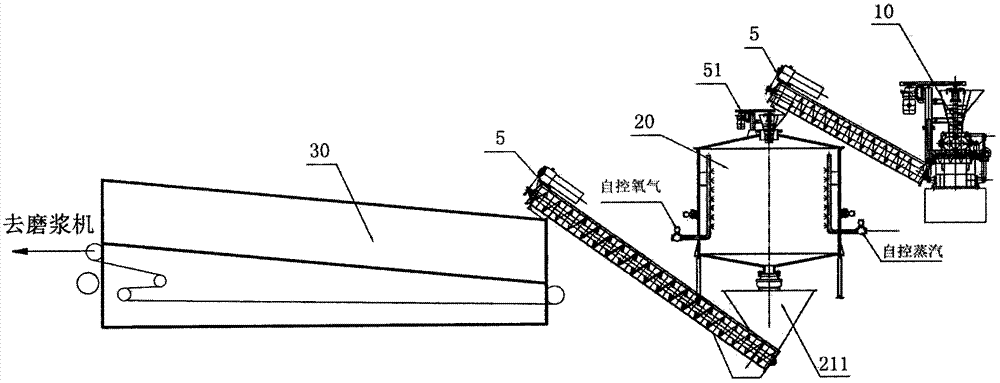

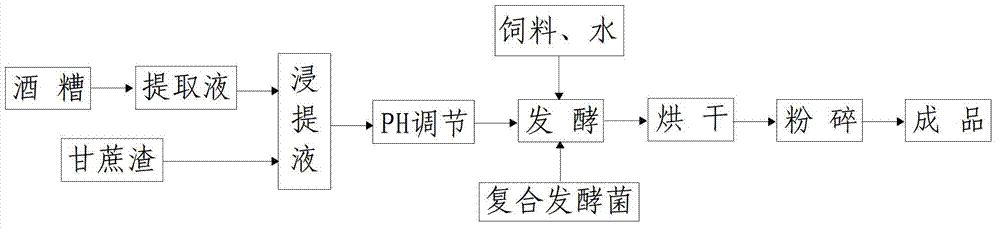

Method for rapidly producing biological fermentation feed

The invention belongs to the field of microbial fermentation feed and particularly relates to a method for utilizing bagasse extract liquid to rapidly produce the biological fermentation feed. The method comprises first adding water in vinasse, filtering after mixing to make the extract liquid, then enabling bagasse and salt which are subjected to coarse grinding to be added into the extract liquid, performing separation after mixing to obtain the bagasse extract liquid, adjusting pH value of the bagasse extract liquid to enable the pH value of the bagasse extract liquid to be the same as that of the biological fermentation feed finished products, finally placing the feed, composite zymocyte, the bagasse extract liquid and water in a mixer to perform mixing, discharging mixed materials after uniform mixing, sending the mixed materials into a fermentation workshop to perform fermentation, drying and smashing the fermented materials, and obtaining the biological fermentation feed finished products. The method effectively shortens production time of the biological fermentation feed and improves unit time yield, large economic benefits are obtained for enterprises, the effects of bagasse and the vinasse are fully achieved and are utilized to the largest extent, and the method meets the development requirements of a modern society.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

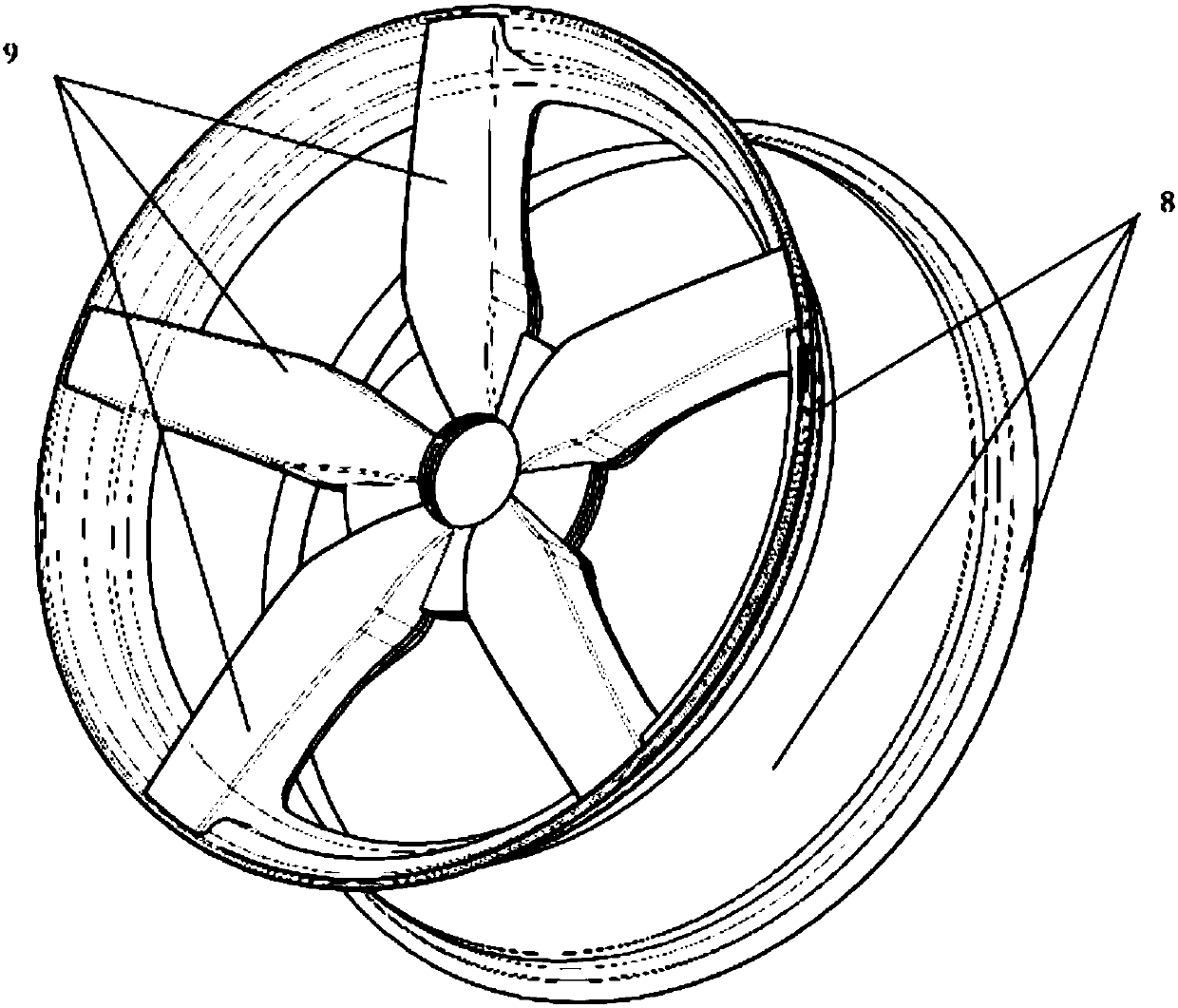

Composite material hub

The invention relates to a composite material hub. The composite material hub comprises a breadth pre-formed body and a wheel rim pre-formed body. In the breadth pre-formed body, after four to six sets of same enhanced fiber material pre-formed bodies are alternately stacked around the axis of a hub, spokes and a hub part used for being connected with an axle are formed. The wheel rim pre-formed body comprises four to six same enhanced fiber material pre-formed bodies, and each pre-formed body set is connected with the two corresponding adjacent spokes at the same time. The weight is smaller while the hub performance requirement is met; and the integrity, safety and reliability of the breadth are further enhanced. Meanwhile, large-scale production of the composite material hub is easy, quality consistency of final products is guaranteed, and the manufacturing cost is reduced. The two-step curing technology of pre-curing inside a die and post-curing outside the die is adopted, the die occupied period is shortened, the number of dies can be reduced during large-scale production, and the unit time yield is increased.

Owner:吴波

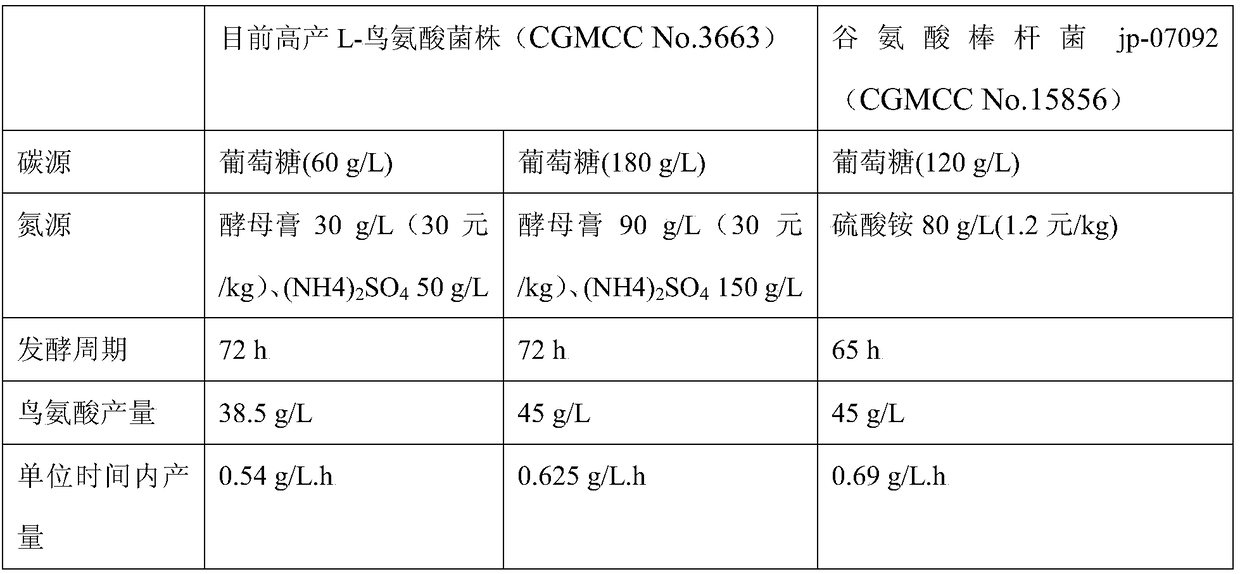

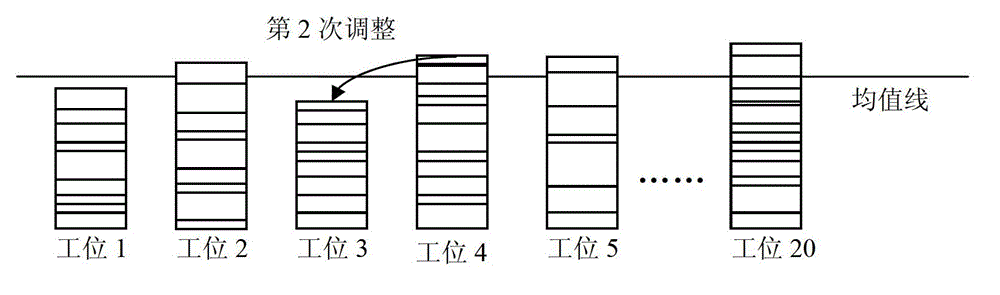

Corynebacterium glutamicum for high production of L-ornithine and application thereof

ActiveCN109161507AImprove metabolic activityReduce usageBacteriaMicroorganism based processesMicroorganismOrnithine synthesis

The invention belongs to the technical field of biological fermentation and discloses corynebacterium glutamicum for high production of L-ornithine and application thereof. The corynebacterium glutamicum is classified and named as corynebacterium glutamicum jp-07092 and is preserved in the China General Microbiological Culture Collection Center (CGMCC), and the preservation number is CGMCC No. 15856. The L-ornithine is produced by utilizing strain fermentation, and the corynebacterium glutamicum has the advantages of being low in cost, short in fermentation period, high in unit time yield, simple in subsequent purification process and the like and is more suitable for industrial popularization.

Owner:NANJING TECH UNIV

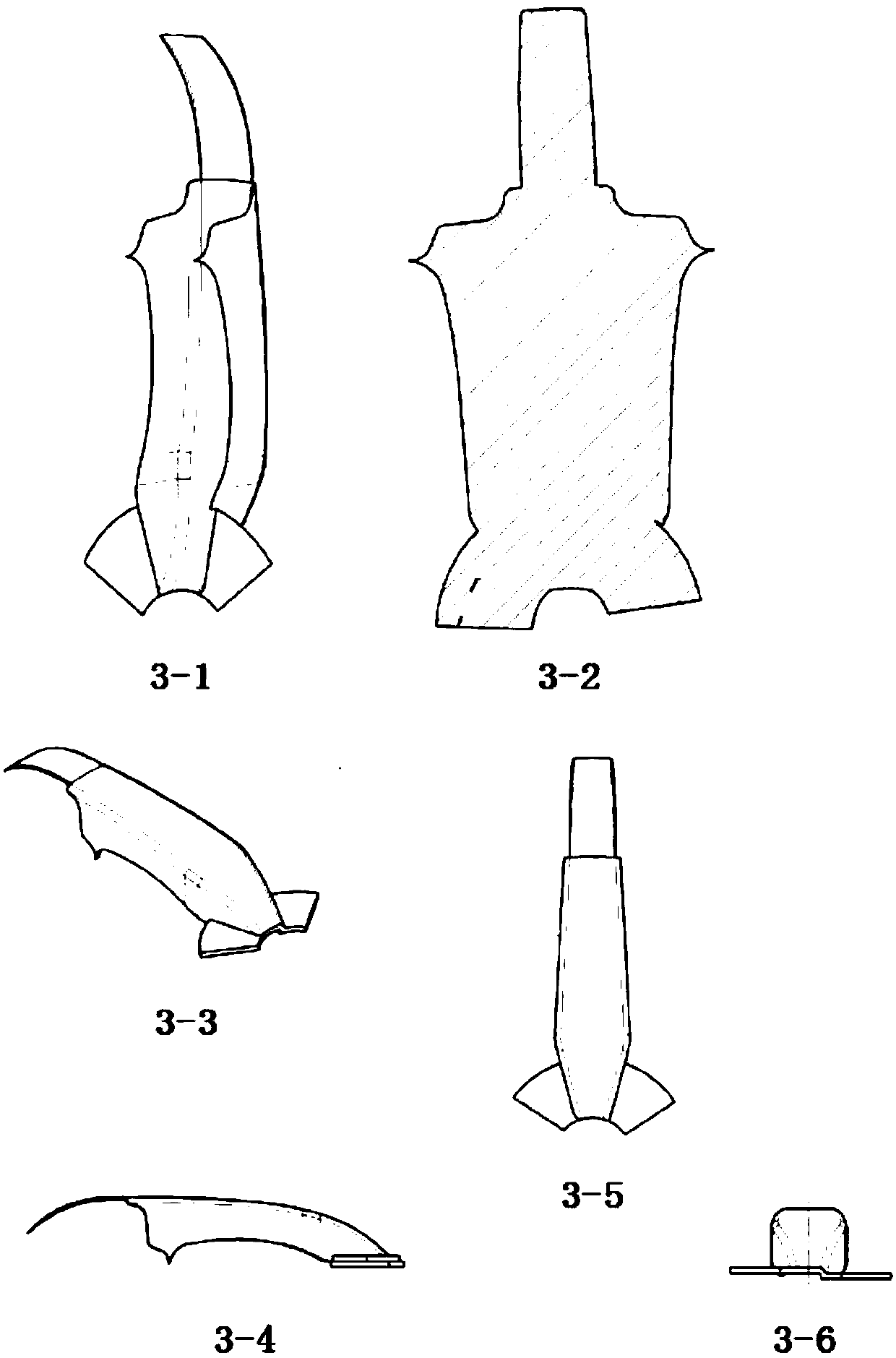

Once forming process to complete carving and embedding on plastic decoration

InactiveCN1847031AImprove output per unit timeIncrease productivityDecorative surface effectsSpecial ornamental structuresState of artLacquer

The present invention relates to once forming process to complete carving and embedding on plastic decoration. The technological process includes the following steps: making mold for the plastic decoration and with decoration pattern and holes; injection molding to form the plastic decoration; polishing and waxing the plastic decoration; spraying lacquer and plating flash layer to the holes for forming diamond imitation. The present invention has the advantages of high production efficiency, simple production process and stable product quality.

Owner:寿加定

Special bacteriostatic medical sanitary compound non-woven fabric production process

The invention discloses a special bacteriostatic medical sanitary compound non-woven fabric production process which includes the steps: firstly, continuously processing a first fiber net, a second fiber net and a third fiber net on corresponding working procedures; secondly, sequentially laying a first melt blown layer and a second melt blown layer on the continuously processed first fiber net, and melting and blowing the first melt blown layer and the second melt blown layer on corresponding working procedures; thirdly, sequentially stacking and laying the second fiber net and the third fiber net on the first fiber net melt blown and laid twice; fourthly, hot rolling and strengthening the first fiber net, the second fiber net and the third fiber net after overlapping. According to the method, the first fiber net, the first melt blown layer, the second melt blown layer, the second fiber net and the third fiber net are compounded on line by a one-step method, and a compound non-woven fabric has good antibacterial property and breathability and high barrier property and hydrostatic pressure resistance.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

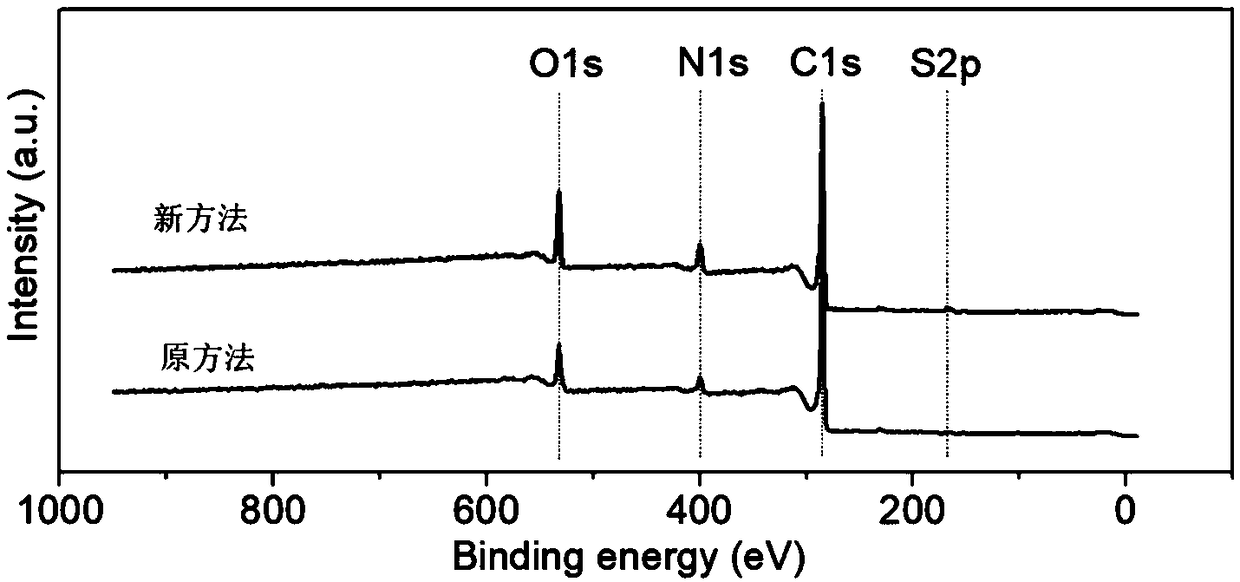

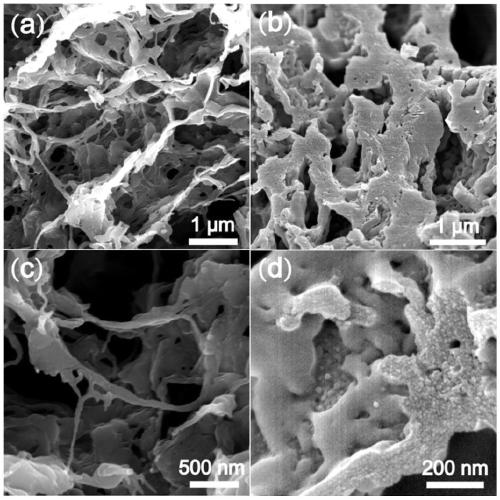

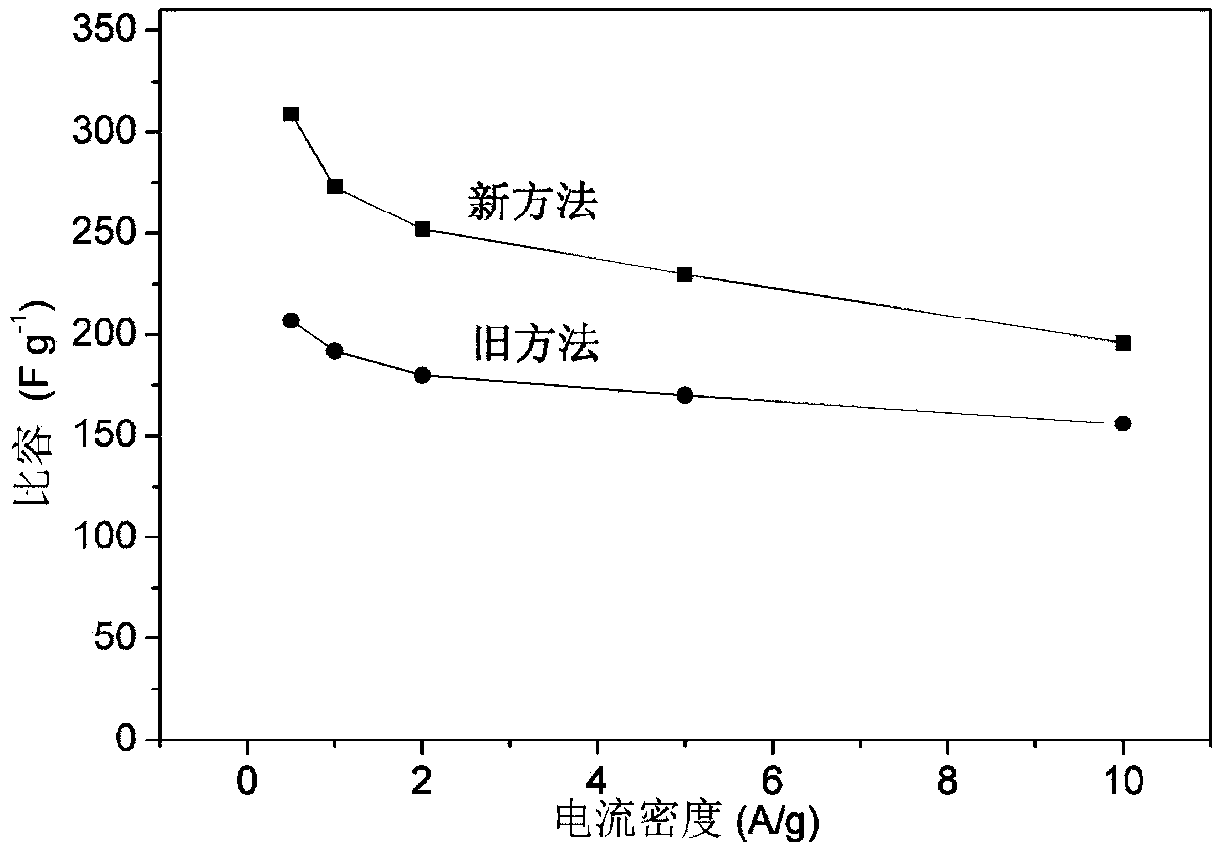

Preparation method of improved type graded porous carbon-doped material

InactiveCN109368636ASimple processImprove output per unit timeCarbon compoundsFreeze-dryingPorous carbon

The invention relates to a preparation method of an improved type graded porous carbon-doped material. The method mainly overcomes the shortcomings of complex technology, long production cycle, relatively low efficiency, much wastewater discharge, relatively high cost and the like of CN105480963A, abandons original steps such as deionized water purifying and balancing treatment and soaking treatment in an acid solution, and adopts a process of directly freeze-drying the prepared hydrogel and performing high-temperature carbonization and then washing and drying to obtain a target product. Compared with the prior art, in particular to the CN105480963A, the graded porous carbon-doped material prepared by the method provided by the invention has the advantages of more abundant doping atoms, more porous structures on the surface and more excellent electrical properties.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

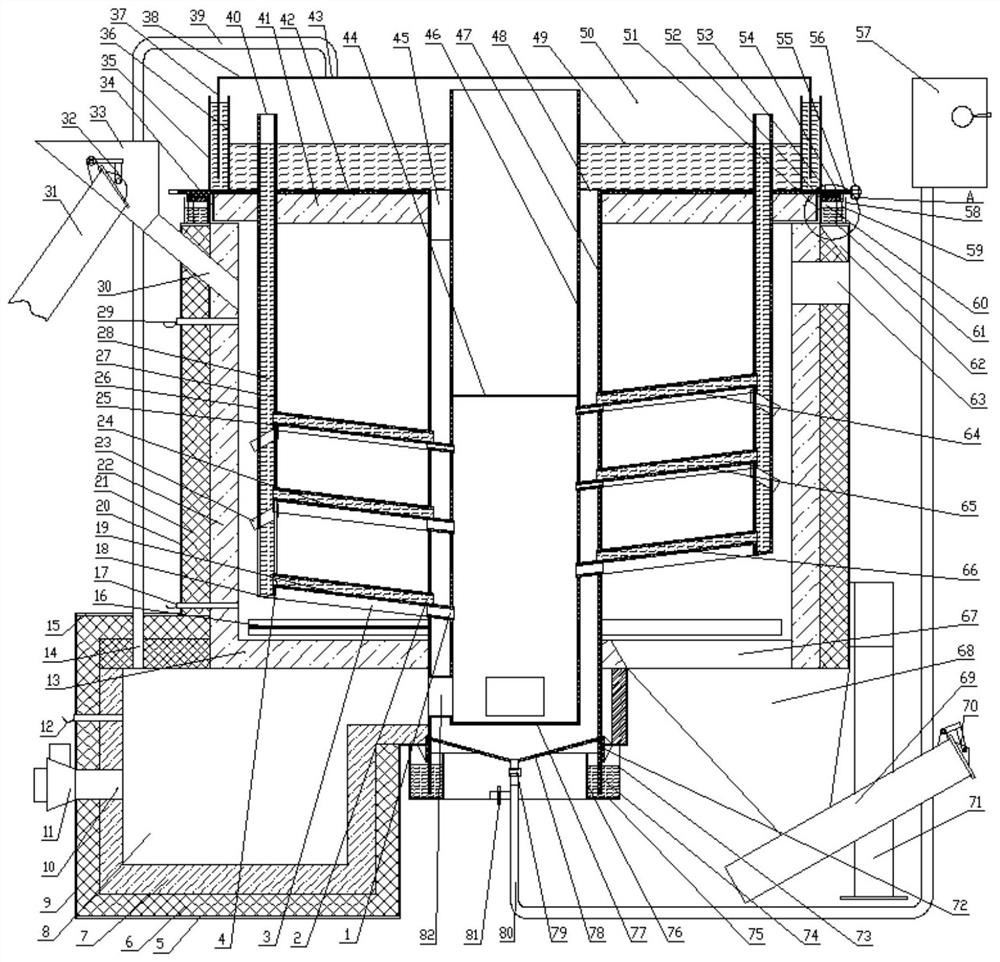

Uniform internal heating stirring type activation kiln

ActiveCN111689499AIncrease the cross-sectional areaReduce the cross-sectional areaCarbon compoundsActivated carbonThermodynamics

The invention discloses a uniform internal heating stirring type activation kiln, and belongs to the field of activated carbon. The uniform internal heating stirring type activation kiln comprises a kiln body, a feeding mechanism, a flow guide stirring mechanism, a water seal mechanism, a discharging mechanism and a hot blast stove, and the feeding mechanism is arranged on the side wall of the kiln body; the kiln main body mainly comprises a kiln upper cover and a kiln lower body, the kiln lower body mainly comprises a hot-blast stove body, a hot-blast stove shell and a lower body shell fixedly connected with the hot-blast stove shell, and the flow guide stirring mechanism is connected in the lower body shell; the kiln has a stirring effect and also has the effect of transporting activators; when the flow guide stirring paddles rotate to any place, the activators is conveyed to any place; the flow guide stirring paddles are uniformly distributed in the material layer; the activated material layer with the thickness of two meters is simultaneously stirred from inside to outside, is simultaneously heated and is in contact with the activators so that the activation is uniform, the specific surface area of the activated carbon is large, the activation time is shortened, and the single-machine productivity is high.

Owner:舒克孝

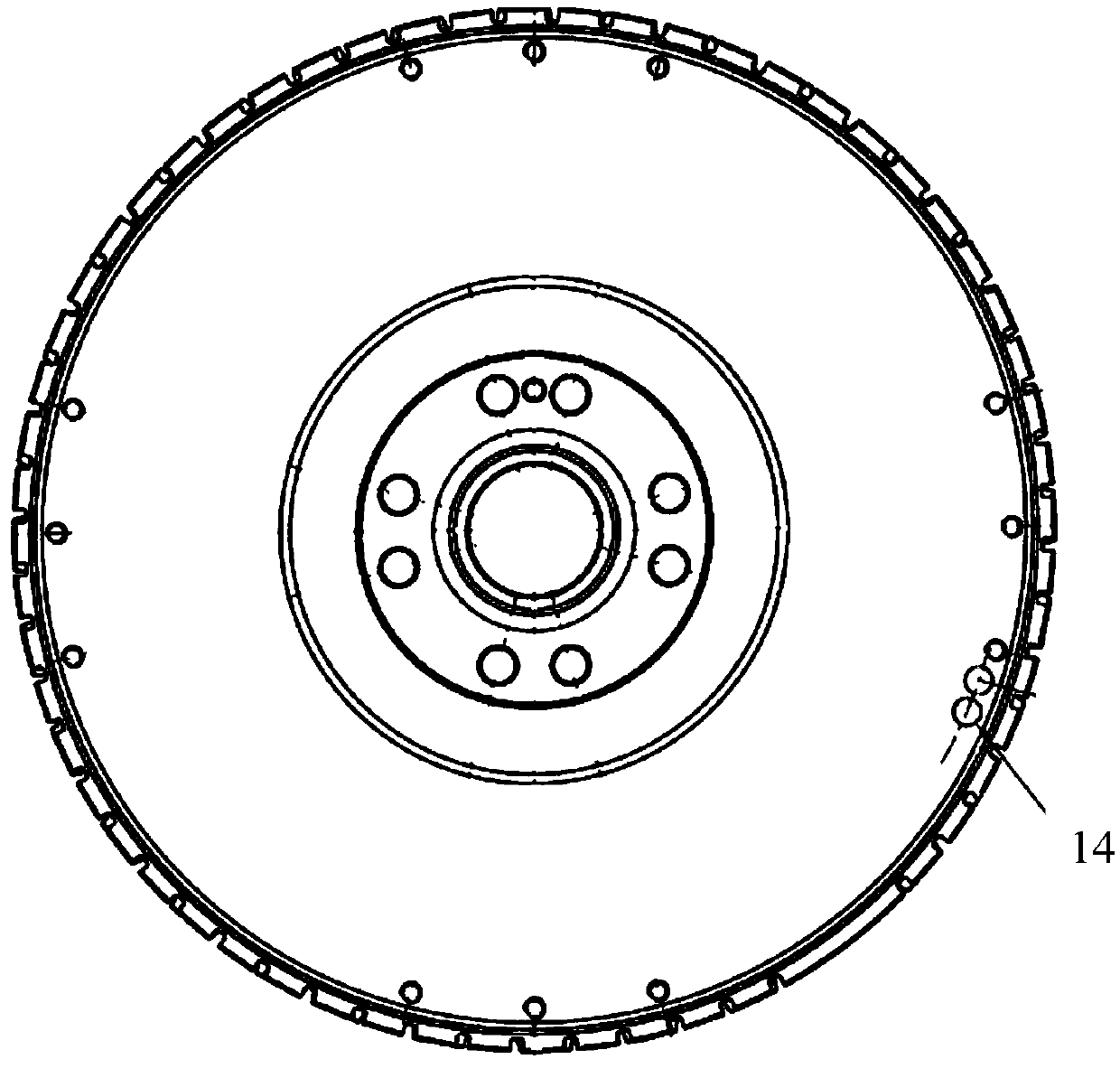

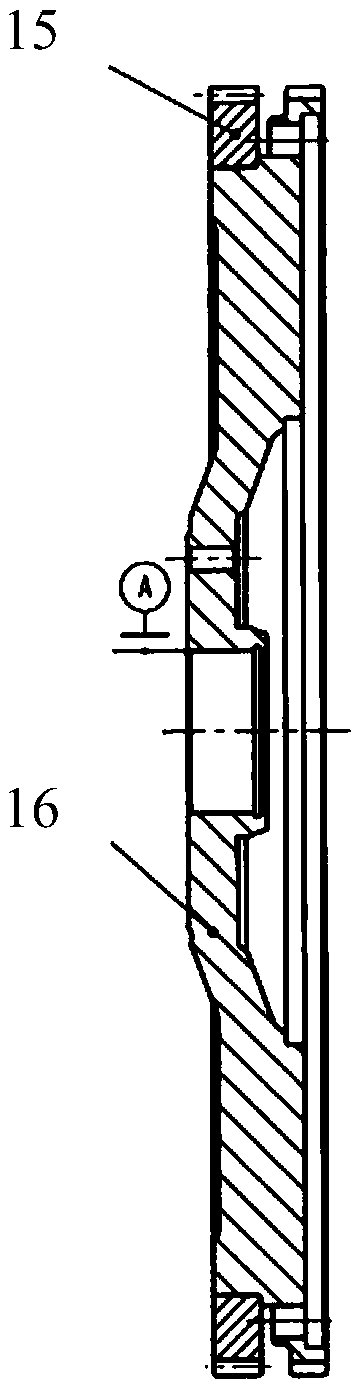

Device and method for machining flywheel assembly

ActiveCN109093397AReduce lossesReduce manual labor intensityOther manufacturing equipments/toolsDynamic balanceEngineering

The invention discloses a device and a method for machining a flywheel assembly. The whole machining processes are sequentially as follows: a first vertical lathe is used for machining the front surface of a flywheel; a horizontal machining unit is used for performing flywheel signal gear machining; a gear ring heating device is used for heating a gear ring; a press machine is used for carrying out gear ring and flywheel pressing and sleeving; a second vertical lathe is used for machining the working face of the flywheel; a cleaning workbench is used for cleaning the flywheel; an online detection device is used for carrying out online detection on the flywheel; an infrared scanning unit is used for carrying out infrared scanning and positioning on the flywheel; a first vertical machining unit is used for carrying out flywheel hole position machining; a second vertical machining unit is used for carrying out flywheel installation hole machining; a laser marking machine is used for carrying out laser printing of an ignition mark; and dynamic balance equipment is used for carrying out dynamic balancing of the flywheel. According to the device and the method, due to the adoption of a roundabout layout of automatic operation of manipulators, the labor intensity of workers and the number of the workers are greatly reduced, the fact the process capabilities of important sizes of products are all 1.67 or above is ensured, the reject ratio of product machining is remarkably reduced, and the monthly waste loss is reduced by 50% or above.

Owner:十堰东风飞斯特机械制造有限公司

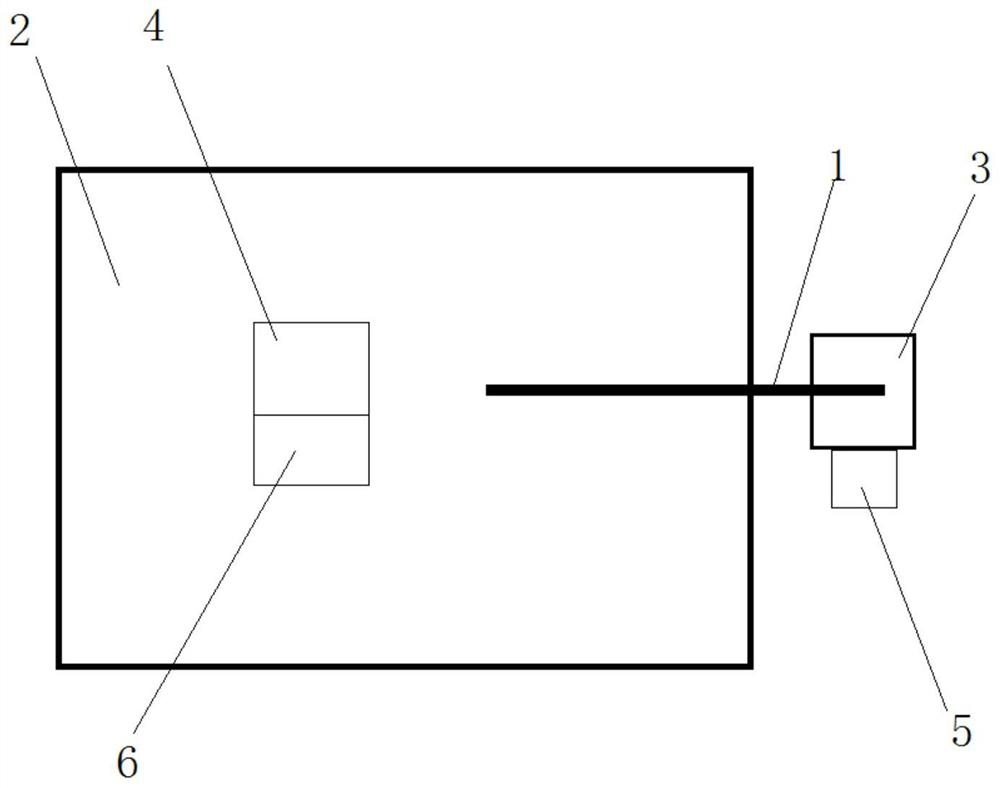

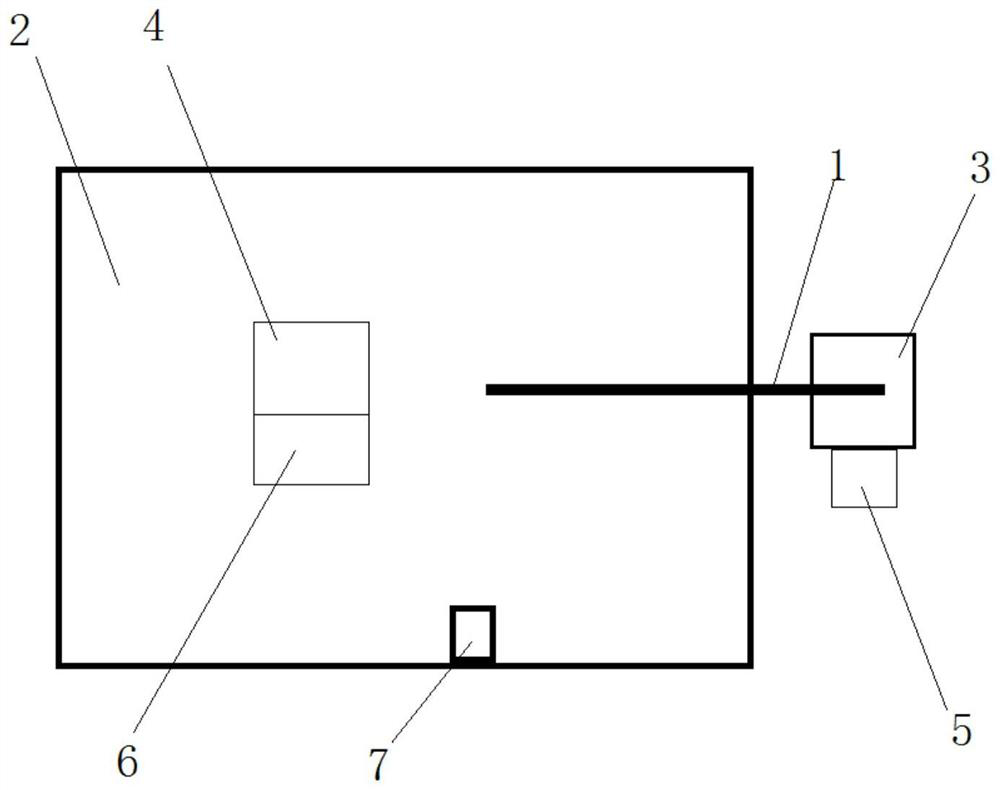

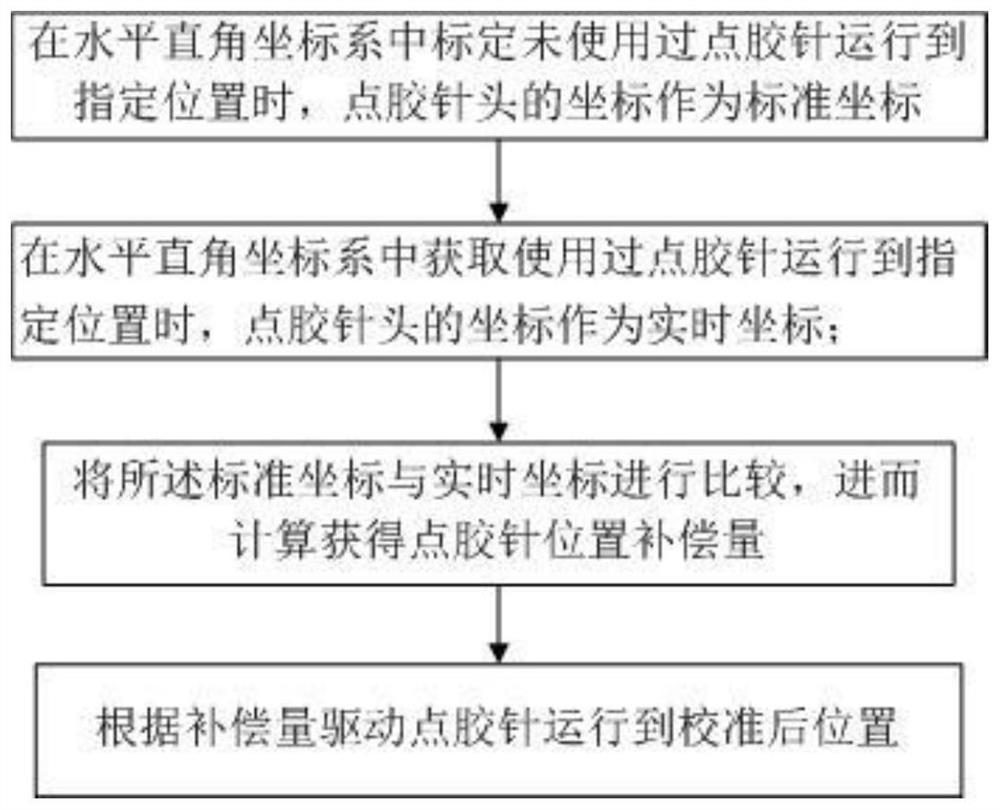

Dispensing needle position calibration system and dispensing needle position calibration method

InactiveCN112756194AAvoid Length EffectsThe result is accurateLiquid surface applicatorsSpraying apparatusMechanical engineeringBiomedical engineering

The invention discloses a dispensing needle position calibration system which is used for position calibration of a dispensing needle of a dispensing machine. The dispensing needle is arranged above a dispensing platform, the dispensing needle is driven by a driving module to move within a specified range above the dispensing platform, and the dispensing needle performs dispensing operation on a product located on the dispensing platform. The dispensing needle position calibration system comprises an acquisition module and a control compensation module; the acquisition module is arranged on the dispensing platform, the control compensation module controls the driving module to drive the dispensing needle to move to a specified position above the acquisition module, the acquisition module acquires preset data for the dispensing needle, the acquisition module sends the acquired preset data to the control compensation module, the control compensation module calculates a compensation amount according to a compensation calculation rule, and the driving module drives the dispensing needle to move to the calibrated position according to the compensation amount sent by the control compensation module. The invention further discloses a dispensing needle position calibration method. According to the device and the method, the position of the dispensing needle can be quickly and accurately calibrated.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Copper-based hydrogenation catalyst prepared by flame jet cracking method and its preparation and application

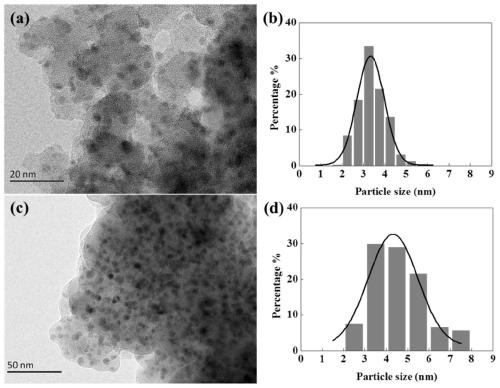

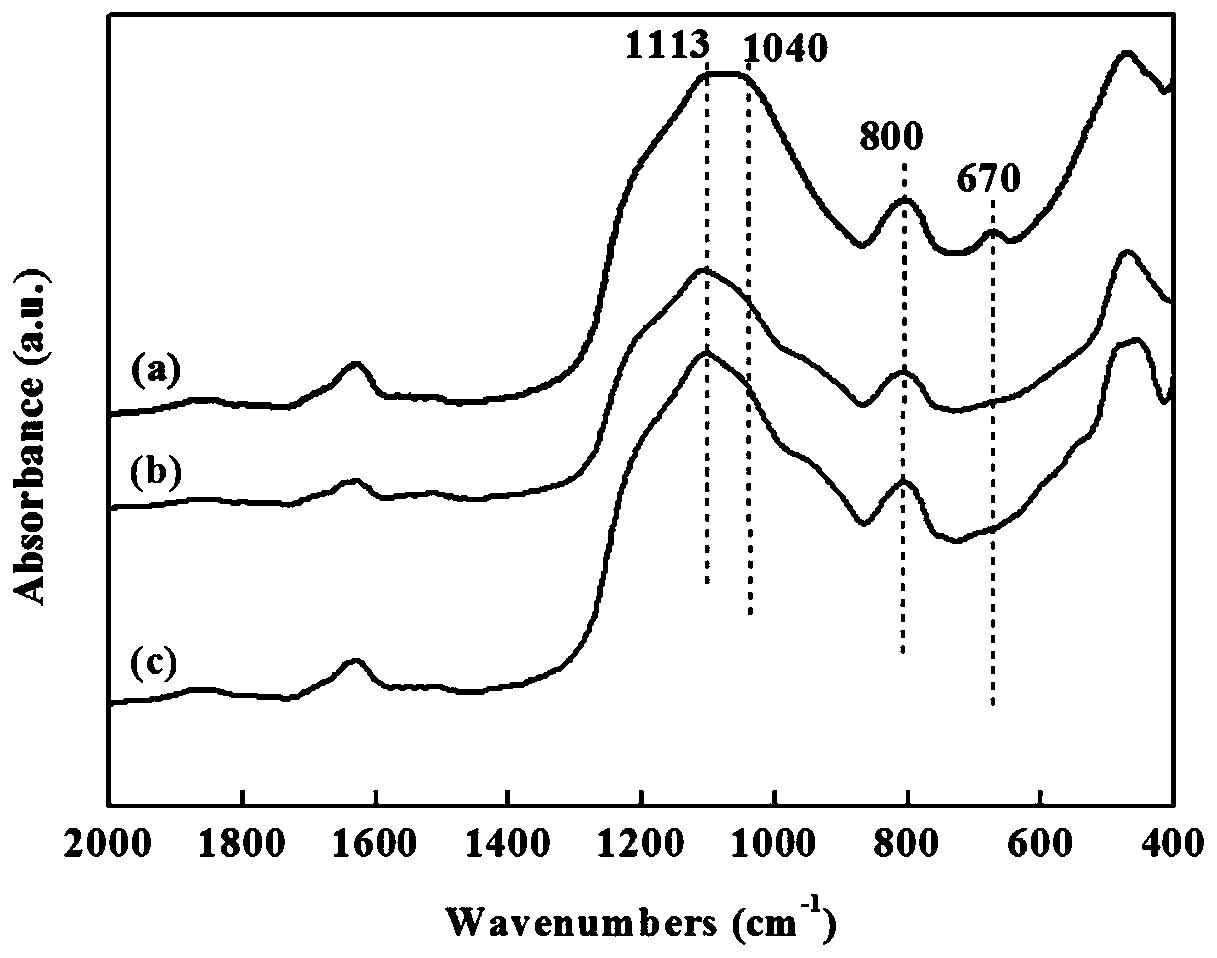

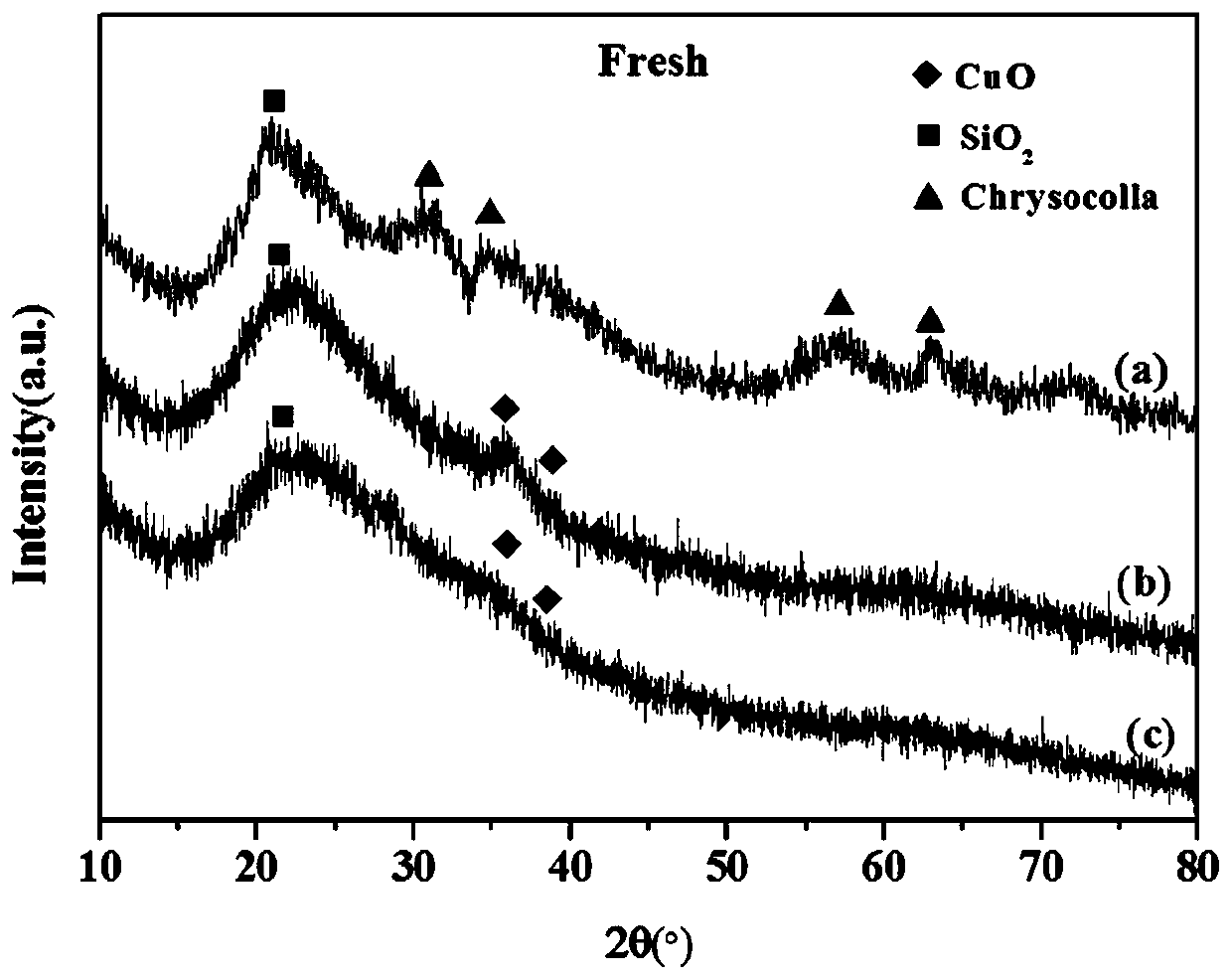

ActiveCN108144610BSmall particle sizeGood dispersionOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystHydrogenation reaction

The invention provides a copper-based hydrogenation catalyst prepared by flame spray cracking method and its application. The catalyst uses copper as the main active component and can be modified by adding one or more auxiliaries. It is made by flame spray Prepared in one step by lysis method. The invention also relates to the application of the copper-based catalyst prepared by the preparation method in the hydrogenation reaction of carbonyl-containing organic matter. The beneficial effects of the catalyst of the present invention are mainly reflected in: (1) the catalyst in the present invention has small particle size, high metal dispersion, and high low-temperature hydrogenation activity after instantaneous high temperature; (2) the catalyst in the present invention can be quickly prepared through a one-step method, The output per unit time is high, there is no subsequent heat treatment process, and sintering aggregation of copper is avoided; (3) The copper-silicon intermediate species of the catalyst in the present invention is different from the catalyst prepared by the ammonia evaporation method, and has the ability to better condition the valence state of copper.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Optimal design method for production line layout

ActiveCN103049801BReduce the impact of volatilityIncrease production capacitySpecial data processing applicationsProduction lineTotal investment

Owner:四川长虹智能制造技术有限公司

Synthesis method for fluoro-ethylene carbonate

A synthesis method for fluoro-ethylene carbonate. The invention belongs to the technical field of battery stabilizers. The synthesis method includes the steps of: 1) under protection of inert gas, adding chloro-ethylene carbonate, a tetraalkyl halogenated amine catalyst, a solvent and a fluoride mixture into a reaction kettle with stirring and mixing, and controlling the temperature to be 60-100 DEG C to perform a halogen exchange reaction for 3-6 h to produce a crude product containing fluoro-ethylene carbonate, wherein molar ratio of the chloro-ethylene carbonate to the fluoride mixture is 1:1.0-1.1, and the mass ratio of the chloro-ethylene carbonate to the solvent is 1:0.9-1.2; and 2) purifying the crude product containing fluoro-ethylene carbonate to produce the fluoro-ethylene carbonate. The method is characterized by one-time addition of the fluorinating agent, mild reaction, high yield, convenient separation and simple operations.

Owner:山东永浩新材料科技有限公司

A kind of Corynebacterium glutamicum and its application of high production L-ornithine

ActiveCN109161507BImprove metabolic activityReduce usageBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention belongs to the technical field of biological fermentation, and discloses a Corynebacterium glutamicum capable of high-yielding L-ornithine and an application thereof. The Corynebacterium glutamicum is classified as Corynebacterium glutamicum jp-07092, and has been deposited in the General Microorganism Center of China Committee for the Collection of Microorganisms, and its preservation number is CGMCC No.15856. Using the strain to ferment and produce L-ornithine has the advantages of low cost, short fermentation cycle, high yield per unit time, simple subsequent purification process, etc., and is more suitable for industrialization.

Owner:NANJING TECH UNIV

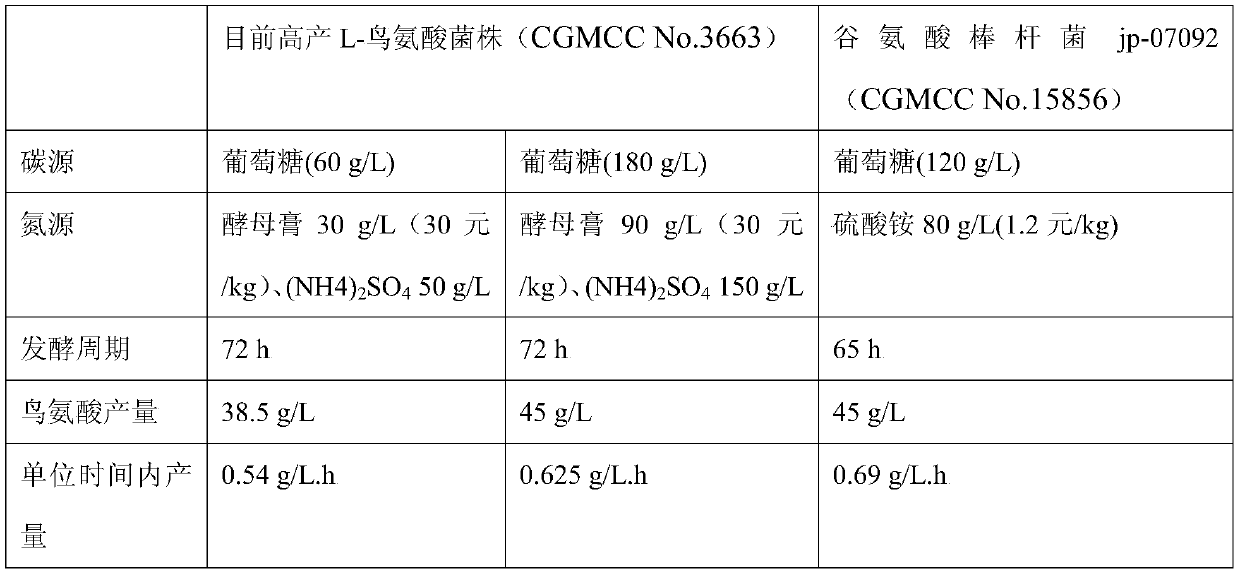

Digital energy product intelligent manufacturing production system and production line making method

PendingCN111861181AAvoid lostTap into energy-saving potentialTechnology managementResourcesData acquisitionProcess engineering

The invention discloses a digital energy product intelligent manufacturing production system and a production line making method. The digital energy product intelligent manufacturing production systemcomprises an installation test module, a data acquisition module, a data analysis module, a comparison module, a controller and an evaluation module. The installation test module is used for adjusting the equipment of the production system to a normal working state according to the total energy consumption difference of the equipment before and after the installation of the production system; thedata acquisition module is used for monitoring the current state of the production system equipment at preset time intervals; the data analysis module is used for analyzing the operation time and theenergy consumption of the production system equipment; the comparison module is used for diagnosing the energy consumption state of the production system equipment; if the diagnosis is abnormal, thecontroller turns off the currently running energy consumption abnormal equipment; and the evaluation module is used for determining the unit product energy consumption of the production system equipment, and performing energy-saving evaluation on the production system equipment according to the industry standard.

Owner:深圳市安科讯电子制造有限公司

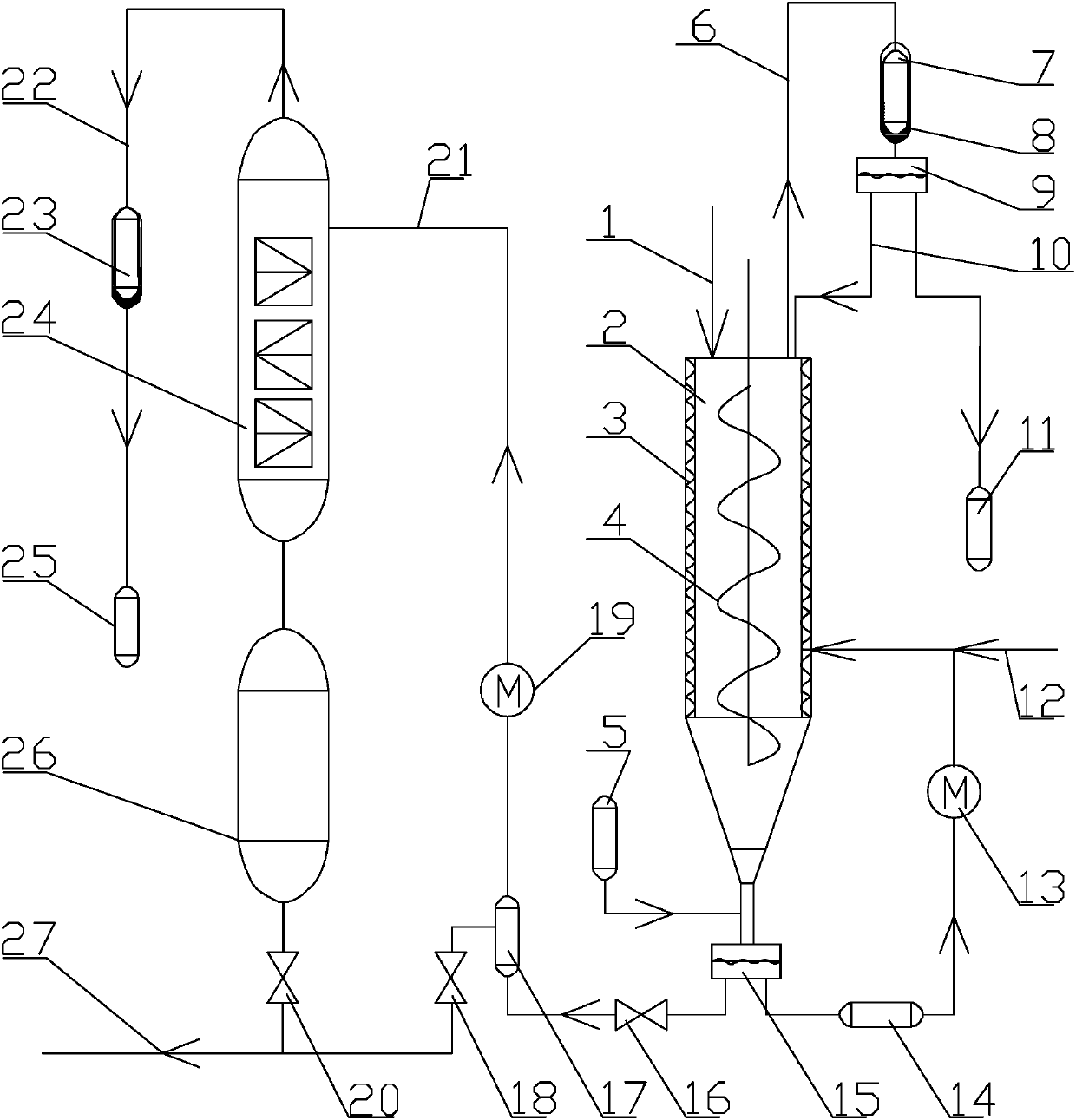

Isooctyl palmitate preparation system with dehydration function

InactiveCN107778172AFacilitate lipidation reactionImprove reaction efficiencyOrganic compound preparationCarboxylic acid esters preparationIsooctyl alcoholPulp and paper industry

The invention relates to an isooctyl palmitate preparation system with a dehydration function. The system comprises a reaction tower, wherein a steam discharge pipe, an isooctanol recovery tube and apalmitic acid inlet are connected at the top of the reaction tower; the steam discharge pipe is connected with an isooctanol receiving pot; the isooctanol receiving pot is connected with a No.1 oil-water separator; an oil outlet of the No.1 oil-water separator is connected with the isooctanol recovery tube; a water outlet of the No.1 oil-water separator is connected with a No.1 water receiving pot; an isooctanol and catalyst inlet is connected on the side surface of the reaction tower; a discharge hole of the reaction tower is connected with a No.2 oil-water separator; a finished product outlet of the No.2 oil-water separator is communicated with a finished product heating pot; the other outlet of the No.2 oil-water separator is connected with a catalyst recovery pot; a dehydration deviceis connected with the finished product heating pot. According to the preparation system, isooctyl palmitate can be prepared efficiently and rapidly, so that the preparation efficiency is improved; meanwhile, the preparation system has the dehydration function, so that the quality and purity of a product are improved, and the production cost is lowered.

Owner:湖北楚怡新材料有限公司

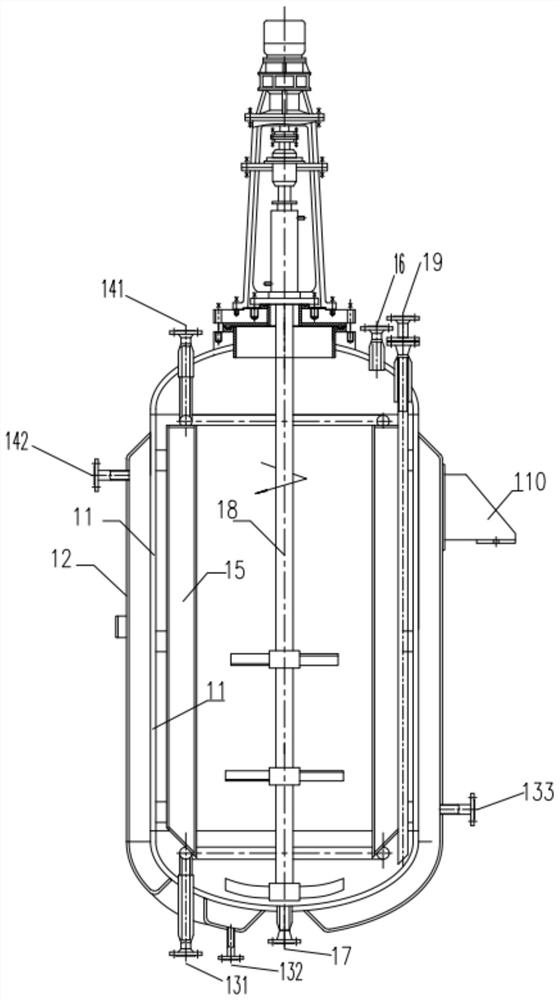

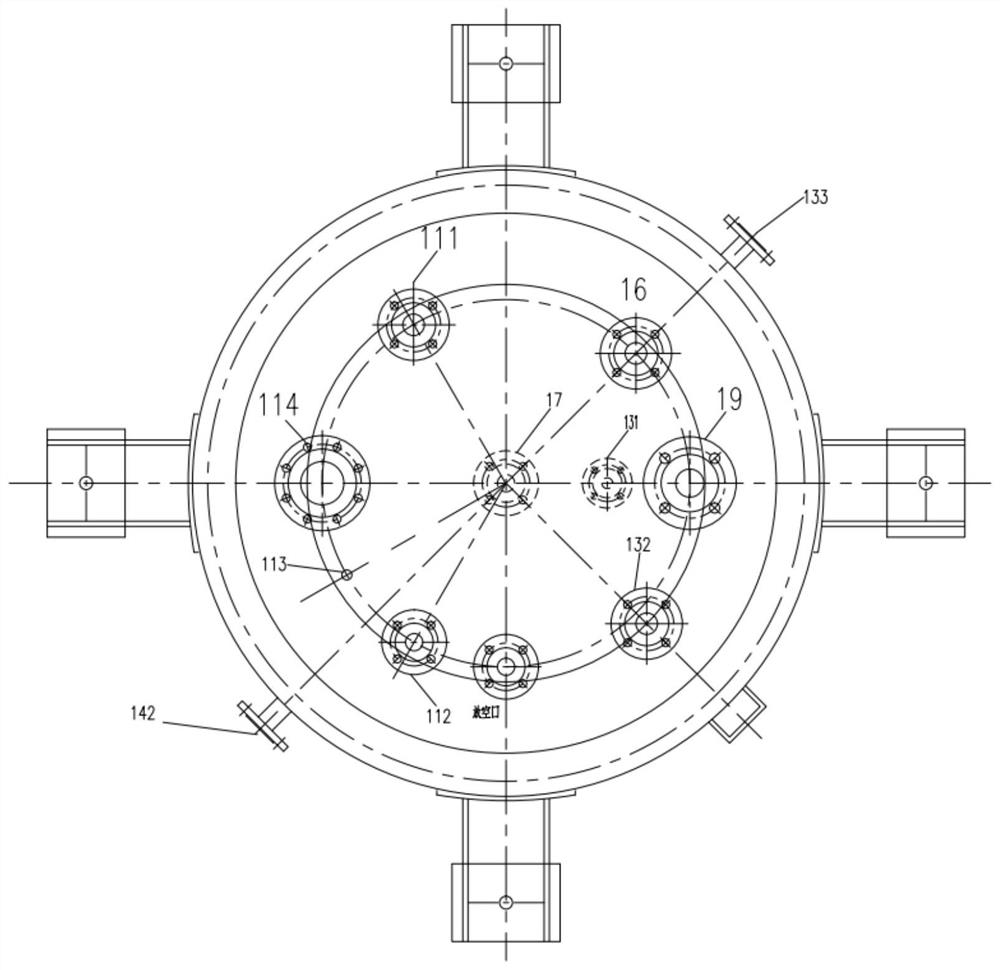

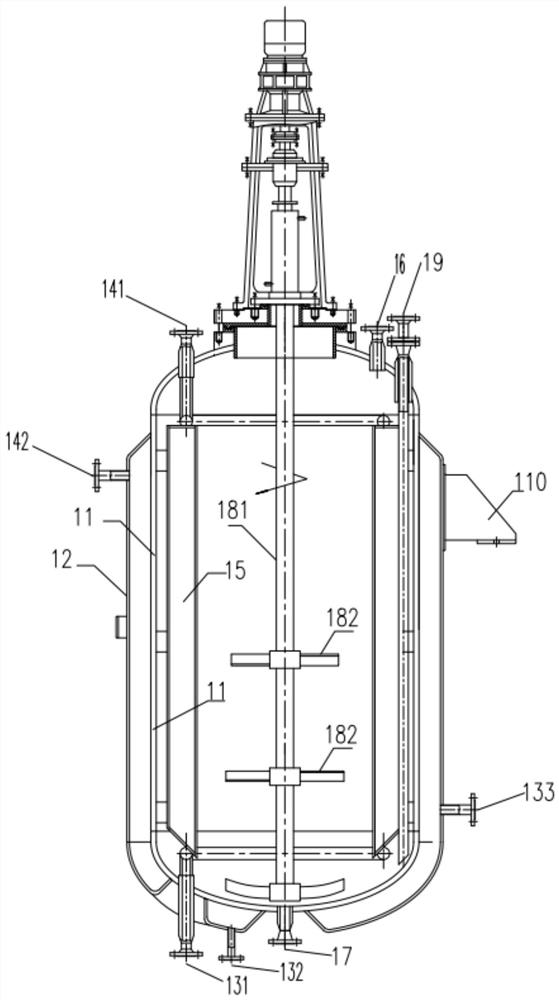

Reaction kettle with built-in cooling and heating functions

PendingCN111617724AIncrease the stirring spaceIncrease disturbanceChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsEngineeringCooling fluid

The invention provides a reaction kettle with built-in cooling and heating functions. The reaction kettle comprises an inner barrel and a jacket on the outer side of the inner barrel; cooling liquid inlets formed in the bottom and the side wall of the jacket and used for introducing cooling liquid; a cooling liquid outlet formed in the side wall of the jacket at the preset height and the upper part of the inner barrel; a baffle arranged in the inner cylinder, wherein a flow guide pipe is arranged on the baffle, and the flow guide pipe is communicated with the cooling liquid inlet and the cooling liquid outlet; a feeding hole formed in the top of the inner barrel and used for introducing a reaction material; a liquid outlet formed in the bottom of the inner barrel; a stirring system arranged in the inner barrel and used for increasing the reaction rate through stirring; and a discharge hole formed in the top of the inner barrel, wherein when the reaction kettle is heated, the cooling liquid outlet is used as a heating substance inlet, and the cooling liquid inlet is used as a heating substance outlet. According to the scheme, the temperature of the reaction solution in the reactionkettle is accurately controlled, and meanwhile, the volume of the reaction kettle per unit volume is effectively ensured.

Owner:江苏跃华石化工程有限公司

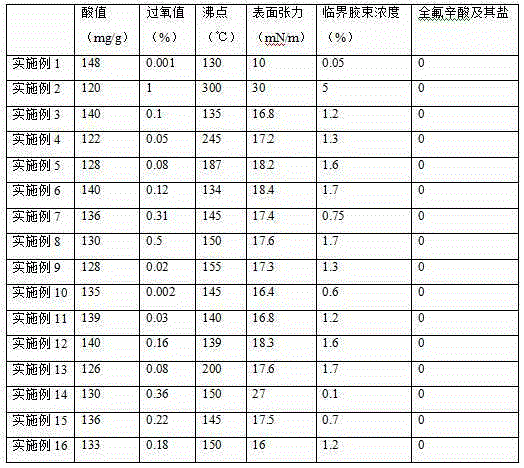

Continuous production technology of fluorine-containing surfactant without perfluorocaprylic acid

InactiveCN105344288AContinuous industrial productionWide molecular weight distributionPreparation from carboxylic acid saltsOrganic compound preparationEtherPerfluorooctanoic acid

The invention discloses a continuous production technology of a fluorine-containing surfactant without perfluorocaprylic acid. The continuous production technology comprises the following steps: using perfluoroolefine, oxygen and a third monomer as reaction raw materials, and adopting a photooxidation reaction loop, a hydrolysis unit and a salt-forming configuration unit respectively to prepare a fluorine-containing surfactant finished product using a C-O-C ether bond structure as a structure body. The finished product indexes not only meet that perfluorocaprylic acid and salt thereof are not contained, the fluorine-containing surfactant is easily degraded in the nature, but also meet data ranges that the peroxide value is 0.001-1% and the surface tension is 10-30 m / Nm. An amphipathic structure having the surfactant has advantages of high product yield, small product quality fluctuation and the like.

Owner:成都晨光博达新材料股份有限公司

Method for preparing crystal round back electrode and wafer

InactiveCN101350296BReduce dosageEliminate FringingSemiconductor/solid-state device manufacturingSemiconductor devicesScreen printingRound back

The invention discloses a wafer whose back side is coated with adhesive through adopting the silk screen printing and a process for preparing a back electrode of the wafer, the preparation process comprises the following five steps: preparing a wafer, and keeping the wafer flat in the subsequent steps, adopting the silk screen printing to coat the adhesive on the back side of the wafer and drying, arranging the wafer which is coated with the adhesive on a scribing blue film, separating, adhering and solidifying the separated wafer. The process eliminates the flanging phenomenon which easily occurs during the preparation of the wafer, the dosage of bonding slurry is reduced by one-third, the cost of the bonding slurry is greatly reduced by about ten percent, and the flatness of the coating surface of a back electrode of the chip is guaranteed, a scribing is easily cut, the intensity of the combination between the chip and the electrode during the eutectic welding is guaranteed, and the production time and cost are greatly saved. The wafer whose back side is coated with the adhesive of the invention can be stored for a long time, and the control to the quality of the stock is improved.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +1

Crushing device for impact type jet mill

PendingCN112264171ARegular shapeImprove output per unit timeGrain treatmentsEngineeringMaterials science

The invention discloses a crushing device for an impact type jet mill. The crushing device for the impact type jet mill comprises a crushing chamber, a target piece and an air source, wherein the crushing chamber comprises a feeding hole, a discharging hole and an air inlet; the discharging hole is formed in the top of the crushing chamber; the feeding hole is formed in the top of the crushing chamber and is positioned in the outer side of the discharging hole; the air inlet is formed in the side face of the crushing chamber; the target piece is used for receiving impact of materials and crushing the materials; and the air source supplies compressed air to the material to impact the target piece. According to the crushing device for the impact type jet mill provided by the invention, the target piece is arranged in the crushing chamber, and materials are driven by compressed air to impact and rub against each other so as to be crushed and then rush to the target piece to be crushed again, so that the unit time yield of ultrafine powder and fine powder is remarkably increased, and the crushed materials are regular in shape.

Owner:KUNSHAN MIYOU EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com