Method for preparing crystal round back electrode and wafer

A back electrode and wafer technology, applied in circuits, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of unstable dispensing product pass rate, lower output per unit time, and low glue fluidity, etc., to eliminate Flanging phenomenon, saving storage costs, improving the effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

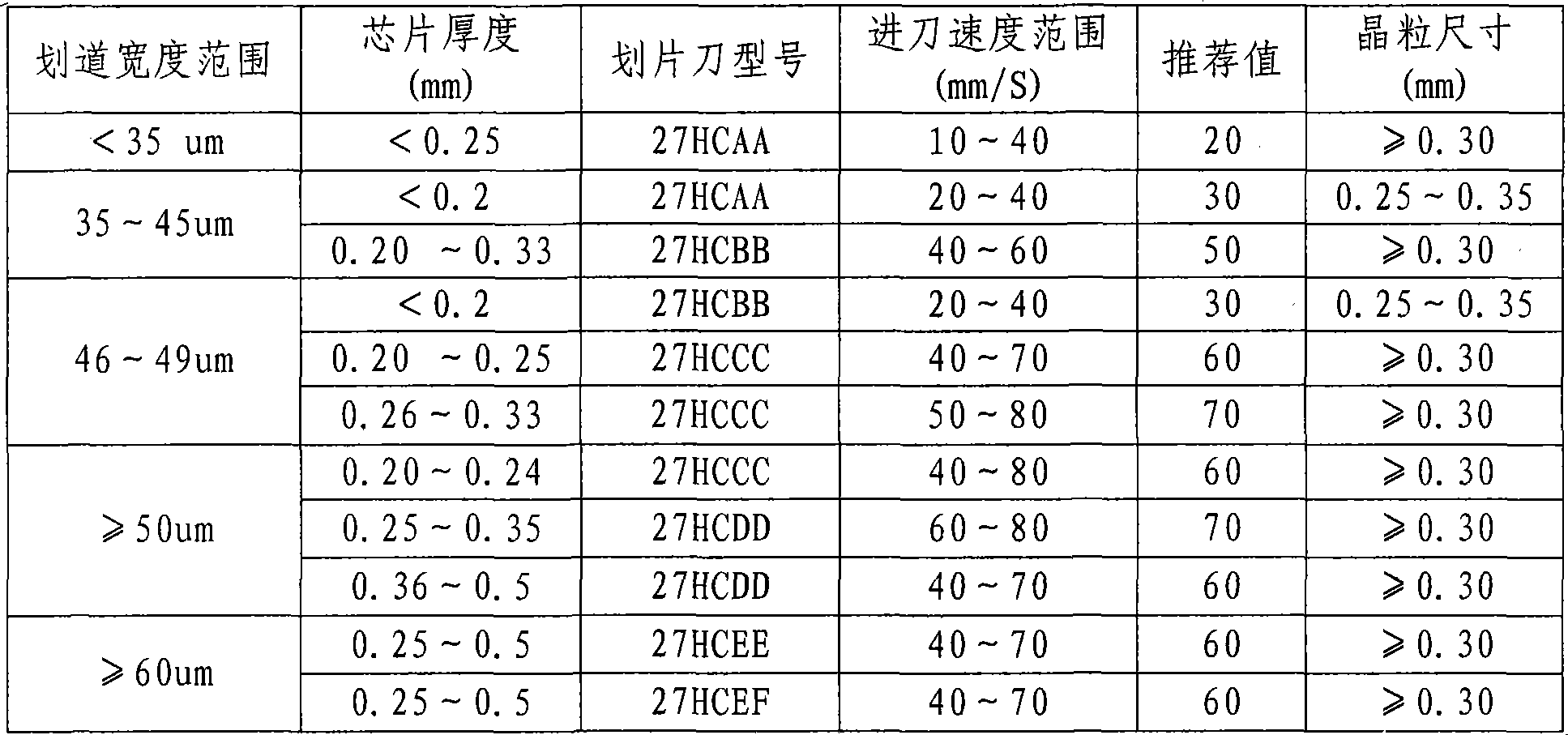

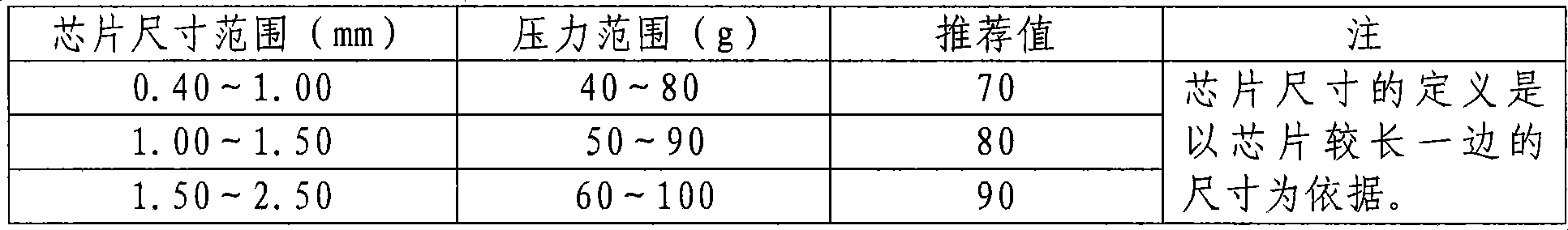

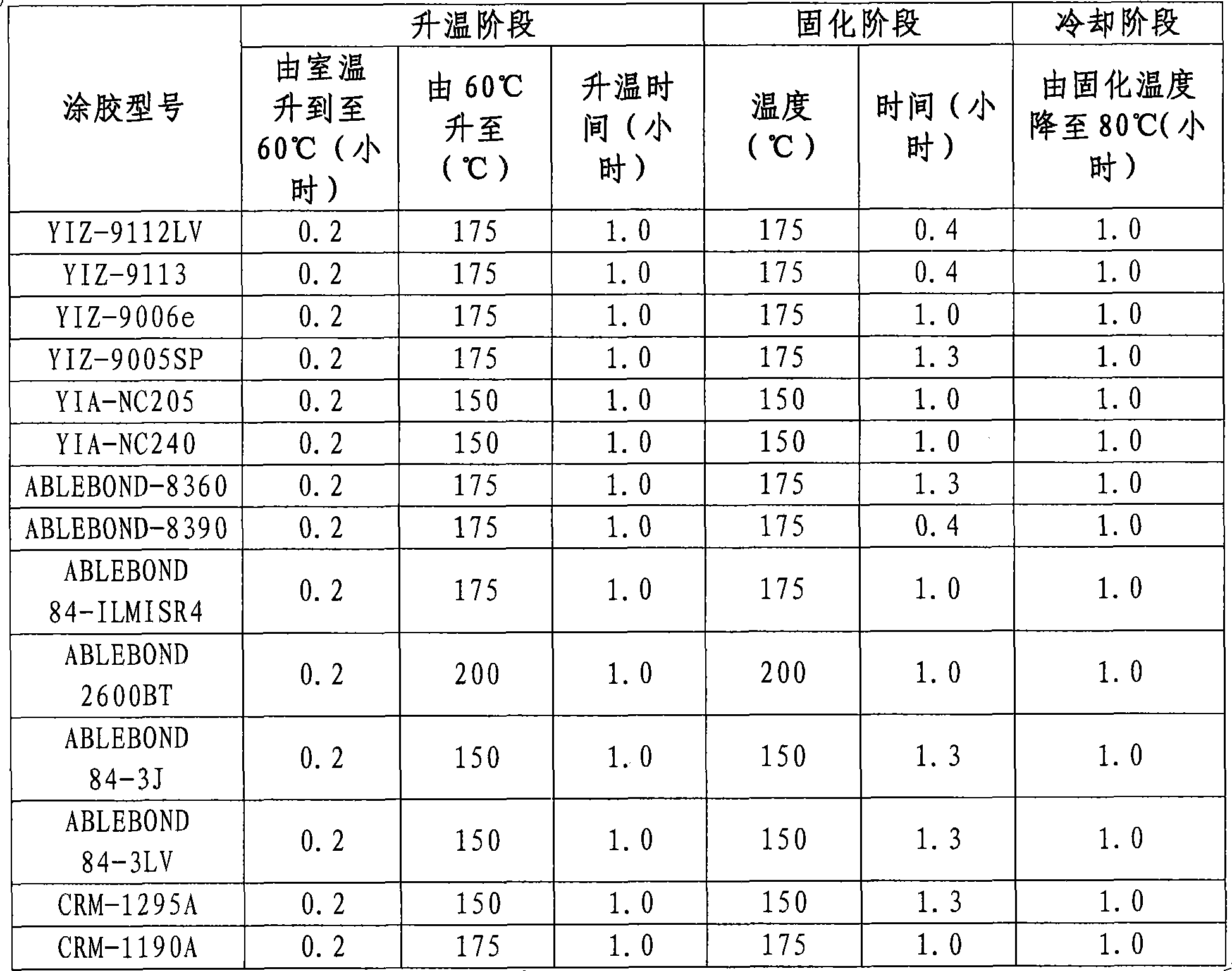

Method used

Image

Examples

Embodiment Construction

[0021] (1) Prepare the wafer and keep the wafer flat during the whole preparation process: use a porous ceramic plate to support the wafer, obtain a vacuum through the channels of the porous ceramic on the plate, suck the wafer firmly without damage and keep the wafer in the subsequent steps remain flat in

[0022] Paste the adhesive film and metal ring on the wafer, and mark the production batch number and product model on the adhesive film. Since the wafer is adsorbed on the surface of the workbench during printing, if the surface is uneven, uneven coating will occur when the adhesive is applied on the back of the next step, which indirectly leads to insufficient dispensing amount and affects product packaging. post pass rate. Therefore, the flatness of the workbench is not greater than 0.025mm; the repeated positioning accuracy of the workbench can only meet the process requirements when it reaches 0.1mm; because the parallelism between the screen and the workbench during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com