Automatic focusing binocular camera calibration and depth calculation method

A binocular camera and auto-focus technology, applied in the field of optical measurement, camera manufacturing, and computer vision, can solve problems such as changes in lens calibration parameters, achieve the effects of reducing production costs, increasing production, and enhancing product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

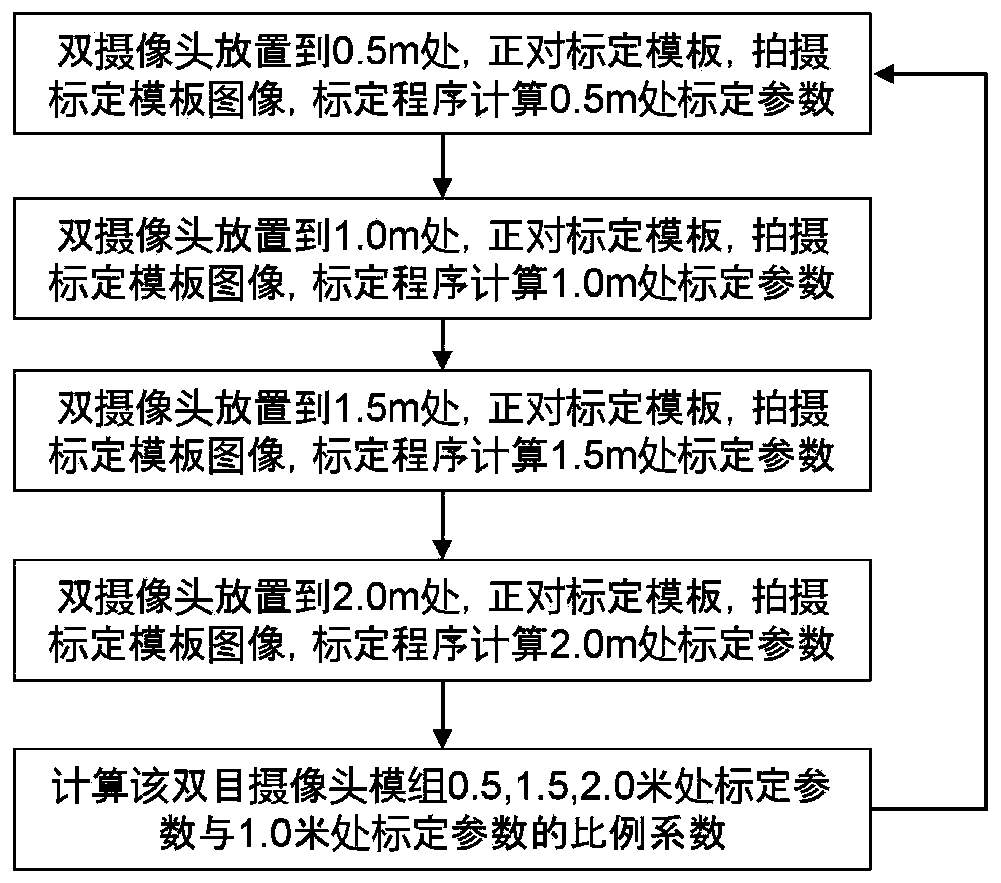

[0111] Figure 2A , Figure 2B , Figure 2C , Figure 2D It is the structural diagram of the pre-calibration device during the trial production of the binocular camera. Place a 2D plane at each of the four distances (the calibration distance can be appropriately selected according to the requirements of the subsequent binocular camera application, production line time requirements, and laboratory equipment size requirements. Here, the four distances are taken as an example, the same below). Calibration template: 0.5, 1.0, 1.5, 2.0 meters. The binocular camera module is placed in the position facing the calibration template in turn, that is, the optical axis of the binocular camera is perpendicular to the calibration template, the camera takes a static picture, and the calibration algorithm calculates the camera calibration parameters. After the distance calibration is completed, the camera moves to the next distance calibration position. After the four distance calibration...

Embodiment 1

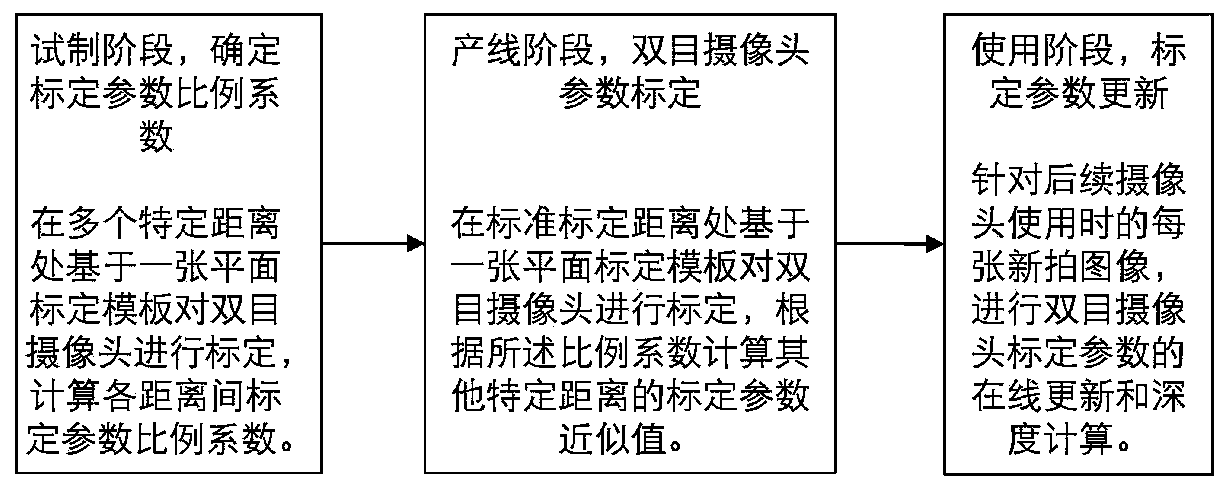

[0114] This embodiment is divided into three stages: trial production stage, production line stage and use stage. The following are detailed implementation steps:

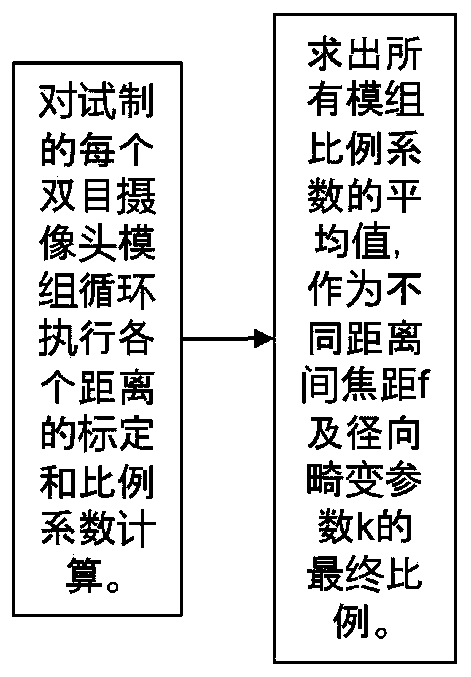

[0115] The first stage: the trial production stage, use 50 binocular camera modules to calibrate at four distances (0.5, 1.0, 1.5, 2.0 meters), and calculate the calibration parameter ratio coefficient between each distance

[0116] The first step: place the module to be tested to the calibration template at 0.5m, take a picture of the calibration template, and the calibration program calculates the calibration parameters at 0.5m

[0117] Obtain a calibration template image, obtained by shooting the calibration template; (corresponding to S1)

[0118] Calibration templates are generally repeated patterns with fixed spacing, such as black and white checkerboard calibration templates, equidistant solid circle array calibration templates, etc. In this example, only one calibration template image needs to be taken fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com