Device for bonding semiconductor chips

A semiconductor and chip technology, applied in semiconductor/solid-state device manufacturing, transportation and packaging, conveyor objects, etc., can solve problems such as material jams, scrapping, chip 10 scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

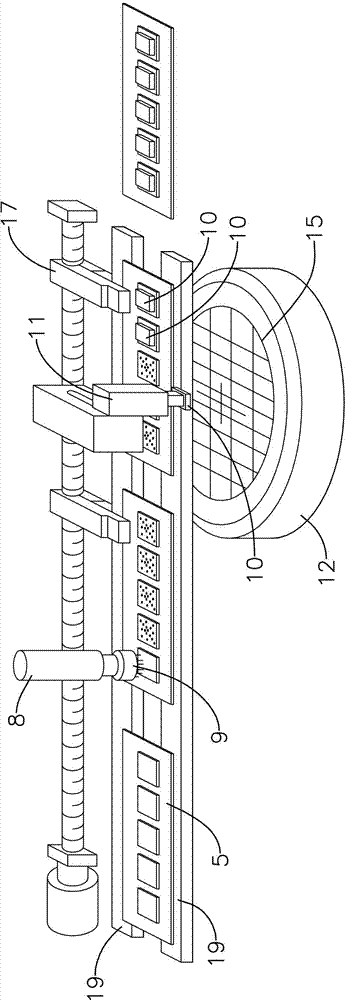

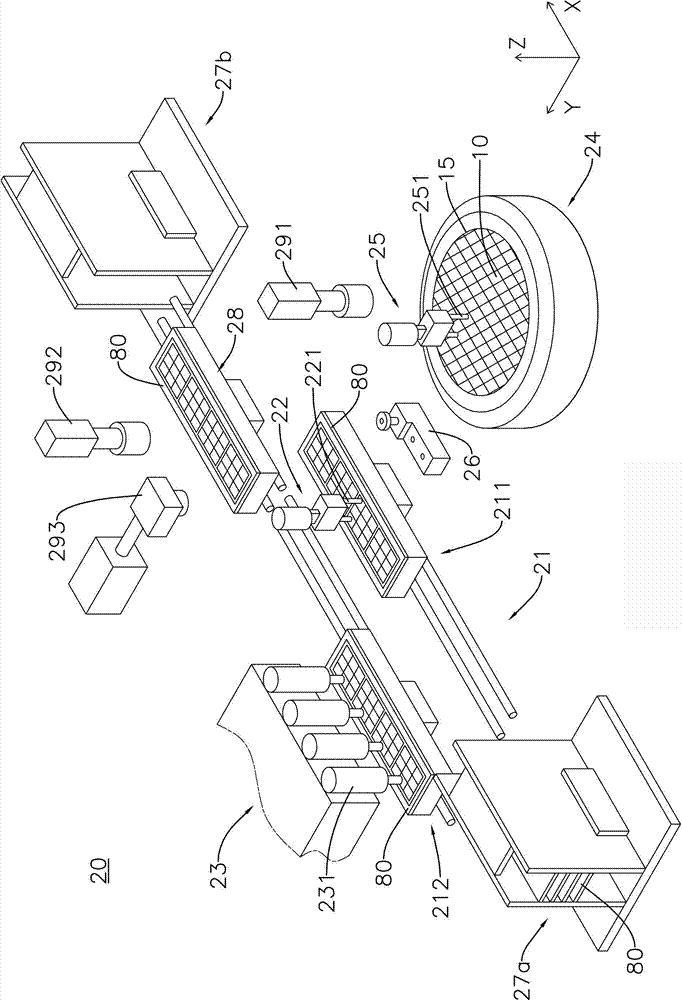

[0045] Example: see image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 Shown:

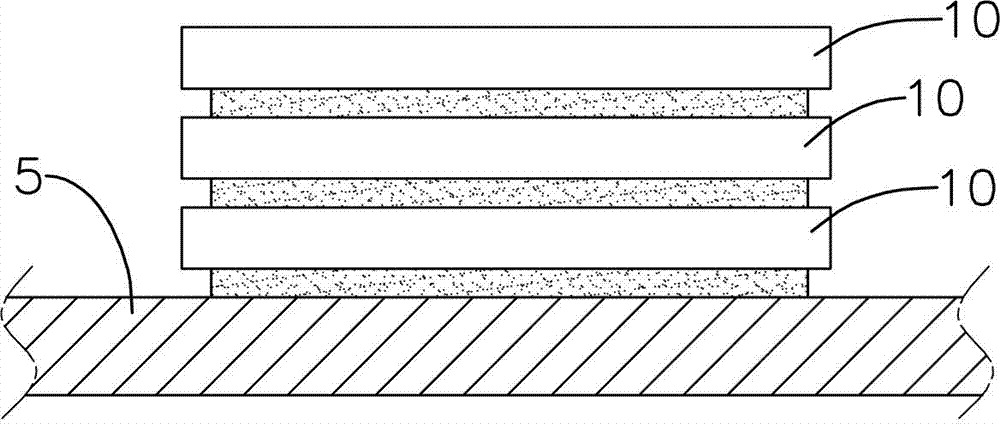

[0046] A device for adhering semiconductor chips is used for adhering and fixing a chip 10 or stacking multiple chips 10 on a packaging carrier 80 . The device for sticking semiconductor chips includes: a pre-pressing module 22, which can take and place and apply pressure so that at least one chip 10 is pre-pressed with a package carrier 80 or another chip 10 on a package carrier 80; a main press-bonding module 23, including a plurality of bonding heads 231, which will simultaneously apply pressure to a plurality of chips 10 that have been pre-bonded, and make the plurality of chips 10 and a package carrier 80 or another plurality of chips 10 on a package carrier 80 perform main Pressing; a first feeding conveying mechanism 211; and a second feeding conveying mechanism 212, the first feeding conveying mechanism 211 and the second feeding conveying mechanism 121 convey the packaging carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com