Crushing device for impact type jet mill

An air-jet pulverizer and pulverizing device technology, which is applied in the field of material pulverization, can solve the problems that cannot meet the requirements of ultra-fine or even fine powder, the particle size is difficult to reach the micron level, and the powder productivity decreases, so as to improve the output per unit time and avoid The effect of pollution and shape regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] In order to realize the purpose of the present invention, the technical scheme provided by the present invention is:

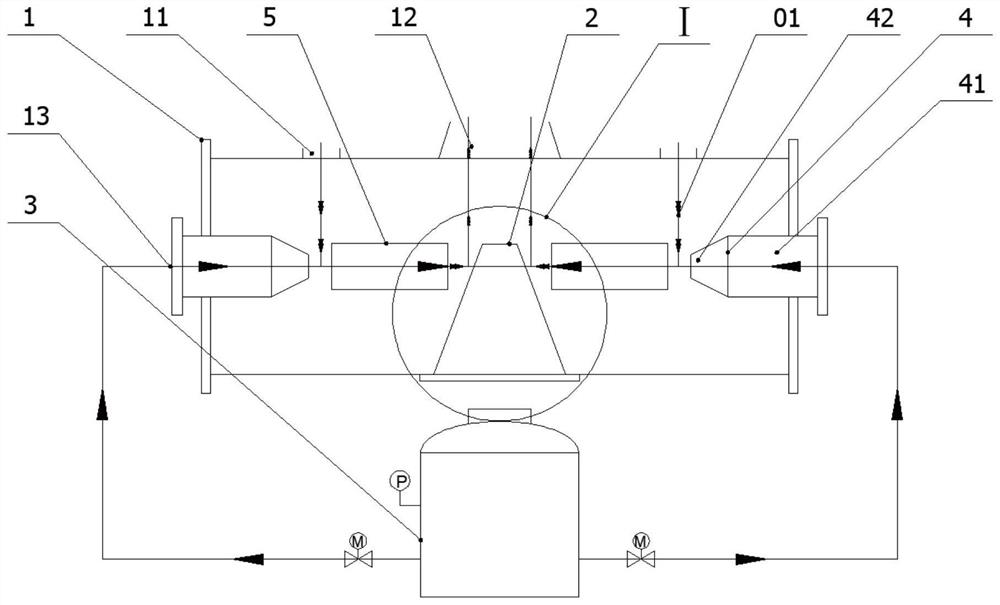

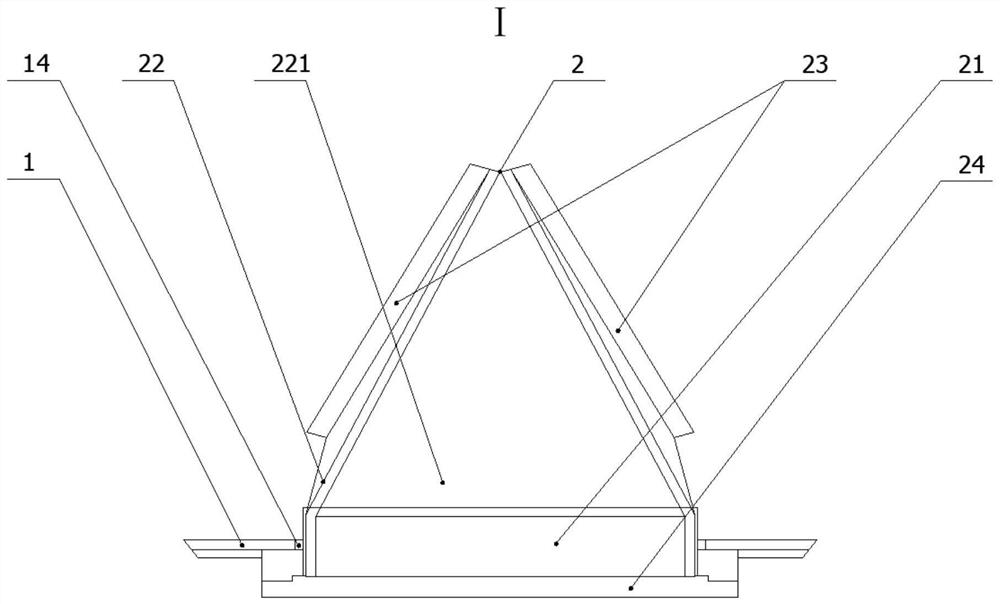

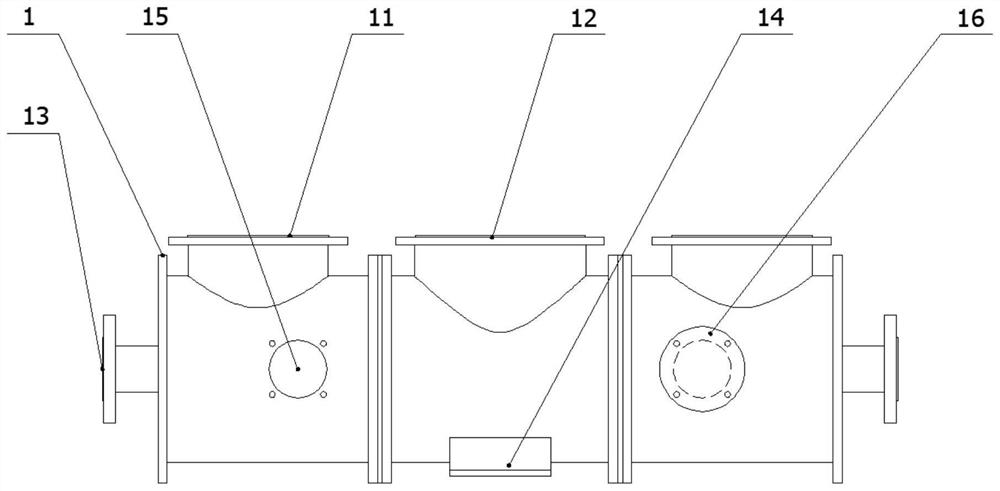

[0035] In some embodiments of the present invention, such as figure 1 As shown, a crushing device for an impact jet mill, including: a crushing chamber 1, a target 2 and an air source 3; the crushing chamber 1 is a hollow chamber that provides a crushing place for the material 01, including a feed port 11 , discharge port 12 and air inlet 13; discharge port 12 is located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com