Composite material hub

A composite material and wheel hub technology is applied in the field of reinforced fiber material preform structure and automobile wheel hub manufacturing, which can solve the problems of high price, long production cycle, and inability to large-scale application, so as to shorten the occupation period, reduce leftover materials, and avoid redundant Effects of the use of excess fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

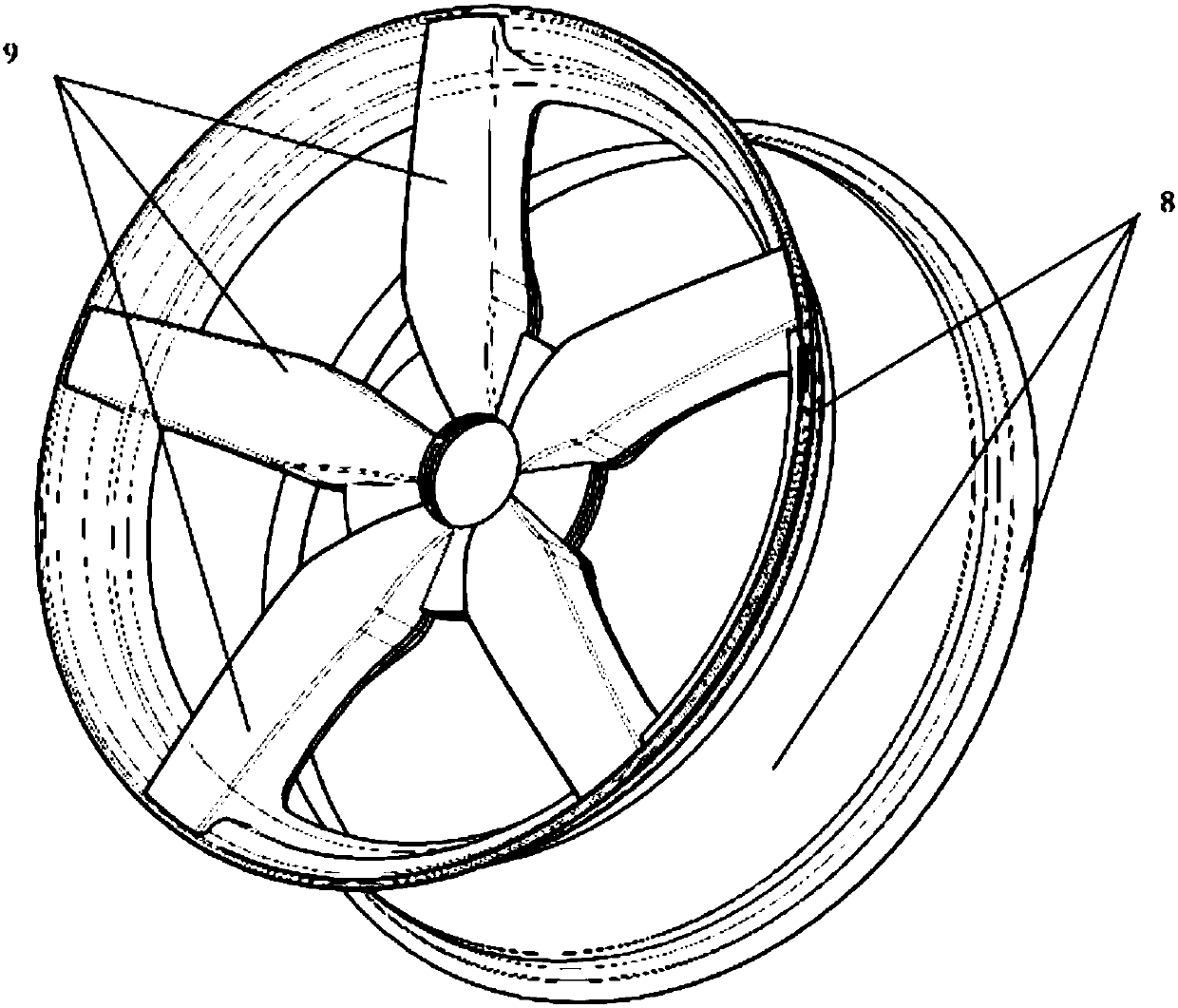

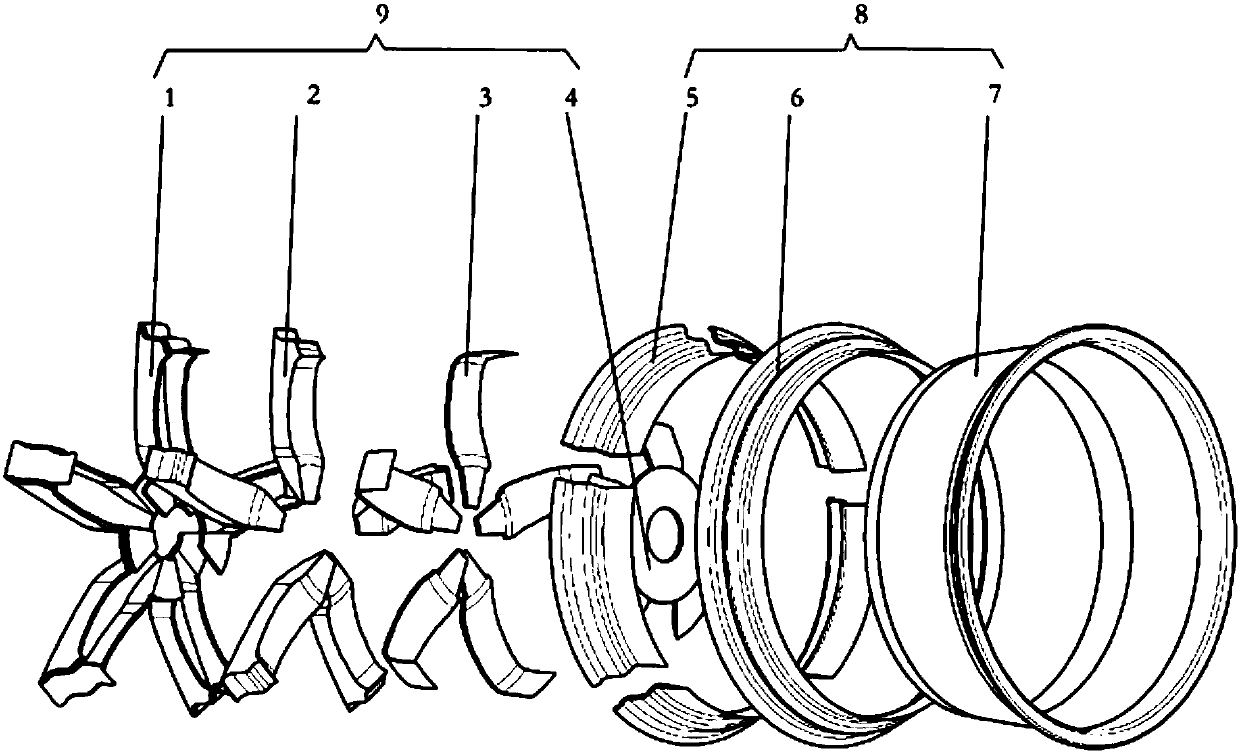

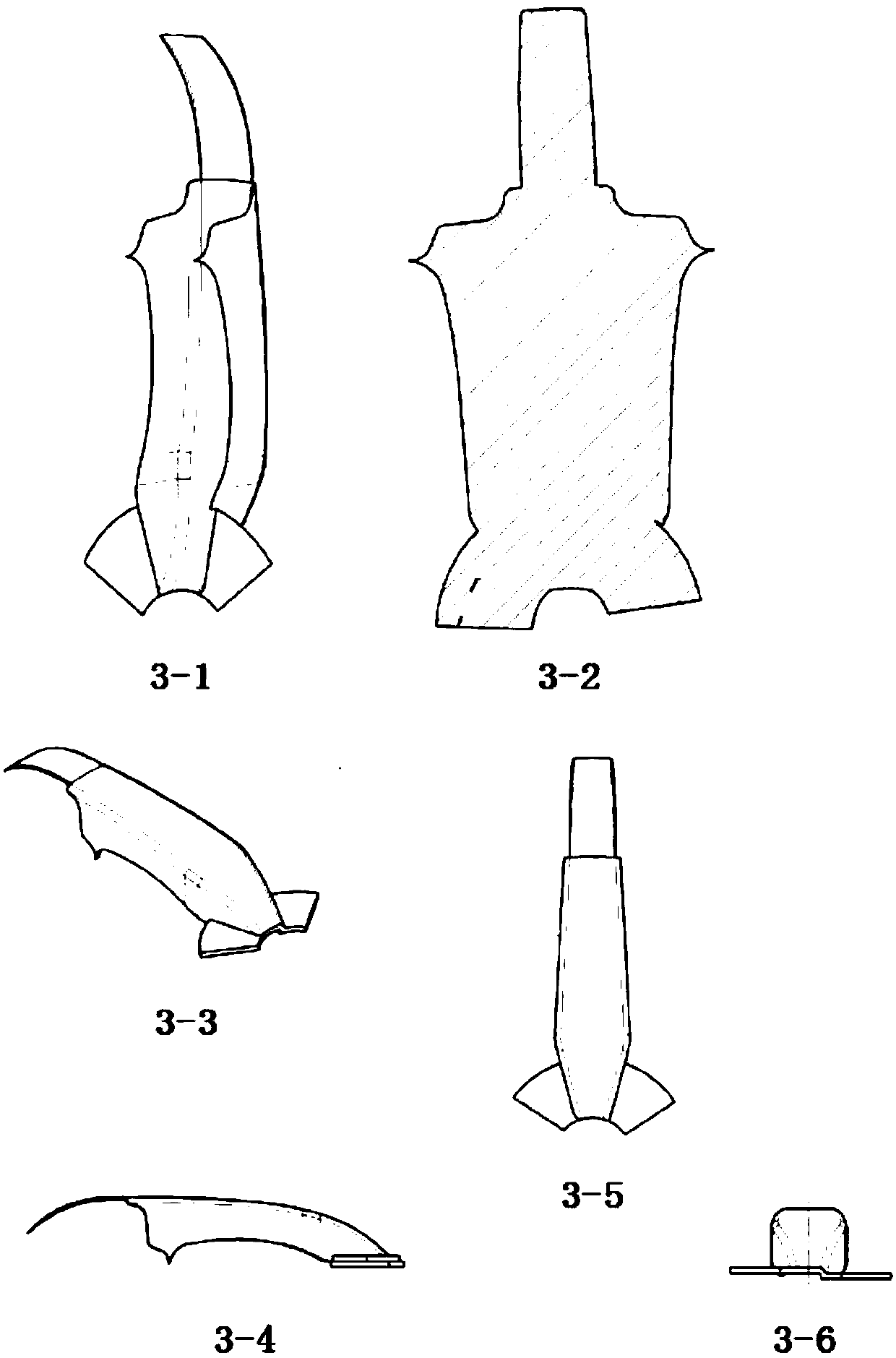

[0026] A composite wheel hub provided in this embodiment, such as Figure 1 to Figure 12 As shown, a web preform 8 and a rim preform 9 are included. Among them, the web preform consists of 4 to 6 groups of the same reinforced fiber material preforms that are staggered and stacked around the central axis of the hub to form spokes and a hub for connecting with the axle. In this embodiment, 5 groups are selected; From the outside to the inside, it includes the spoke surface layer 1, the material filling layer 2, the spoke back layer 3 and the hub reinforcement layer 4. The rim preforms also include 4 to 6 groups of the same reinforced fiber material preforms, and 5 groups are also used in this embodiment; each group of preforms is connected to two adjacent spokes at the same time, including the inter-spoke Connect the reinforcement layer 6 with the rim ring 7 .

[0027] Wherein, the reinforcing fiber material is one or a combination of fiber bundles, fiber mats, unidirectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com