Patents

Literature

99results about How to "Reduce leftovers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula of sole material

InactiveCN102250407AGuaranteed wear resistanceGuaranteed compression performanceSolesElastomerPolyolefin

The invention discloses a formula of a sole material. The sole made of the sole material can be formed in one piece to save cost, and the sole does not contain heavy metal and is light and breathable. The sole material comprises the following substances in percentage by weight: 1, 11.6 to 52.4 percent of ethylene vinyl acetute (EVA); 2, 7 to 13 percent of polyolefin elastomer (POE); 3, 1.4 to 2.6percent of ethylene-propylene-diene monomer; 4, 12.6 to 23.4 percent of standard rubber; 5, 12.6 to 23.4 percent of cis-polybutadiene; 6, 3.5 to 6.5 percent of butylbenzene; 7, 2.8 to 5.2 percent of talc powder; 8, 2.1 to 3.9 percent of white carbon black; 9, 2.1 to 3.9 percent of stearic acid; 10, 0.7 to 1.3 percent of modifier; 11, 1.05 to 1.95 percent of zinc oxide; 12, 1.4 to 2.6 percent of cross-linking agent; and 13, 0.35 to 0.65 percent of sulfur.

Owner:JINJIANG GUOSHENG SHOE MATERIAL LTD

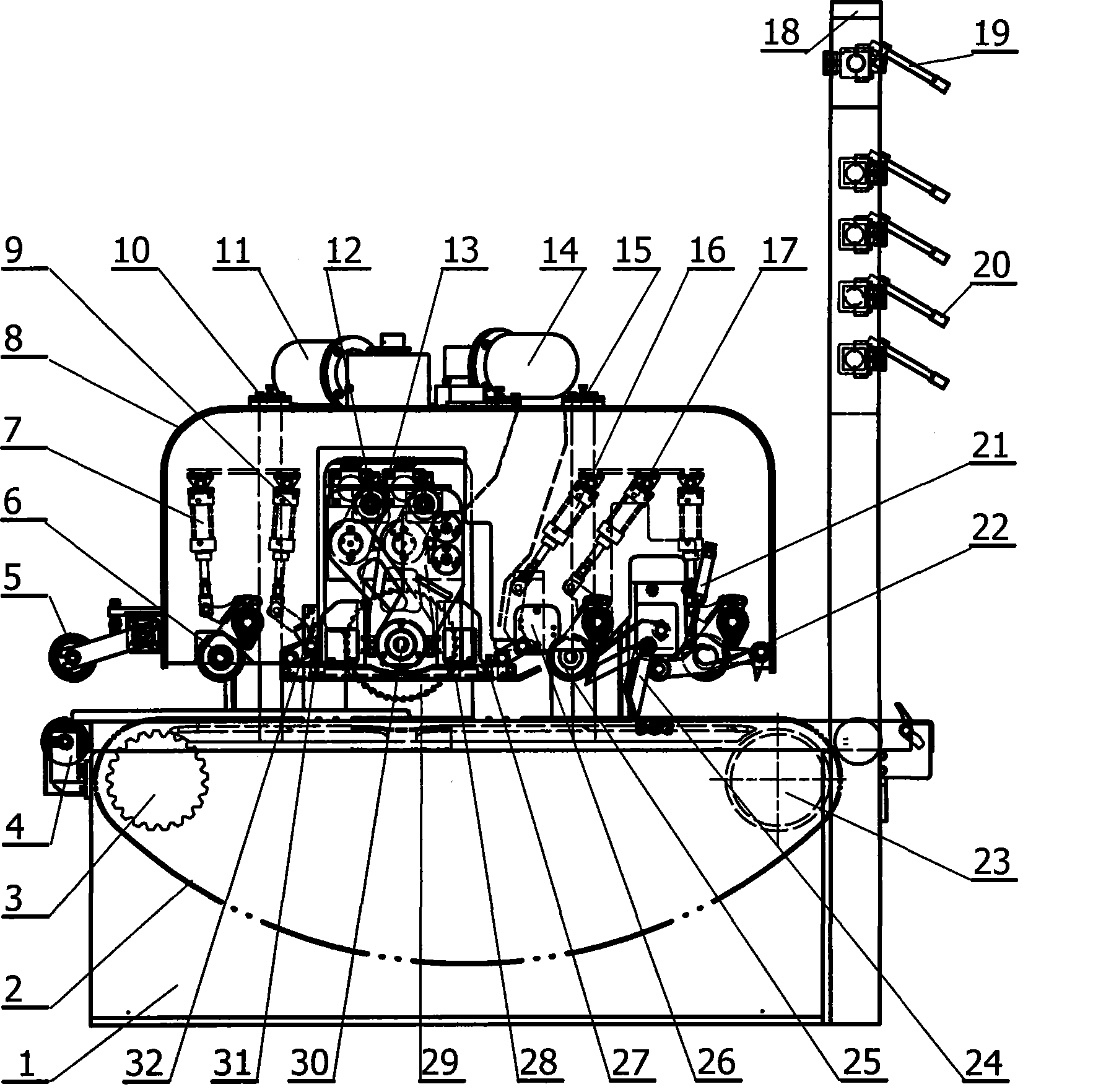

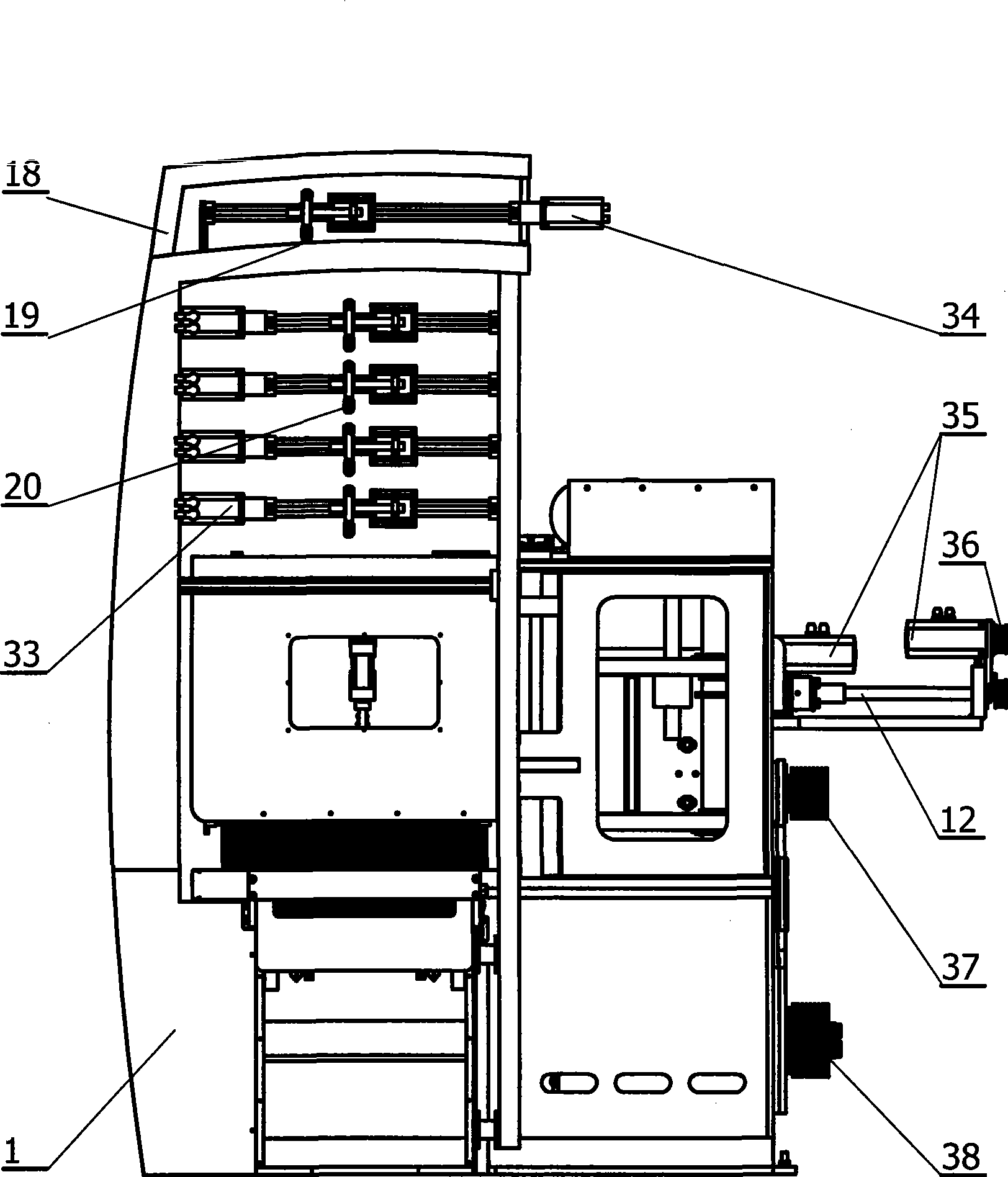

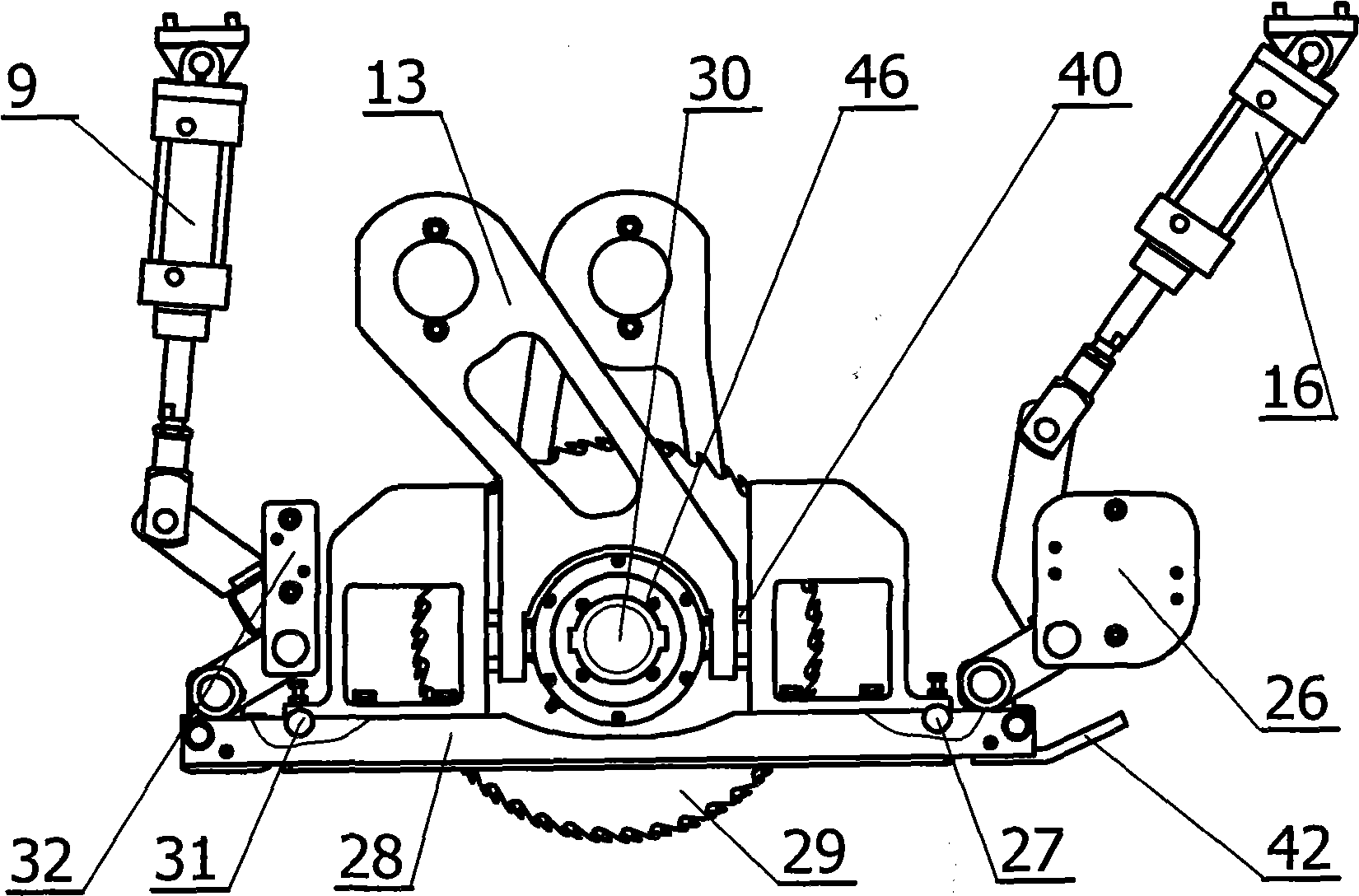

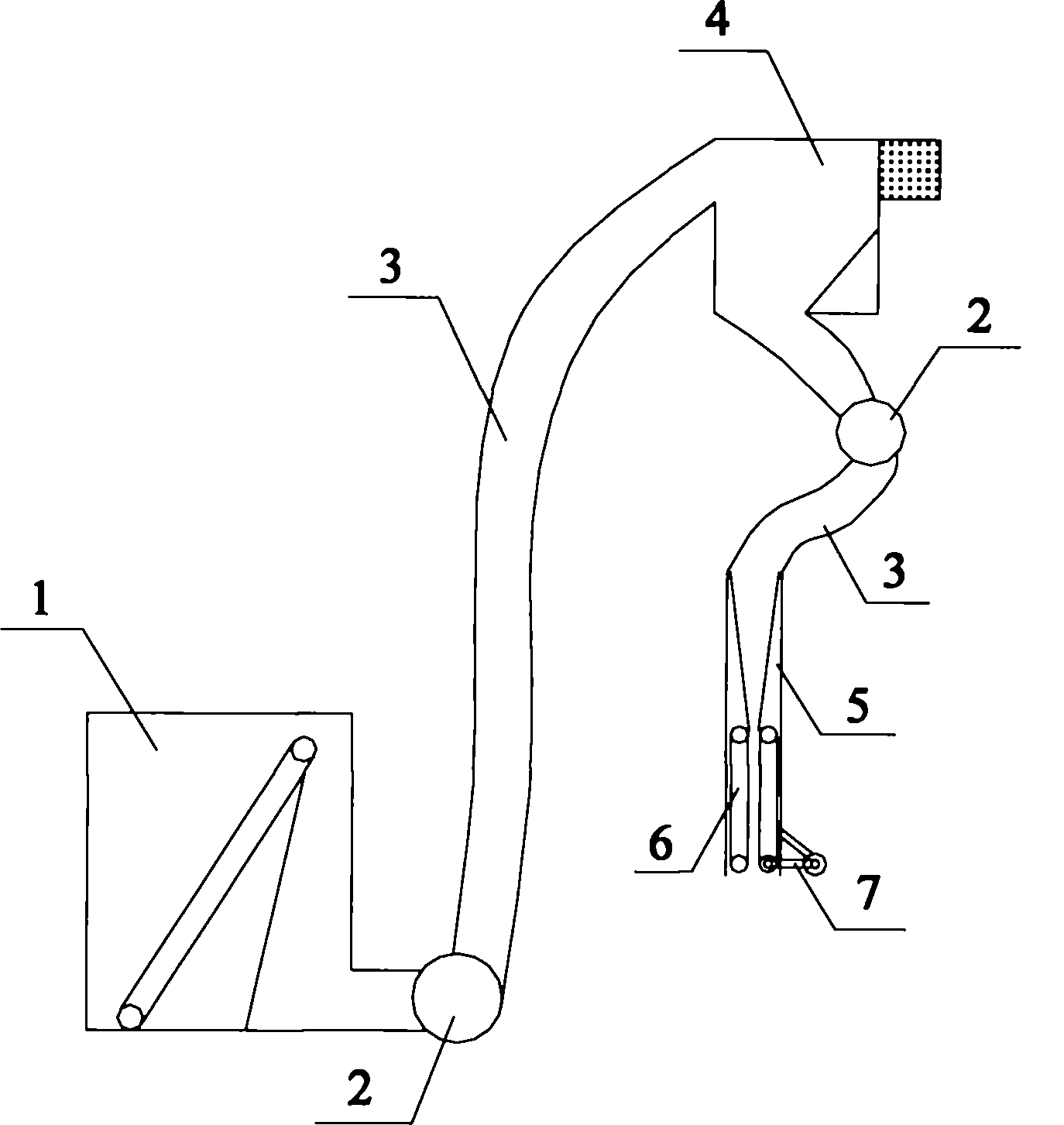

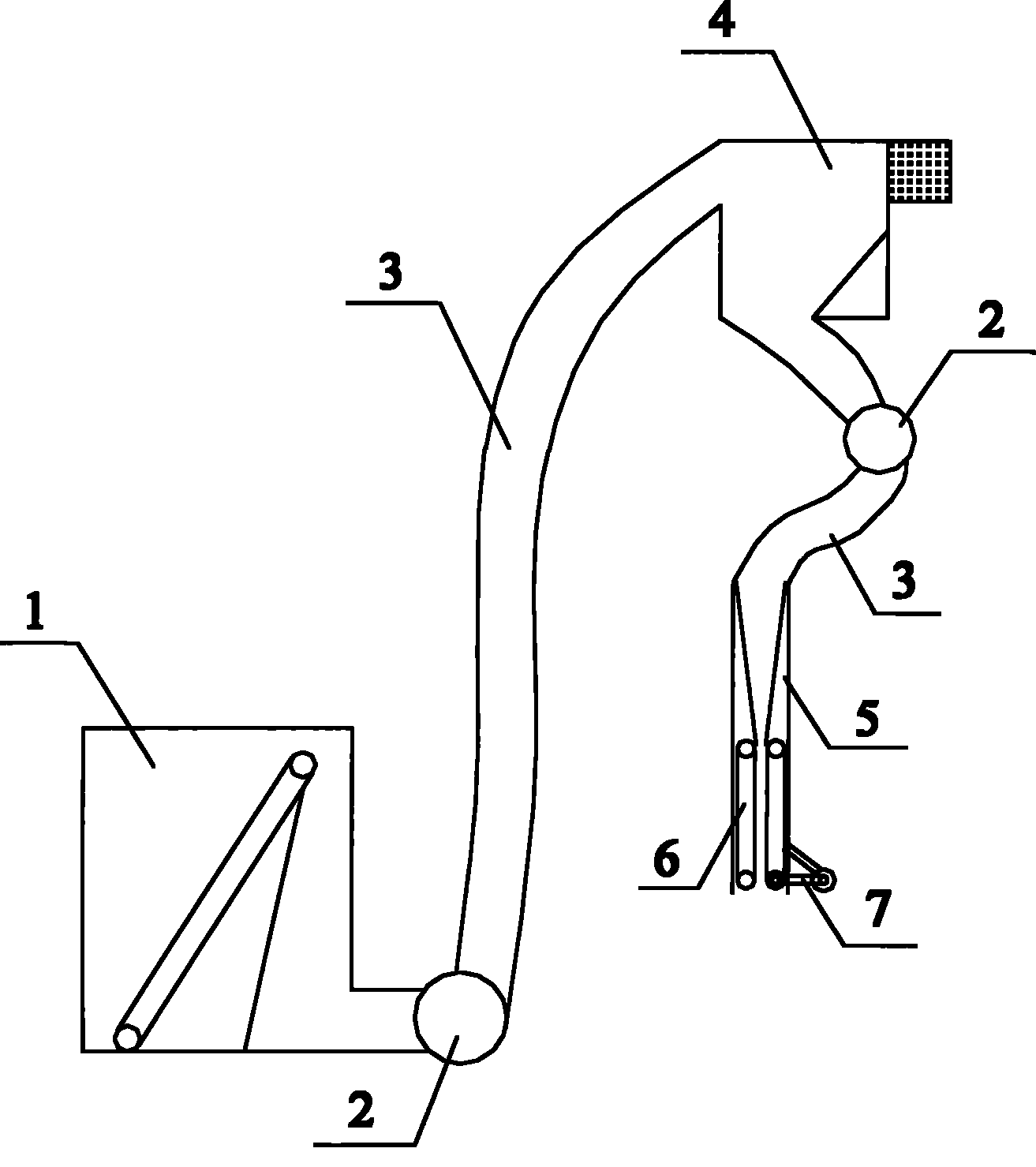

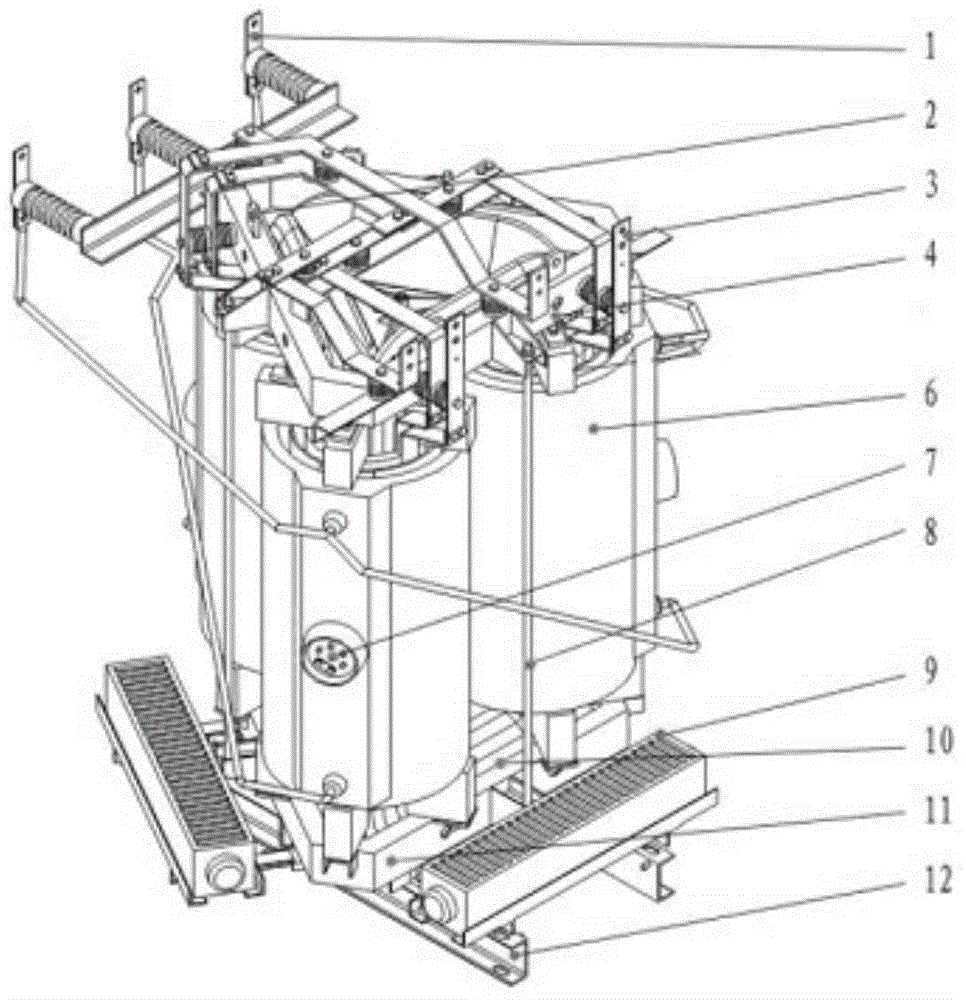

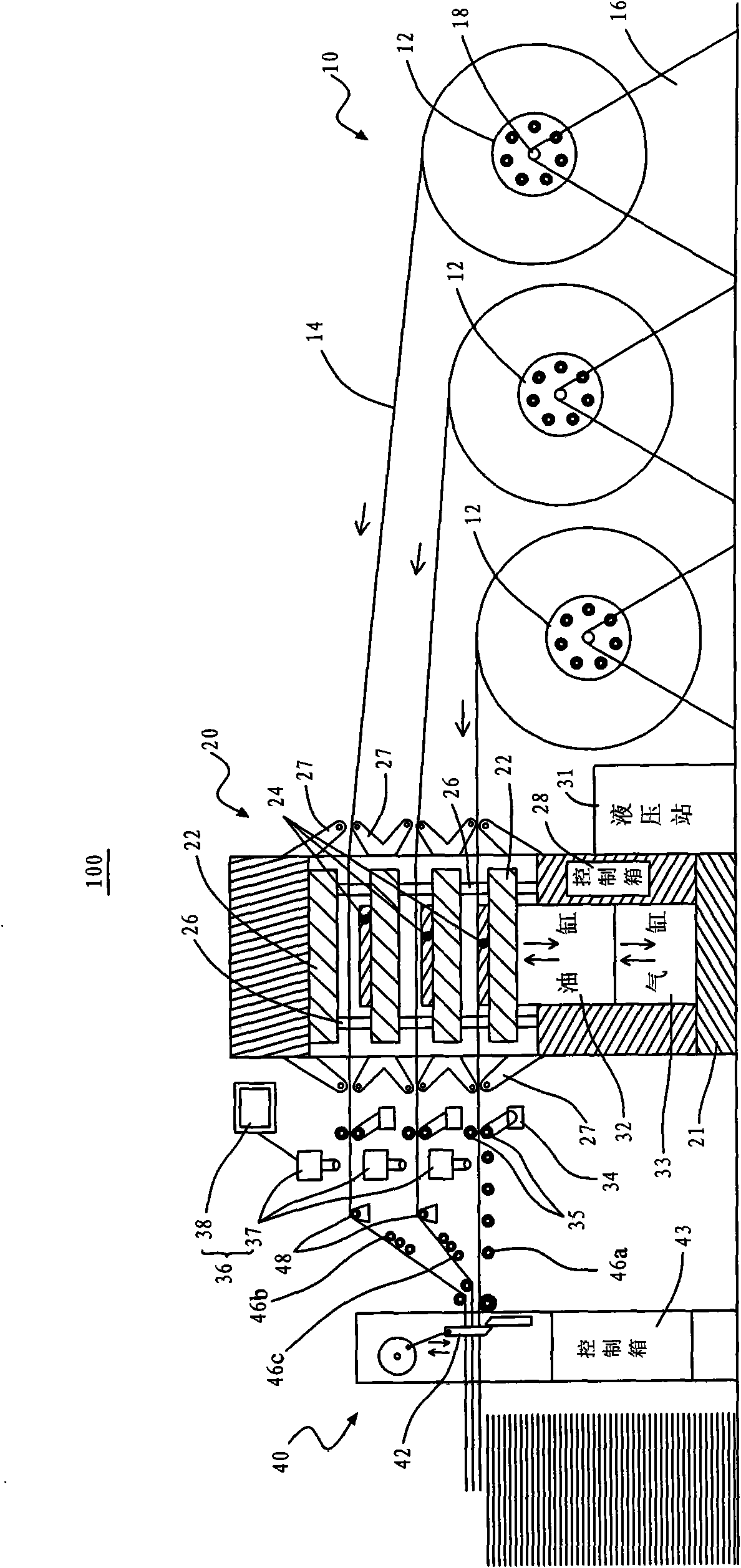

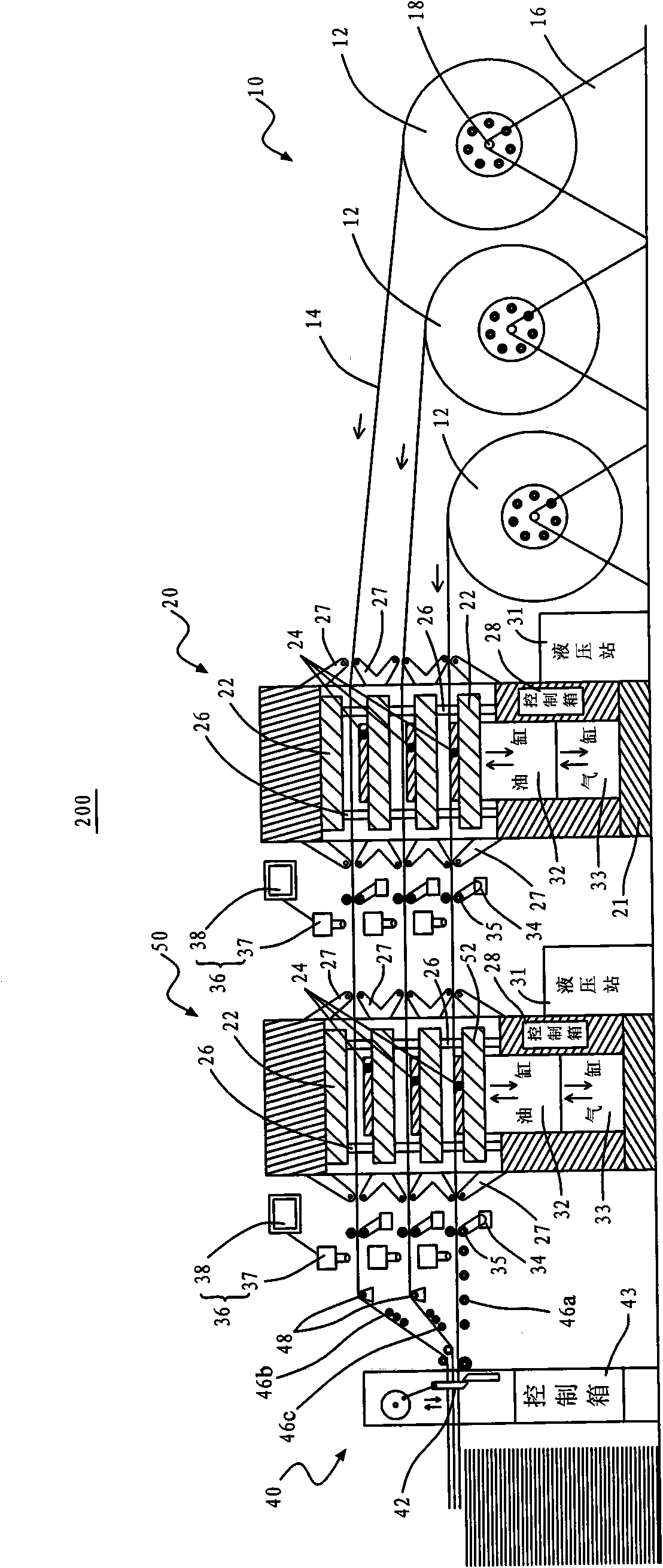

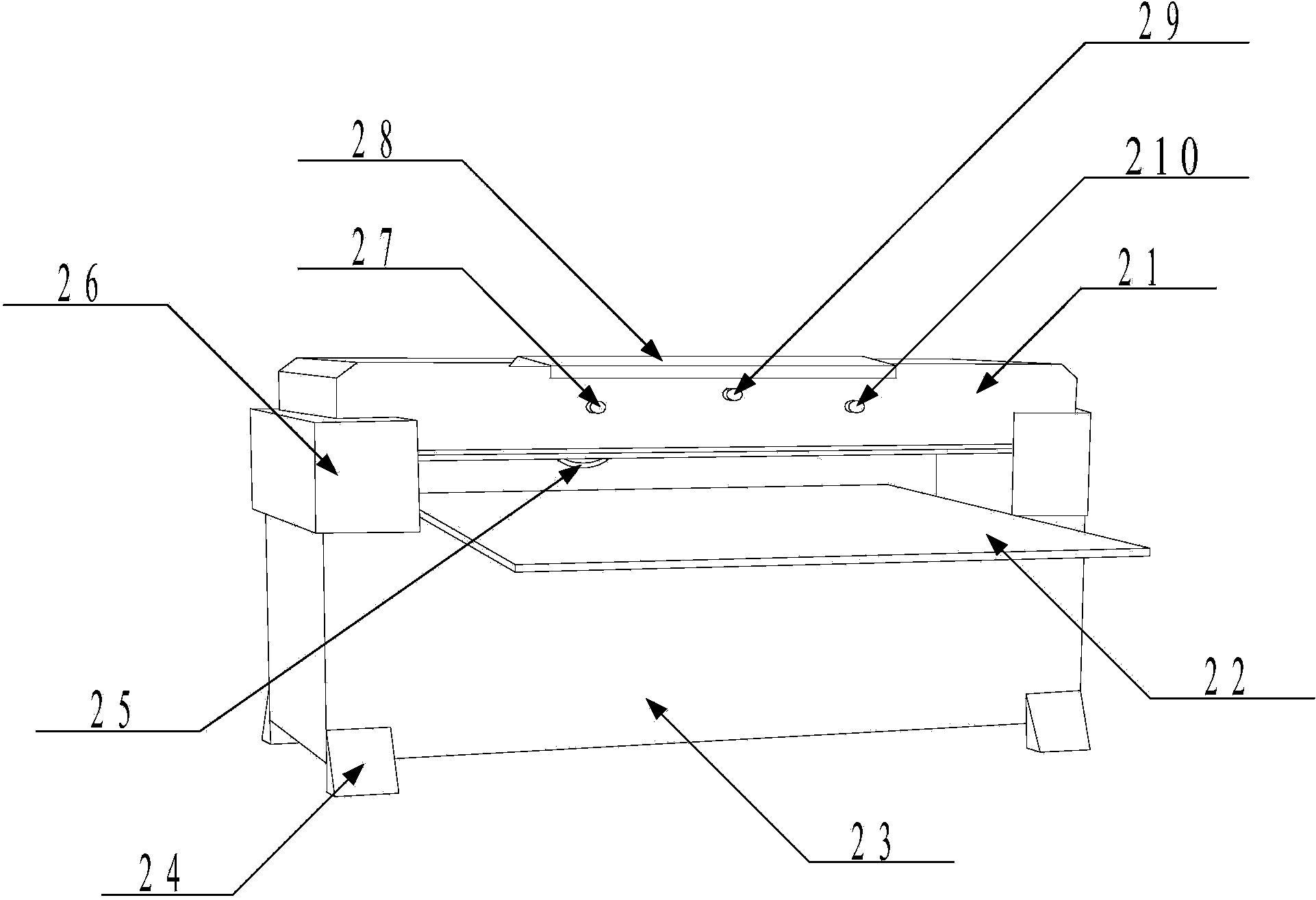

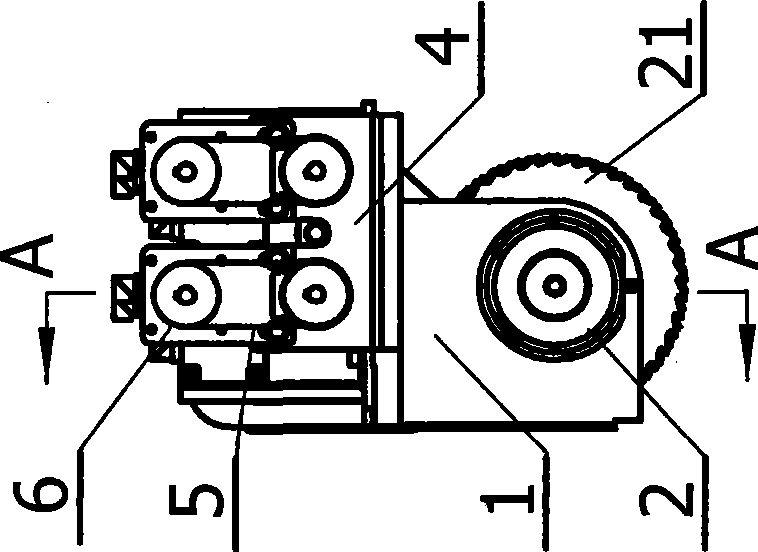

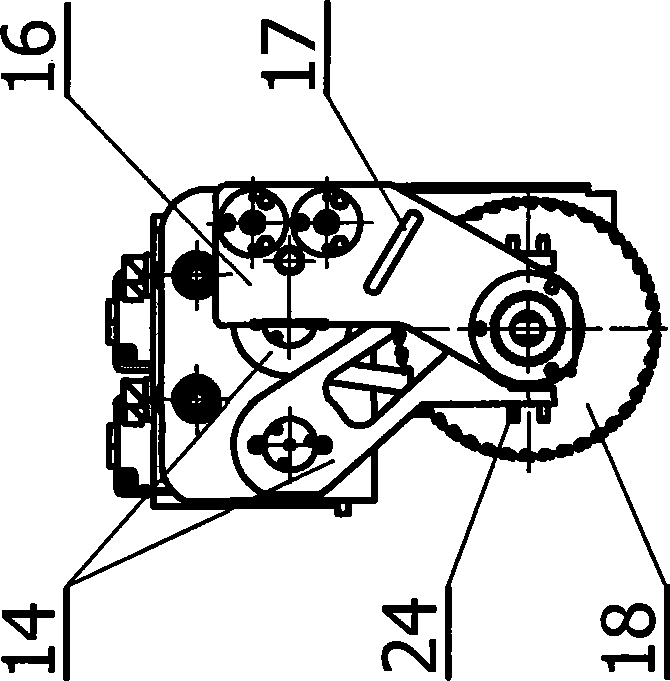

Method for preferably cutting timber in longitudinal direction and circular saw machine for preferably cutting timber in longitudinal direction

The present invention discloses a method for longitudinally optimizing cutting timber. The method comprises the following steps: inputting a cutting data list into a computer device beforehand, selecting a width reference border of sawtimber to be cut for confirming the maximum width of sawtimber to be cut, transmitting the information to the computer device for selecting an optimal cutting plan through analyzation and calculation, axially moving the circular saw blade of saw cutting machine to a cut line position corresponding with the sawtimber to be cut according to instruction of computer device for longitudinally cutting the sawtimber to be cut to finished sawtimber and waste edge material. The timber cutting optimizing circular sawing machine for realizing the method of the invention comprises a circular sawing machine base, a feeding chain plate, a sawblade main shaft, a front compression roller and a back compression roller, wherein the front compression roller and the back compression roller are positioned at the front side and the back side. The marking-off equipment stand which is fixedly installed at the front end of engine base is installed with follower marking-off equipment. A moving circular saw blade is installed on the main shaft of sawblade. The main shaft assembly and the upper frame are respectively supported on the front lifting upright post and the back lifting upright post with a liftable mode. The method of the invention can greatly increase the material yielding rate and production efficiency and has the advantages of high automatization degree and wide application sphere.

Owner:JIANGSU JIANGJIA MACHINERY

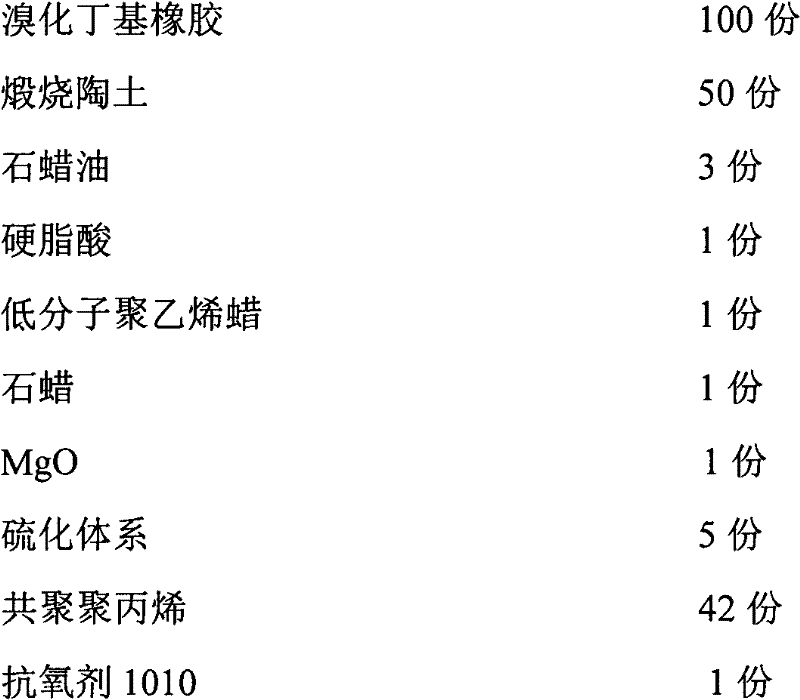

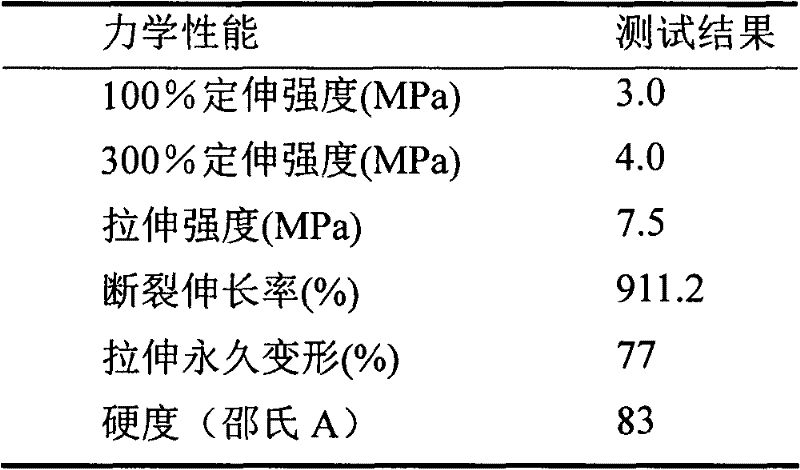

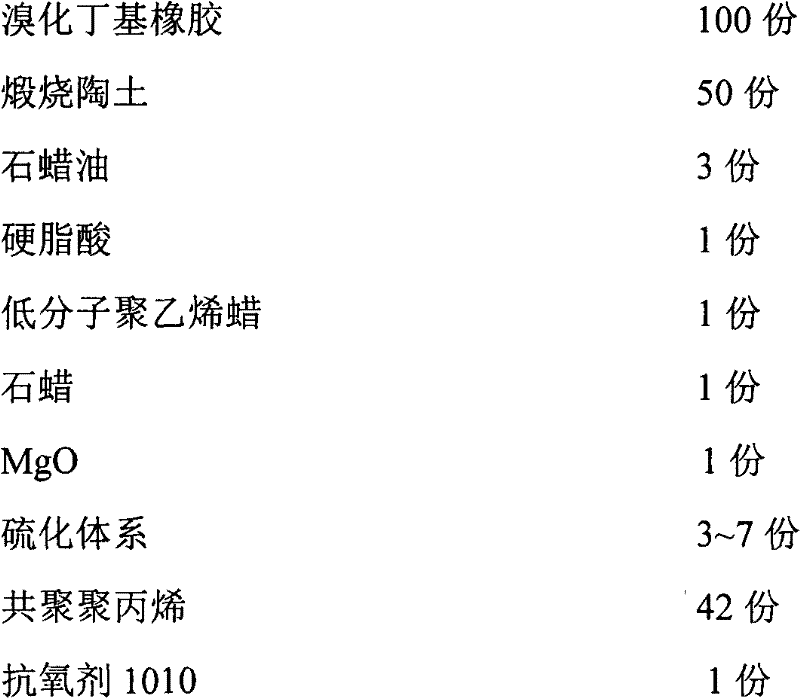

Vulcanizing system of brominated butyl rubber/ polypropylene thermoplastic elastomer sealing material and preparation method for sealing material

InactiveCN102585319APlay a role in vulcanizationHigh elongation at breakOther chemical processesCross-linkPolymer science

The invention provides a vulcanizing system of a brominated butyl rubber / polypropylene thermoplastic elastomer sealing material and a preparation method for the sealing material. The vulcanizing system comprises a vulcanizing agent, a catalyst and an active agent. The vulcanizing agent is a sulfur-free vulcanizing system, is granular and dustless, and is easy to weigh, calculate and disperse and safe in operation. The preparation method is a dynamic vulcanizing blending method, and can comprise injection and extrusion molding; the cross-linked rubber phase is dispersed uniformly in a plastic phase; and the preparation method has the advantages of simple process, a small amount of waste, high production efficiency and the like. The performance of the prepared sealing material meets the requirement of national standard YBB00232004. The vulcanizing system can substitute brominated butyl vulcanized rubber and can be applied in various fields.

Owner:EAST CHINA UNIV OF SCI & TECH

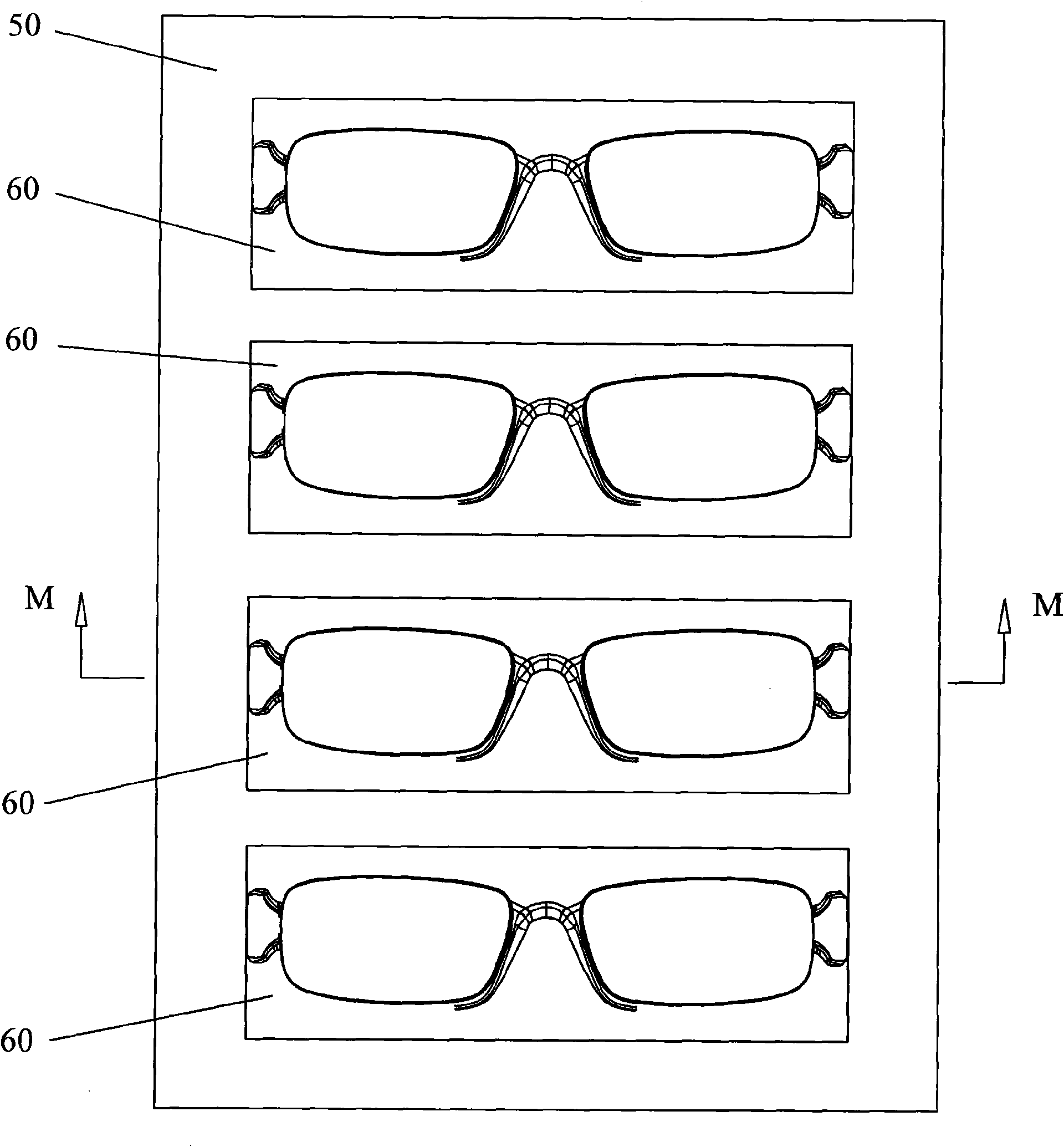

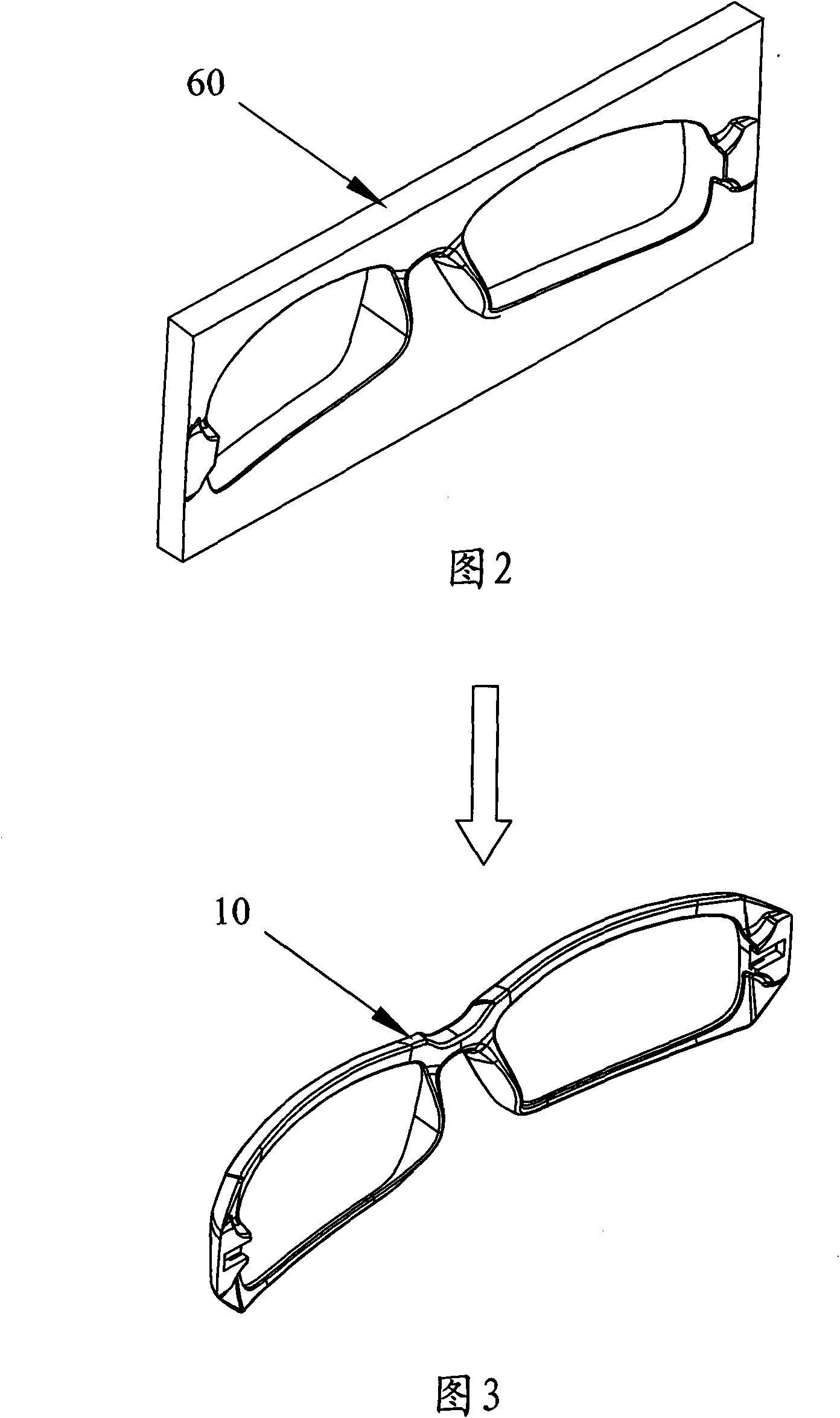

Manufacturing method for decorated eyeglass frame or eyeglass leg

The invention discloses a manufacturing method for a decorated eyeglass frame or eyeglass leg, comprising the steps of molding and processing, wherein the step of molding comprises the step of puttingdecoration and plastic raw materials into a molding cavity of a die mold, once die-casting a hard base material, and the step of processing comprises the step of machining the base material to manufacture the final eyeglass frame or eyeglass leg. Compared with the traditional manufacturing method of eyeglass frame or eyeglass leg, the invention has the advantages that a same eyeglass frame or eyeglass leg can be molded with a double-color or multi-color effect, the processing efficiency and processing quality are higher and the method is more environment-friendly because the processing needsno glue or solvent.

Owner:邱湟鏻

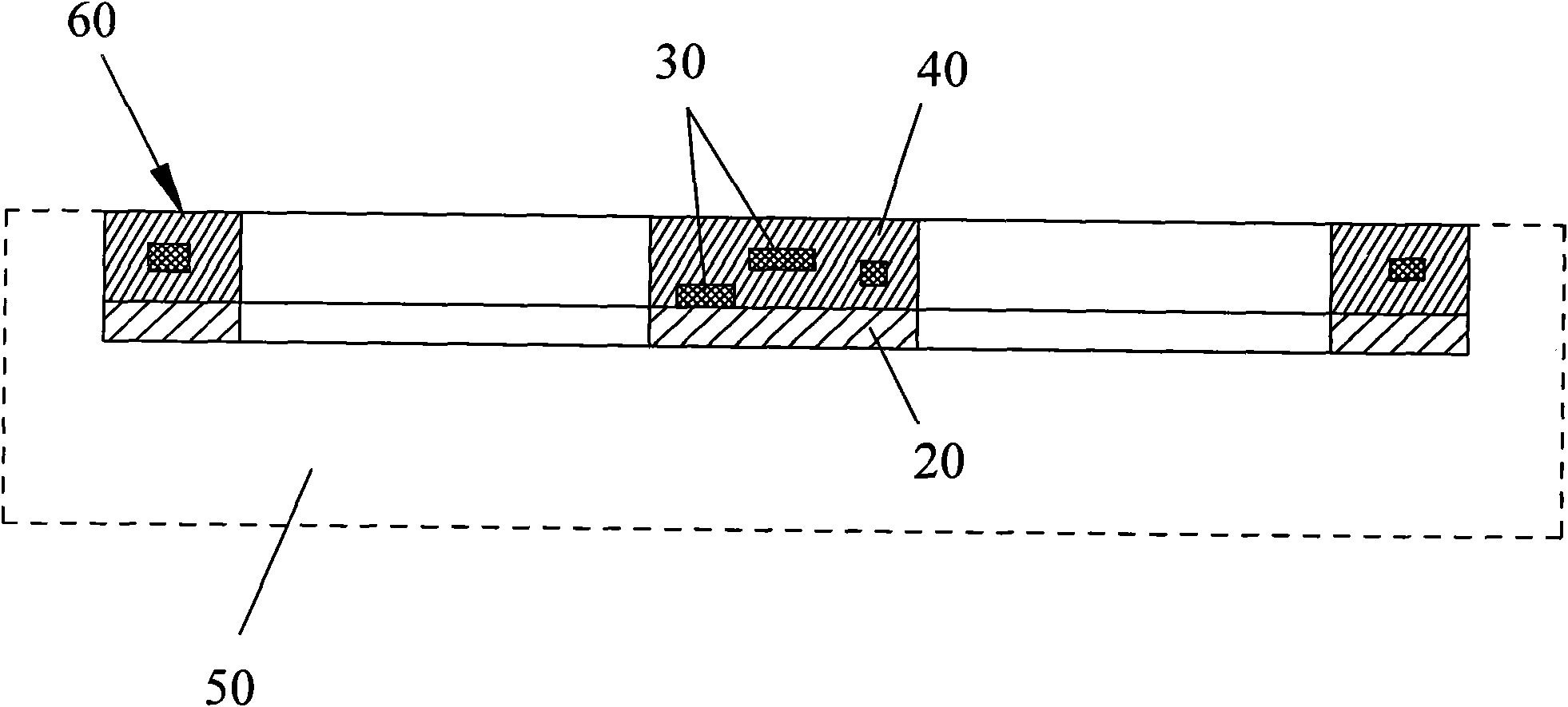

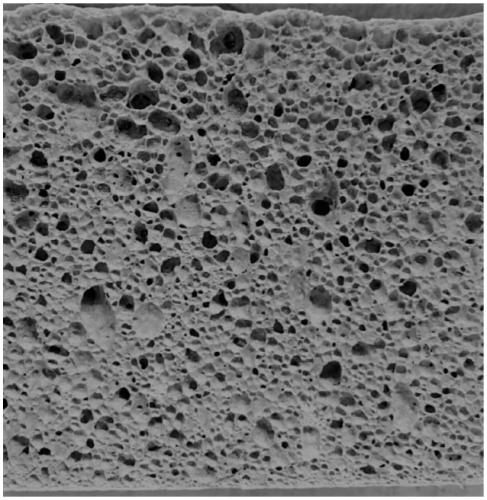

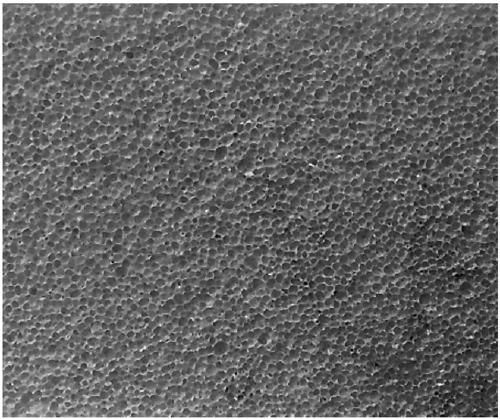

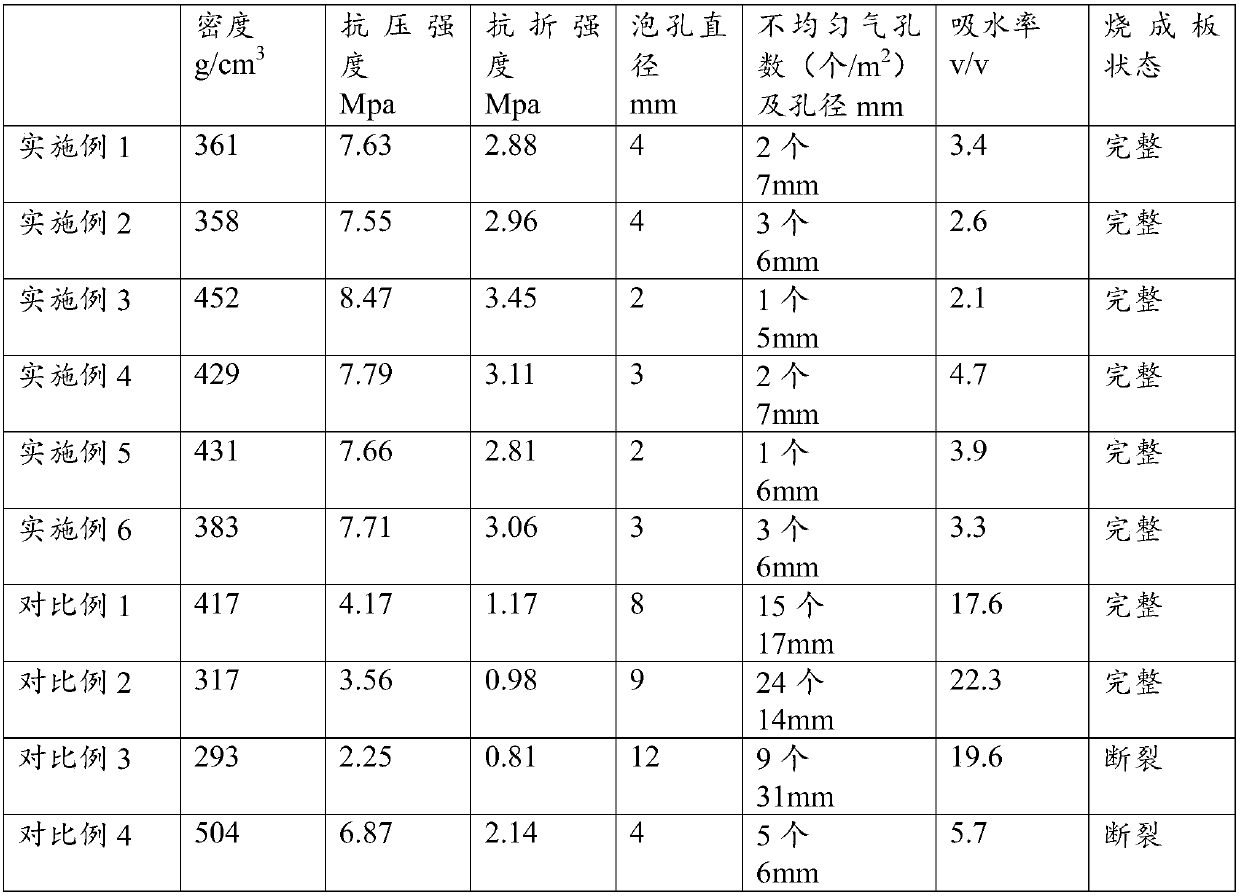

Ultra-thick foamed ceramic plate and production process

The invention provides an ultra-thick foamed ceramic plate and a production process thereof, and belongs to the technical field of foamed ceramics. The components of the ultra-thick foamed ceramic plate comprise a raw material, a foaming agent, a foam stabilizer and a thermal inert modifier, wherein the components of the raw material include 40-60 parts of fluorite tailings, 5-15 parts of potassium feldspar, 10-20 parts of bluestone powder, and 15-30 parts of waste porcelain powder; the foaming agent is at least one of silicon carbide, carbon powder, calcium carbonate, manganese dioxide, sodium nitrate and potassium nitrate; the foam stabilizer is at least one of borax, boric acid, zinc oxide and barium carbonate; the thermal inert modifier is at least one of high borosilicate glass, potash-lime glass, silica, alumina and glass fiber powder; and the mass percentage ratio of the raw material to the foaming agent to the foam stabilizer to the thermal inert modifier is 100:(0.5-2):(1-3):(2-10). The ultra-thick foamed ceramic plate of the invention can be directly used as a wall material of a building partition wall, is less in leftovers of a unit finished material, and is used for processing large-sized special-shaped parts.

Owner:江西璞晶新材料股份有限公司

Method for manufacturing filled formed sound insulation pad for automobile

ActiveCN102336025AThe same degree of softness and hardnessGood molding effectDomestic articlesFiberEngineering

The invention relates to a method for manufacturing a filled formed sound insulation pad for an automobile. The method comprises the following steps of: filling a fibre material in a mesh mould according to the thickness conditions of various parts by utilizing a filling system and adopting an airflow mixed filling and forming manner; then mould pressing and forming; and finally, water cutting and punching an edge material to obtain the sound insulation pad. Compared with the prior art, by utilizing a specific filling hole, the parts with non-uniform thicknesses can be up to same density; that is to say, the parts are same in density and different in thicknesses; therefore, the various parts are same in flexibility; furthermore, the forming effect is good; the materials can also be saved; the thin parts and the thick parts in the cavity of the mould are unnecessary to be filled with same materials; and, because the materials are directly punched in the mould, leftover materials are reduced.

Owner:SHANGHAI XINAN CAR DEADENING FELT

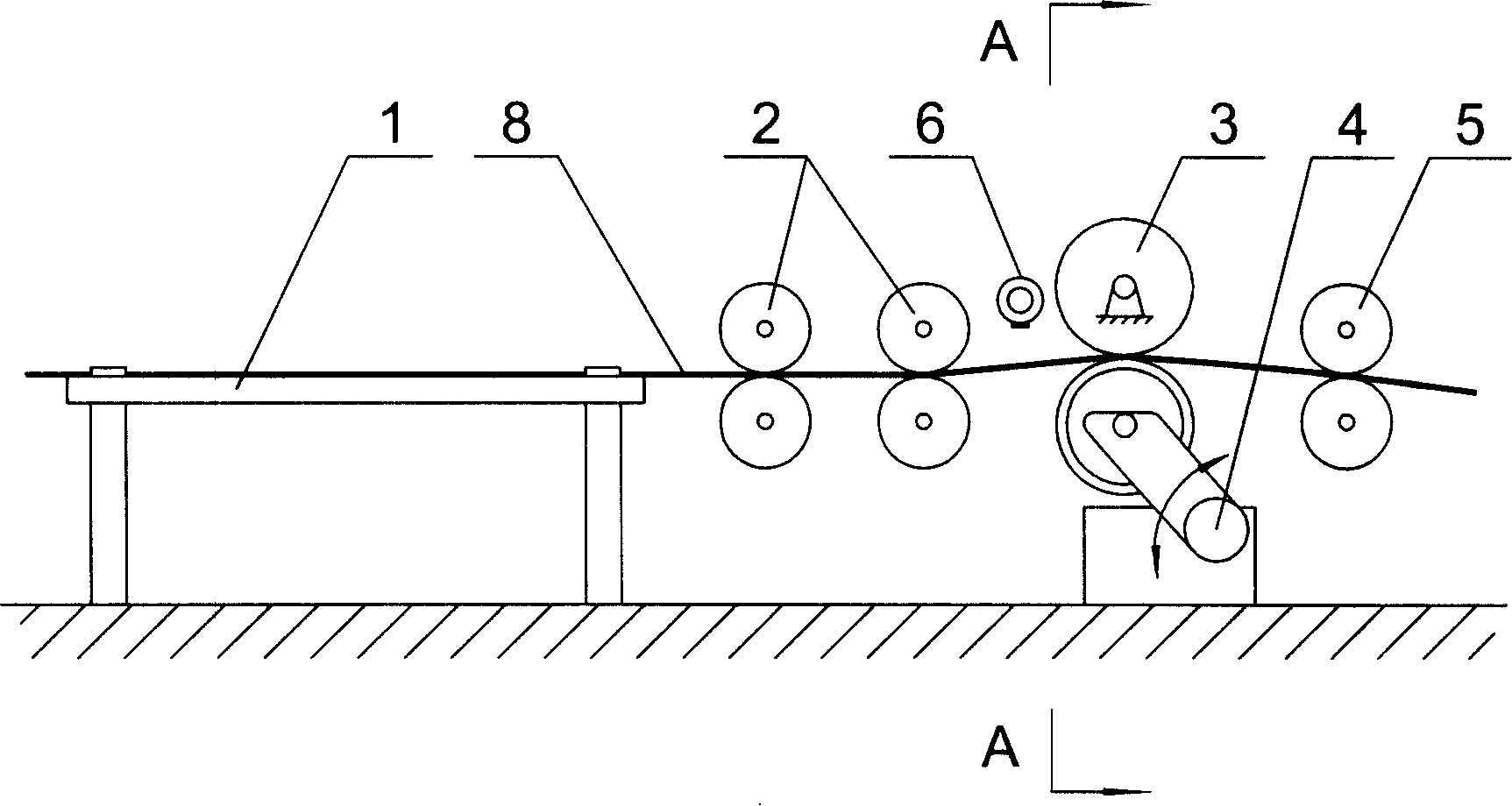

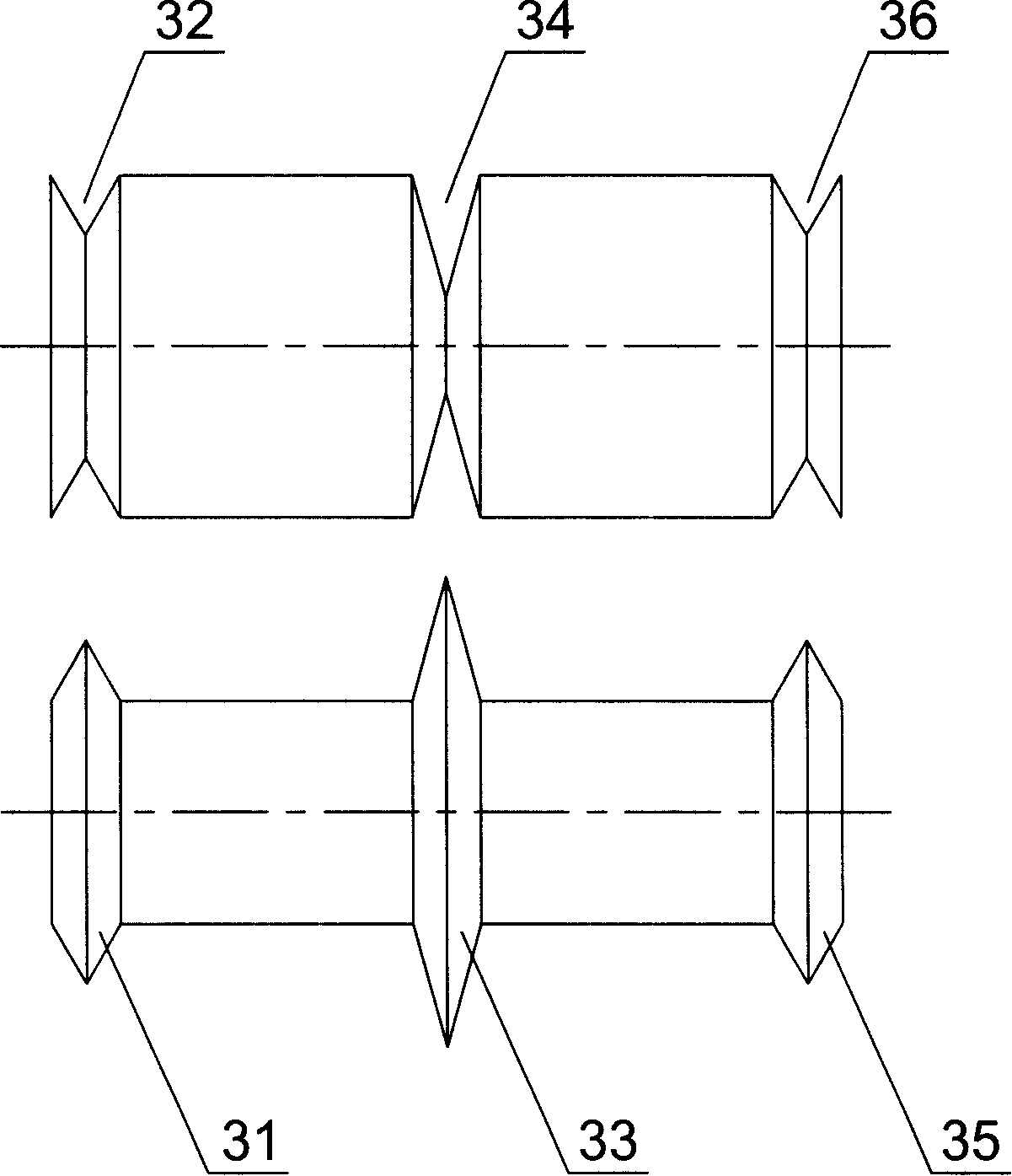

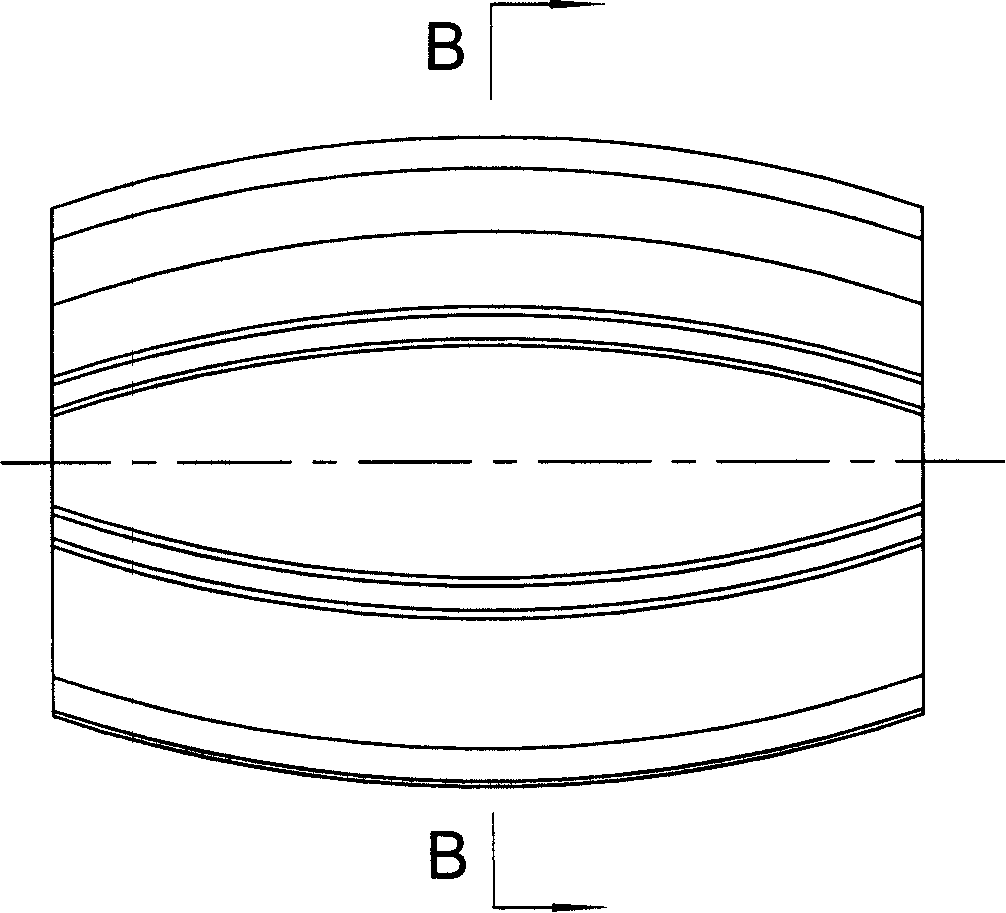

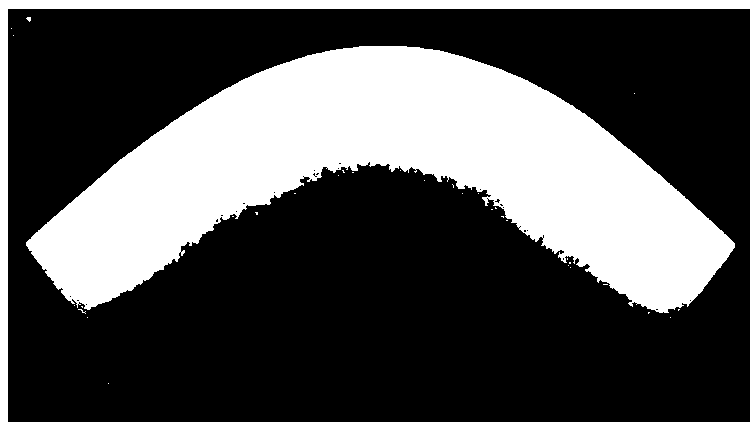

Method and equipment for forming roof board

InactiveCN101181728AMulti-surfaceMeet the needs of streamlinedProgramme controlShaping toolsNumerical controlEngineering

The invention discloses equipment and a molding method for fabricating multi-curved surface and streamlined roof plate with simple and convenient technical process, material conservation and high production efficiency. The process of the invention is divided into material feeding, molding and discharging. During the molding process, a numerical control device calculates a lifting movement track of a molding roller group (3) according to input data and controls a lifting device (4) of the molding roller to move the molding roller group (3) according to the movement track and extrude and press a metal plate (8) to different extents to obtain shapes with different curvatures. The equipment comprises a spacing platform (1) used for feeding, a feeding roller group (2), the molding roller group (3), the lifting device (4) of the molding roller, a discharging roller group (5) and the numerical control device; the molding roller group (3) comprises an upper roller which comprises three grooves (32, 34 and 36) and a lower roller which comprises three molding wheels (31, 33 and 35) with different outer diameters; the molding wheels (31, 33 and 35) are respectively matched with the three grooves (32, 34 and 36). The invention is applicable in the slab molding field.

Owner:BAIANLI STEEL STRUCTURE APPL SCI TECH

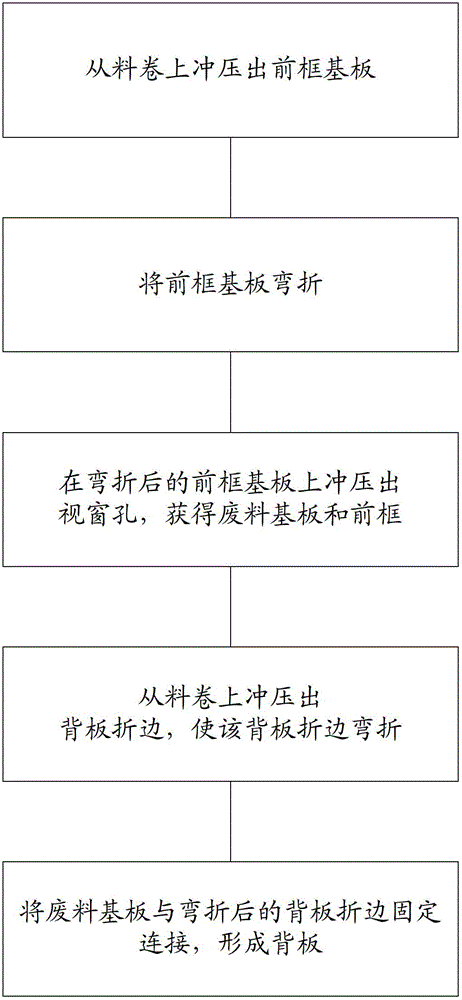

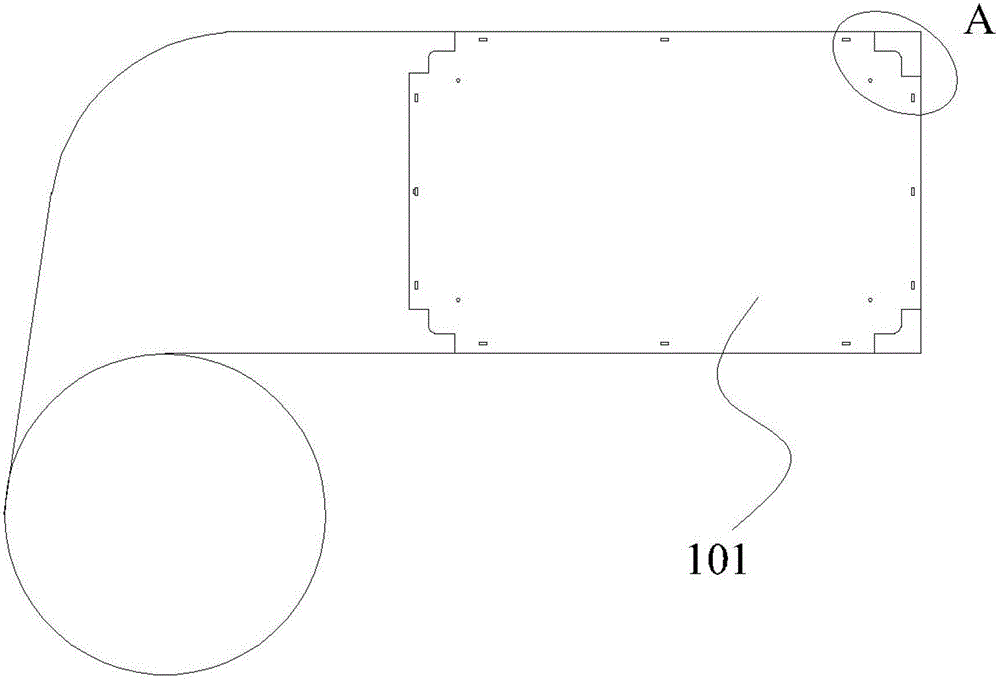

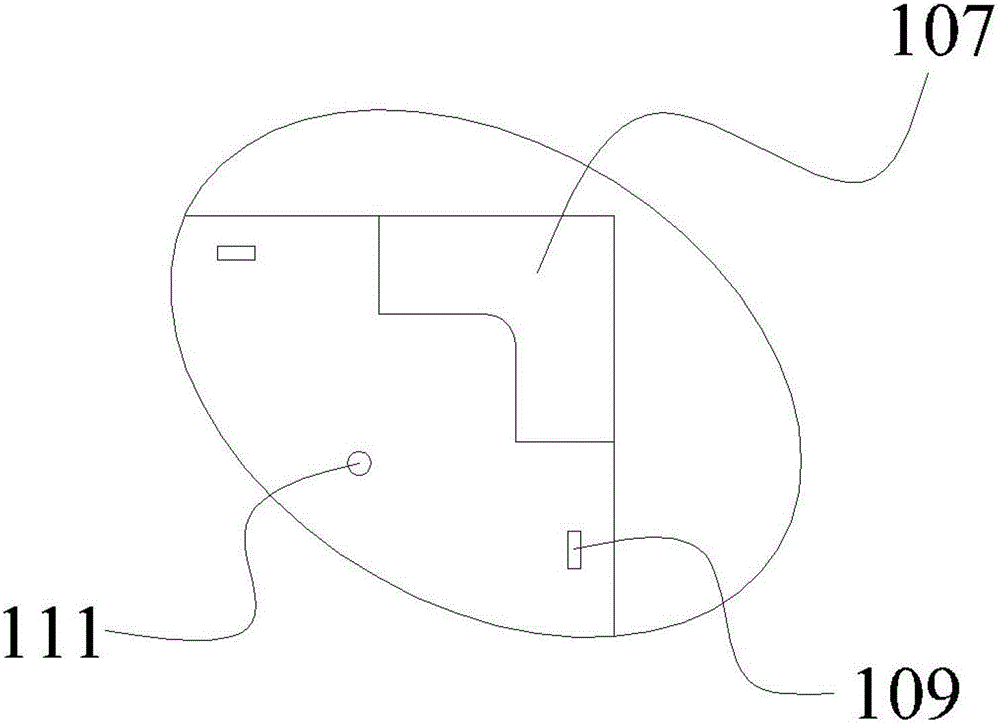

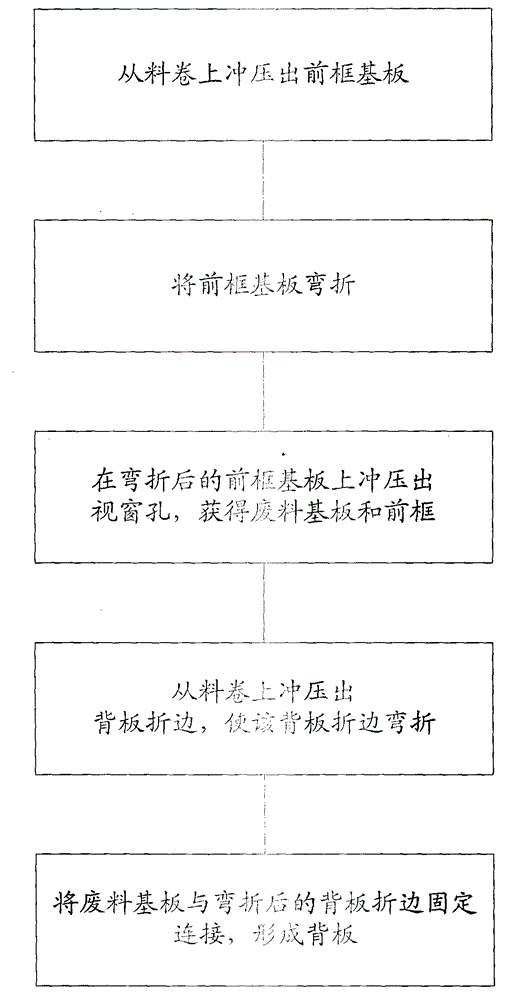

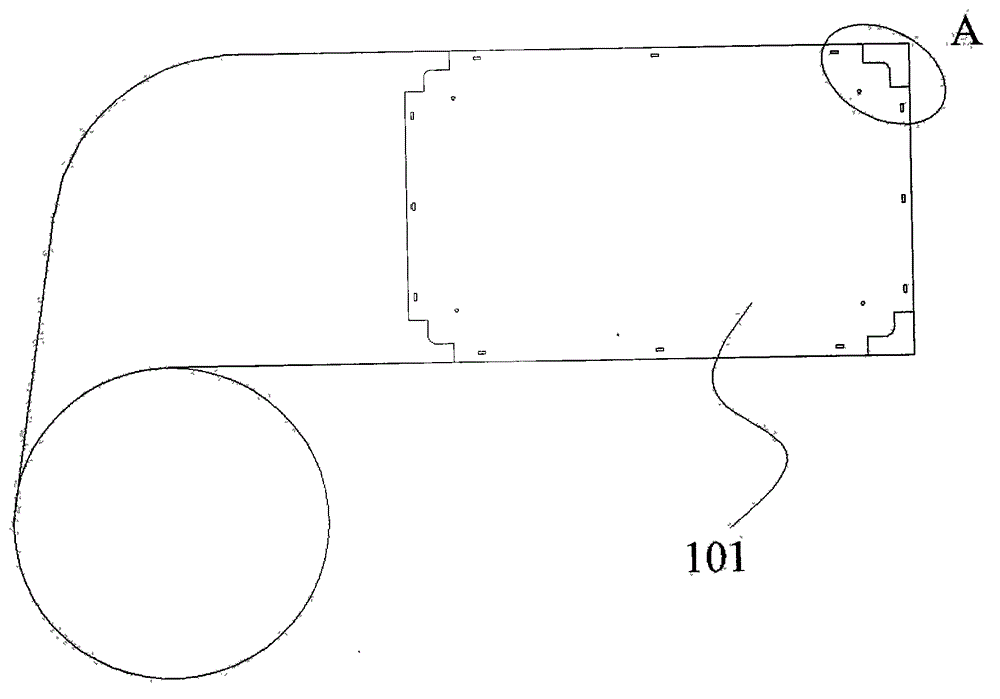

Production method of liquid crystal display frame

InactiveCN102744317AReduce manufacturing costReduce leftoversNon-linear opticsLiquid-crystal displayEngineering

The invention relates to a production method of a liquid crystal display frame. The method comprises the following steps of: stamping a front frame substrate from a material coil, then bending the front frame substrate and stamping a window hole on the bent front frame substrate to obtain a waste substrate and a front frame; then stamping a back plate flanging from the material coil and bending the back plate flanging; and finally, fixedly connecting the waste substrate with the bent back plate flanging to form a back plate. The middle waste substrate generated in the production process of the front frame is used for producing a back plate substrate, so that the material use cost is greatly reduced and the raw materials are saved.

Owner:邓洋阳

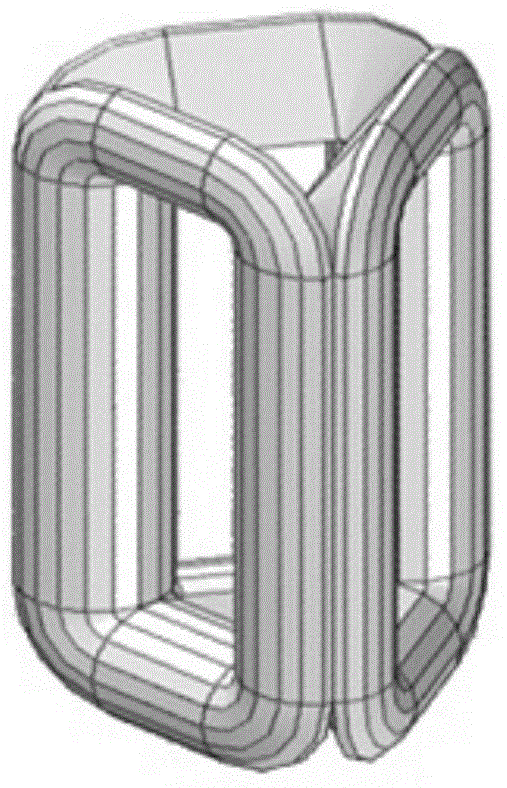

Resin insulation dry type transformer with three-dimensional roll iron core

InactiveCN105529145AReduce leftoversImprove fill factorTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLow noiseEpoxy

The invention discloses a resin insulation dry type transformer with a three-dimensional roll iron core. The resin insulation dry type transformer comprises a transformer base, an upper clamping part, a lower clamping part and a three-dimensional roll iron core, wherein the upper clamping part and the lower clamping part are correspondingly arranged on the transformer base up and down, and the three-dimensional roll iron core is clamped between the upper clamping part and the lower clamping part; the three-dimensional roll iron core comprises three single frames, the middle parts of the single frames are hollowed out, and the single frames are of rounded rectangle structures in shape; the three single frames are arranged and spliced together in an equilateral triangle shape three-dimensionally; each single frame is formed by continuously winding a plurality of silicon steel trapezoid material straps in sequence; a coil is wound at the joint of every two single frames respectively; each coil is integrally poured by a curing agent and is formed through heating curing; and the exterior of each coil is encapsulated by epoxy resin respectively. The resin insulation dry type transformer is provided with the three-dimensional roll iron core, and has the characteristics of energy conservation and material saving, low no-load loss, low no-load current, low noise, good electrical performance, low partial discharge value, high lightning impulse resistance, high short-circuit resistance and high mechanical strength.

Owner:STATE GRID CORP OF CHINA +1

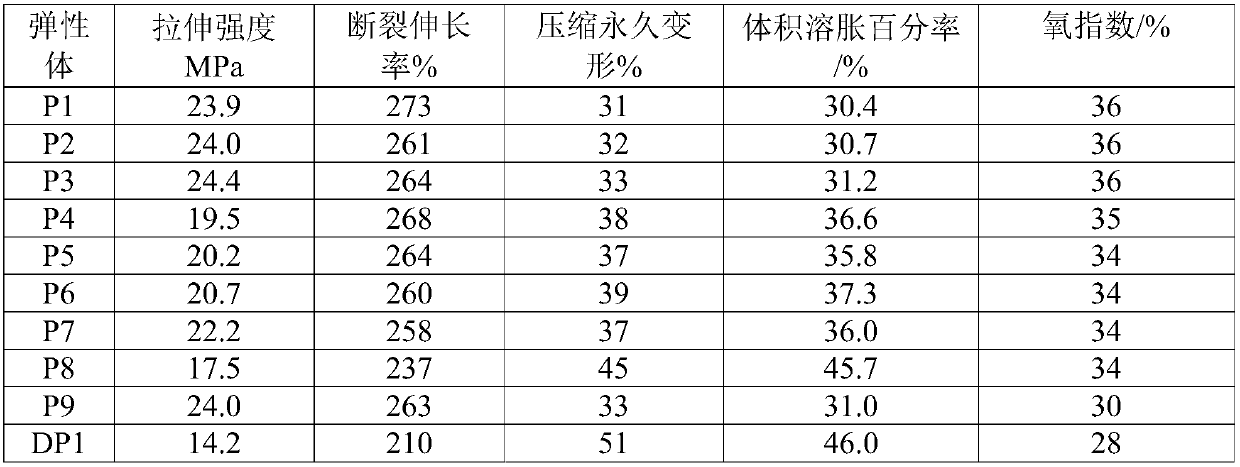

Halogen-free flame-retardant nitrile rubber/nylon thermoplastic elastomer and preparation method thereof

The invention relates to the field of thermoplastic elastomers, and discloses a halogen-free flame-retardant nitrile rubber / nylon thermoplastic elastomer and a preparation method thereof, wherein thethermoplastic elastomer contains a nitrile rubber, nylon, a flame retardant, a vulcanizing agent, an anti-aging agent, an antioxidant and an auxiliary agent, the vulcanizing agent is an organic peroxide, and the organic peroxide is at least one selected from dicumyl peroxide, bis(t-butylperoxyisopropyl)benzene, t-butyl cumene peroxide, 2,5-bis(t-butyl peroxy)-2,5-dimethyl-3-hexyne, 2,5-bis-(tert-butyl peroxy)-2,5-dimethyl hexane, dibenzoyl peroxide, tert-butyl peroxybenzoate, and di-tert-butyl peroxide. According to the present invention, the nitrile rubber / nylon thermoplastic elastomer has characteristics of high elasticity, easy processing, repeated processing, good flame retardant performance and the like, and can be used for vehicle oil pipelines and sealing members.

Owner:CHINA PETROLEUM & CHEM CORP +1

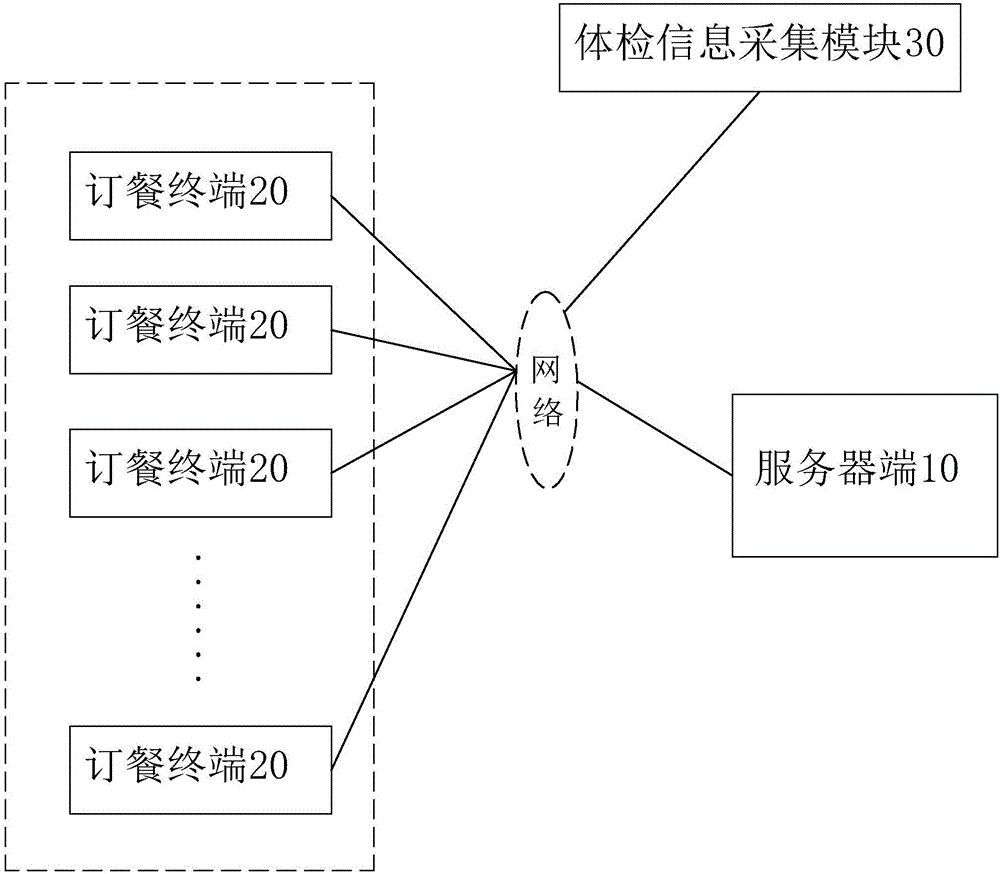

Interactive reservation system

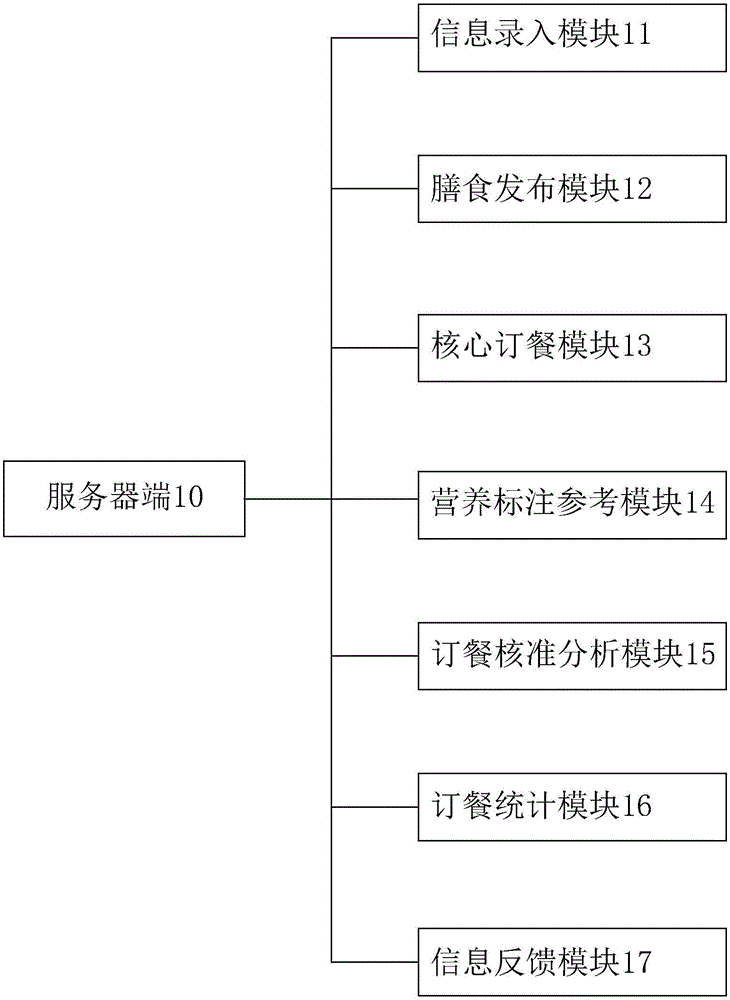

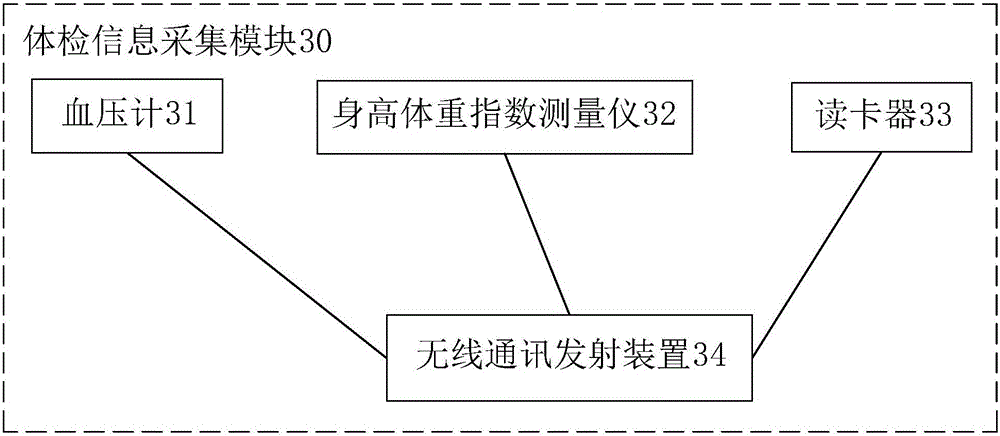

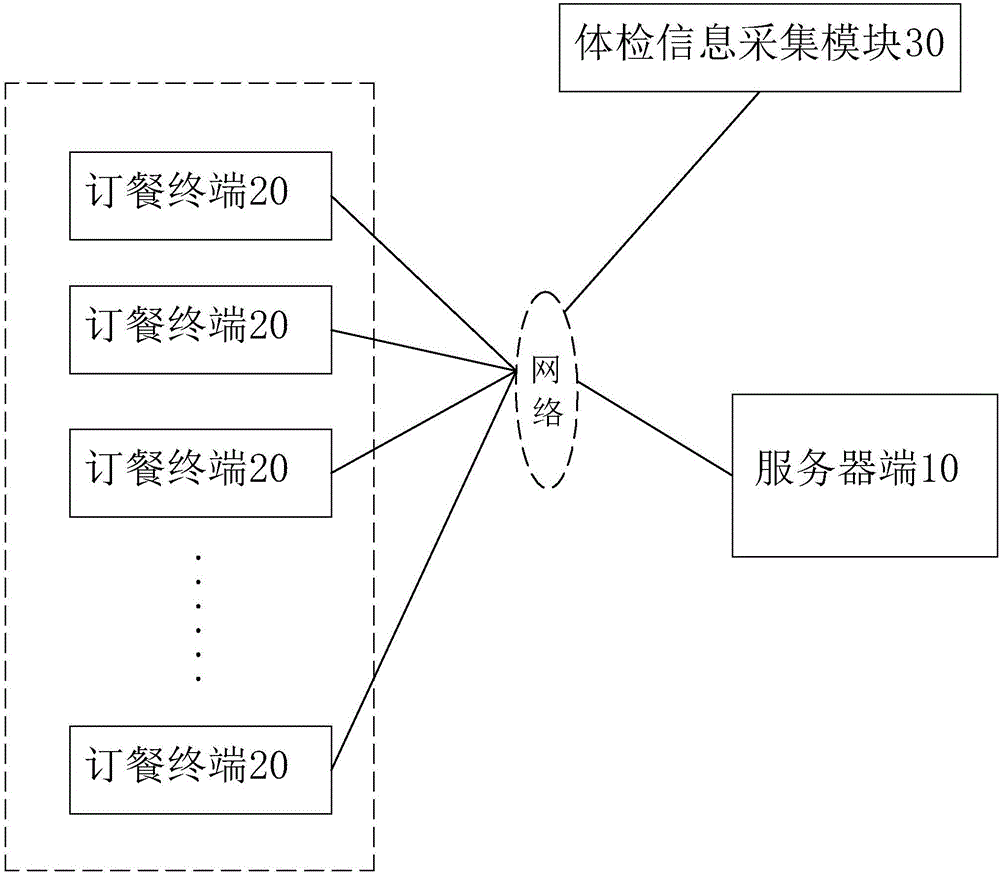

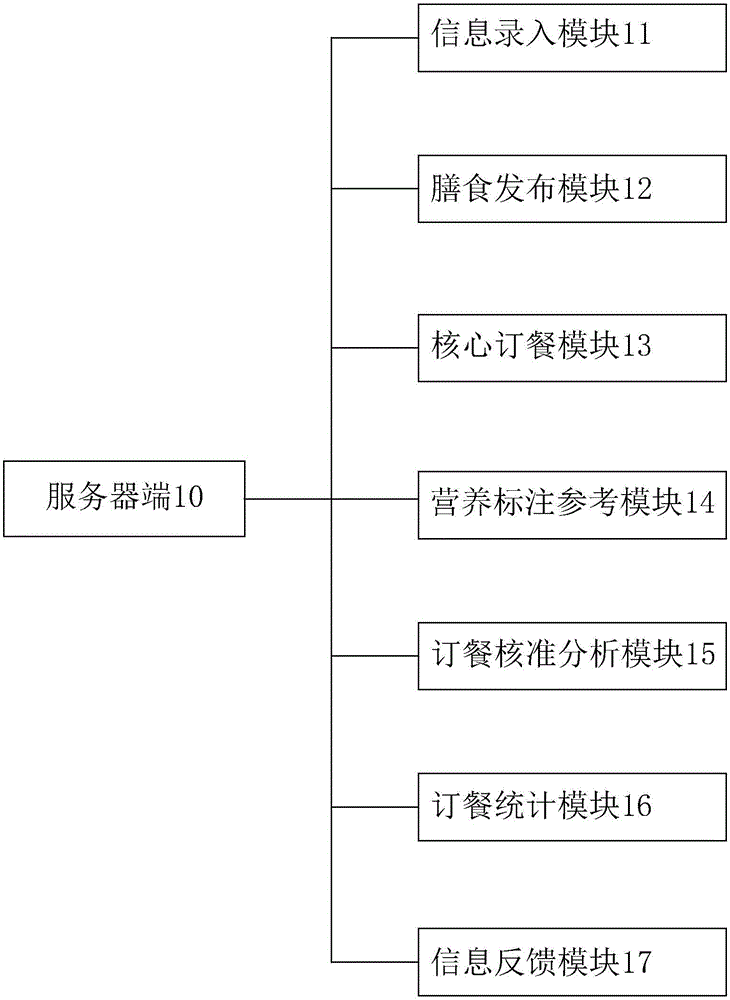

ActiveCN105956676AGood food serviceEnsure safetyReservationsBuying/selling/leasing transactionsAdditive ingredientInteractive television

The invention relates to an interactive reservation system, comprising a server terminal, a reservation terminal and a unique dining card hold by each consumer. The server terminal records consumer information, and issues kinds of diets of each meal in 1-10 days; a core reservation module of the sever terminal is used for receiving the reservation information of each meal uploaded by the consumer through the reservation terminal, comparing the nutritional intake standard of each meal with the nutrient content of each meal calculated by the core reservation module, listing the amount of each nutritional ingredient, giving warning marks when ingredients are excessive or insufficient compared with recommended nutritional ingredients, and meanwhile sending information to the reservation terminal; and the reservation terminal is used for running statistics on the final reservation information of all consumers of a unit for tomorrow between 4 and 6 in the afternoon of a former day, and on the quantity of raw materials required to be bought according to the reservation information.

Owner:常州市卫生监督所

Interactive dish-ordering system based on network

The invention relates to an interactive dish-ordering system based on a network, and the system comprises a server, a dish-ordering terminal, and dinning cards which are held by consumers and matched with one corresponding consumer in a unique manner. The dish-ordering terminal is connected with the server through the Internet for data communication. The server records the information of the consumers, and publishes the types of dishes of each meal of the following one to ten days. A core dish-ordering module of the server is used for receiving the dish-ordering information, which is uploaded to the server through the dish-ordering terminal, of the consumer for each meal, carries out the comparison of the intake nutrition standard of each meal with the nutrition content, calculated by the core dish-ordering module, of the consumer at each meal for analysis, lists the total amount of each nutritional ingredient, gives a warning mark if the total amount of one nutritional ingredient exceeds or is lower than the recommended amount of the nutritional ingredient, and sends the warning mark to the dish-ordering terminal. A dish-ordering statistics module carries out the statistics of the final dish-ordering information of all consumers in a unit for tomorrow in a period from 16 o'clock to 18 o'clock of a dinning day, and counts the number of raw materials to be bought according to the dish-ordering information.

Owner:常州市卫生监督所

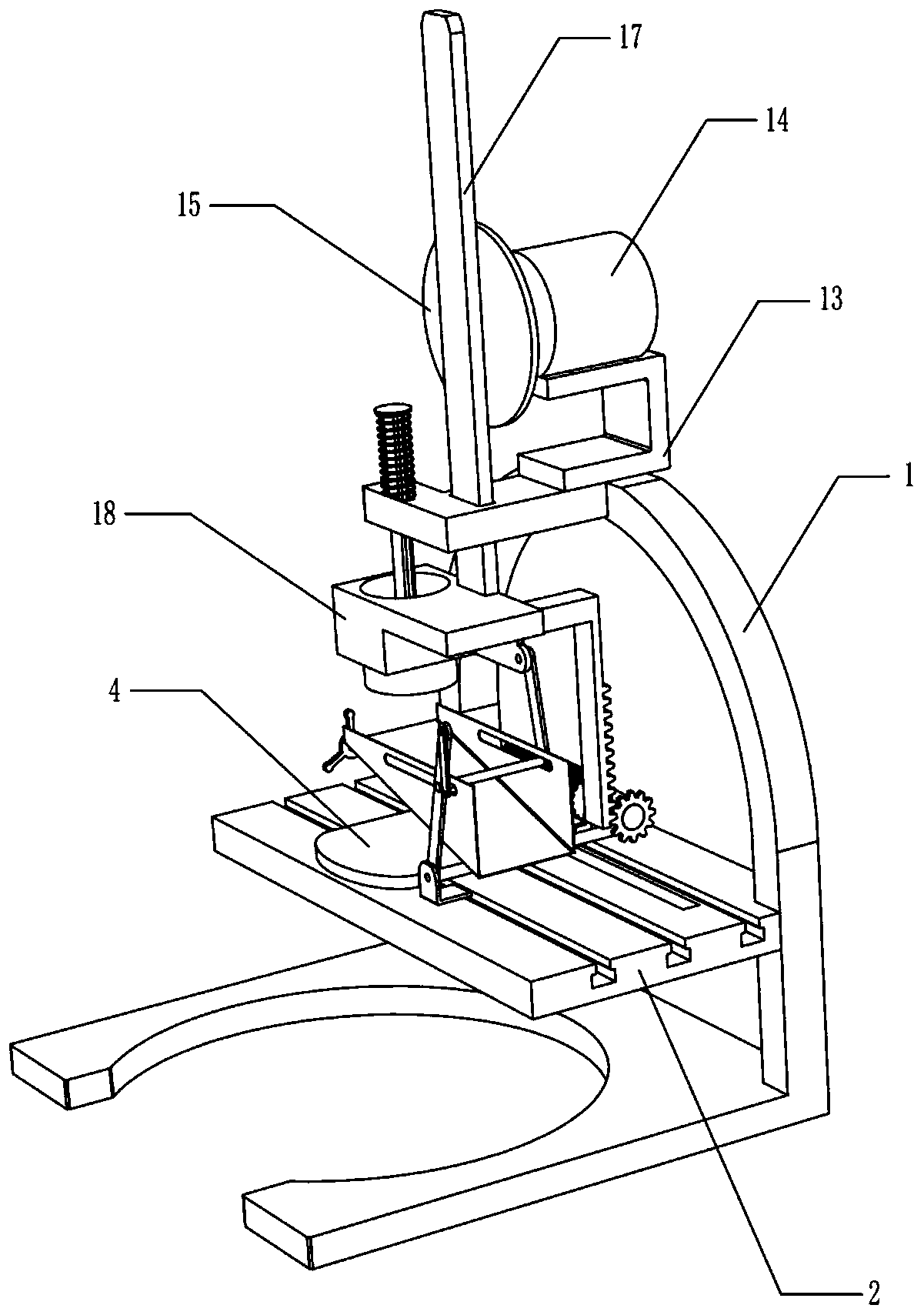

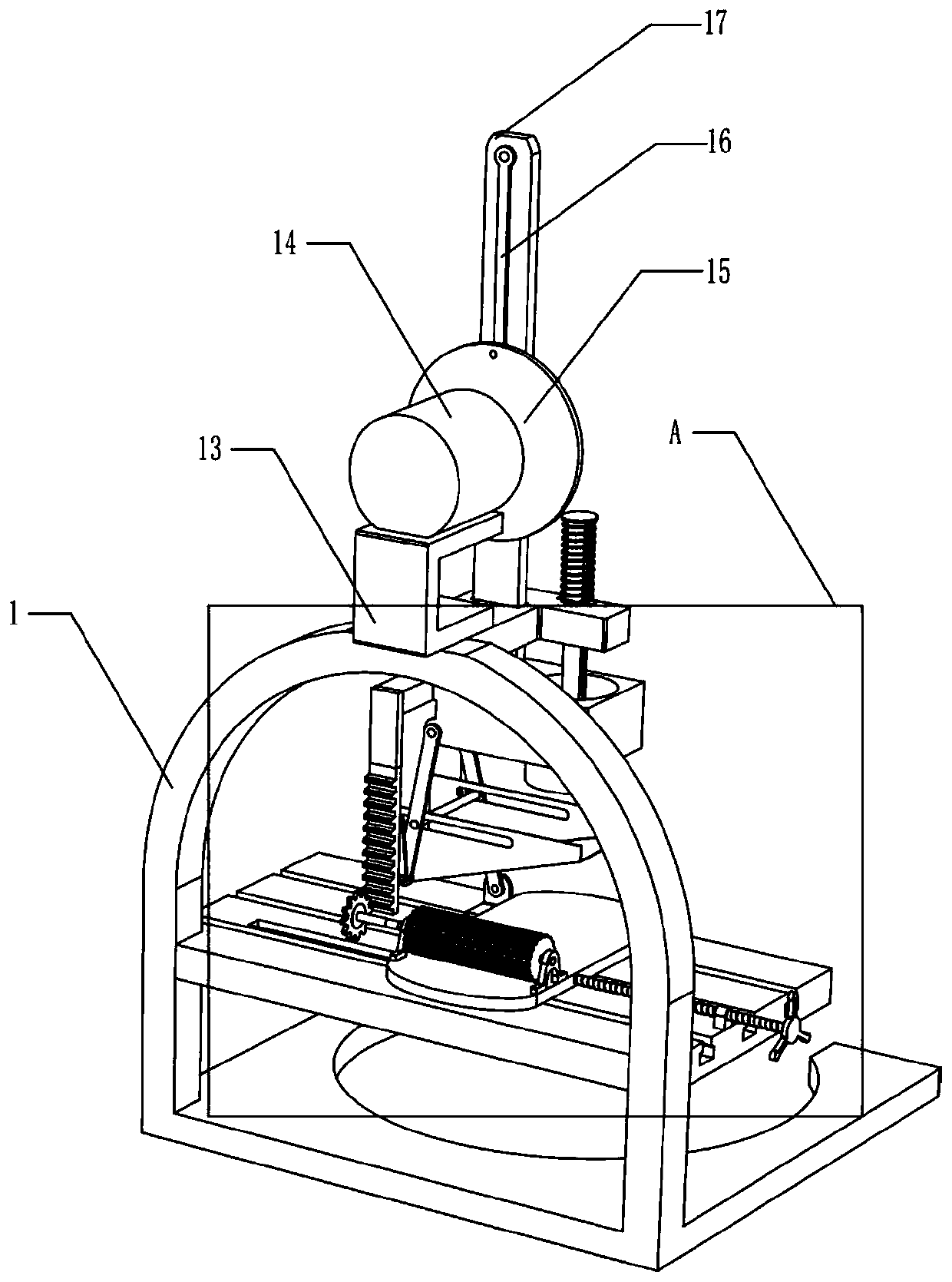

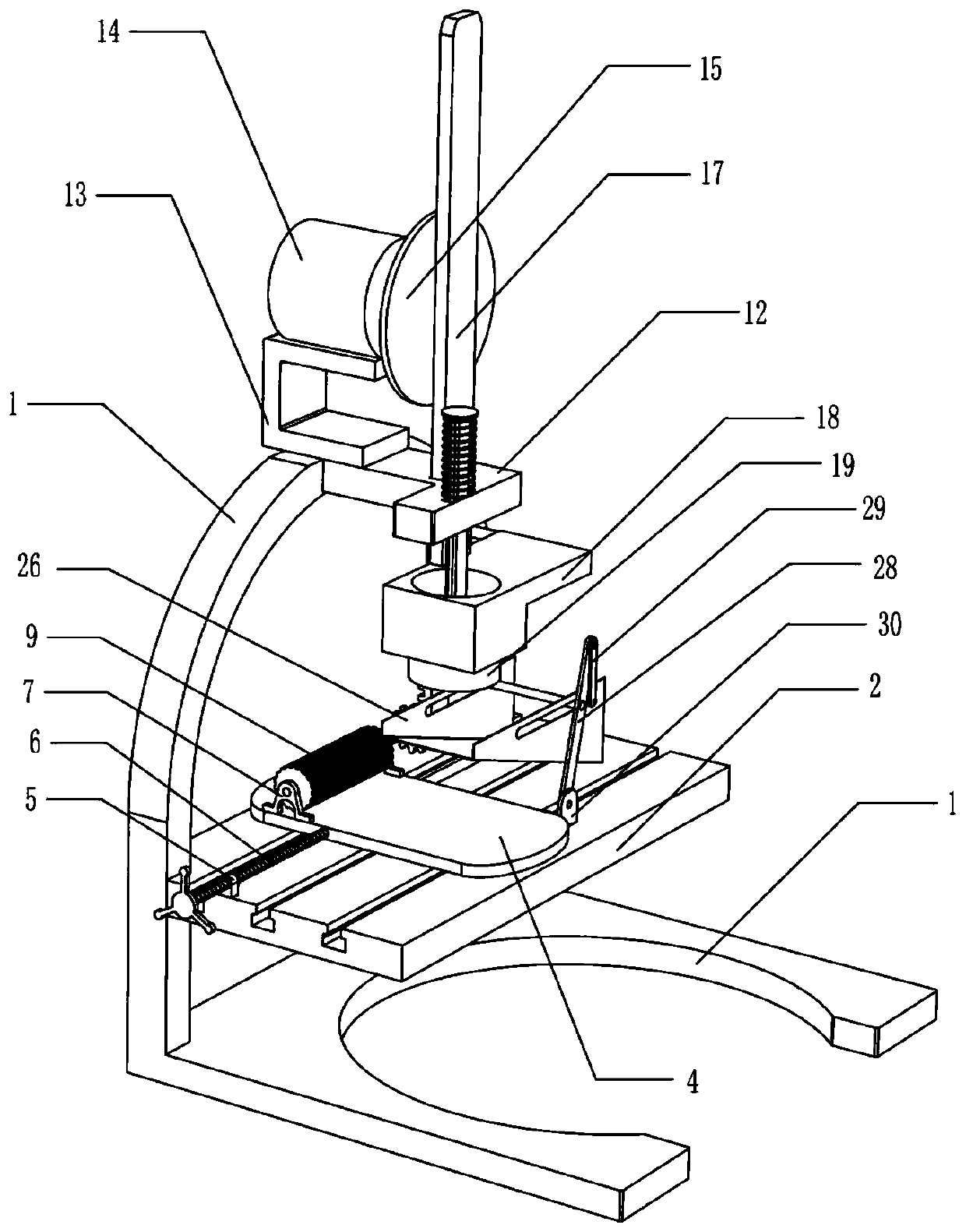

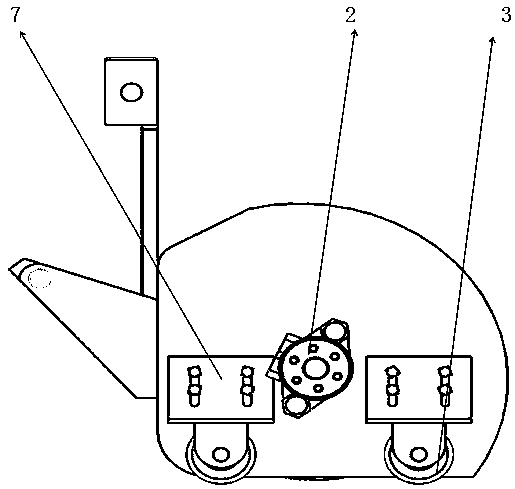

Circular rubber pad cutting device

ActiveCN111516049AIncrease profitReduce leftoversMetal working apparatusElectric machineryStructural engineering

The invention relates to the technical field of rubber processing, in particular to a circular rubber pad cutting device. The invention aims at solving the technical problem so as to provide the circular rubber pad cutting device capable of quickly pressing and cutting a rubber sheet, obtaining a circular rubber pad with the accurate size, and conveniently collecting the cut rubber pad. The invention provides the following technical scheme that the circular rubber pad cutting device comprises a support leg, a slide rail, sliding blocks, a support plate, a fixed seat, a fixed plate, a support seat, a motor, a rotary plate, a transmission connecting rod, a guide rod I, a hollow plate, a circular cutter and the like, wherein the slide rail is fixedly arranged on the support leg; a plurality of sliding blocks are slidably arranged on the slide rail; and the support plate is fixedly arranged on the sliding blocks. According to the circular rubber pad cutting device provided by the invention, the position of the support plate can be adjusted through manually rotating a screw rod, so that the circular cutter can be used for cutting the circular rubber pad at different positions in the horizontal direction of the rubber sheet, and the rubber sheet utilization rate is improved.

Owner:无锡市西海科技有限公司

Nitrile rubber/nylon thermoplastic elastomer and preparation method thereof

The invention relates to the field of thermoplastic elastomers, and discloses a nitrile rubber / nylon thermoplastic elastomer and a preparation method thereof, wherein the thermoplastic elastomer contains a nitrile rubber, nylon, a vulcanizing agent, an anti-aging agent, an antioxidant and an auxiliary agent, the vulcanizing agent is an organic peroxide, and the organic peroxide is at least one selected from dicumyl peroxide, bis(t-butylperoxyisopropyl)benzene, t-butyl cumene peroxide, 2,5-bis(t-butyl peroxy)-2,5-dimethyl-3-hexyne, 2,5-bis-(tert-butyl peroxy)-2,5-dimethyl hexane, dibenzoyl peroxide, tert-butyl peroxybenzoate, and di-tert-butyl peroxide. According to the present invention, the nitrile rubber / nylon thermoplastic elastomer has characteristics of high elasticity, easy processing, repeated processing and the like, and can be used for vehicle oil pipelines and sealing components.

Owner:CHINA PETROLEUM & CHEM CORP +1

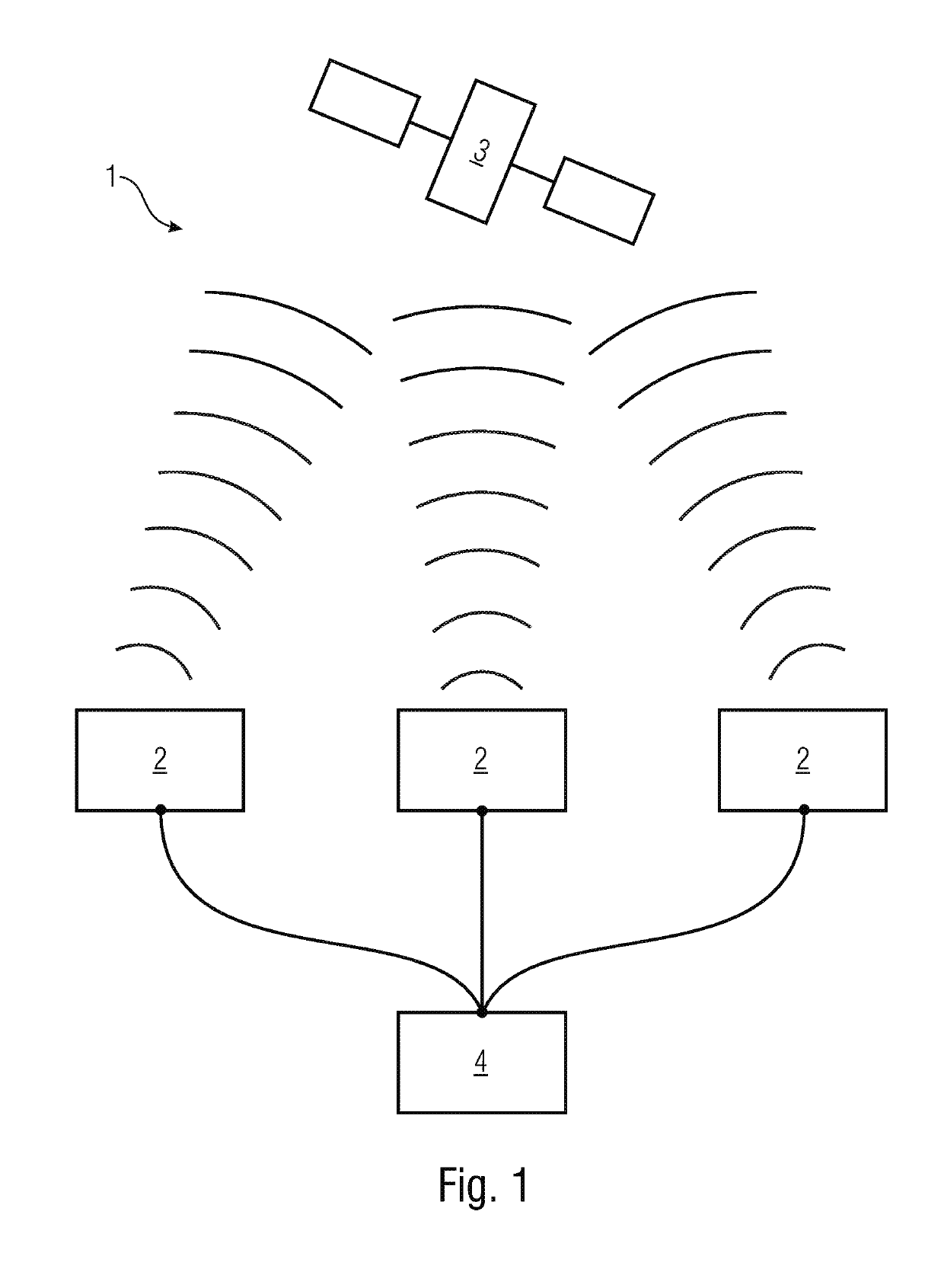

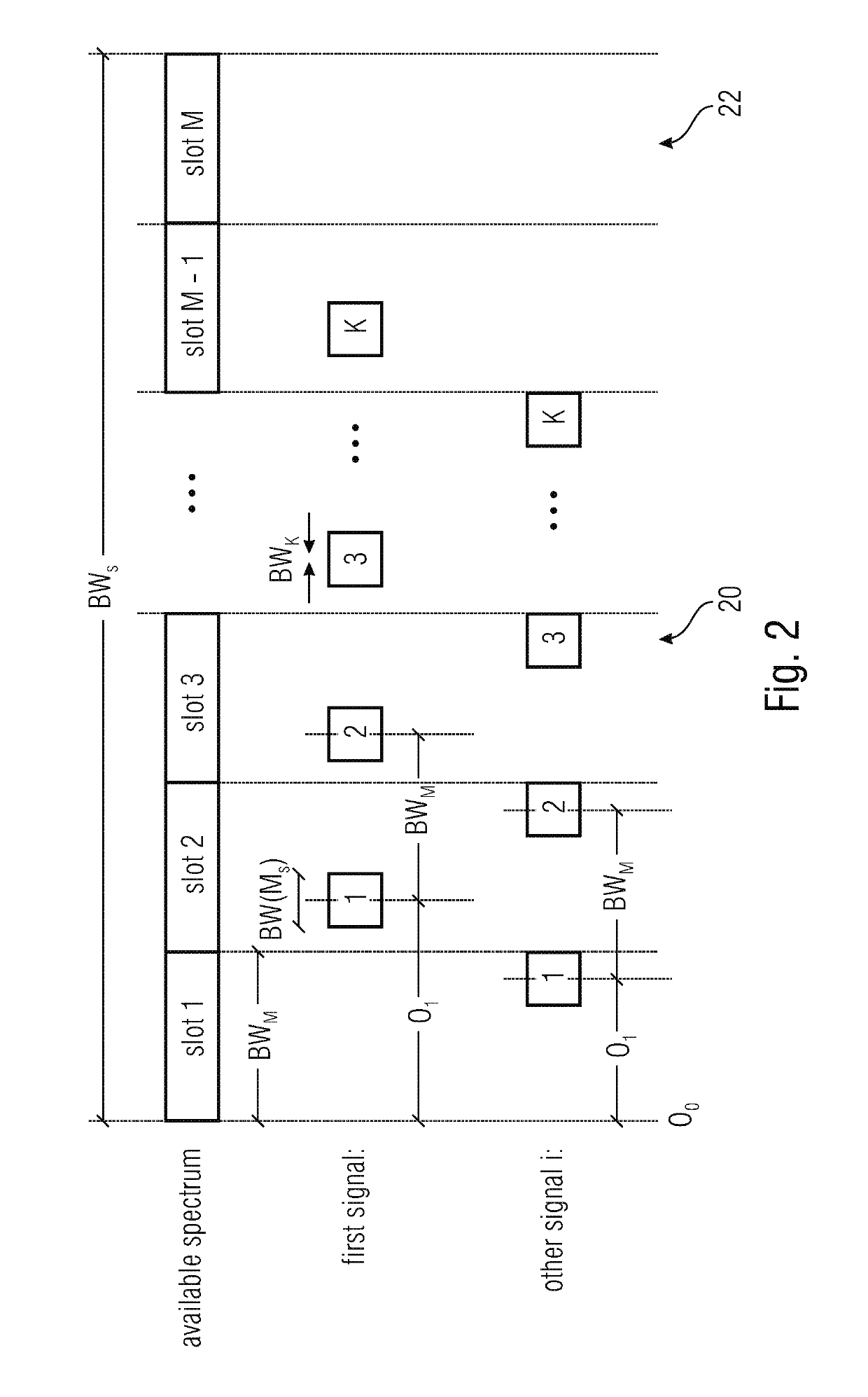

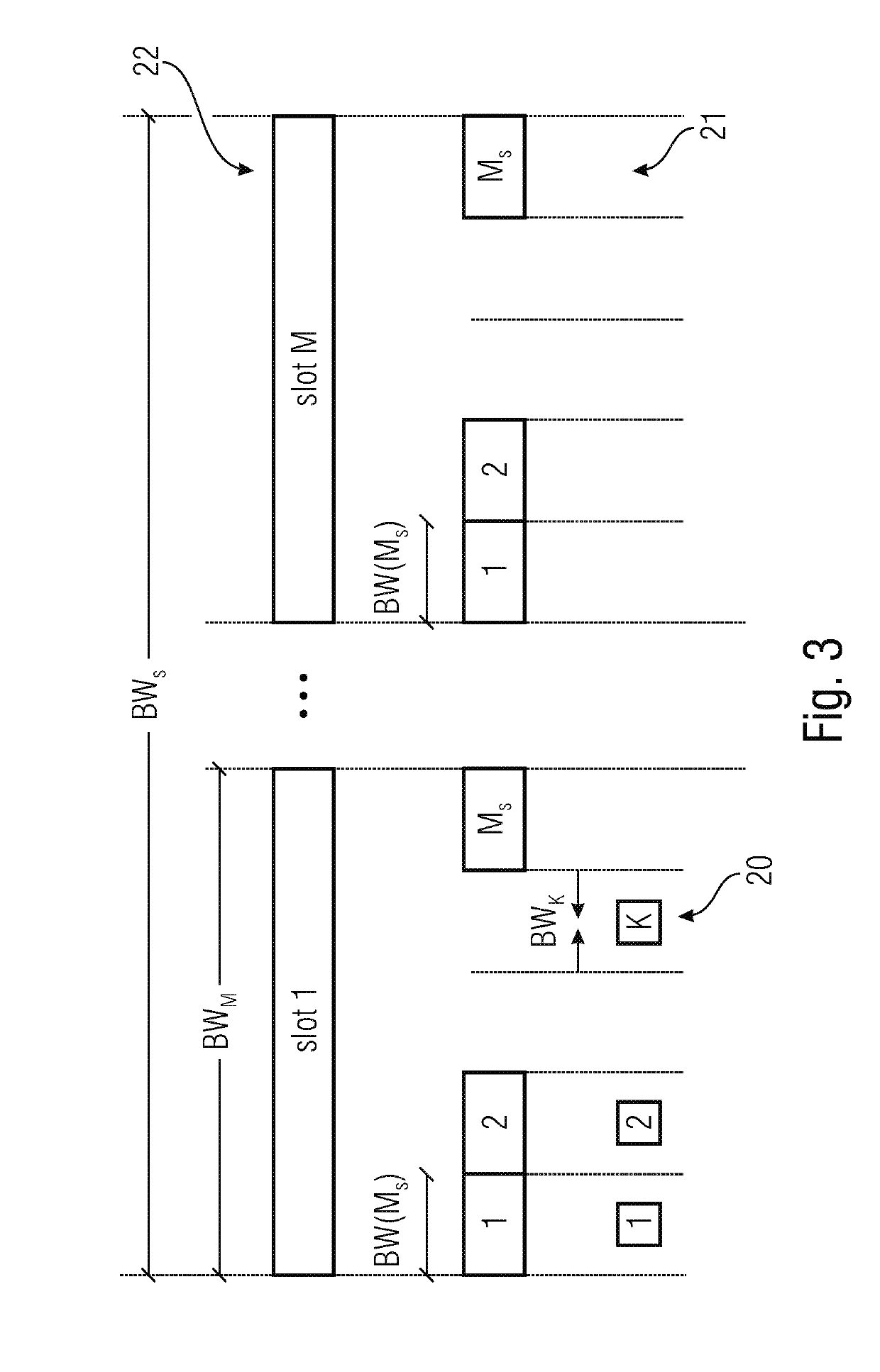

Communication system and transmitter

ActiveUS20190173654A1Easy to calculateGood choiceTransmission path divisionCriteria allocationCommunications systemCarrier signal

A communication system includes a plurality of transmitters and a receiving unit. The transmitters are configured to divide signals to be emitted into K part signals and to emit the K part signals using K sub-carriers. K is an integer. The K sub-carriers are frequency bands having a sub-carrier bandwidth and are spaced in frequency. The receiving unit is configured to receive signals emitted by the transmitters. The invention further refers to a transmitter.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

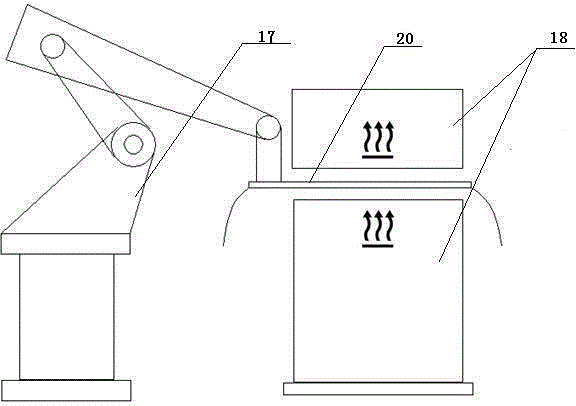

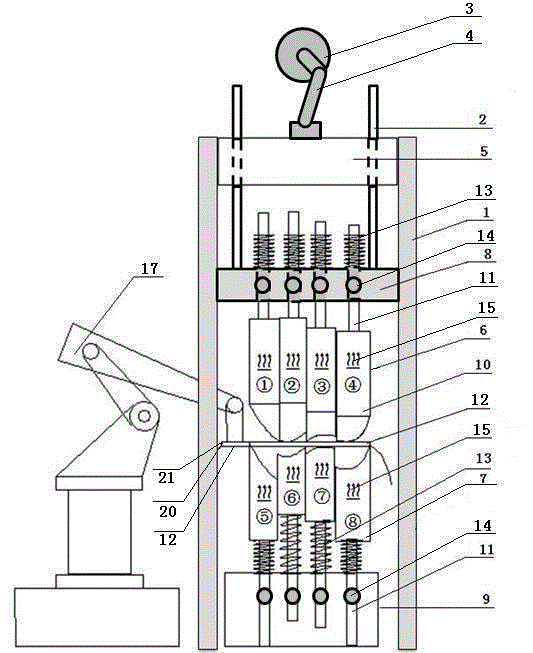

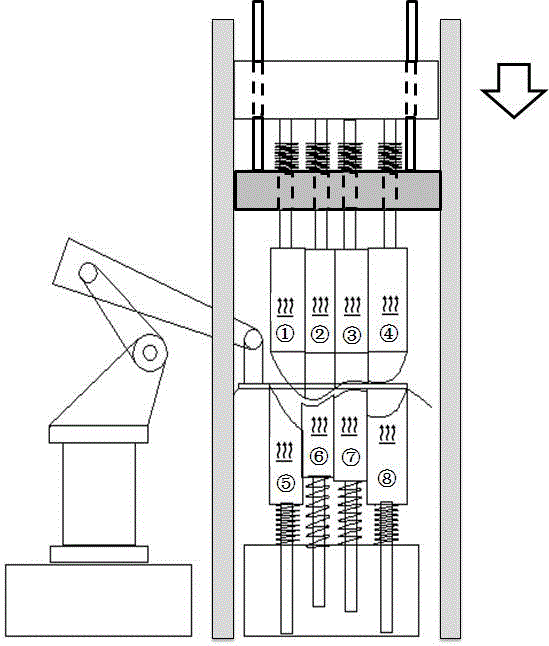

Drum-surface processing device

The invention relates to a drum-surface processing device which comprises a drum device for conveying materials to be processed, a hot press, a pressure output device and a dividing and cutting machine, wherein the hot press is used for pressing and modeling the materials conveyed by the drum device, the dividing and cutting machine is used for dividing and cutting the processed material, the hot press is connected in series and interlocked with the dividing and cutting machine and is internally connected in series with a plurality of heating plates and guide posts passing through the plurality of heating plates, and the spaces among the heating plates are divided into a plurality of heating spaces in which dies are arranged; the drum device comprises a plurality of drums corresponding to the heating spaces in amount and used for conveying materials to be processed to the corresponding heating spaces for heating and pressurizing; the pressure output device is located at the outer end of the first heating space that faces outside so as to push the heating plates to move upwards and downwards along the guide posts and combine together or separate from each other; and by pressure transfer, the heating plates are pressurized simultaneously. The device has the advantages of low energy consumption, high efficiency, low heat loss and wide application prospect.

Owner:JINCAI PRINTING & PACKAGING

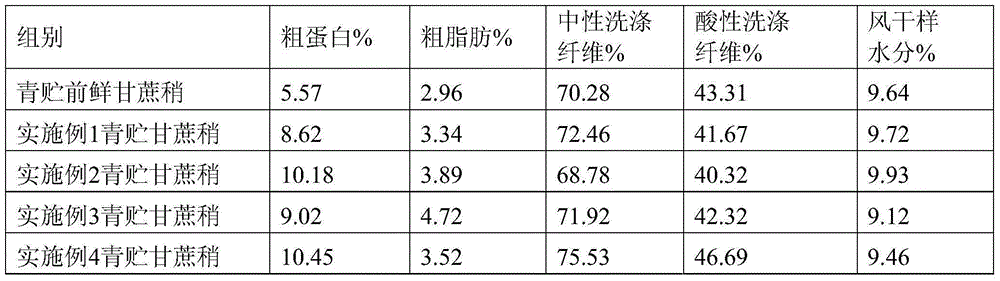

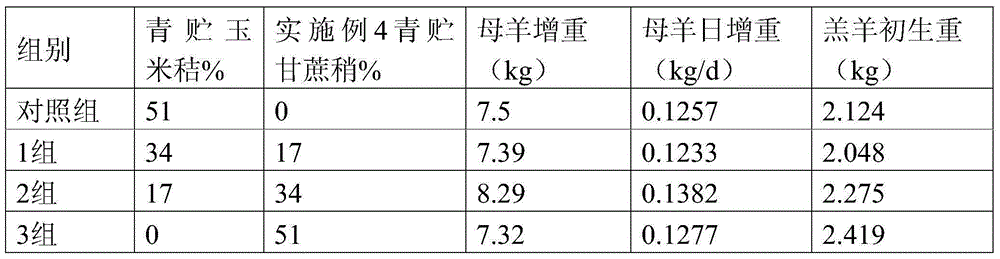

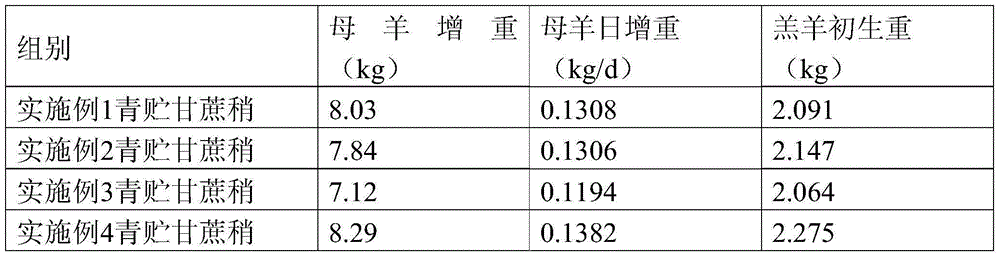

Long-term storable efficient forage sugarcane tip, preparation method and application thereof

ActiveCN105028917AAvoid damageEasy to carryFood processingAnimal feeding stuffNutritive valuesAnimal Foraging

The invention discloses a long-term storable forage sugarcane tip, a preparation method and application thereof. The preparation method includes the steps of: (1) collection; (2) water regulation; (3) kneading crushing: kneading the material into filaments or sheets by a kneading crushing machine, and controlling the top part length within 6cm; (4) stretch film wrapping and silaging: bundling the sugarcane tip subjected to kneading crushing, and conducting wrapping and sealing, conducting low temperature fermentation for 30-50d in winter and fermentation for 20-40d in spring. With the technology of kneading, modulation, stretch film wrapping and silaging, the storage life is long, nutrient loss is little, setae can be softened, the digestibility and nutritive value are enhanced, carrying and long distance transportation can be convenient, and the forage cost of grass-feeding livestock is reduced.

Owner:江苏南京农大科技开发有限责任公司

Stamping method and equipment for producing fiber-enhanced composite preforms

The invention discloses a stamping method and stamping equipment for producing fiber-enhanced composite preforms. The existing fiber laying technology can be used for producing two-dimensional and simple three-dimensional preforms, but for more complicated geometrical shapes, such as a car B column, the existing fiber laying technology does not work. According to the stamping method, by a stamping technology, the preforms with the complicated geometrical shapes are manufactured; the preforms can be manufactured into superlight and superstrong composite components by using an autoclave and by a resin injection process and the like, so that the production cost of the components is greatly reduced, and the components are applied to civilian products, such as a car frame; the stamping method also can be applied to a stamping process of carbon fiber, glass fiber and other braided fabric; the stamping process simulates manual moulding; in the whole process, uniform in-plane and out-of-plane supports are given to a laying layer, so that excessive lateral slippage, corrugation and breakage of fibers in the stamping process are greatly reduced, and further the production efficiency is improved and automation, digitalization and unattended operation are achieved on the premise of ensuring the product quality.

Owner:徐剑

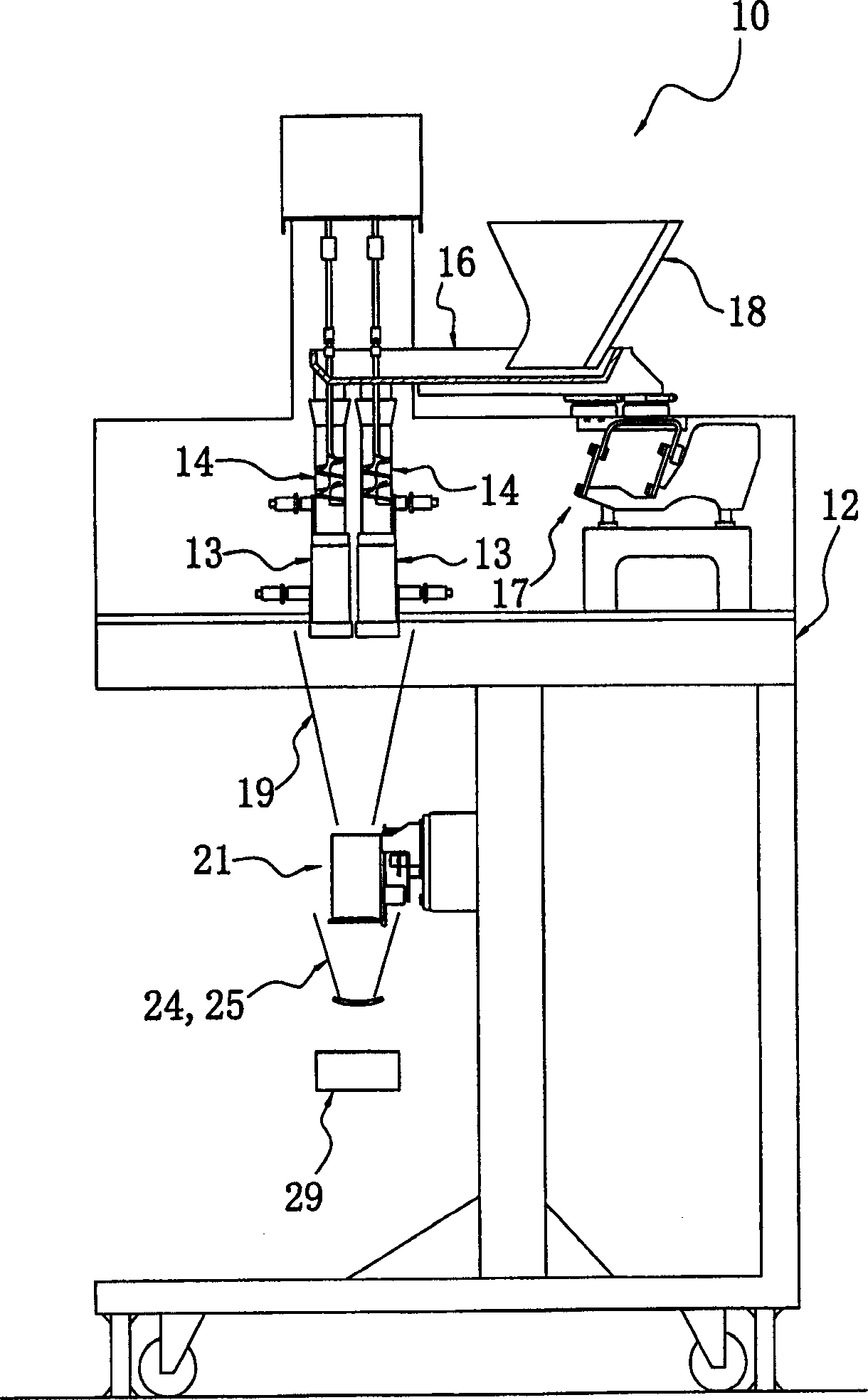

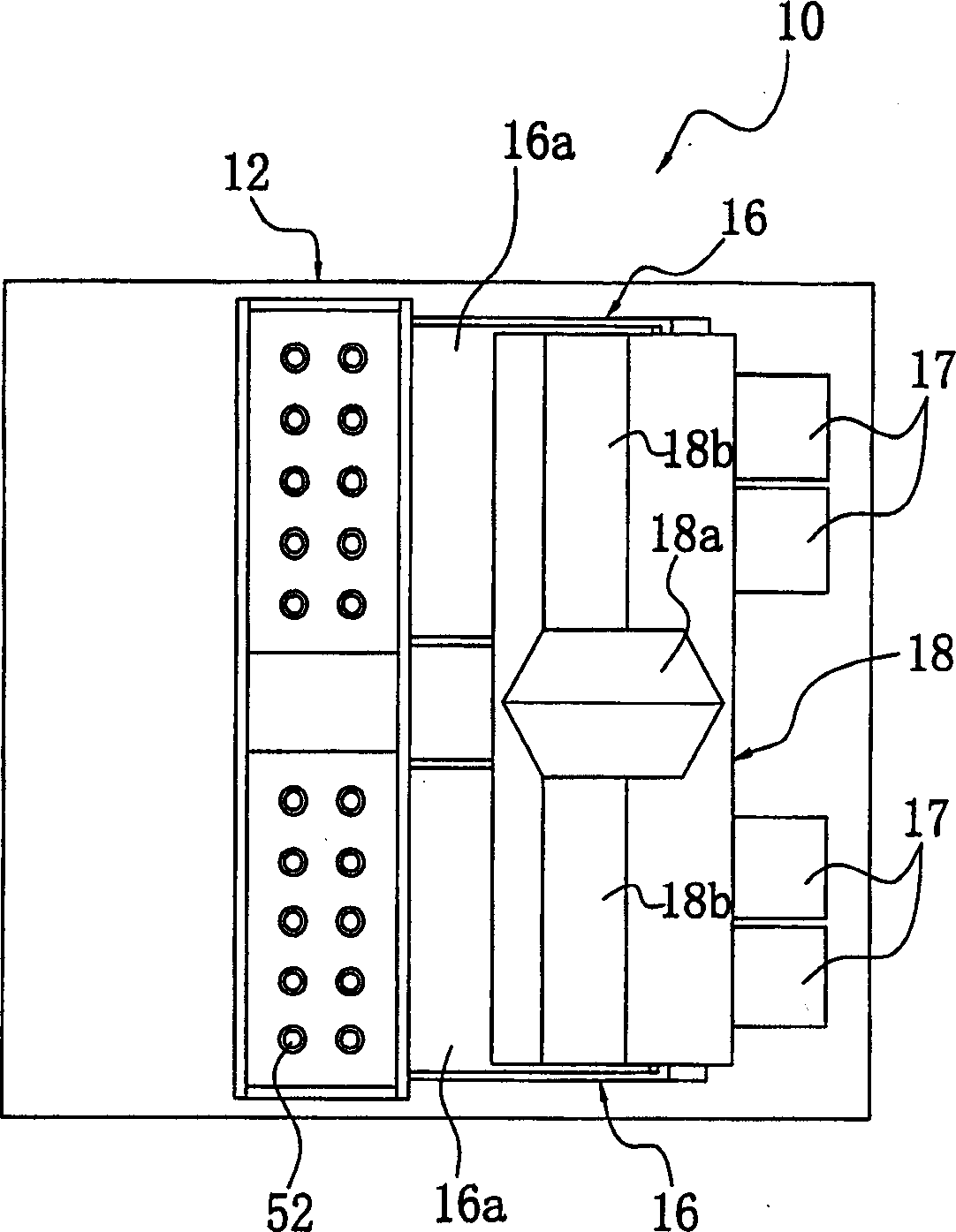

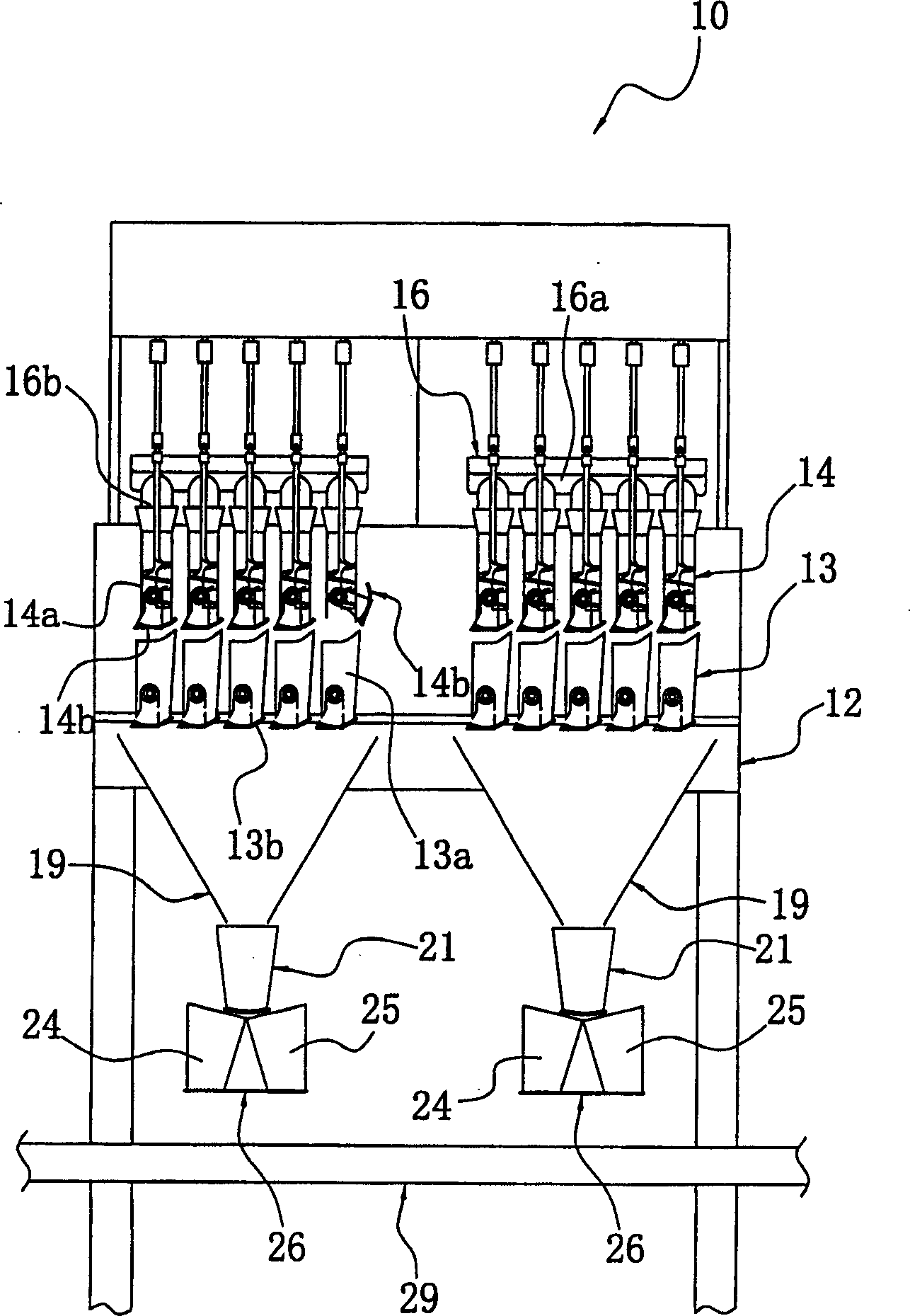

Distributing mechanism of meter

InactiveCN1344916AReduce leftoversWeighing apparatus with automatic feed/dischargeSpecial purpose weighing apparatusDrive motorEngineering

Owner:ISHIDA CO LTD

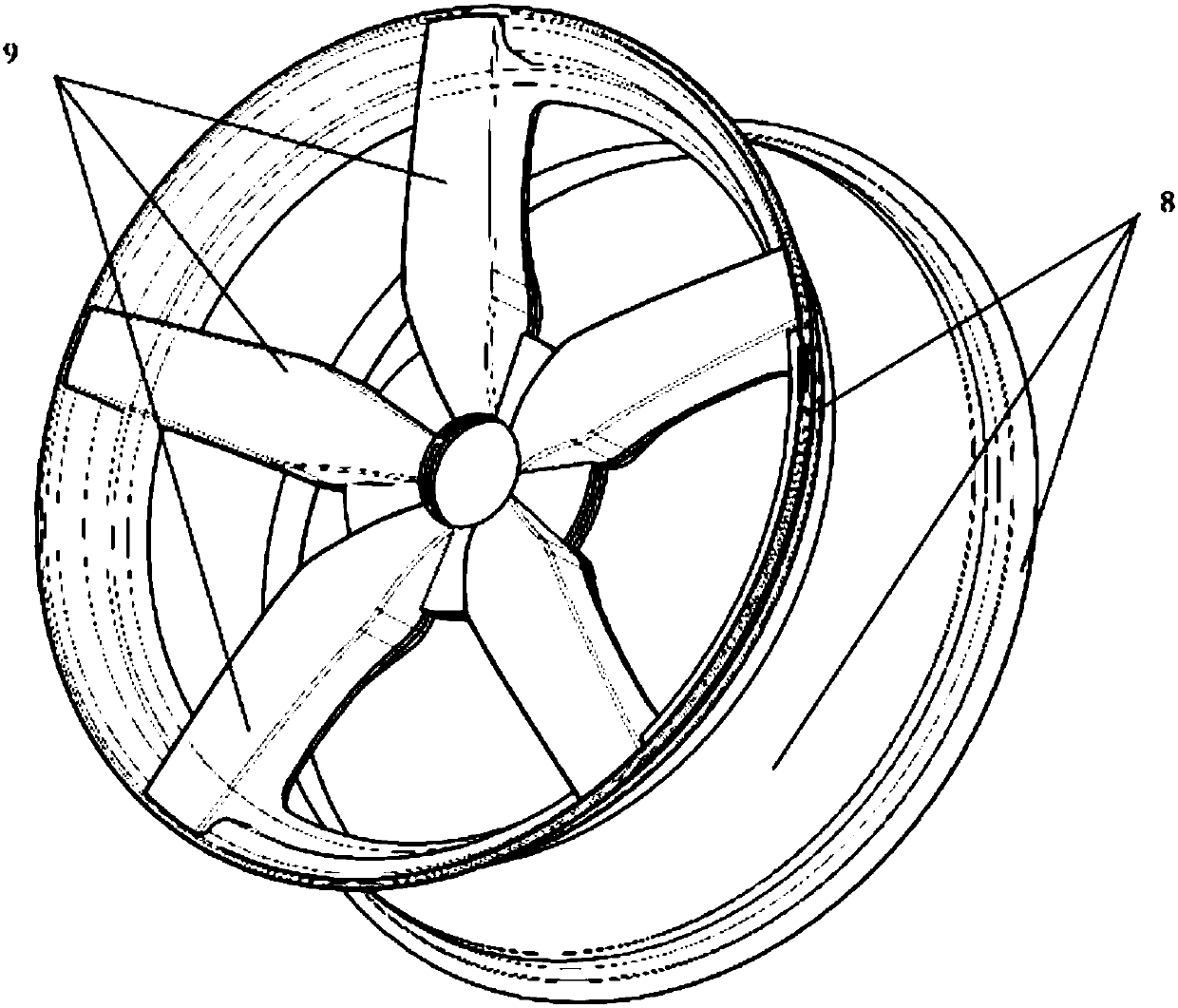

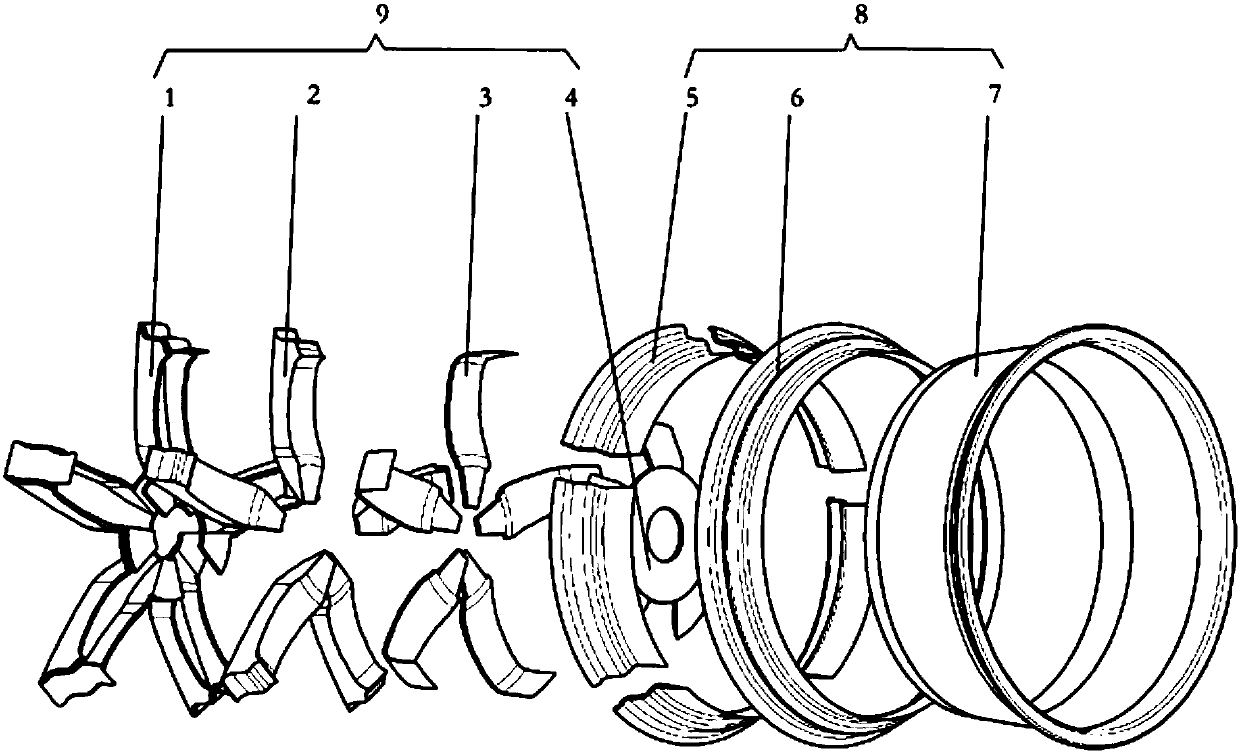

Composite material hub

The invention relates to a composite material hub. The composite material hub comprises a breadth pre-formed body and a wheel rim pre-formed body. In the breadth pre-formed body, after four to six sets of same enhanced fiber material pre-formed bodies are alternately stacked around the axis of a hub, spokes and a hub part used for being connected with an axle are formed. The wheel rim pre-formed body comprises four to six same enhanced fiber material pre-formed bodies, and each pre-formed body set is connected with the two corresponding adjacent spokes at the same time. The weight is smaller while the hub performance requirement is met; and the integrity, safety and reliability of the breadth are further enhanced. Meanwhile, large-scale production of the composite material hub is easy, quality consistency of final products is guaranteed, and the manufacturing cost is reduced. The two-step curing technology of pre-curing inside a die and post-curing outside the die is adopted, the die occupied period is shortened, the number of dies can be reduced during large-scale production, and the unit time yield is increased.

Owner:吴波

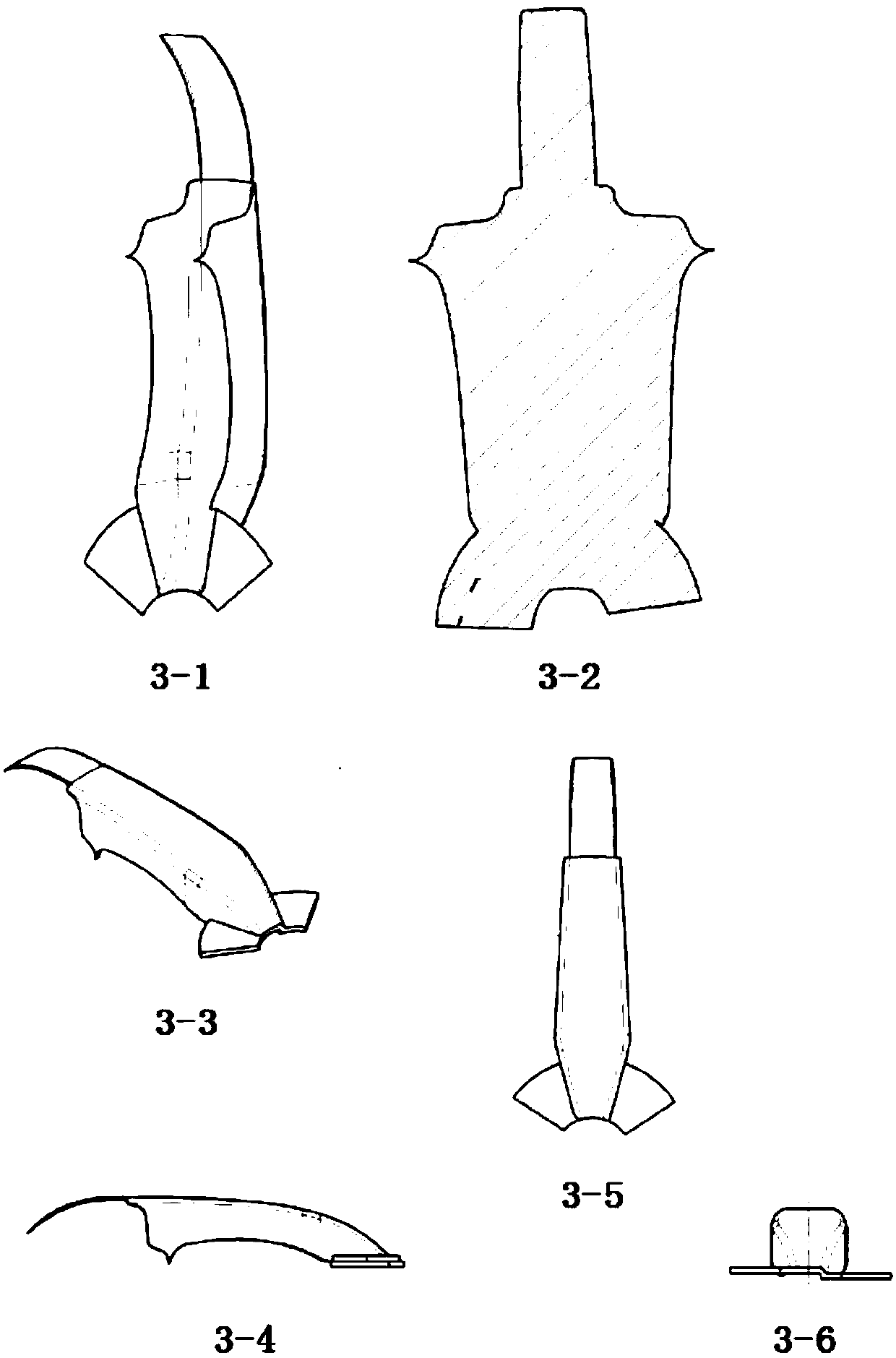

PMI (polymethacrylimide) foam elbow core material and forming method thereof

The invention discloses a PMI (polymethacrylimide) foam elbow core material and a forming method thereof and belongs to the technical field of foam core material forming. The forming method of the PMIfoam elbow core material comprises the steps as follows: gaps are formed in two sides of a straight pipe PMI foam core material through cutting, then, the core material is bent to be at the requiredangle by use of the gaps, the gaps are filled with mixed paste consisting of epoxy resin, a curing agent and hollow glass beads, and the PMI foam elbow core material is prepared after curing. The machining process is simple, the operability is high, the PMI foam elbow core material can be molded without special machining equipment (milling machine), a large quantity of manpower and material resources are saved, and the machining cost of the core material is reduced.

Owner:CHENGDU AERONAUTIC POLYTECHNIC

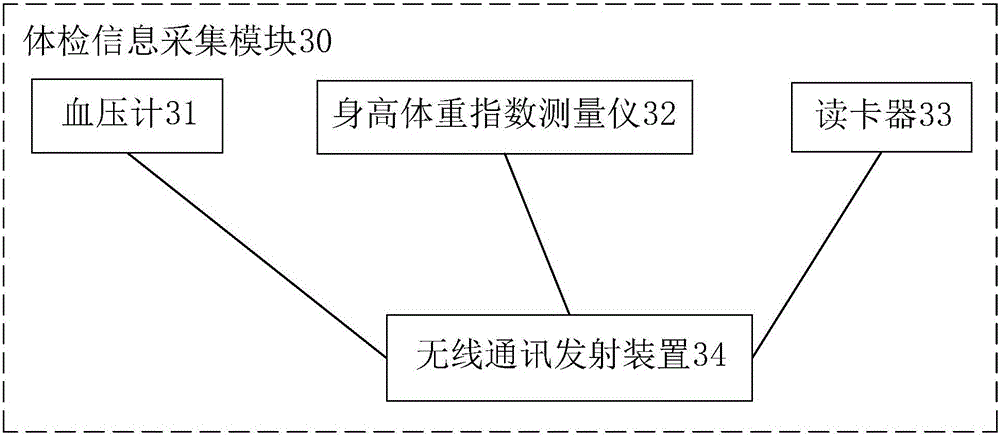

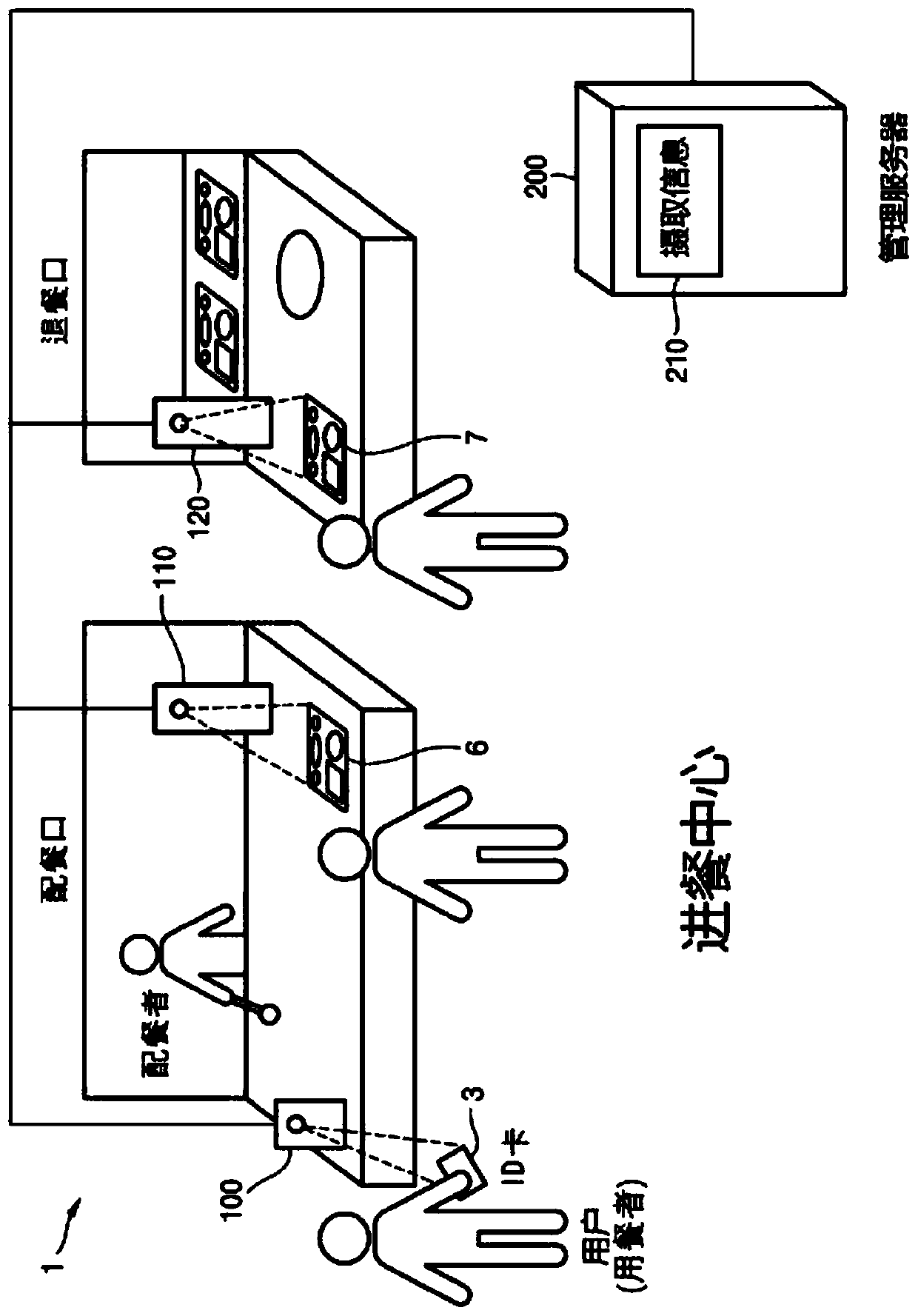

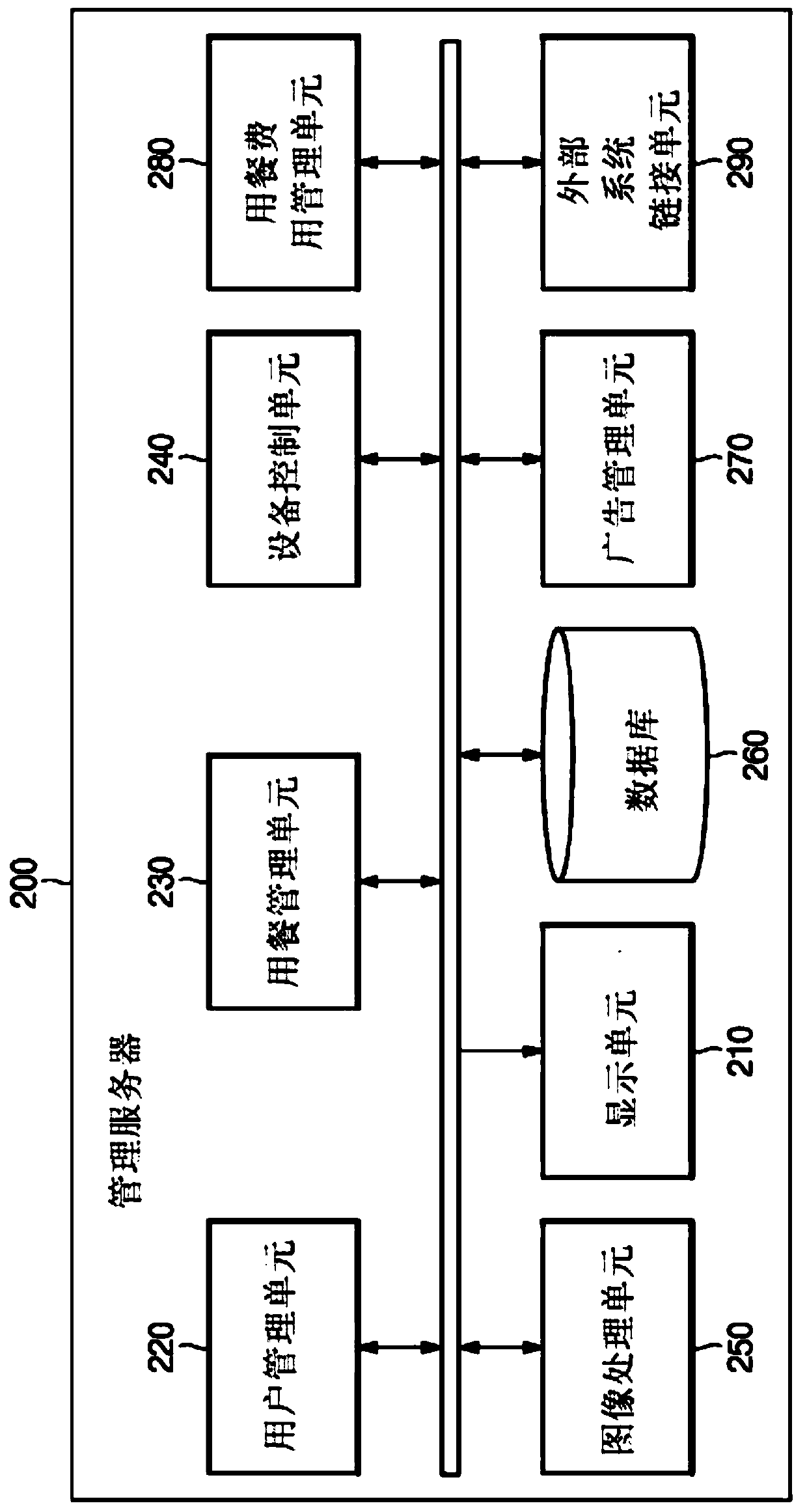

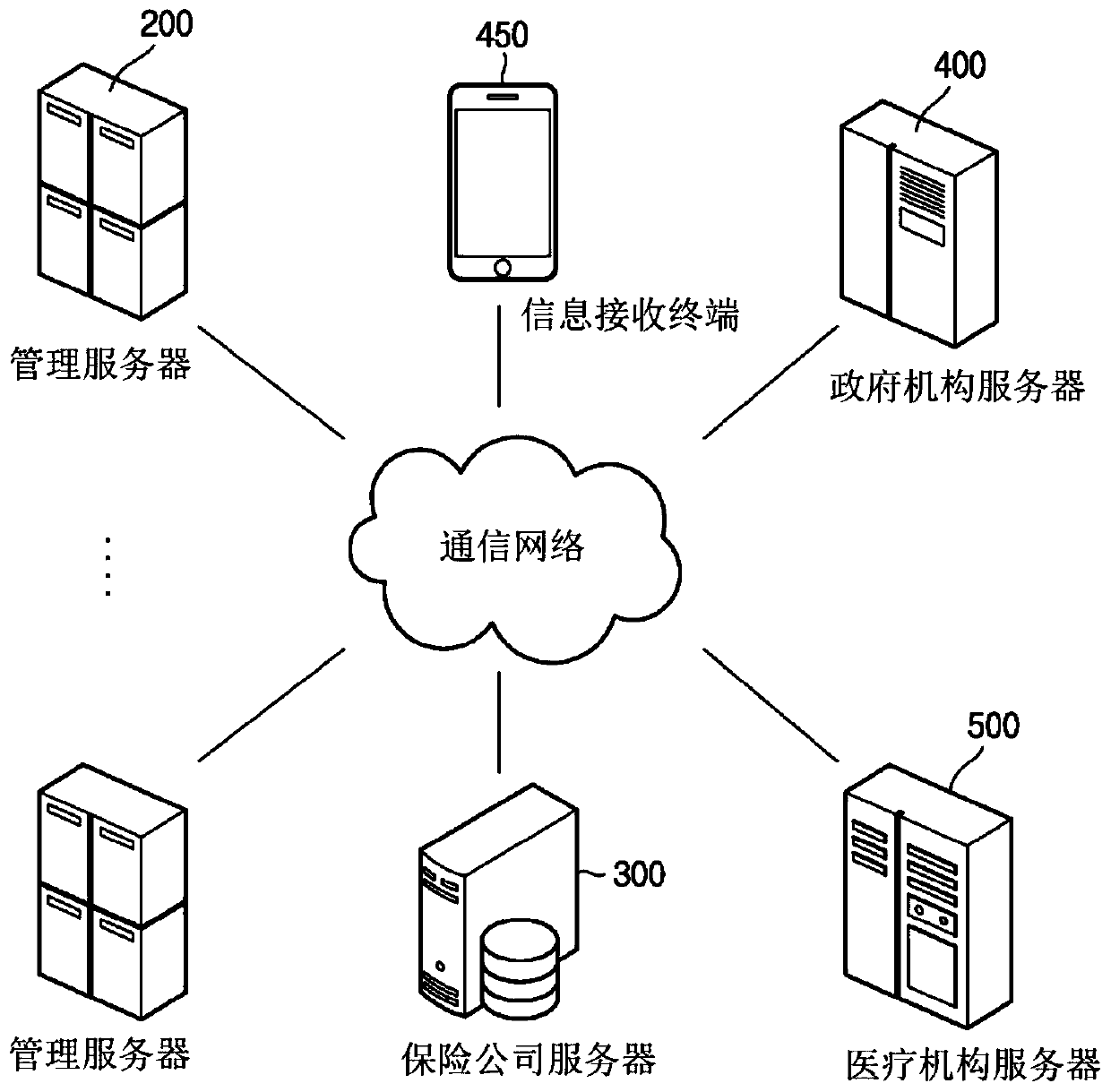

Meal service management system and operating method therefor

PendingCN111344734AEasily judge eating habitsEasily determine nutritional statusTelevision system detailsImage enhancementNutritional statusDiet habits

A meal service management system is disclosed. More specifically, the present invention relates to a meal service management system and an operating method therefor, the system being capable of providing information on food ingested by a user to whom a meal service is to be provided and customized information related thereto, and managing food leftover in a meal service. According to an embodimentof the present invention, a scanner device is used such that a user to whom a meal service is to be provided and a food tray before and after meals are identified, and thus a meal service amount anda leftover food amount are acquired, and leftover food information of each user and useful information associated therewith are provided on the basis of the same, and thus users can easily determine their eating habits, nutritional status and the like and the users can be induced to attempt reducing leftover food by themselves.

Owner:金大熏

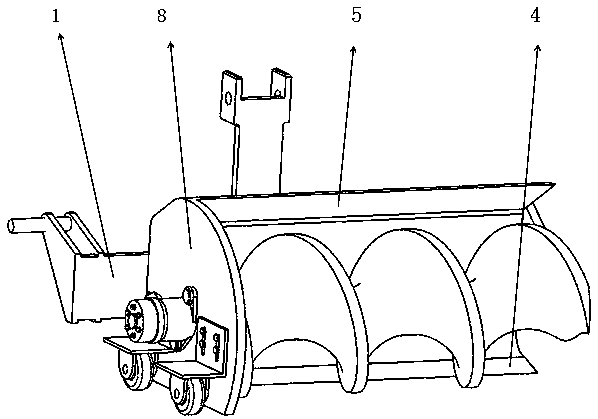

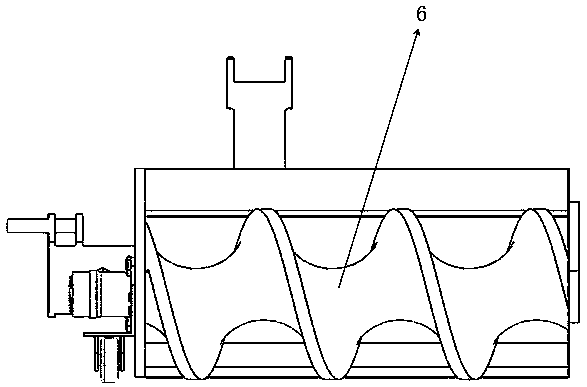

Spiral pushing type cow feed pushing robot and feed pushing method

PendingCN110710464ASimple structureEasy to manufactureAnimal feeding devicesHydraulic motorMachine building

The invention relates to a spiral pushing type cow feed pushing robot and a feed pushing method. The feed pushing robot comprises a traveling device and a body shell connected with the traveling device through a connecting device and is characterized in that a spiral feed pushing auger extending towards the side where cows are located is arranged in the body shell; the body shell comprises a backplate whose extension direction is consistent to the extension direction of the spiral feed pushing auger and a lateral plate fixedly connected to one side, away from the cows, of the back plate, theback plate is located on one side, close to the traveling device, of the spiral feed pushing auger, and a hydraulic motor for driving the spiral feed pushing auger to rotate is fixedly arranged on thelateral plate. The spiral pushing type cow feed pushing robot has the advantages that the body shell and the auger of the robot are simple and practical in structure and convenient in mechanical manufacturing, and large-scale industrial manufacturing can be performed; one end and the front side of the auger are open, so that mounting and maintenance are facilitated; the feed pushing efficiency isincreased greatly as compared with that traditional manual feed pushing, and the problems of excessive residual feed, feed loss, manpower consumption and labor increasing caused by the manual feed pushing can be effectively reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

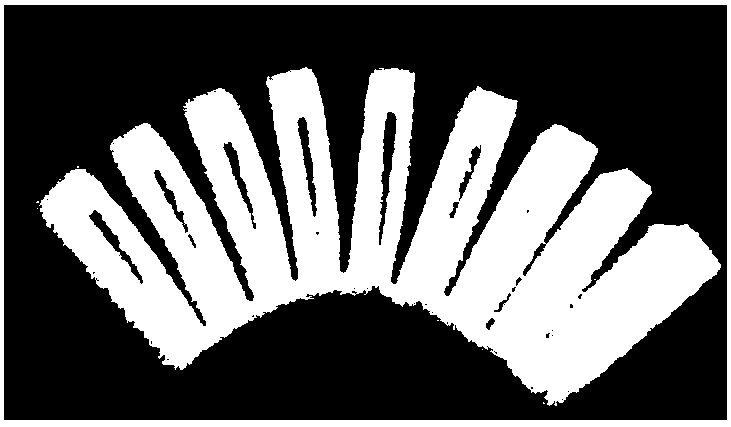

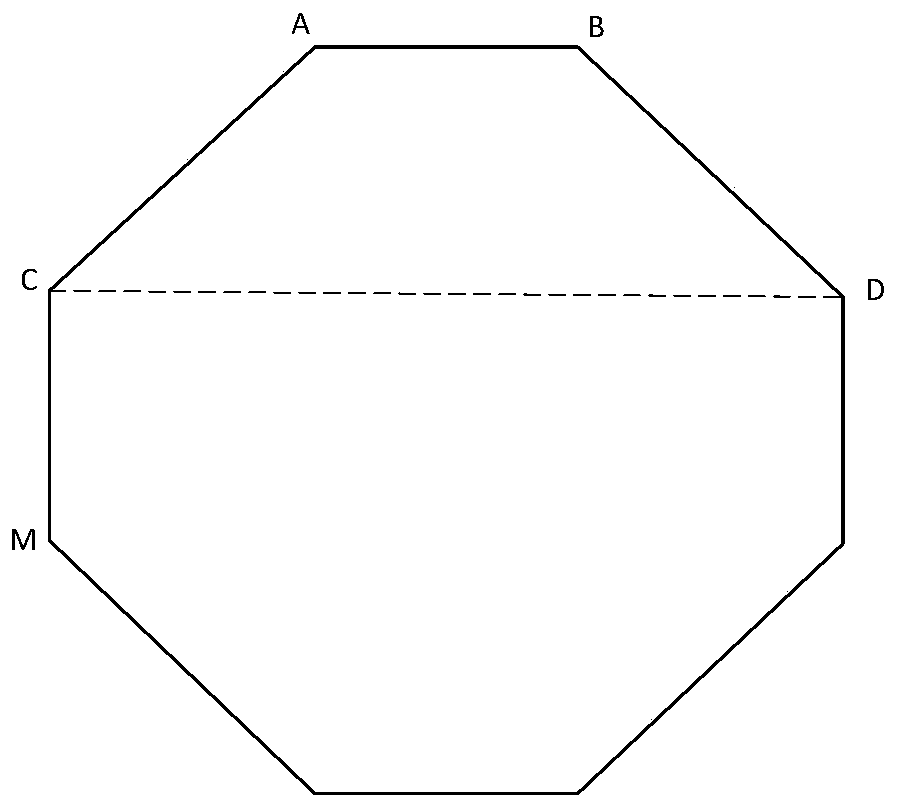

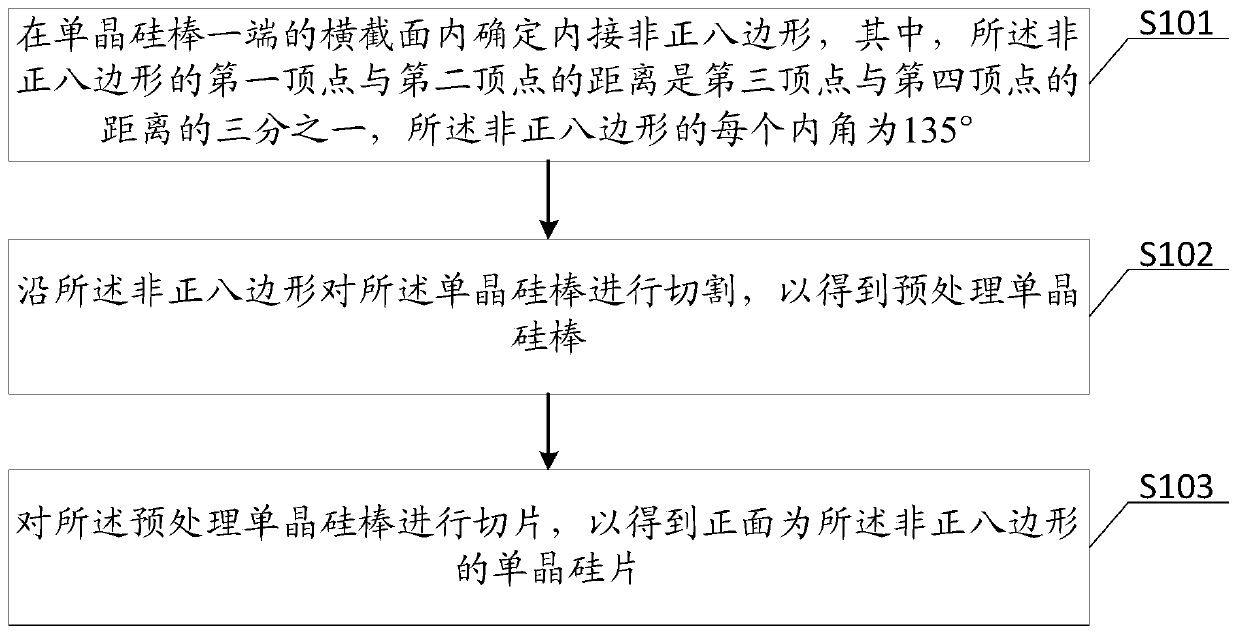

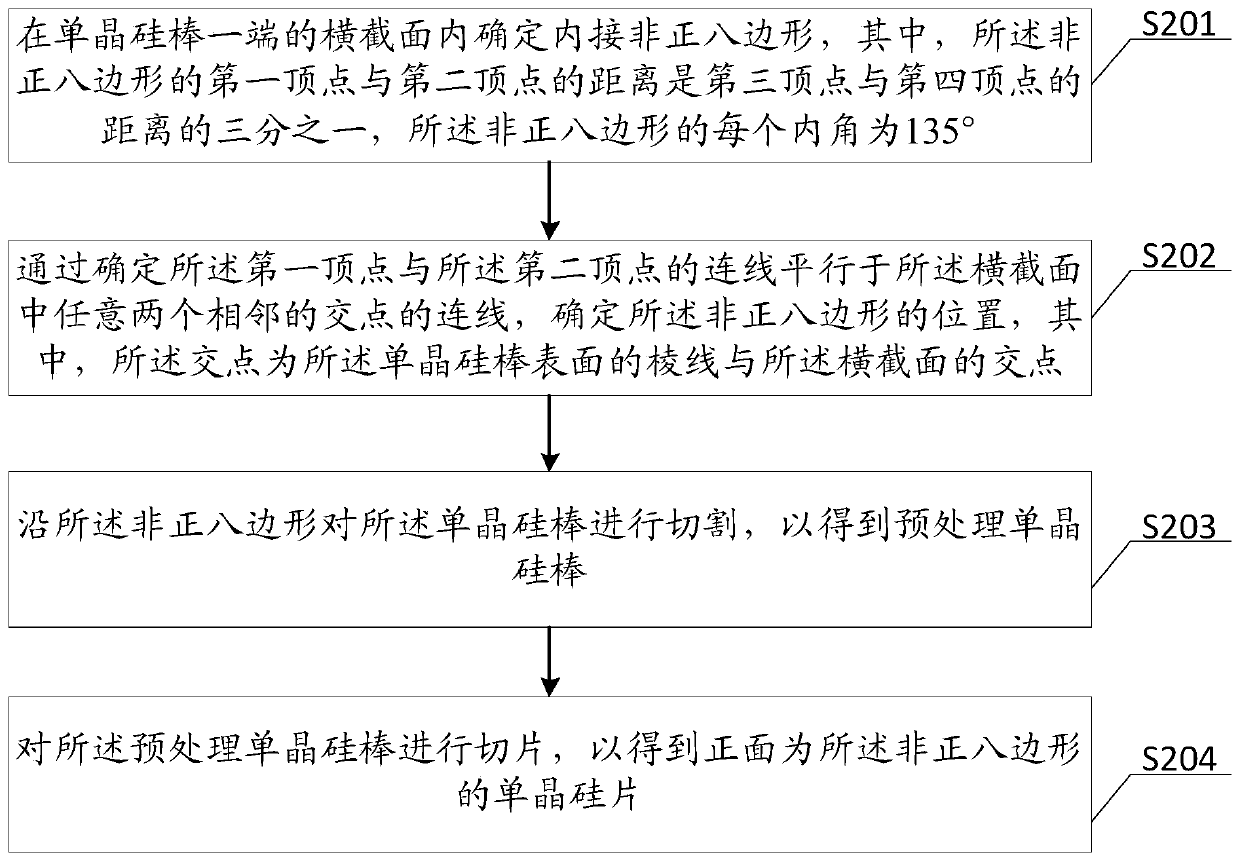

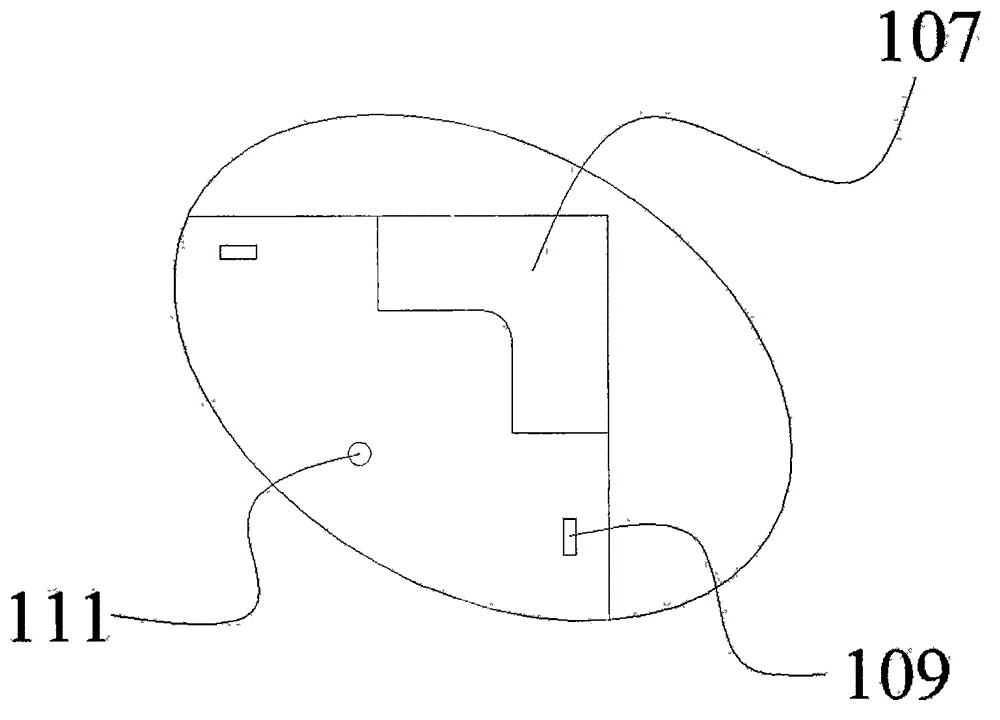

Monocrystalline silicon wafer, preparation method thereof and cutting method for battery piece

ActiveCN109873051AReduce leftoversIncrease profitFinal product manufactureFine working devicesSolar cellSingle crystal silicon

The invention discloses a monocrystalline silicon wafer. A front face of the monocrystalline silicon wafer is an irregular octagon. A distance from a first vertex to a second vertex of the irregular octagon is one third of the distance from a third vertex to a fourth vertex of the irregular octagon. The second vertex and the third vertex are adjacent vertexes of the first vertex. The fourth vertexis the adjacent vertex of the second vertex. Each inner angle of the irregular octagon is 135 degrees. According to the monocrystalline silicon wafer, the front face is the irregular octagon, so waste leftover materials of a monocrystalline silicon rod are greatly reduced, a utilization rate of the monocrystalline silicon rod is improved, and cost is reduced. The invention also provides a preparation method for the monocrystalline silicon wafer with the advantages, a cutting method for a battery piece prepared by the monocrystalline silicon wafer, and a solar cell module.

Owner:JINKO SOLAR CO LTD +1

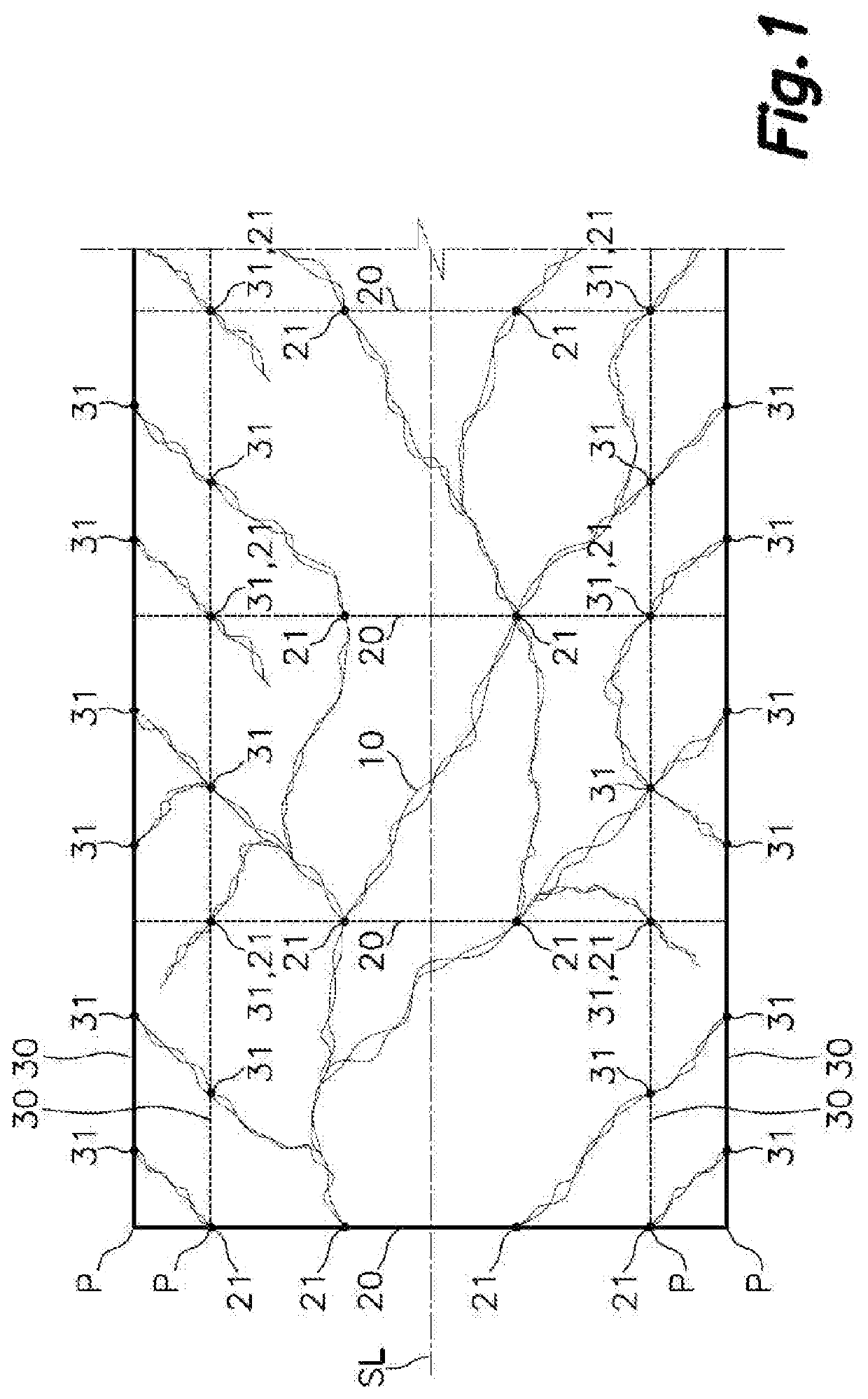

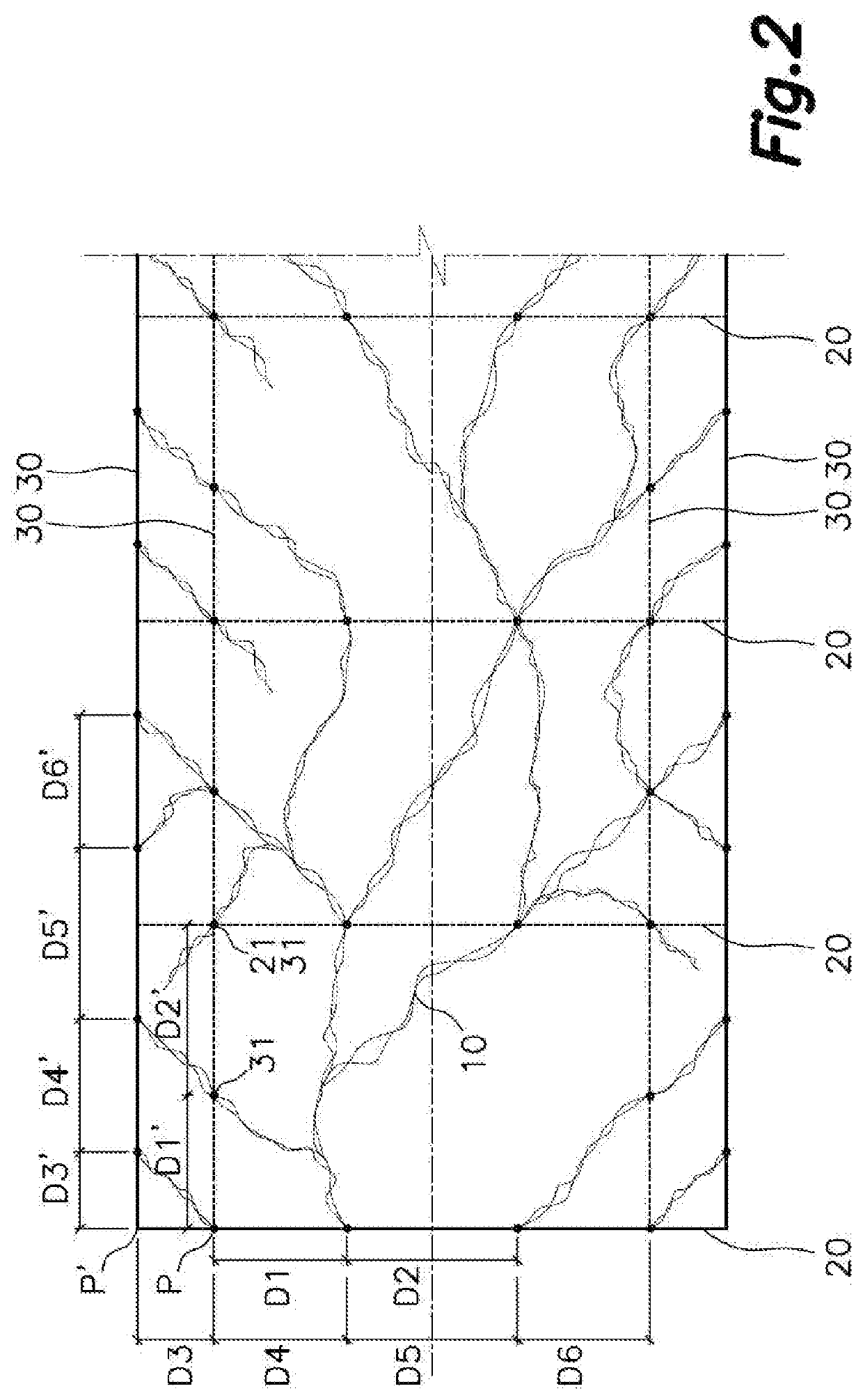

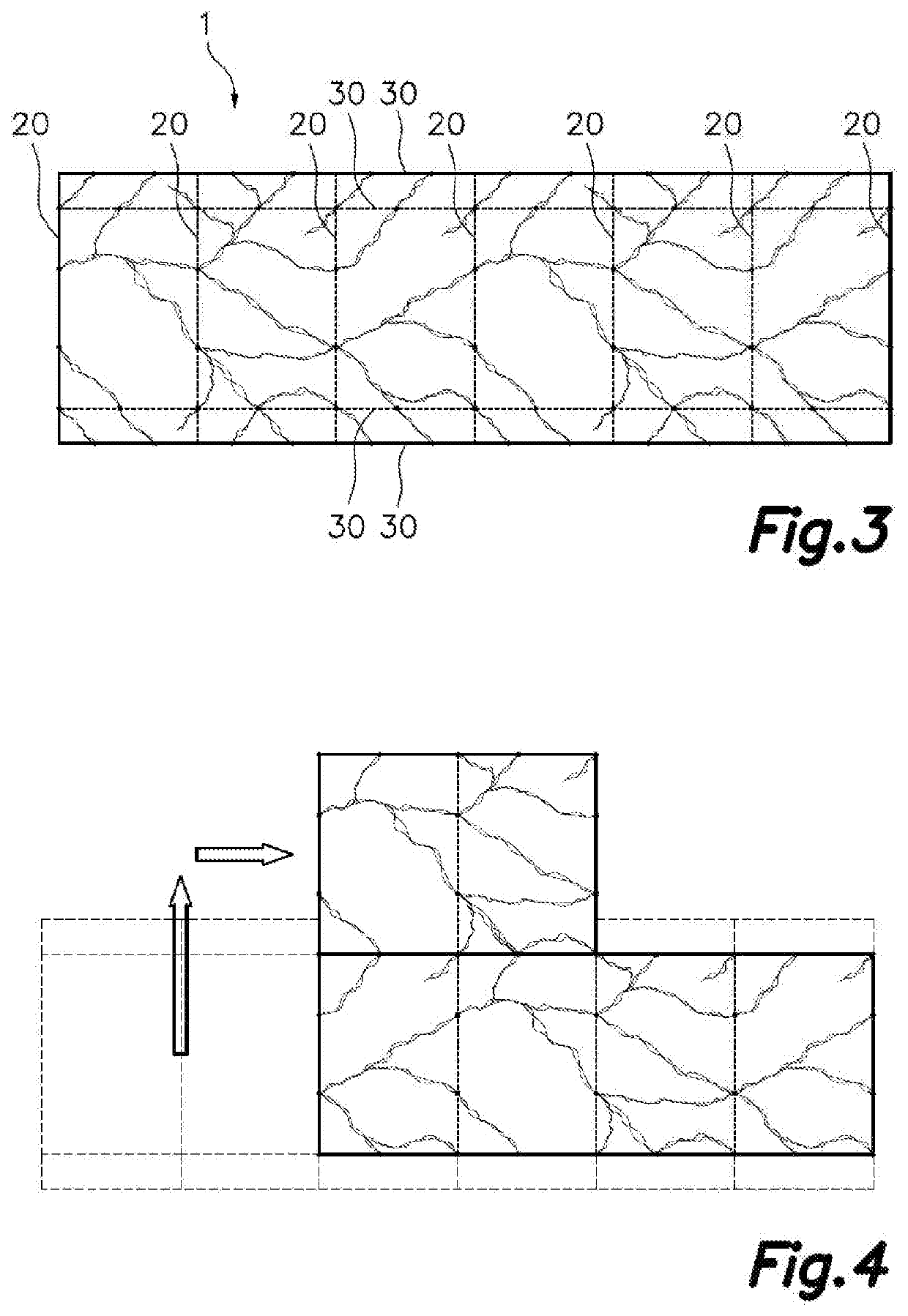

Cuttable cladding panel with a matching pattern, use and manufacturing method thereof

PendingUS20210123243A1Maintain continuityVisual resultCovering/liningsNatural patternsAxis of symmetryStructural engineering

The present invention relates to a cuttable cladding panel with a matching pattern, the use, and the design method thereof. The cladding panel comprises an irregular pattern (10) of elongated lines, veins, and / or strips; transverse cutting lines (20) all of them cutting through the pattern at identical transverse intersecting points symmetrical with respect to a longitudinal axis of symmetry (SL); pairs of longitudinal cutting lines (30) symmetrical with respect to the longitudinal axis of symmetry (SL), each pair of longitudinal cutting lines cutting through the pattern at identical longitudinal intersecting points; with said cutting lines crossing one another at corner points (P); wherein each transverse intersecting point (21) is at the same distance from a corner point (P) as a corresponding longitudinal intersecting point (31); with two parts obtained by cutting the cladding panel (1) along any cutting line having a matching and continuous irregular pattern (10).

Owner:COMPACSTONE USA INC

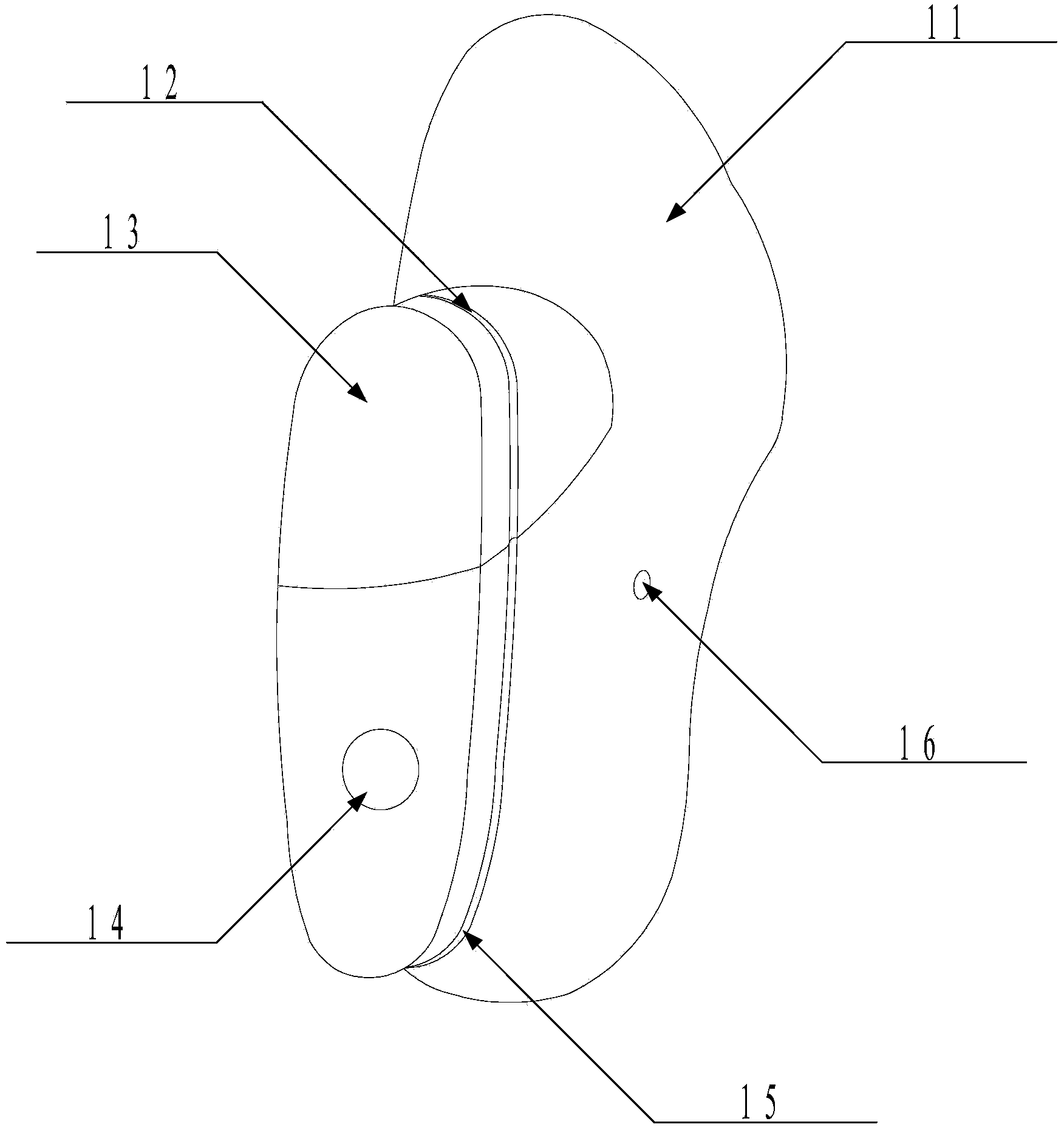

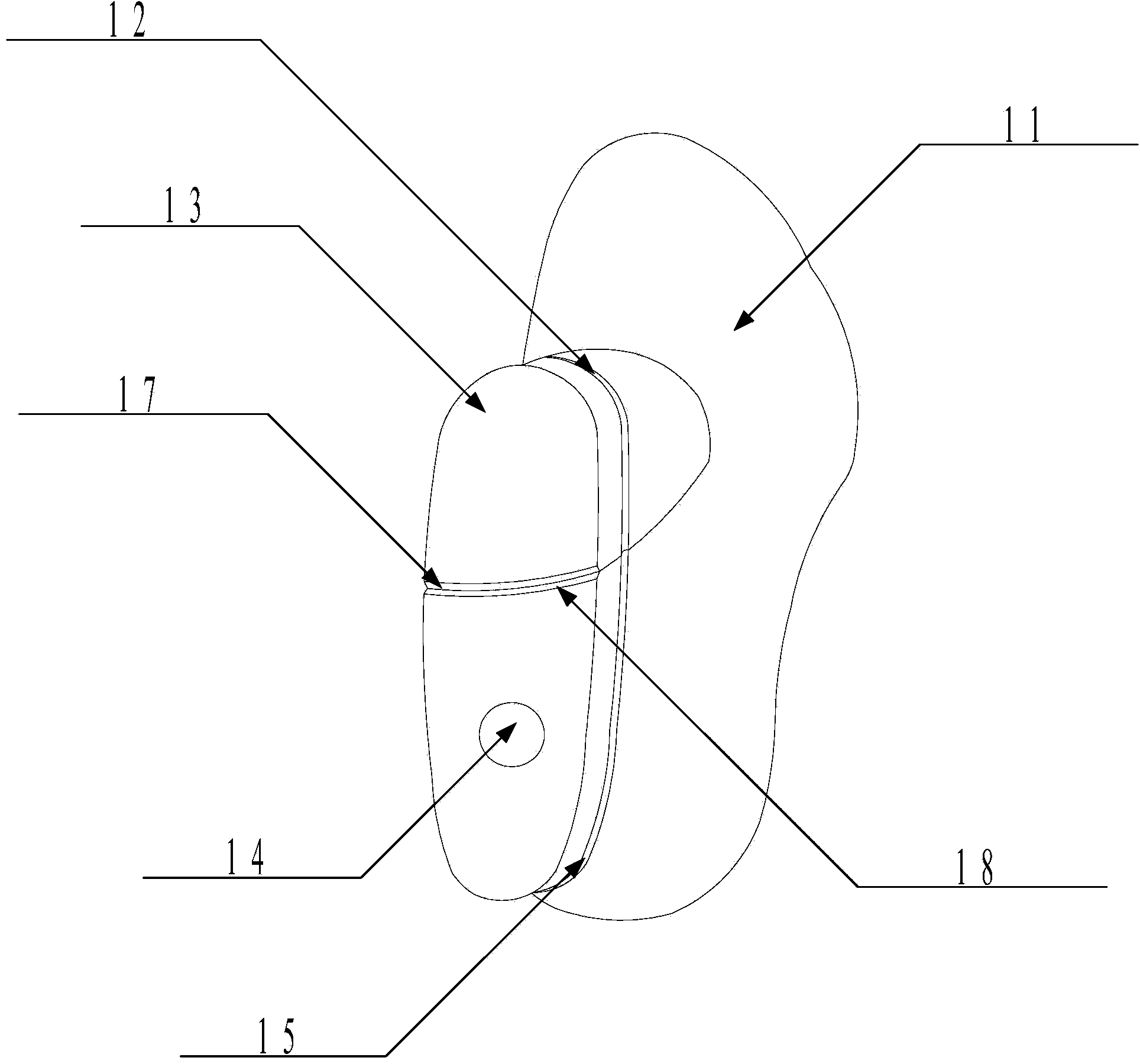

Fashion boot production process

The invention discloses a fashion boot production process which comprises the following production steps: A, carrying out combination forming of a shoe tree; B, preparing and selecting materials; C, carrying out primary processing forming on the materials; and D, carrying out production line forming of a fashion boot. The shoe tree in the step A is a safety shoe tree; the materials in the step B comprise a surface fabric, a lining, sewing threads, a counter, lining cloth, glue and die cutters for each part; and the step C of carrying out primary processing forming on the materials comprises the following sub-steps: a, cutting off the materials; and b, carrying out primary sizing of each part. The invention provides the fashion boot production process; resources of the shoe tree, which need to be invested in use, are reduced; production cost is saved; safety, convenience and the utilization rate of the space in the machining process are improved; production cost is further saved; and the utilization rate of production funds is promoted.

Owner:LEZHI YUYUAN SHOES

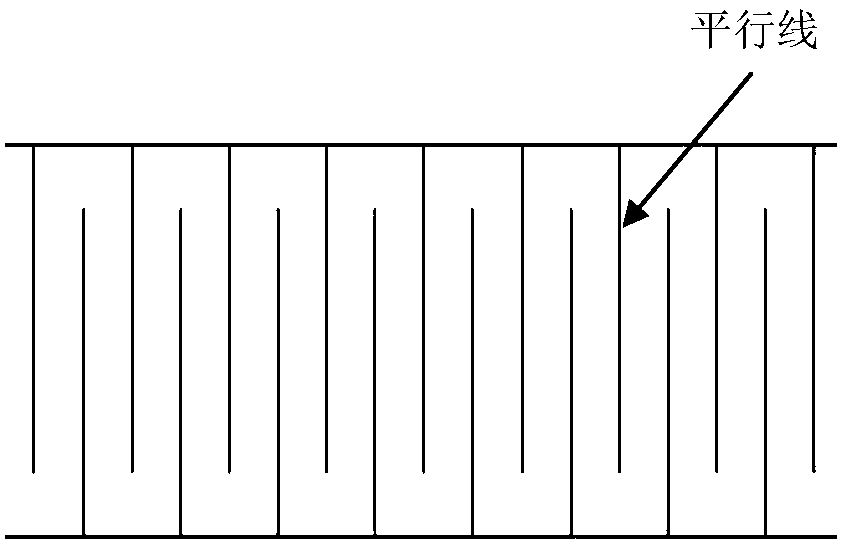

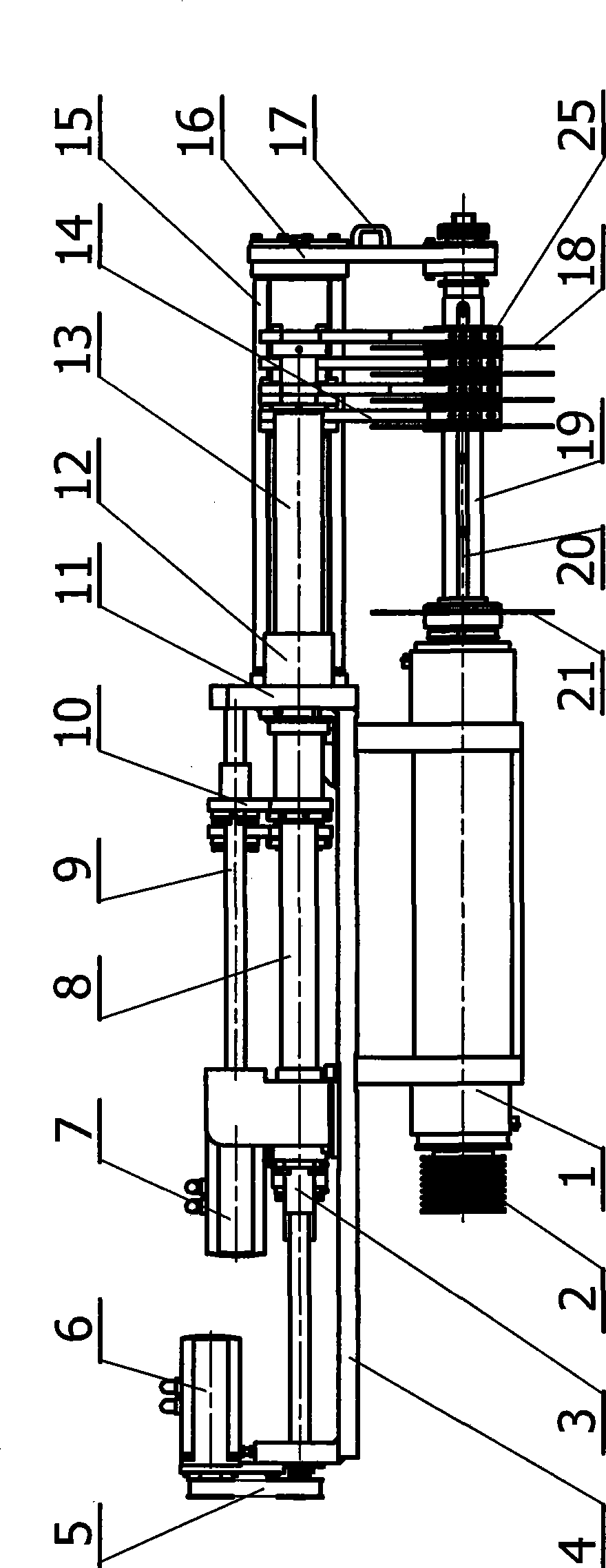

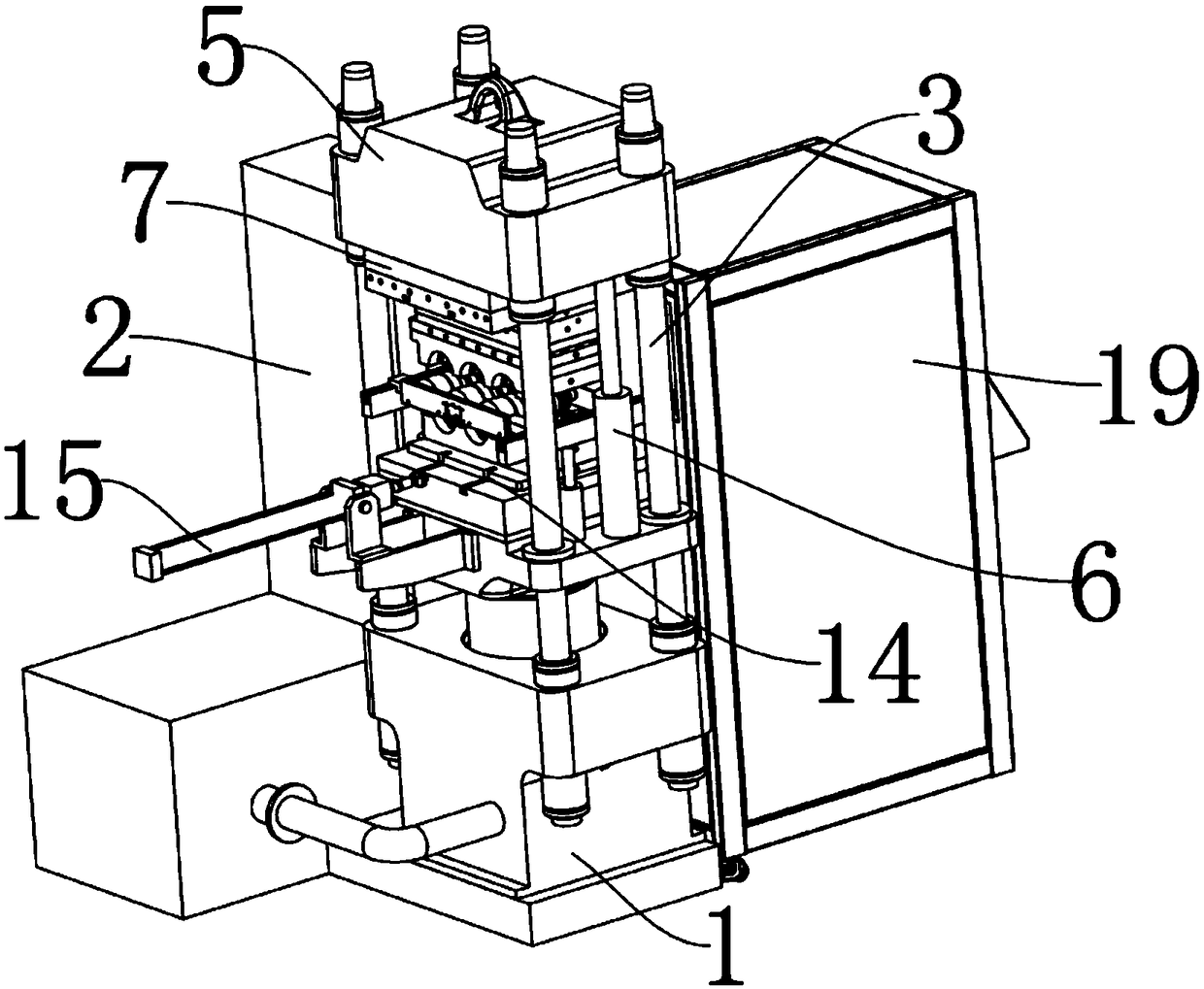

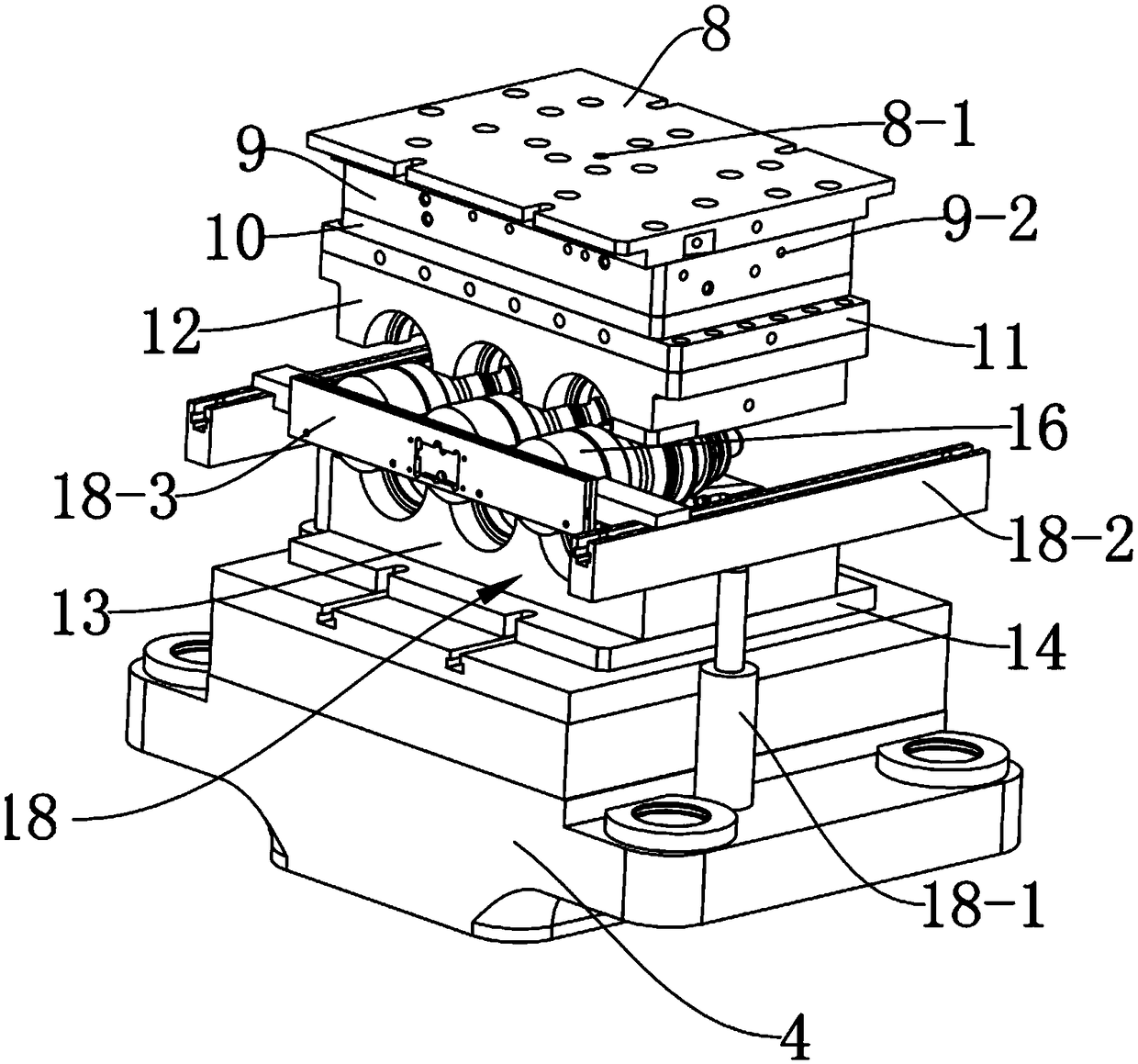

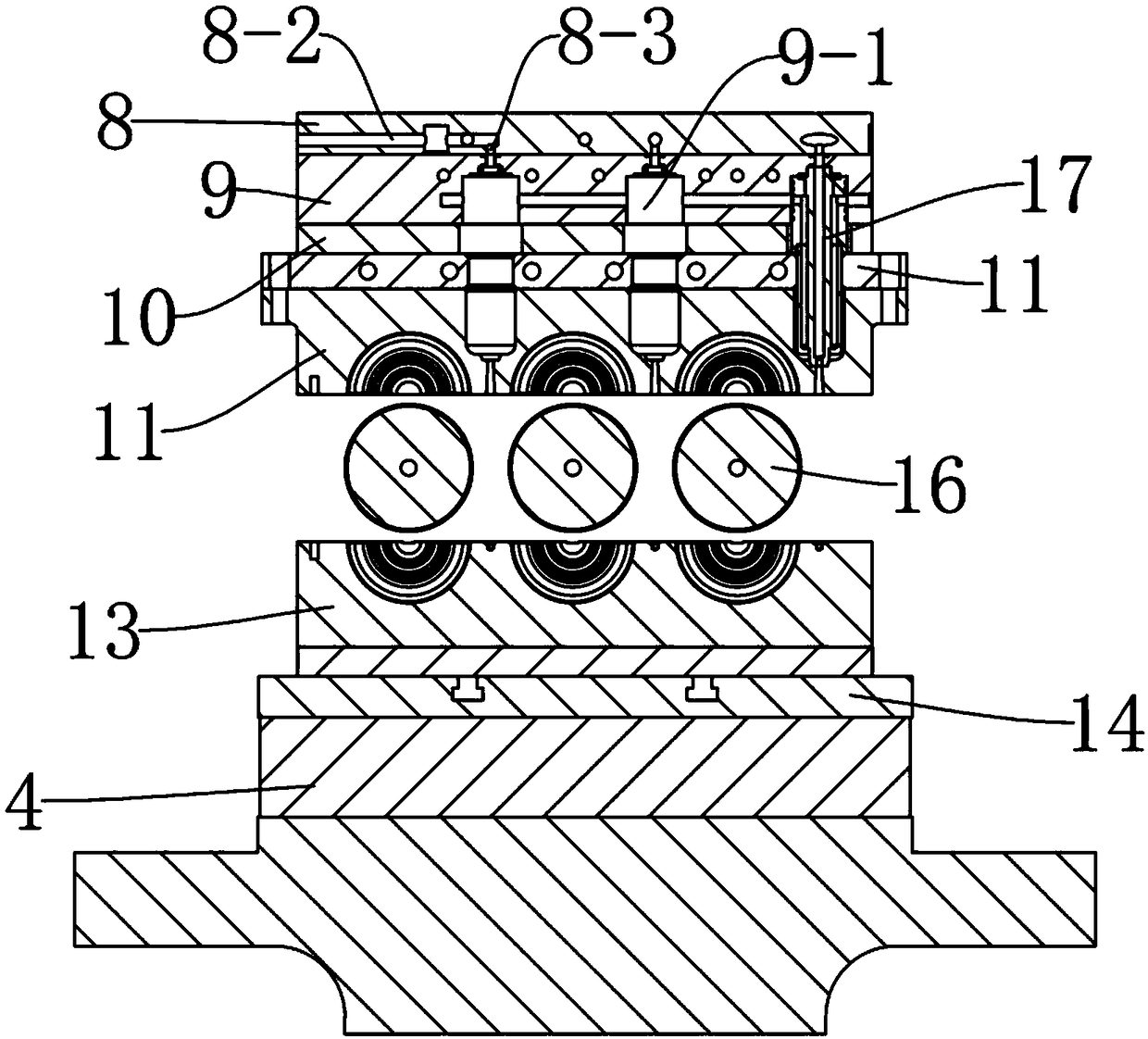

Mandrel structure of circular saw machine for preferably cutting timber in longitudinal direction

The present invention discloses a saw shaft structure of optimized longitudinal cutting circular sawing machine, which comprises a saw shaft and a saw shaft base that is used for supporting the saw shaft. The saw shaft is at least sleeved with a sawblade sliding sleeve which can move along the axial direction and rotate along with the saw shaft. The sawblade sliding sleeve is at least fixedly installed with a movable circular saw blade which is movably connected with a circular saw blade shifting fork. The circular saw blade shifting fork is connected with a screw pair. The saw shaft is at least fixedly installed with a fixed circular saw blade and is at least fixedly installed with a saw shaft driving key. The shaft hole of sawblade sliding sleeve is at least internally provided with a driving key groove that is corresponding with the saw shaft driving key. The saw shaft structure can realize the axial sliding adjustment to the circular saw blade conveniently and flexibly. Longitudinally material cutting can be executed according to an optimal cutting plan. The saw shaft structure also has higher material yielding rate and production efficiency, and is widely used in various multi-blade circular sawing machine.

Owner:JIANGSU JIANGJIA MACHINERY

Displayer frame production method

InactiveCN104965328AReduce manufacturing costReduce leftoversNon-linear opticsLiquid-crystal displayDisplay device

The invention relates to a liquid crystal displayer frame production method. The method includes the steps that a front frame substrate is punched from a material roll and is then bent, a window hole is punched in the bent front frame substrate, a waste substrate and a front frame are obtained, a back plate bent edge is punched on the material roll and is bent, and finally the waste substrate and the bent back plate bent edge are fixedly connected to form a back plate. In the front frame production process, the middle waste substrate is used for producing a back plate substrate, so that the material cost is greatly reduced, and raw materials are saved.

Owner:朱卫东

Automatic molding device

The invention discloses an automatic molding device. The molding device comprises a machine body and a control box disposed on the machine body. The machine body is provided with a base. The base is provided with a lower mold. The lower mold comprises a lower mold base, and the lower mold base is provided with a lower molding groove. A plurality of guiding columns are vertically disposed on the machine body, and an upper mold beam is disposed on the guiding columns in the sliding mode. An upper mold is connected to the mold beam, and the upper mold includes a runner plate provided with a plurality of hot runners, a cold runner plate provided with a plurality of cold runners, a heat insulation plate, an upper heating plate and an upper mold base. The mold base is provided with an upper molding groove, and the upper molding groove and the lower molding groove are matched to form a forming cavity. The upper mold is provided with an injection nozzle communicated with the forming cavity, the injection nozzle is in communication with the hot runners on the runner plate, and the base is provided with a first lifting portion for driving a molded material to break away from the upper mold.The automatic molding device has the advantage of improving the cyclic utilization rate of rubber molded materials.

Owner:浙江橡企科技有限公司

Casting forming weight control method

The invention provides a casting forming weight control method. The casting forming weight control method comprises the following steps that 1, lead melting is conducted, specifically, a lead ingot isput into a lead pan to be melted; 2, pressurizing is conducted, specifically, the interior of the lead pan is pressurized through an air cylinder; 3, material conveying is conducted, specifically, through pressure applied by the air cylinder, liquid lead is poured into a lead mold through a material conveying pipe; 4, forming is conducted, specifically, the liquid lead is cast into a solid grid through the lead mold and a cooling system; 5, discharging is conducted, specifically, the grid after cooling forming is put on an excess material workbench; and 6, excess material removal is conducted, specifically, irregular excess materials of the grid are removed through a cutting device. According to the casting forming weight control method, the lead liquid is poured into the lead mold in anaccelerated mode through pressure action, the grid production efficiency is improved, meanwhile, the weight of the lead poured into the lead mold is controlled more precisely through air pressure, thus, the excess materials of the product grid are decreased, production raw material wasting is avoided, and the production benefits are increased.

Owner:TIANNENG BATTERY WUHU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com