Fashion boot production process

A production process and fashion technology, applied in clothing, shoe lasts, footwear, etc., can solve problems such as protection against personal safety of operators, waste of production resources and funds, and unfavorable saving of production resources, etc., so as to reduce the difficulty of fixing and improve the Utilization, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

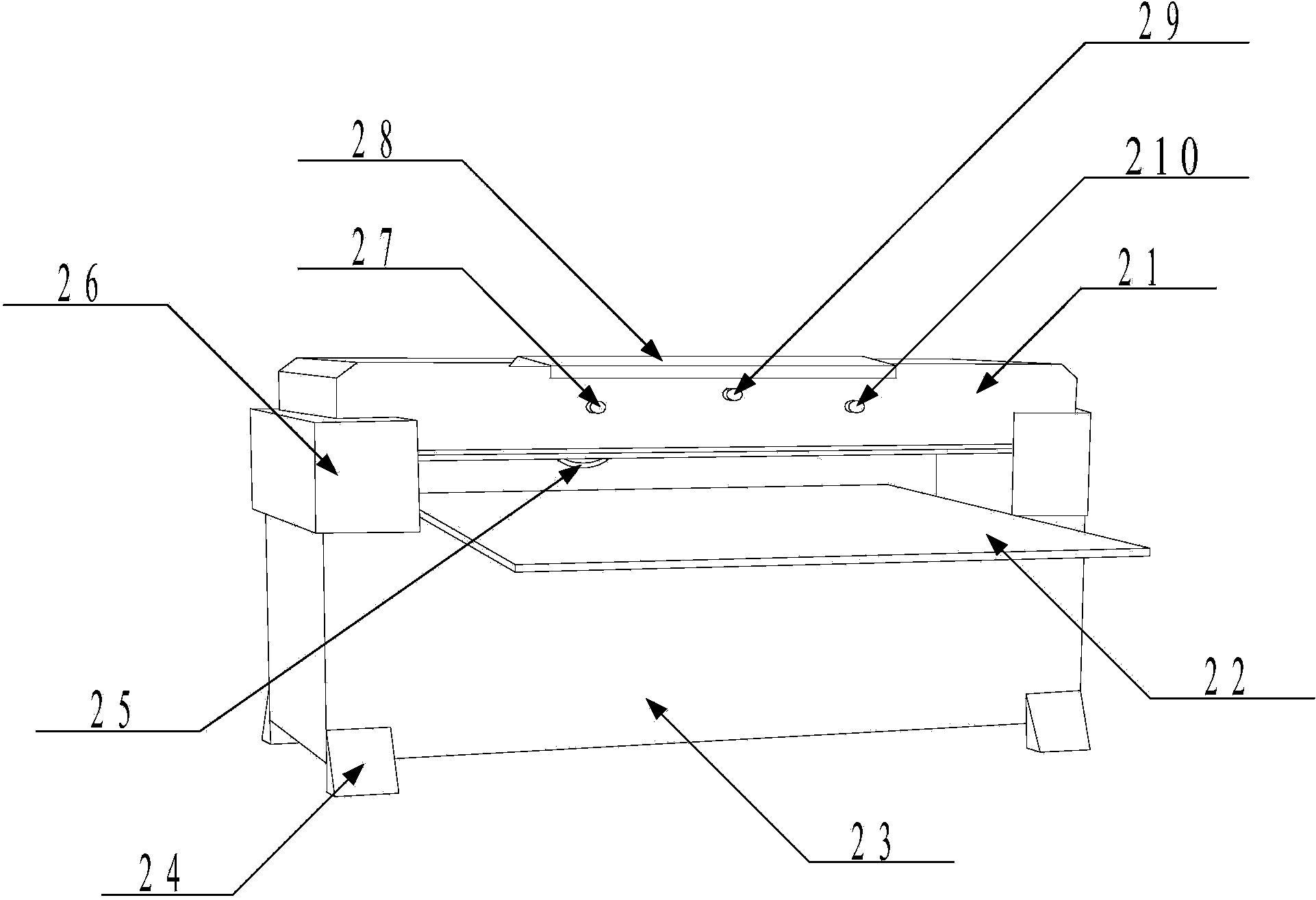

[0036] Such as figure 1 , 3 , 4, 5, and 6, the production process of fashion boots includes the following production steps:

[0037] A. Shoe last combination molding;

[0038] B. Material preparation and selection;

[0039] C. Preliminary processing of materials;

[0040] D. Fashion boot assembly line molding.

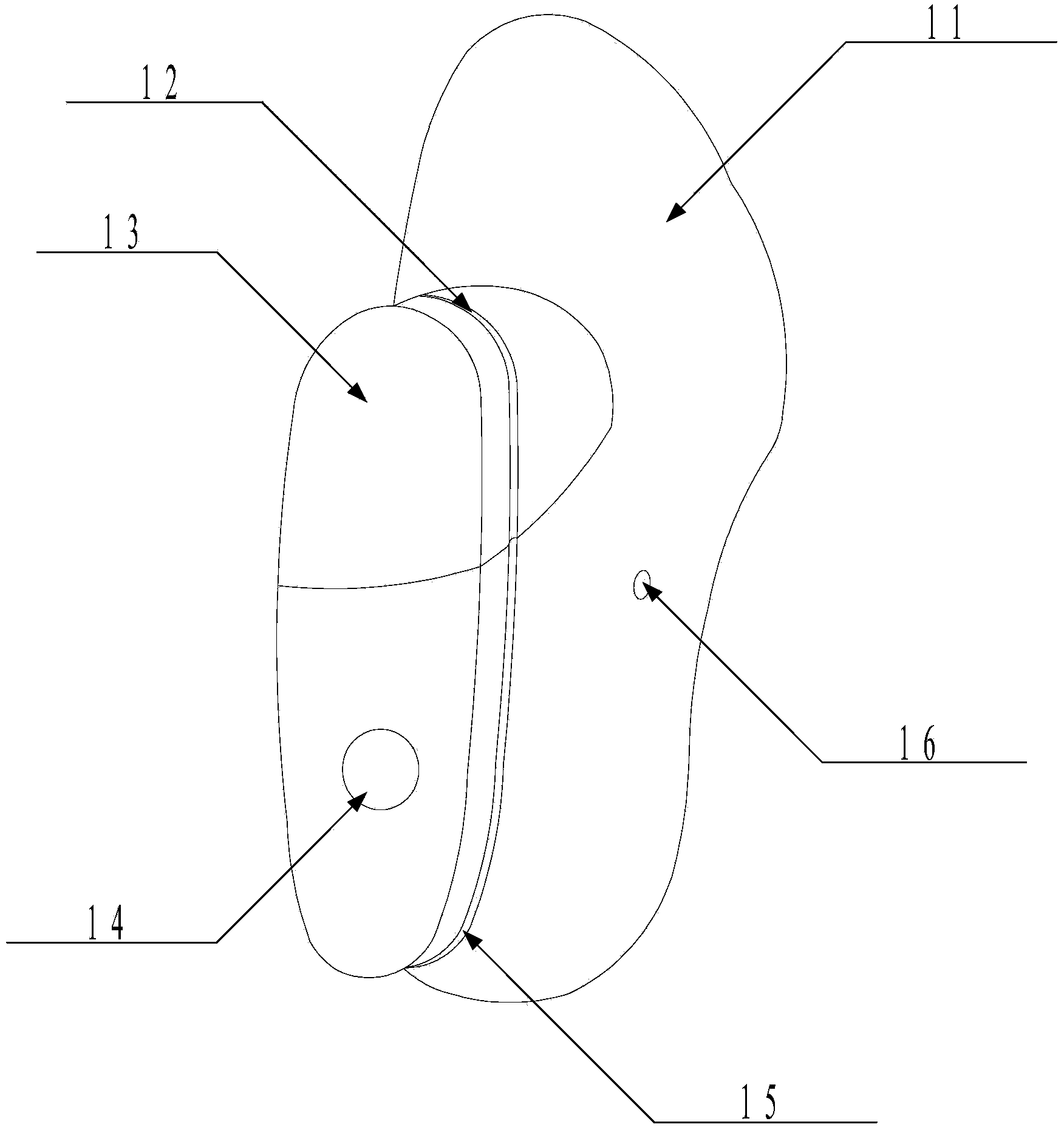

[0041] In step A, the shoe last is a safety shoe last, including a shoe last main body 11 and a splicing block 13, the splicing block 13 is fixed on the shoe last main body 11, and the shoe last main body 11 and the splicing block 13 are also provided with a fixing structure and Fastening structure; the side of the splicing block 13 close to the last body 11 matches the last body 11, the number of splicing blocks 13 is at least one, and the size is different; the fastening structure includes the The main body fixing groove 15 on the shoe last body 11 further includes a splicing block fixing groove 12 arranged on the splicing block 13; the main fixing groove 15 and the splicing...

Embodiment 2

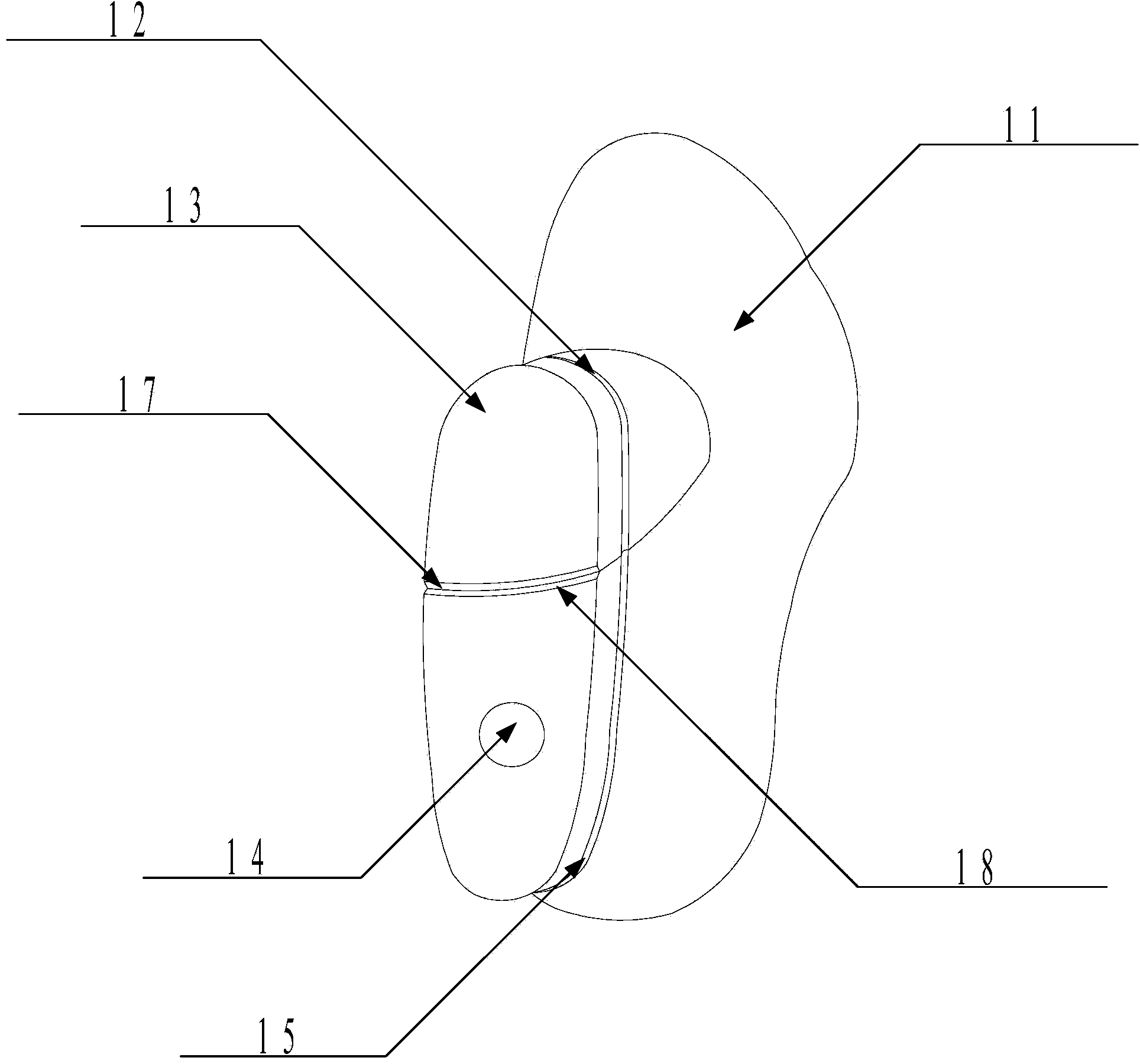

[0052] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is only that the fixed structure includes a front fixed slope 17 and a rear fixed slope 18; the front fixed slope 17 is arranged on the upper end of the splicing block 13 close to the shoe last body 11. The rear fixed slope 18 is a slope set on the upper end surface of the shoe last body 11 near the edge of the splicing block 13; the front fixed slope 17 and the rear fixed slope 18 have the same depth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com