PMI (polymethacrylimide) foam elbow core material and forming method thereof

A molding method and technology of foam core materials, applied in the field of foam core material molding, can solve the problems of complex procedures and inability to quickly process bent pipe PMI foam core materials, etc., and achieve the goals of saving a lot of materials, beautiful appearance, and reducing raw material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The PMI foam elbow core material molding method of the present embodiment comprises:

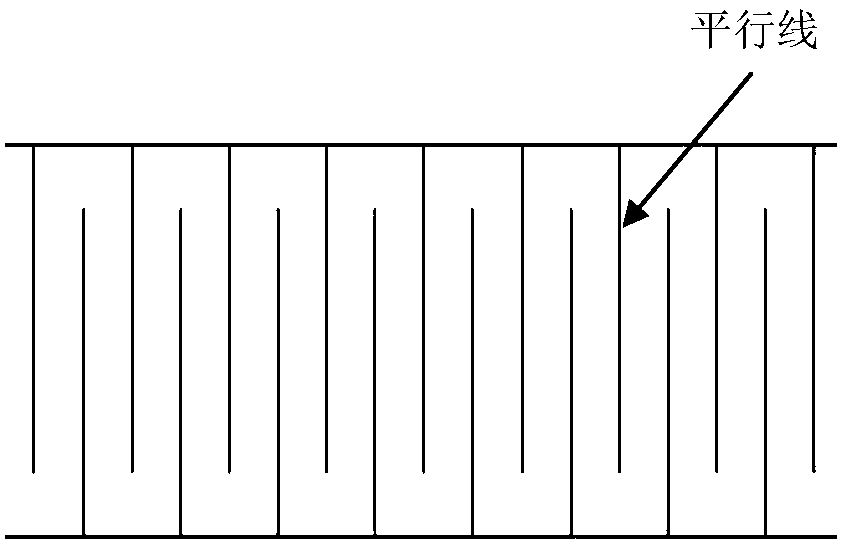

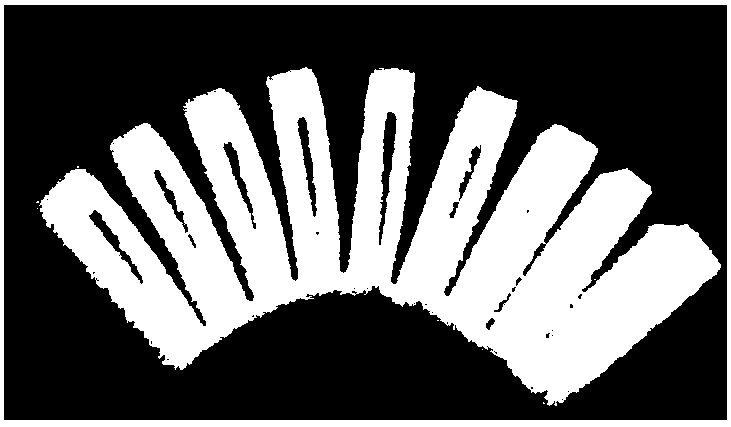

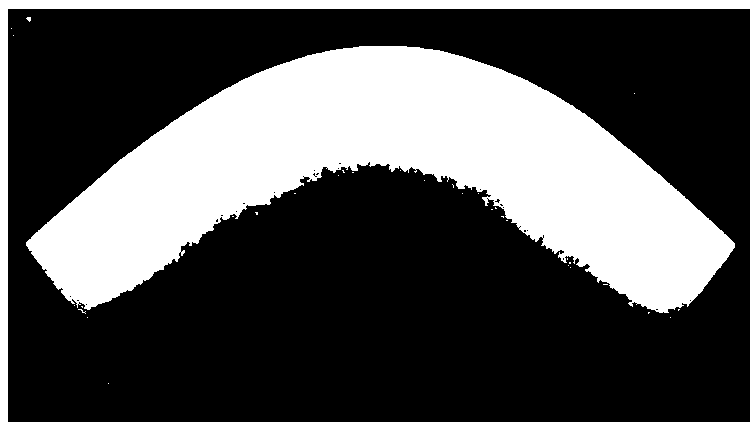

[0026] (1) Take the PMI foam core material processed into a straight tube, draw a line along the circumferential direction of the straight tube at the part that needs to be bent, draw multiple parallel lines at intervals of 2-5mm on both sides of the straight tube, and The parallel lines of the straight pipe are distributed in a staggered manner, and then cut along the parallel lines on both sides of the straight pipe to form a gap, and each side is not cut off when cutting.

[0027] Such as figure 1 As shown, lines are drawn along the circumferential direction on both sides of the straight tube PMI foam core material, the lines on both sides are distributed alternately, and the interval between two adjacent cutting lines on the same side is 2-5mm. Those skilled in the art can determine according to the size of the bending arc, for example, 2 mm is suitable for the case of a small be...

Embodiment 2

[0034] The difference between the present embodiment 1 and embodiment 1 is that step (3) is different, specifically as follows:

[0035] (3) epoxy resin and curing agent are mixed according to the weight ratio of 2.5:1, and mixed glue is obtained, and described mixed glue is mixed with thickener according to the weight ratio of 6.5:1, and mixed paste is obtained, The mixed paste was filled into the bent gap, and then heated and cured at 130° C. for 3 hours to obtain a PMI foam bent pipe core material.

Embodiment 3

[0037] The difference between the present embodiment 1 and embodiment 1 is that step (3) is different, specifically as follows:

[0038] (3) Mix the epoxy resin and the curing agent according to the weight ratio of 3.5:1 to prepare the mixed glue, and mix the mixed glue with the hollow glass microspheres according to the weight ratio of 7.5:1 to make the mixed paste , the mixed paste was filled into the bent gap, and then heated and cured at 140° C. for 2 hours to obtain a PMI foam bent pipe core material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com