Stamping method and equipment for producing fiber-enhanced composite preforms

A technology of composite materials and stamping equipment, which is applied in the field of stamping and equipment for the production of fiber-reinforced composite material preforms, can solve the problems of reducing the production cost of composite material parts and the inability to apply fiber laying technology, and achieve a high degree of automation. Cost, product The effect of quality assurance and low error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

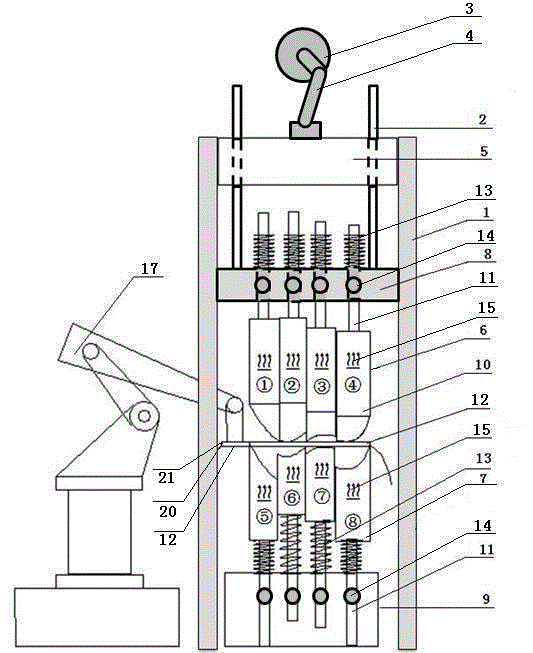

[0034] The application will be further explained below in conjunction with the accompanying drawings.

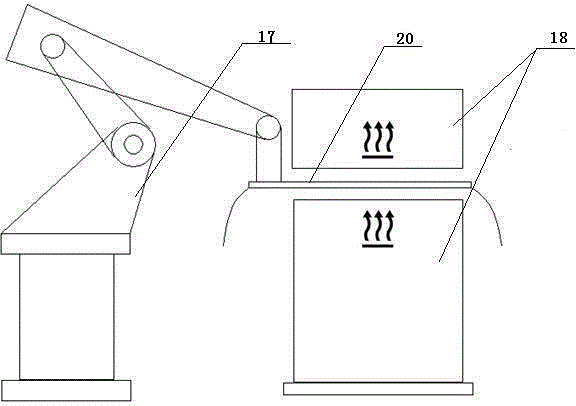

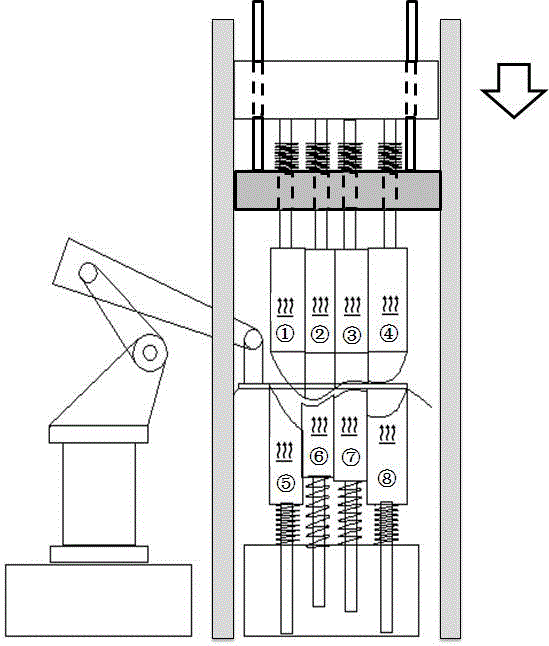

[0035] The stamping equipment used to produce fiber-reinforced composite material preforms provided by this application has a basic structure as follows: figure 2 As shown, it includes a support 1, a column 2 on the support, a motor 3, a crankshaft 4, a total stamping block 5, an upper module 6, a lower module 7, and an upper fixed slideway 8 and a lower fixed slideway 9. The upper fixed slideway 8 and the lower fixed slideway 9 are respectively connected with the upper module 6 and the lower module 7, wherein the upper fixed slideway 8 is fixed on the upper end of the support 1 and below the column 2, and the lower fixed slideway 9 is located at the bottom of the support 1, It can also be fixed on the ground, and the support frame 21 can be clamped by a mechanical arm clamp for easy transportation. During the stamping process, the support frame 21 is fixed on the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com