Patents

Literature

250results about How to "High scrap rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

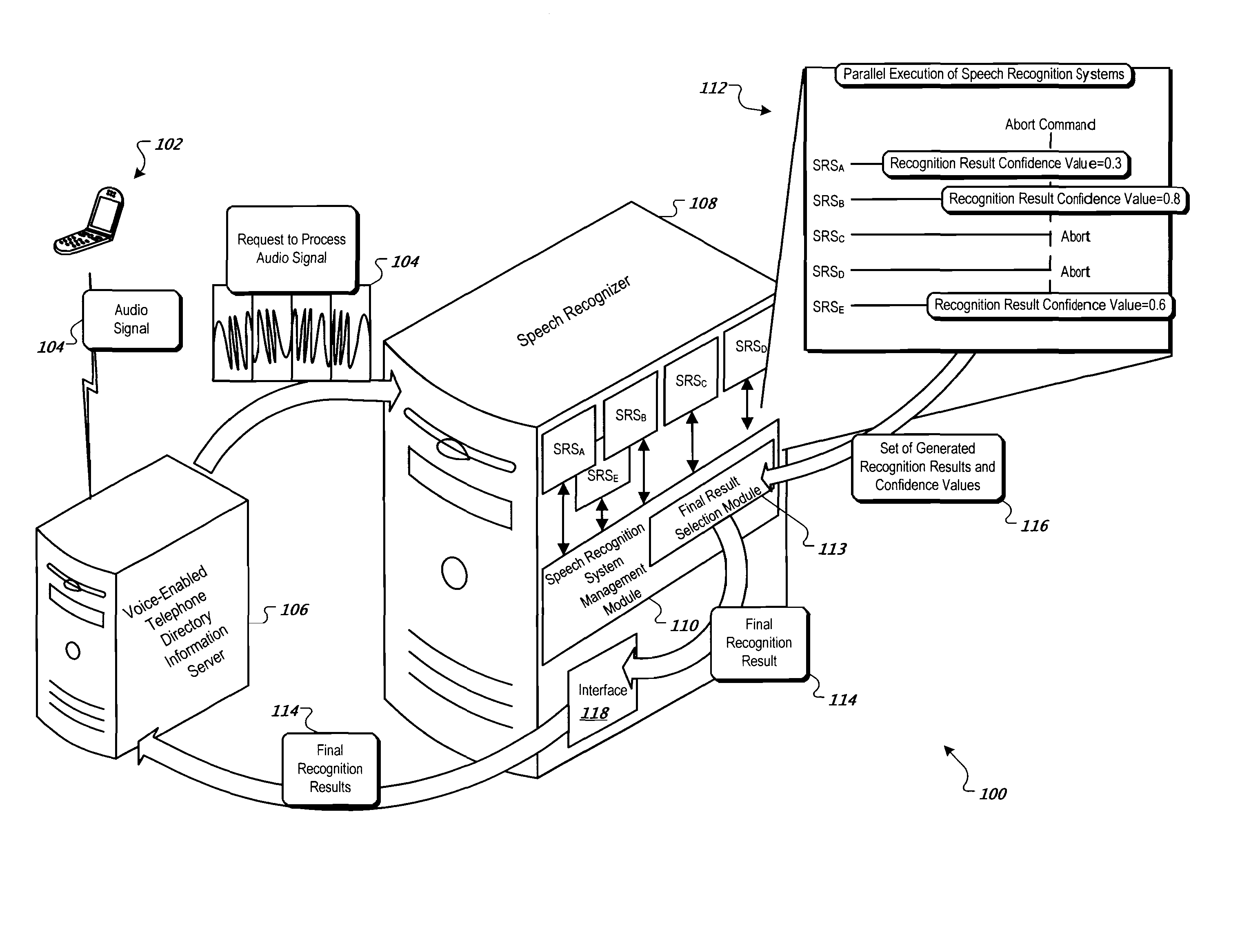

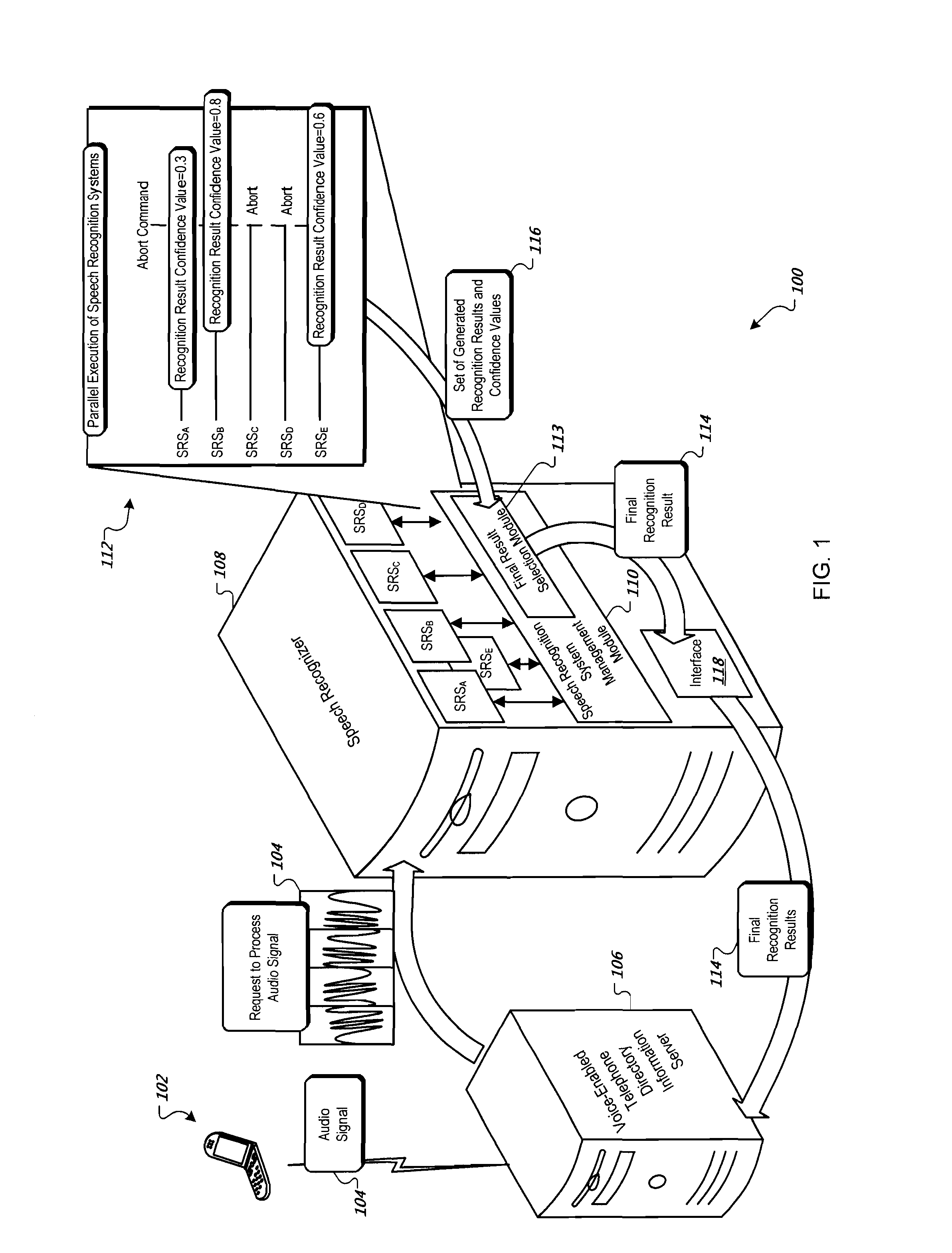

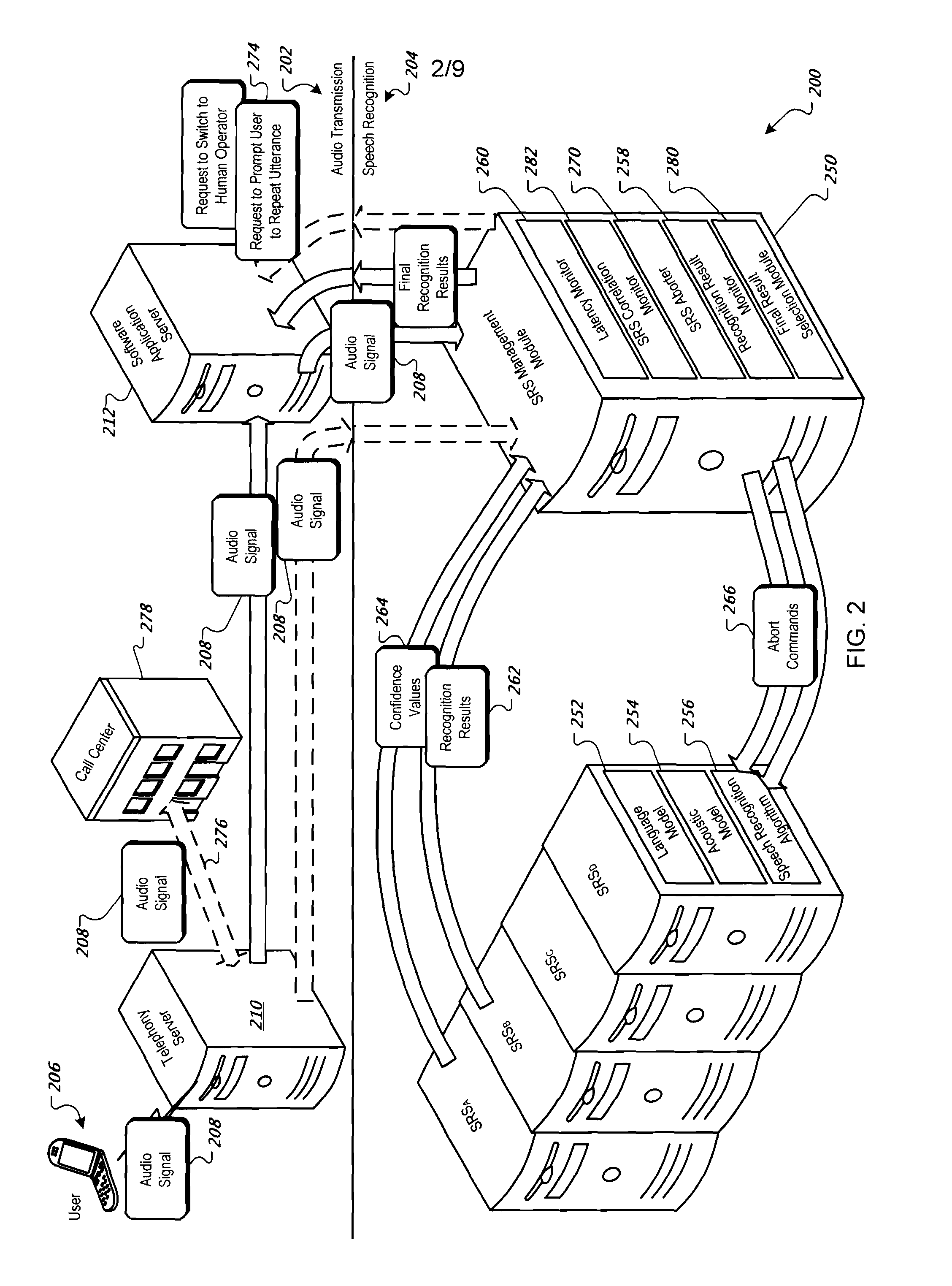

Speech Recognition with Parallel Recognition Tasks

ActiveUS20100004930A1High confidence in resultConfidence in resultSpeech recognitionConfidence thresholdSpeech identification

The subject matter of this specification can be embodied in, among other things, a method that includes receiving an audio signal and initiating speech recognition tasks by a plurality of speech recognition systems (SRS's). Each SRS is configured to generate a recognition result specifying possible speech included in the audio signal and a confidence value indicating a confidence in a correctness of the speech result. The method also includes completing a portion of the speech recognition tasks including generating one or more recognition results and one or more confidence values for the one or more recognition results, determining whether the one or more confidence values meets a confidence threshold, aborting a remaining portion of the speech recognition tasks for SRS's that have not completed generating a recognition result, and outputting a final recognition result based on at least one of the generated one or more speech results.

Owner:GOOGLE LLC

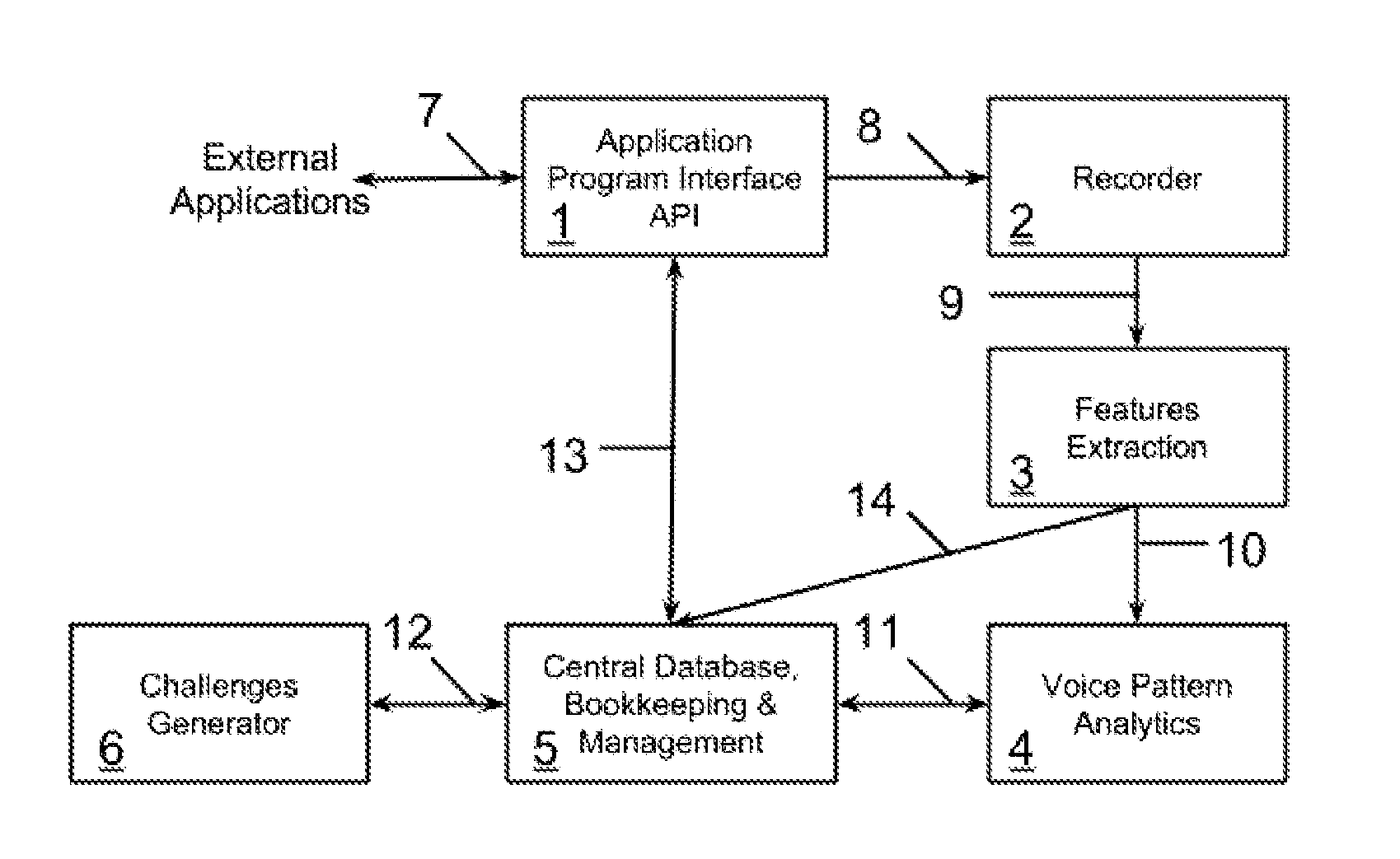

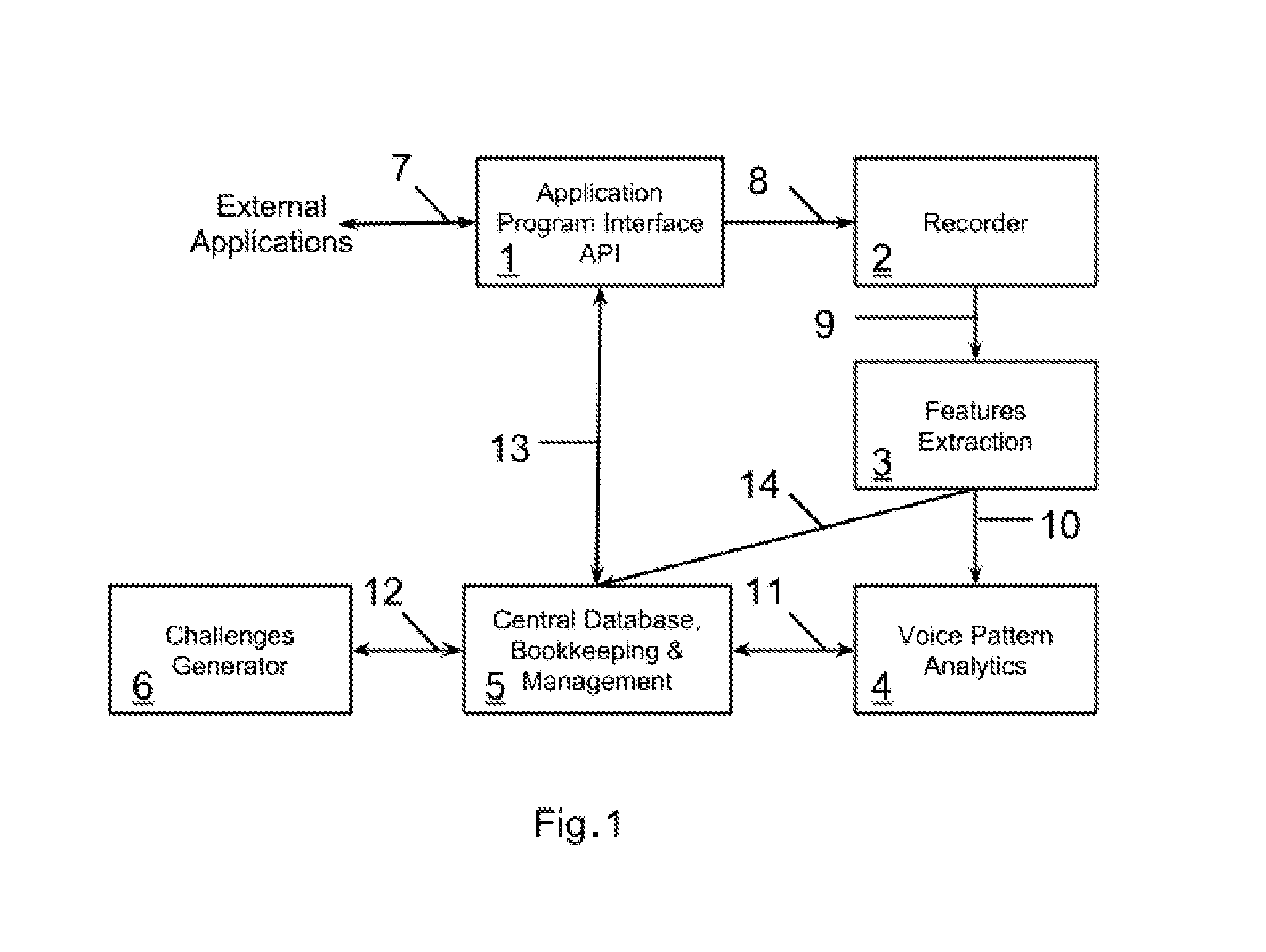

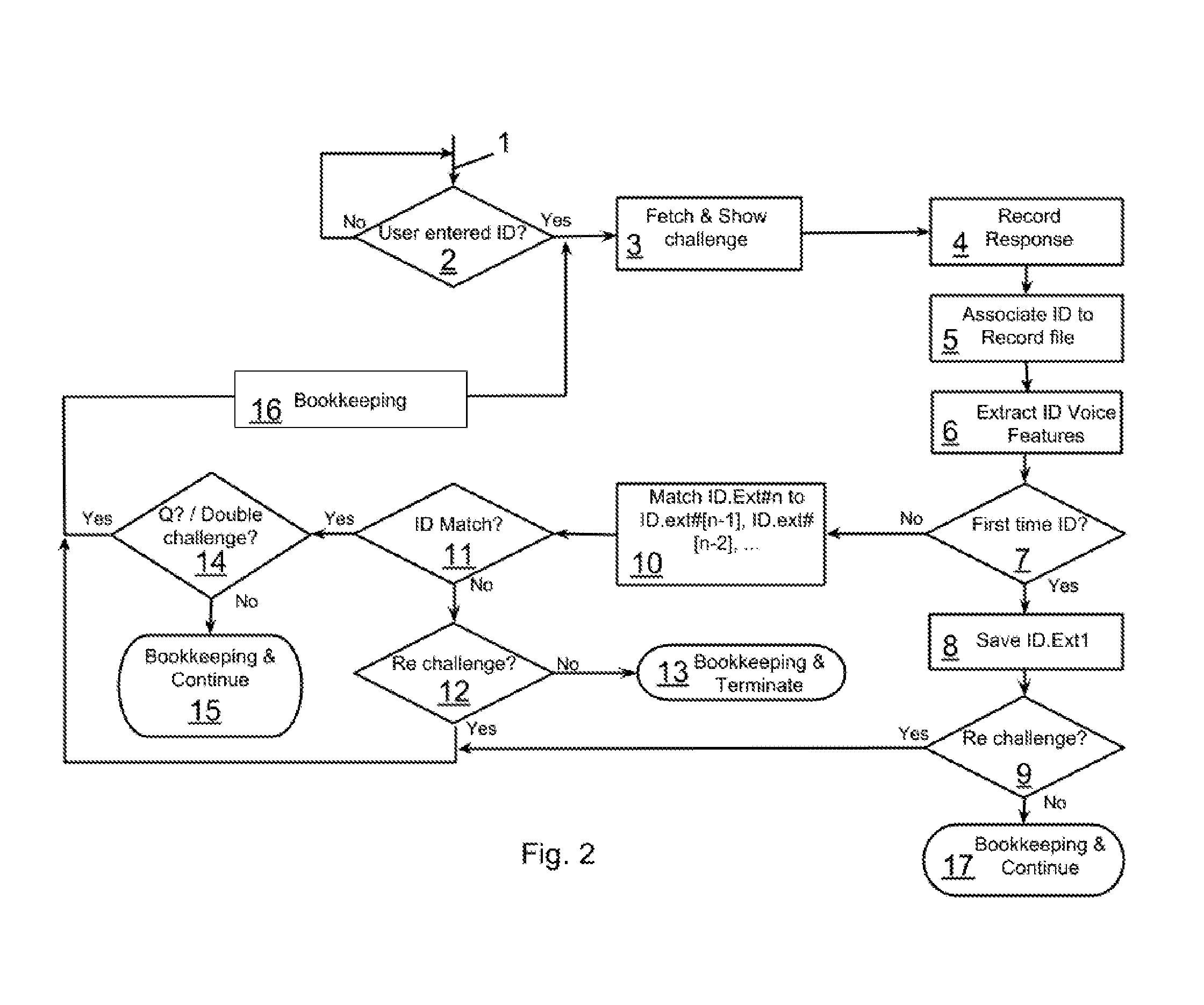

Automatic Learning Fraud Prevention (LFP) System

InactiveUS20140214676A1Read more difficultIncrease probabilityFinanceSpeech analysisE-commerceFigure of merit

A computerized learning fraud prevention system and method for generating a voice signature of a user, such as one engaged in electronic commerce, to prevent fraudulent activities by machines and persons imitating the user. Steps comprise: fetching a signal of a user's signature stored in memory; generating at least one challenge sequence based on the signal to create a second signature; presenting the generated challenge sequence to the user; collecting the user's challenge voice response to the generated challenge sequence; computing a quality factor between the user's challenge response and the generated challenge sequence; computing a transaction quality factor and content quality factor and reporting an impostor or re-challenging if the quality factor is below a threshold. Lastly, generating new signature based on any portion of user's challenge voice response and / or any portion of the previously generated signature and / or any portion of collectable information from user's device memory.

Owner:BUKAI DROR

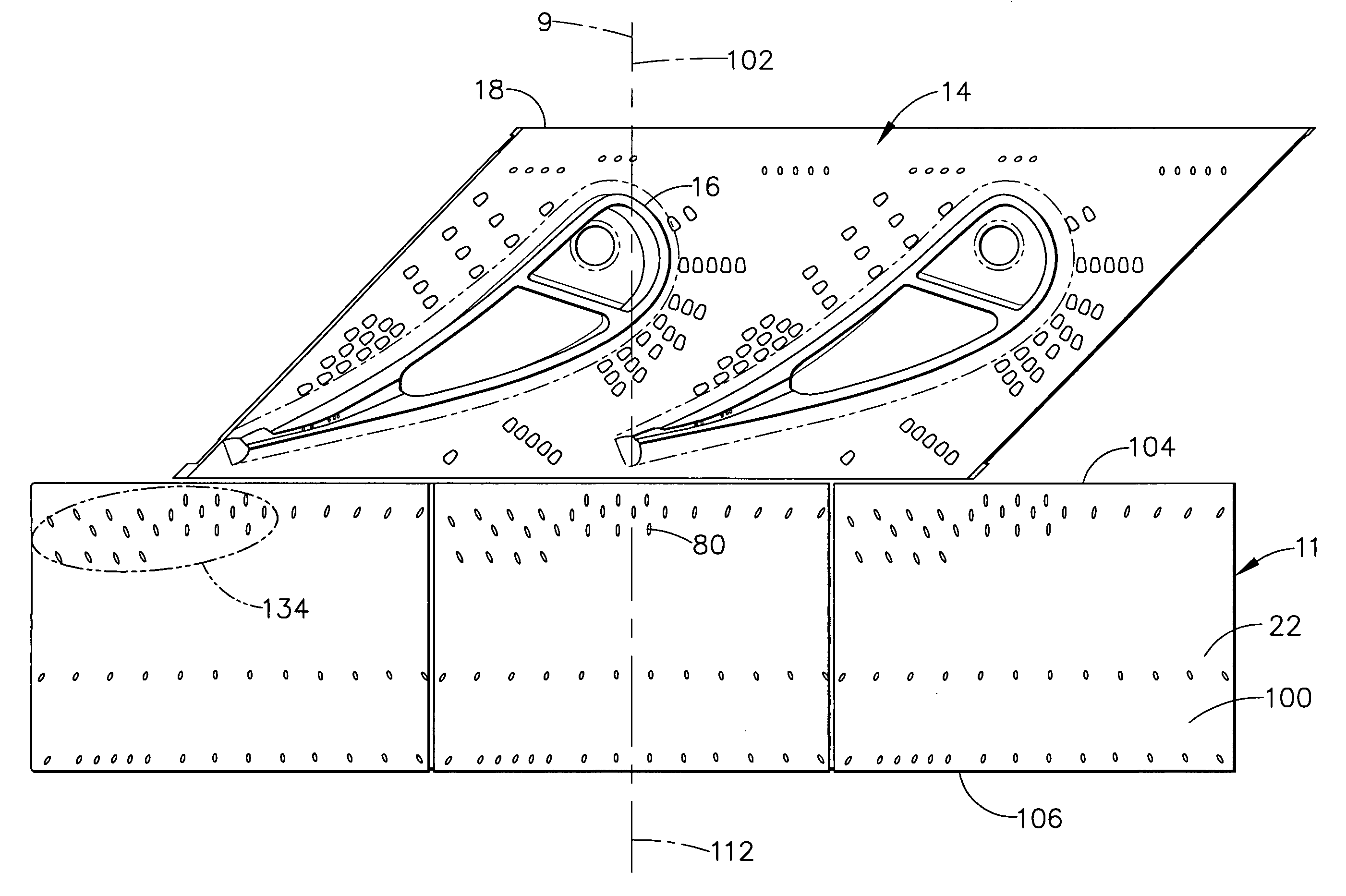

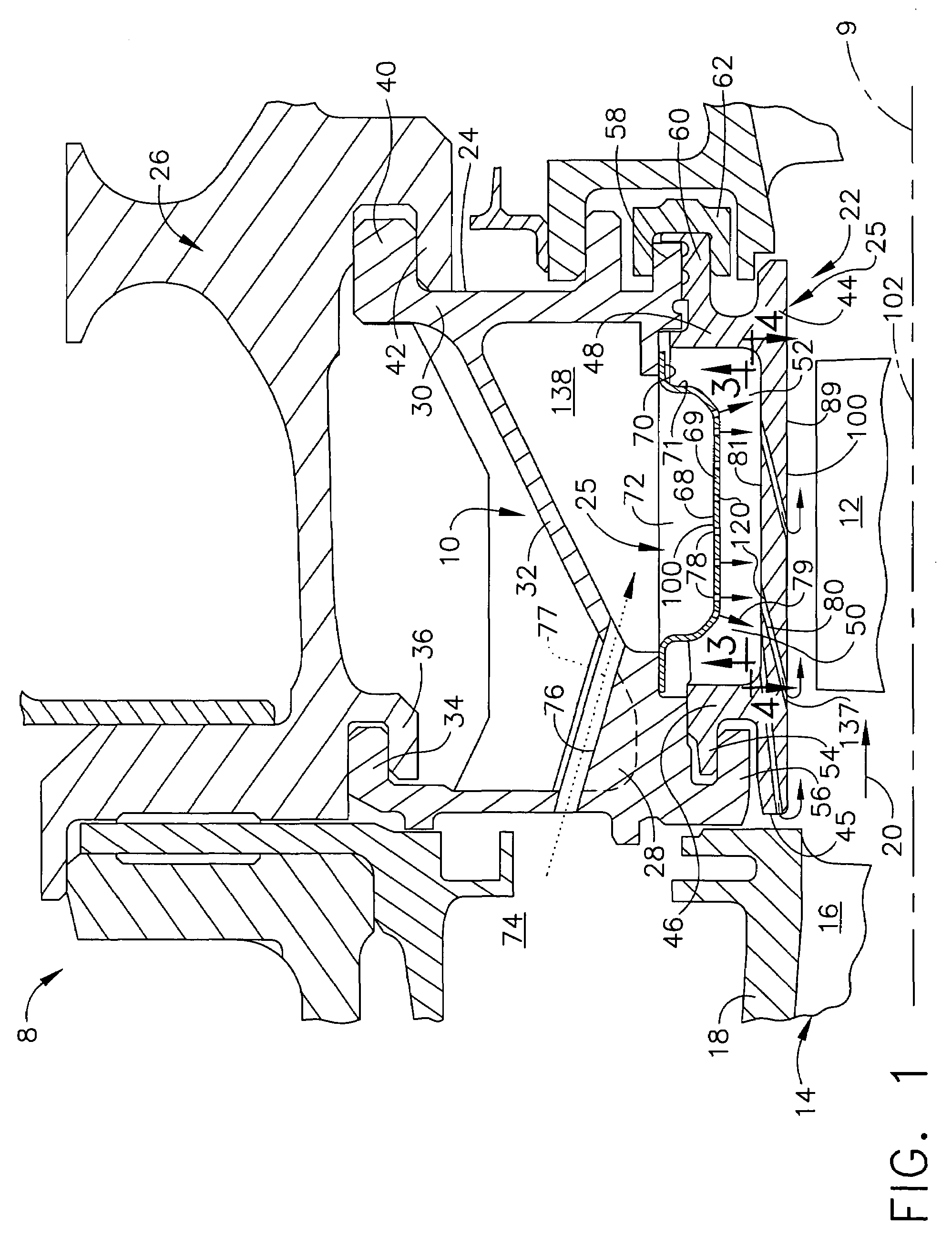

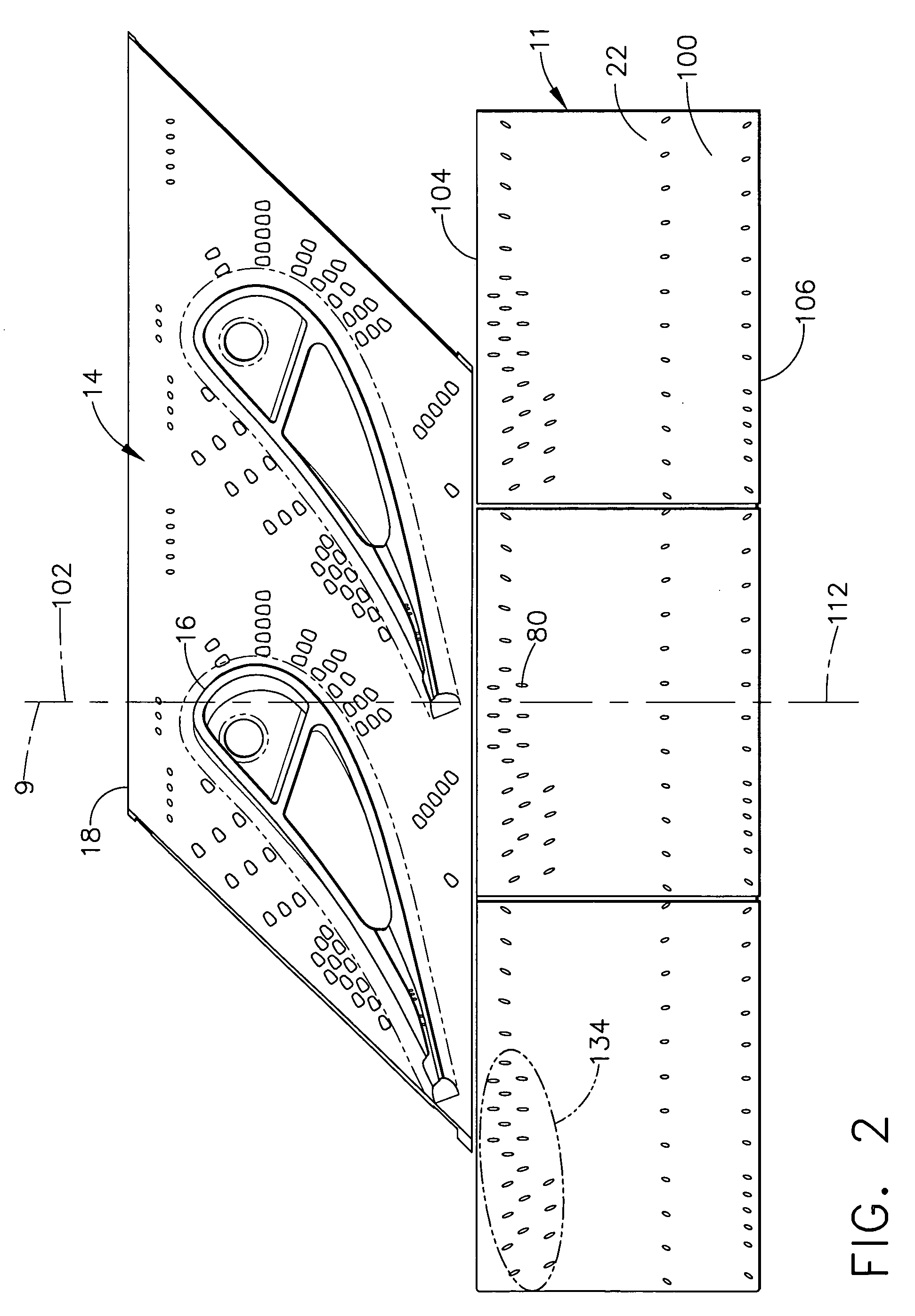

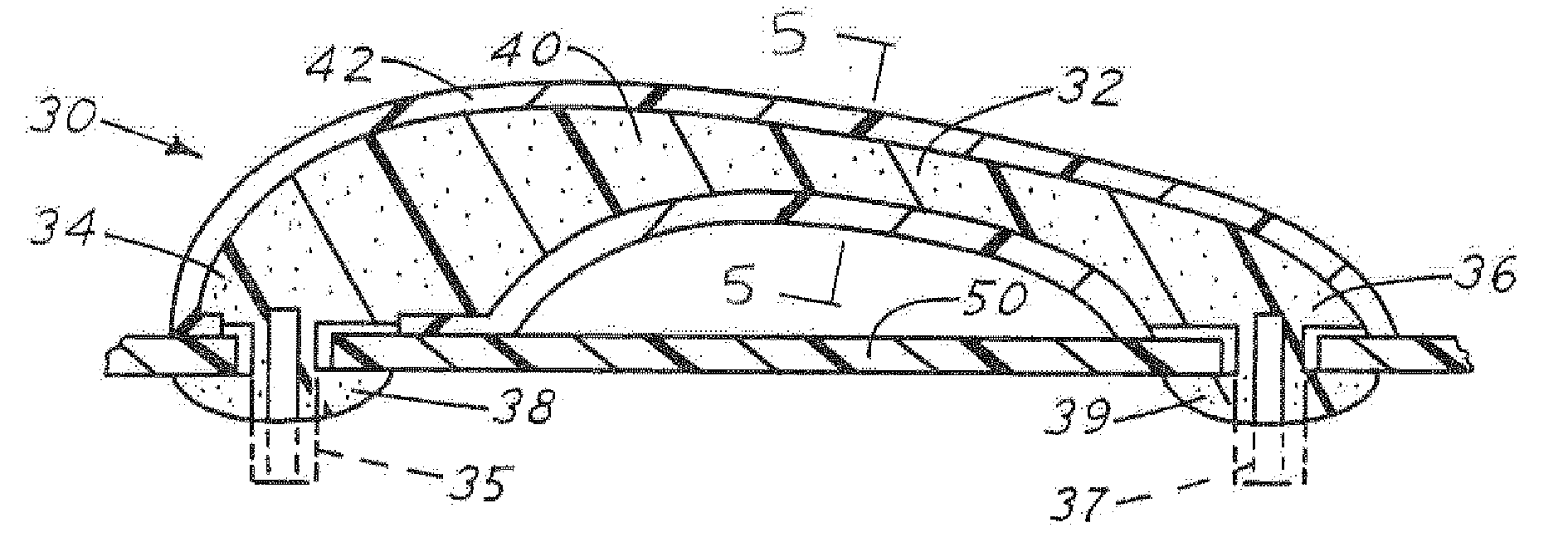

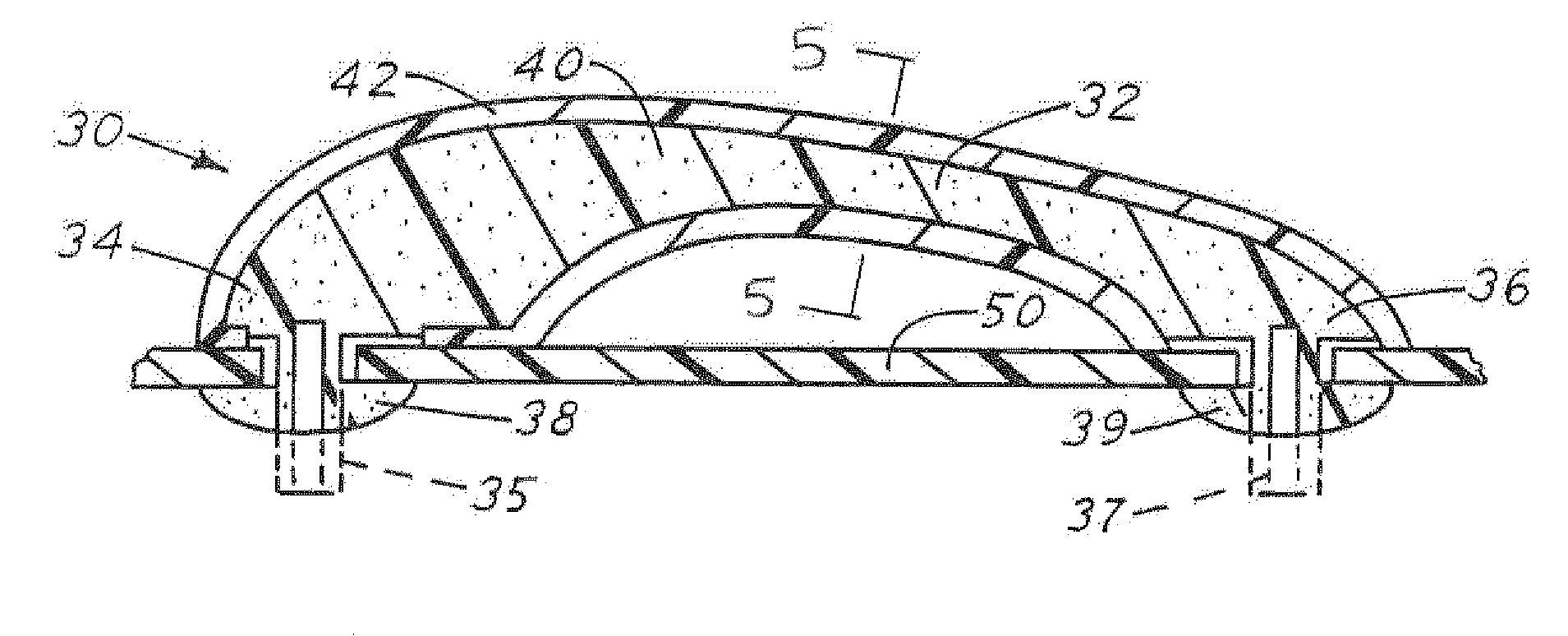

Turbine shroud asymmetrical cooling elements

ActiveUS7147432B2Degree of reductionReduce gradientPump componentsEngine fuctionsHigh densityEngineering

A turbine shroud assembly asymmetrical cooling element such as a shroud segment or a baffle includes an arcuate panel. The panel has a plurality of cooling apertures extending through the panel and an axially extending midline of the panel parallel to an axis of rotation of the arcuate panel. A symmetric portion of the cooling apertures have a symmetrical density of aperture inlets that is symmetric with respect to the axially extending midline. An asymmetric portion of the cooling apertures have an asymmetrical density of aperture inlets that is asymmetric with respect to the axially extending midline. One exemplary cooling element includes a high density area of the cooling apertures in the asymmetric portion having a higher density of aperture inlets than in the symmetric portion. A low density area of the cooling apertures in the asymmetric portion has a lower density of aperture inlets than in the symmetric portion of the cooling apertures.

Owner:GENERAL ELECTRIC CO

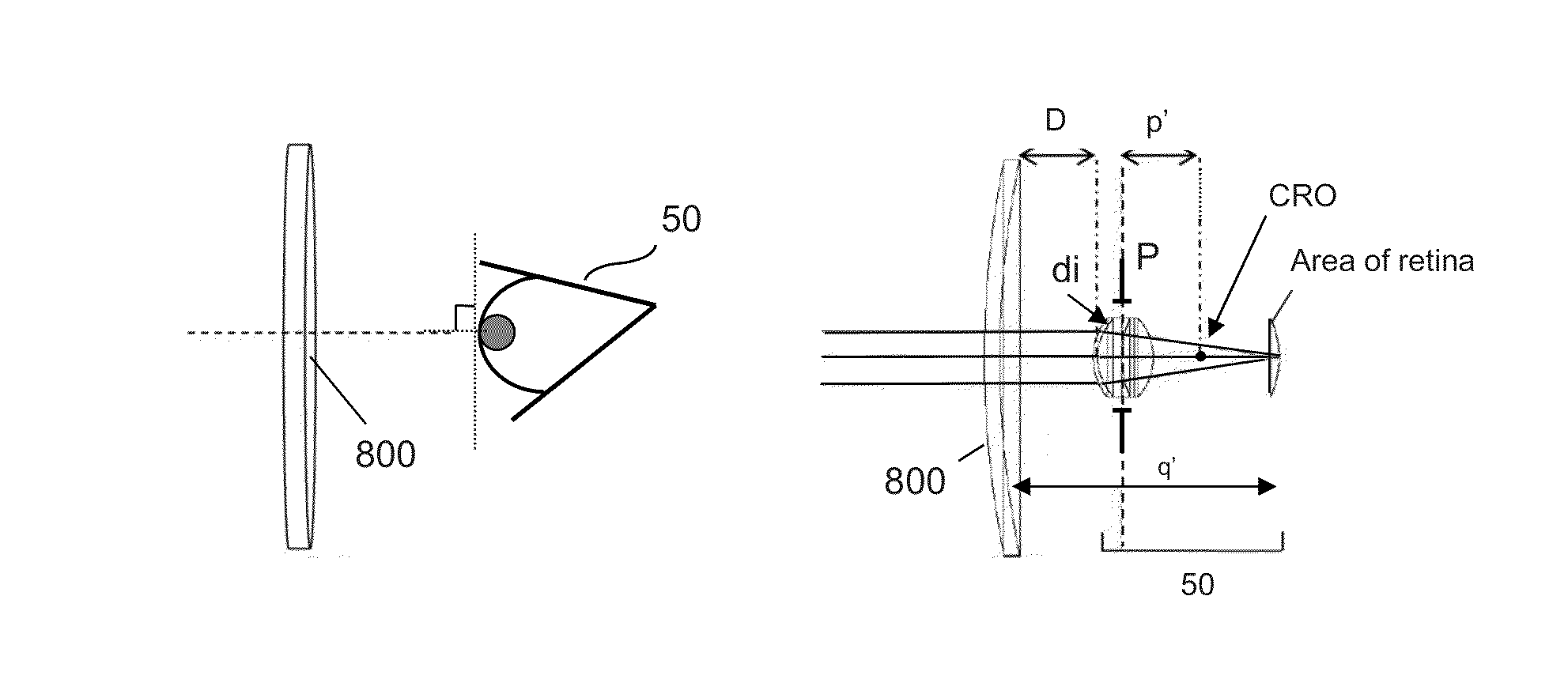

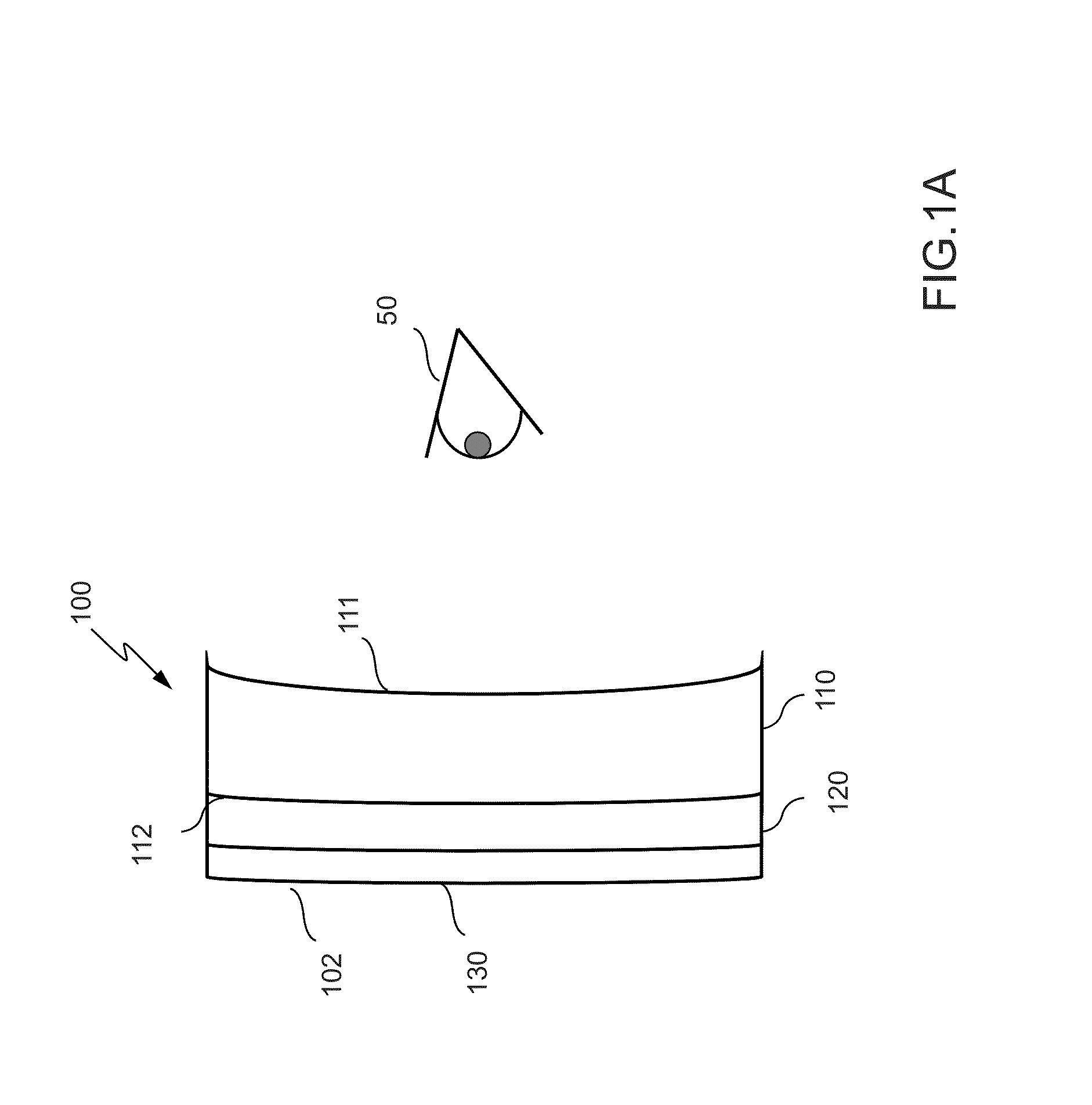

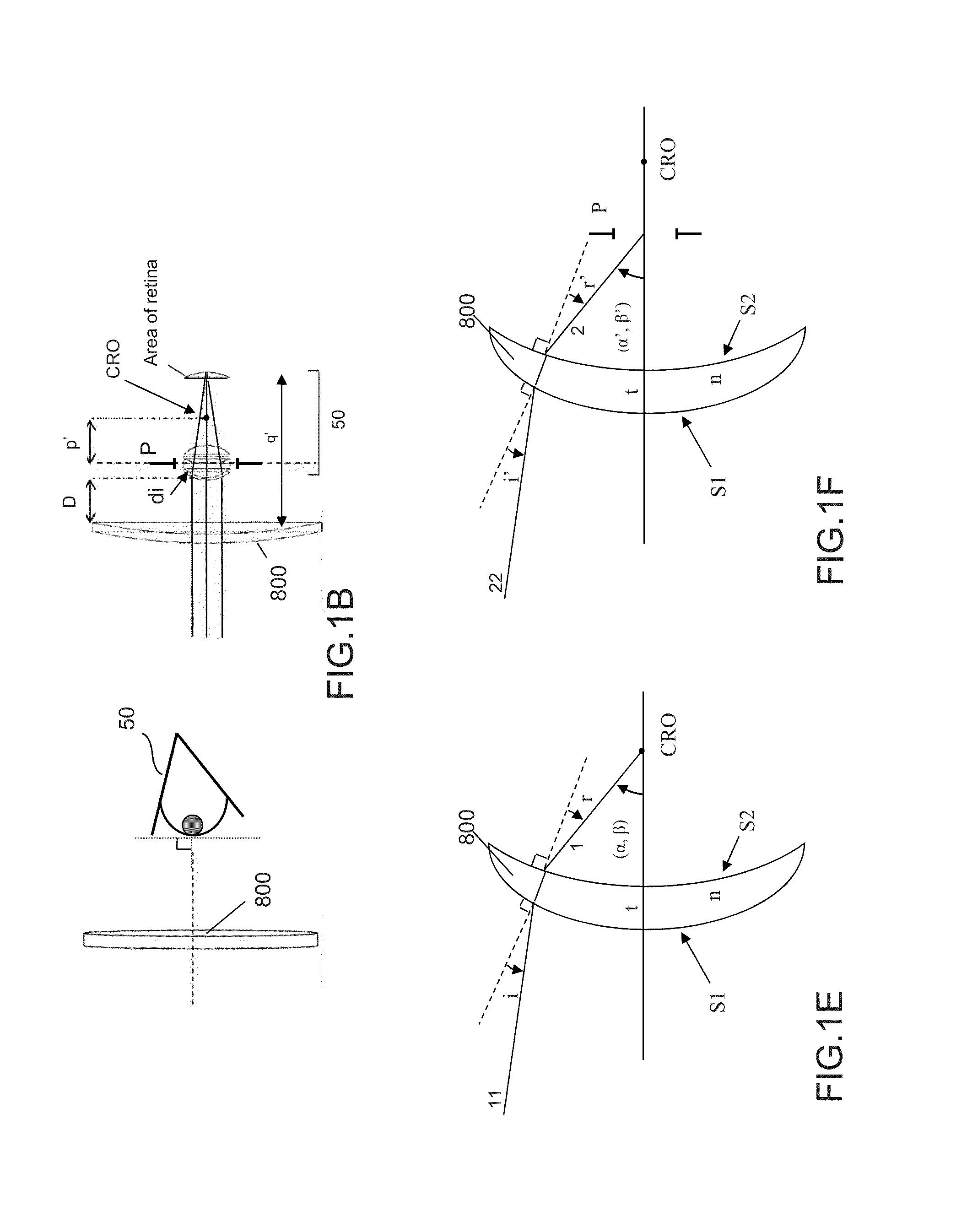

Method of determining the configuration of an ophthalmic filter

ActiveUS20140320806A1High selectivityControl distortionSpectales/gogglesEye diagnosticsAngle of incidenceTransmittance

Method of determining configuration of interferential filtering elements for an optical device having an optical substrate for a user, includes:providing a first set of parameters representative of at least one main line of sight of the user;determining a first selected range of angles of incidence based on the first parameters;providing a second set of parameters characterizing, for the user, a range of wavelengths to be at least partially inhibited;determining a first selected range of wavelengths of incident light to be at least partially inhibited, based on the second parameters; andconfiguring a first selective interferential filtering element and a first zone of a surface of the optical substrate based on the first selected range of angles of incidence and wavelengths such that the first selective interferential filtering elements inhibit, at a first rate of rejection, transmission of the first selected range of wavelengths of incident light.

Owner:ESSILOR INT CIE GEN DOPTIQUE +1

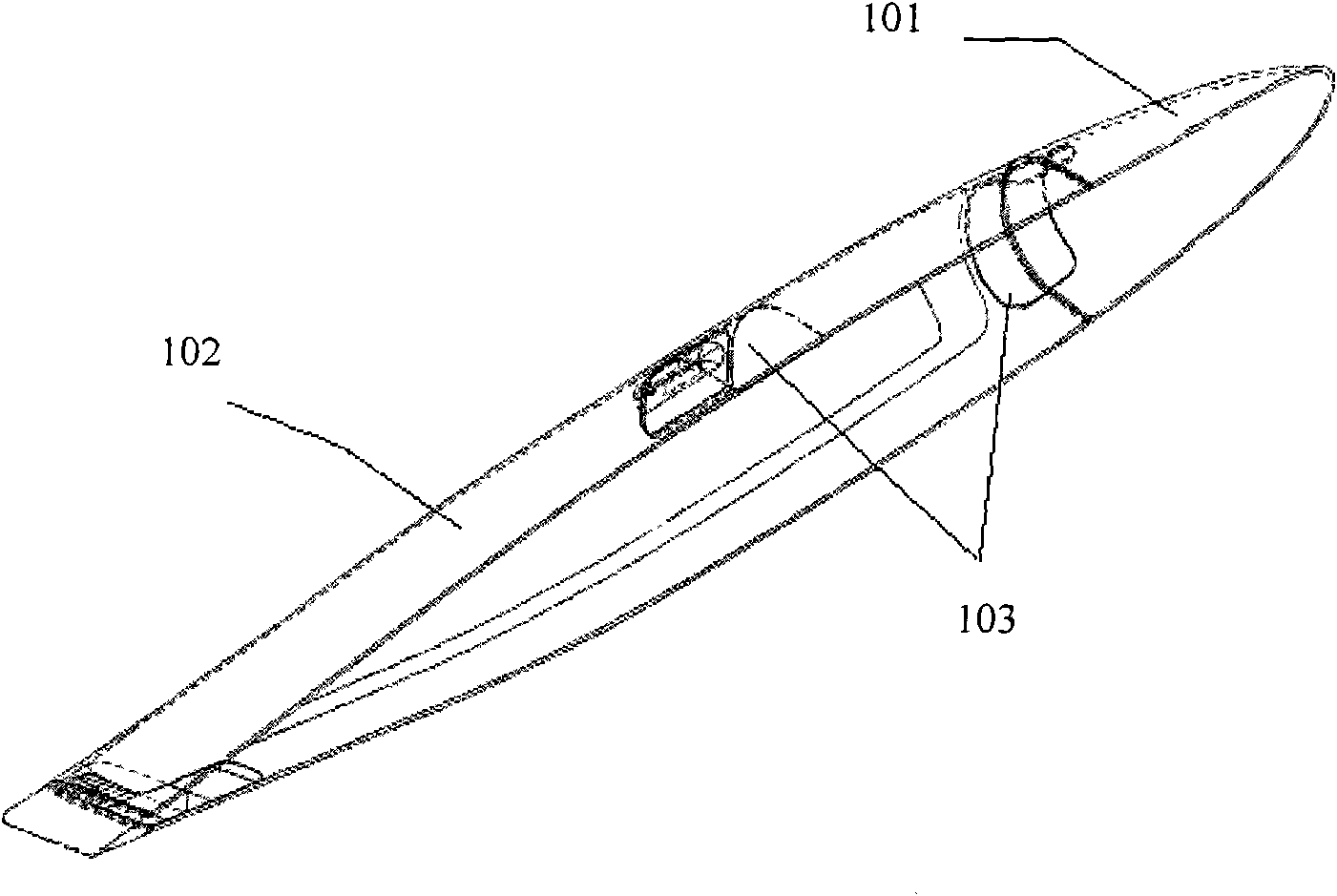

Wingtip cover mirror face part drawing processing method

The invention discloses a wingtip cover mirror face part drawing processing method, which comprises the following steps: according to a size, which is obtained after the contour line of the opening of a female die is deflected outwards at a preset value, of the drawing die, making blank materials in irregular elliptic shapes by using a mechanically polished skin material; uniformly applying lubricating oil on the round corner parts of the female die as well as the inside and outside surfaces of an upper molding cavity in a pressing face of the drawing die consisting of the female die and a male die, and the surfaces, which are contacted with the round corner parts and the inside and outside surfaces, of the blank materials; placing the blank materials in a drawing die with the fiber direction of the blank materials consistent with the length direction of the blank materials; covering a layer of rubber skin between the female die and the blank materials; drawing under a drawing pressure of 3 to 5Mpa and an edge pressure of 3 to 5Mpa; keeping for 5 to 10 seconds after drawing; and relieving pressure, and taking part out. The surface of the mirror face part thus obtained does not have slip lines and coarse grains and is smooth without scraps, so the mirror face part meets the quality requirements for mirror parts and defect products are avoided basically.

Owner:COMAC +1

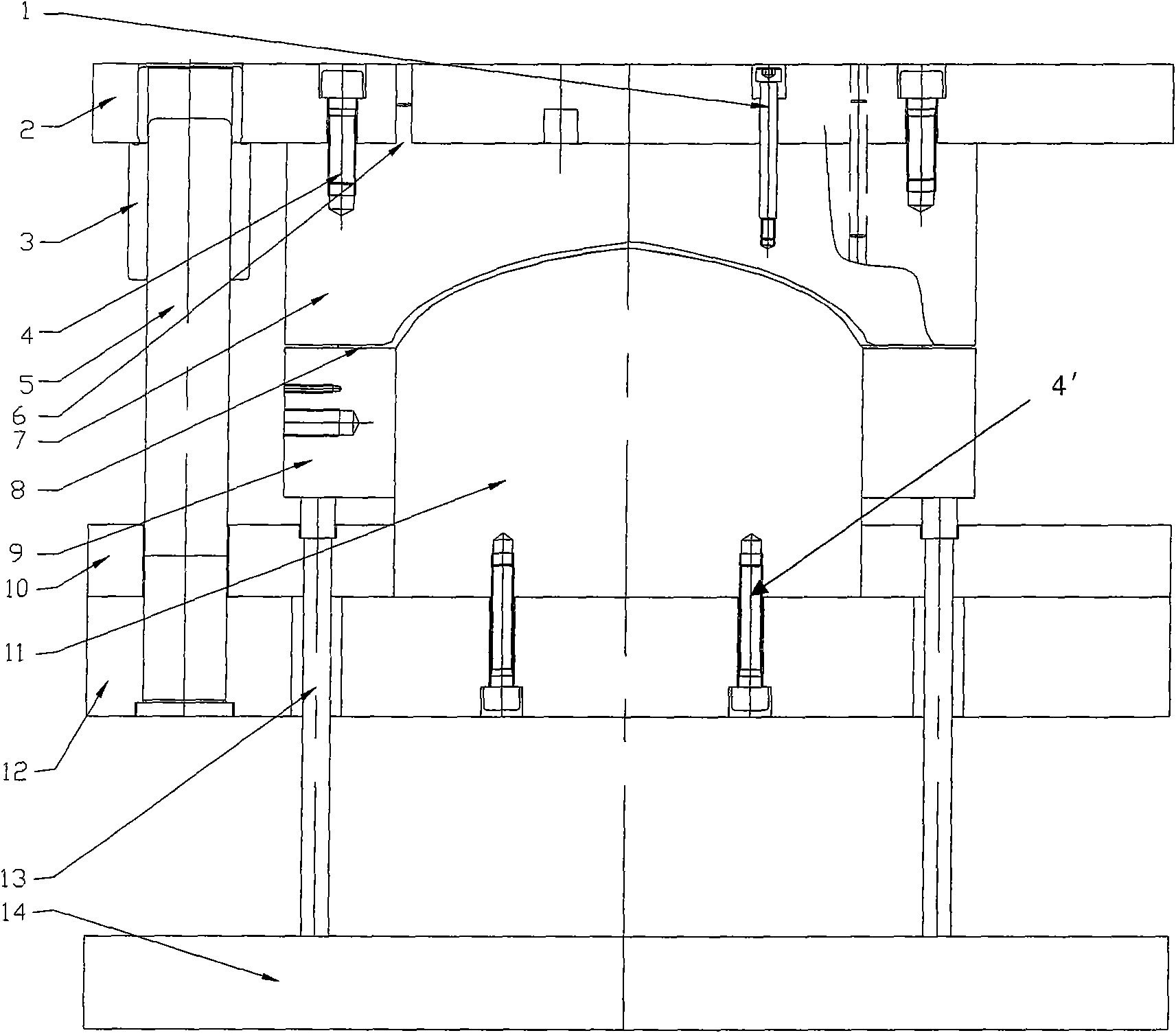

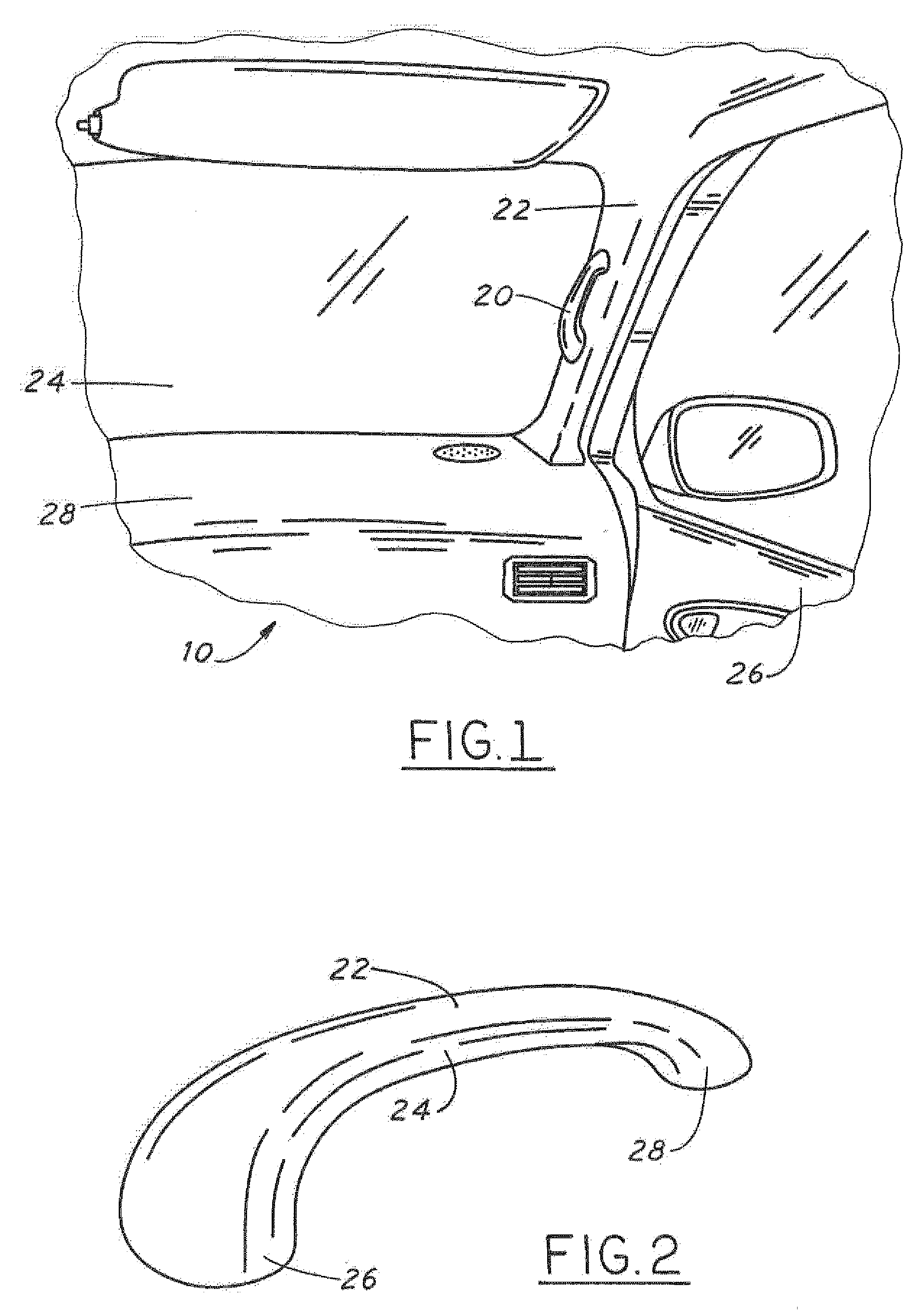

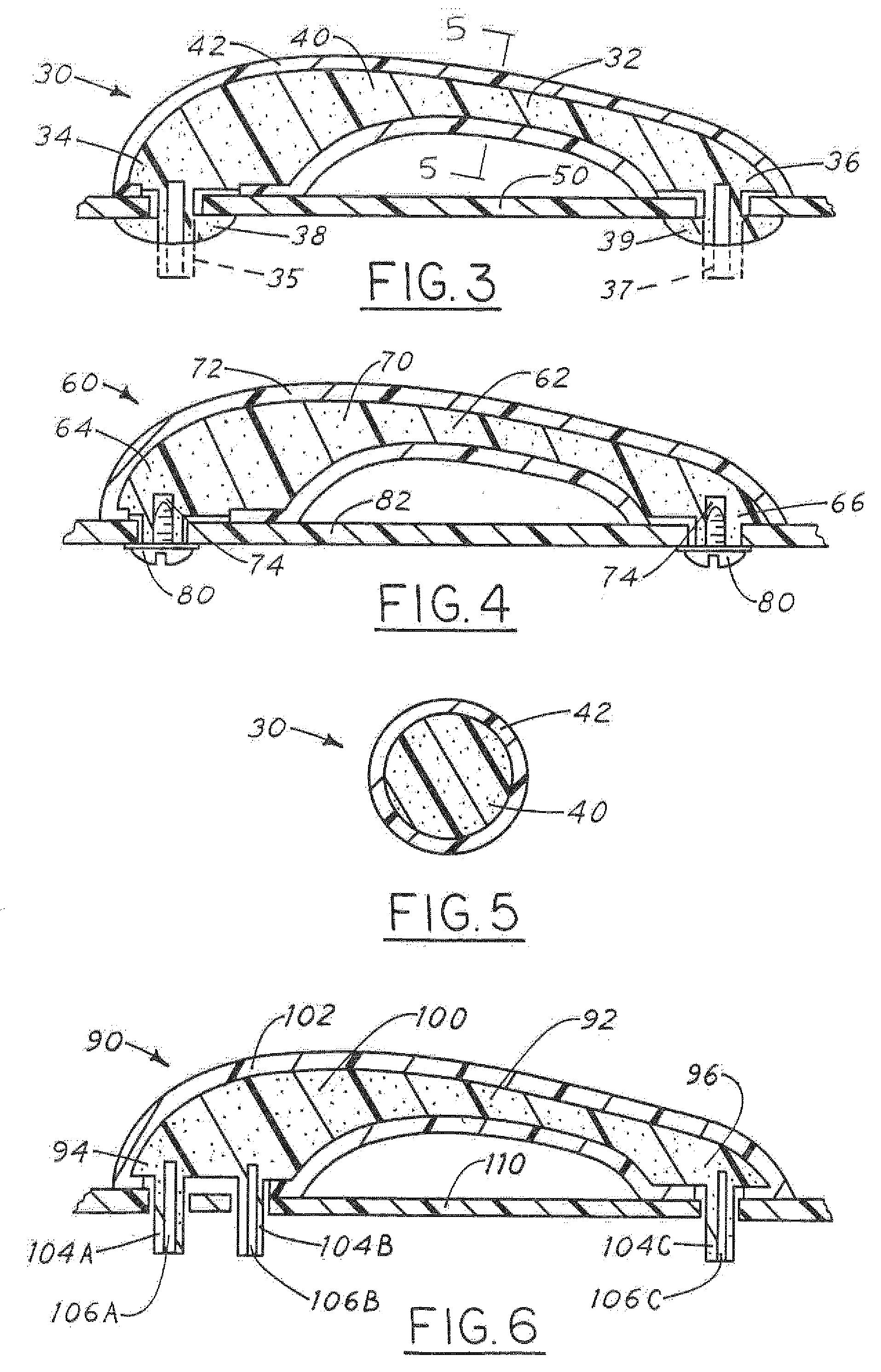

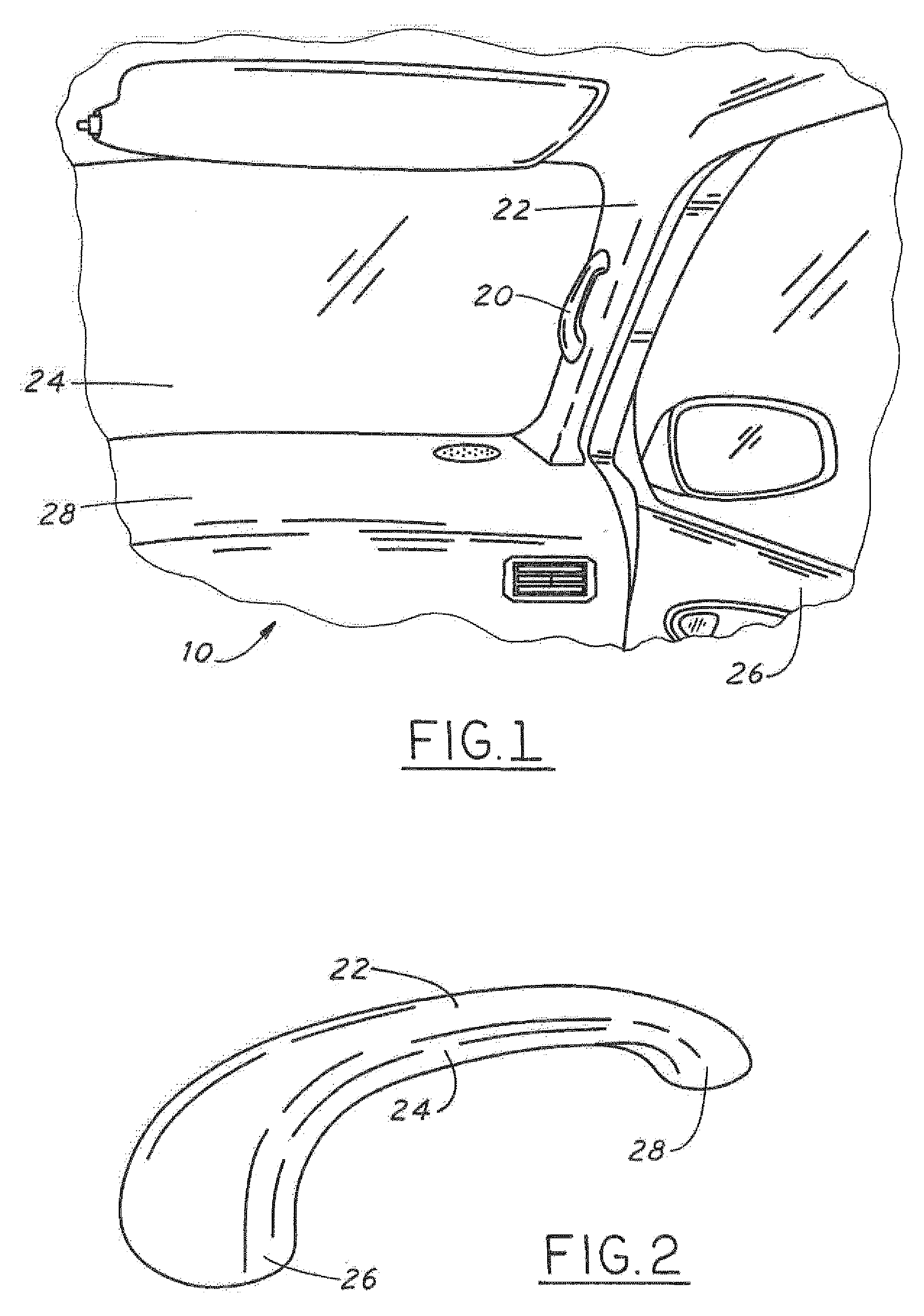

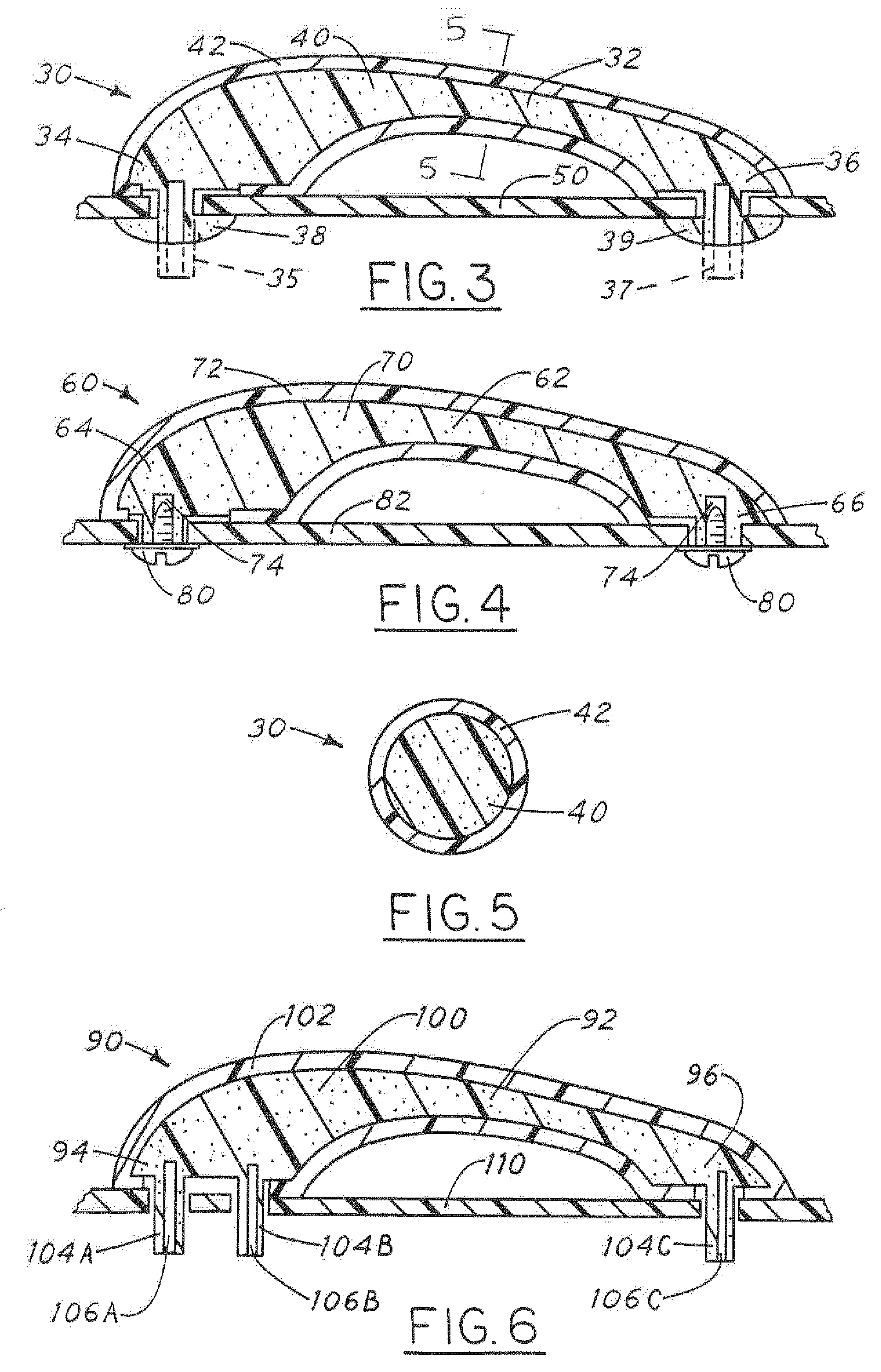

Foamed core process for large cross-sections of grab handles

InactiveUS20050079336A1Speed up the processHigh scrap rateButtonsVehicle arrangementsEngineeringStructural element

A plastic product for particular use as grab handles, door closure handles, and other trim and component products. A foam core, either structural or non-structural, is over-molded with a hard or soft plastic shell or skin. Structural members for heat staking, mechanical fastenings, and the like, are integrally formed on the ends of the handles in order to affix the handles to a door pillar, door panel, or the like.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

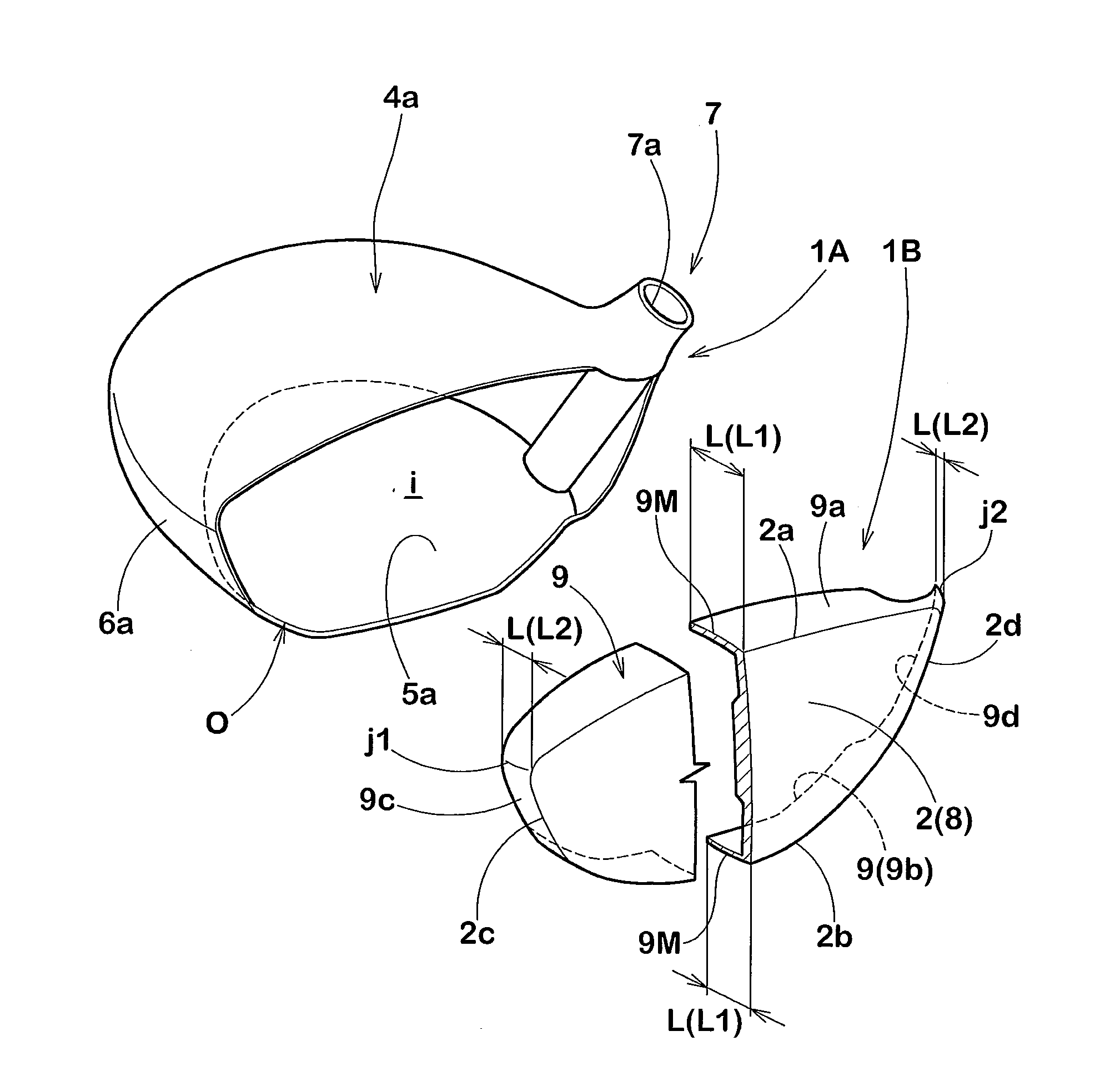

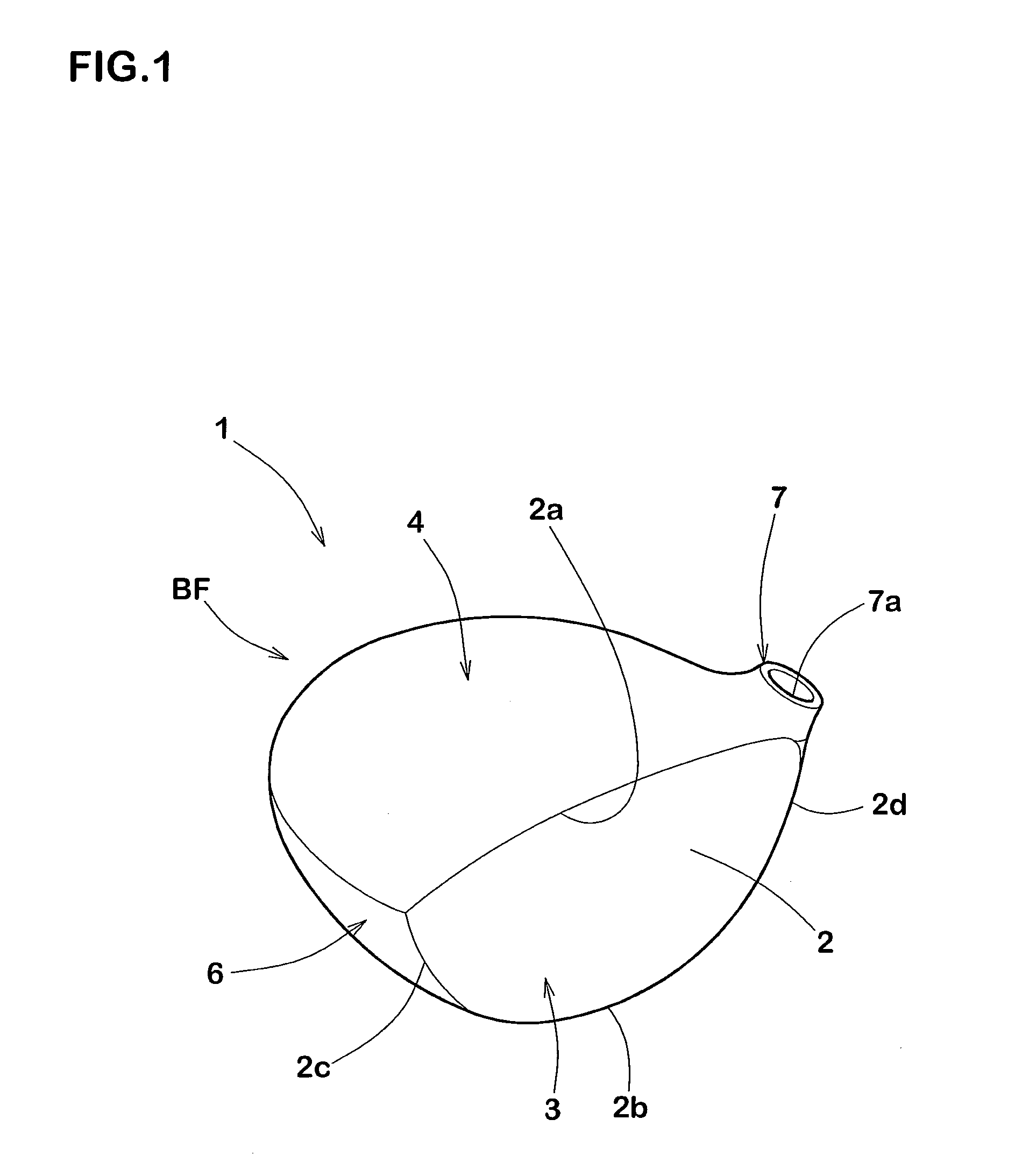

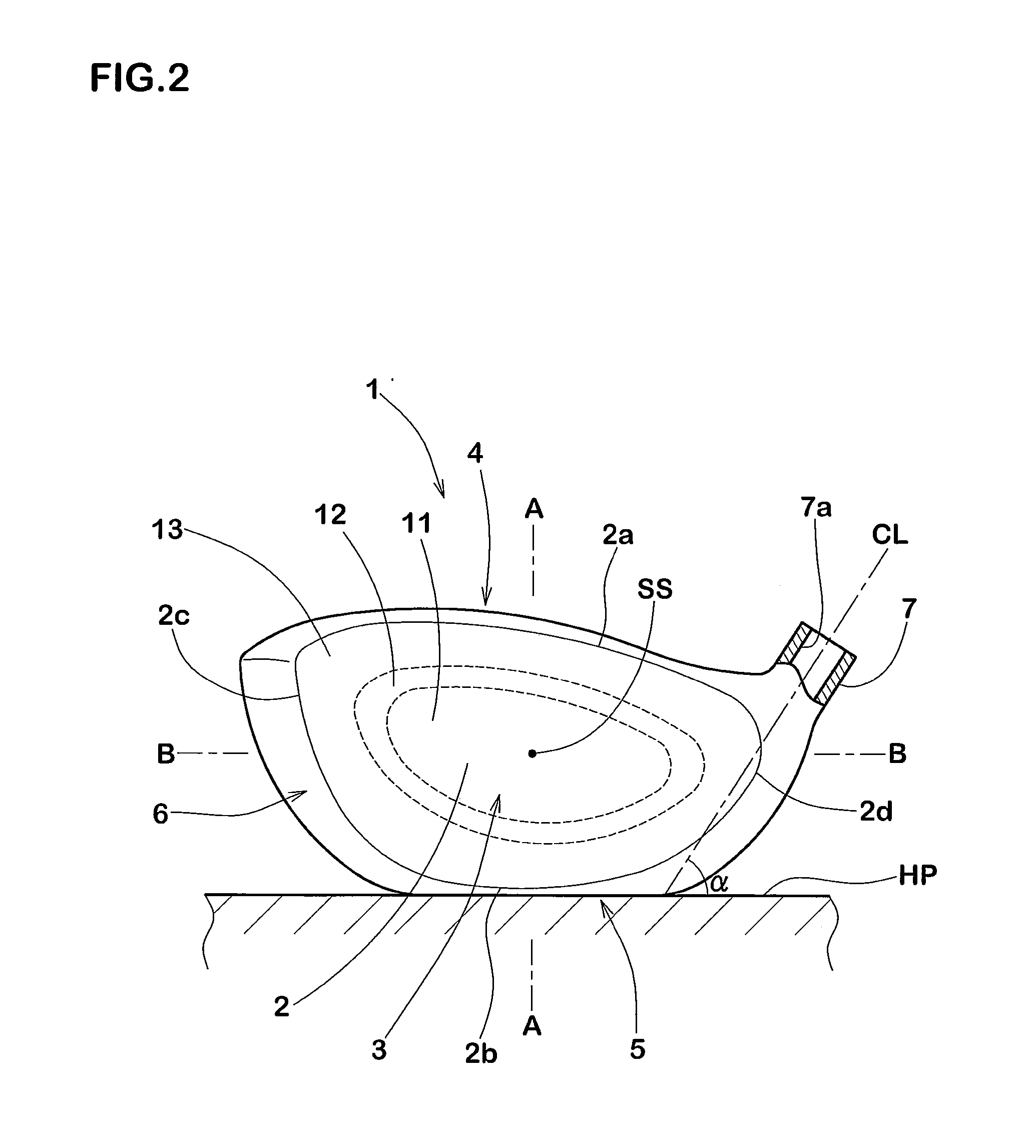

Method for manufacturing golf club head

ActiveUS20100154196A1High strengthSolve the lack of durabilityMetal rolling stand detailsMetal working apparatusEngineeringGolf Ball

Owner:SUMITOMO RUBBER IND LTD

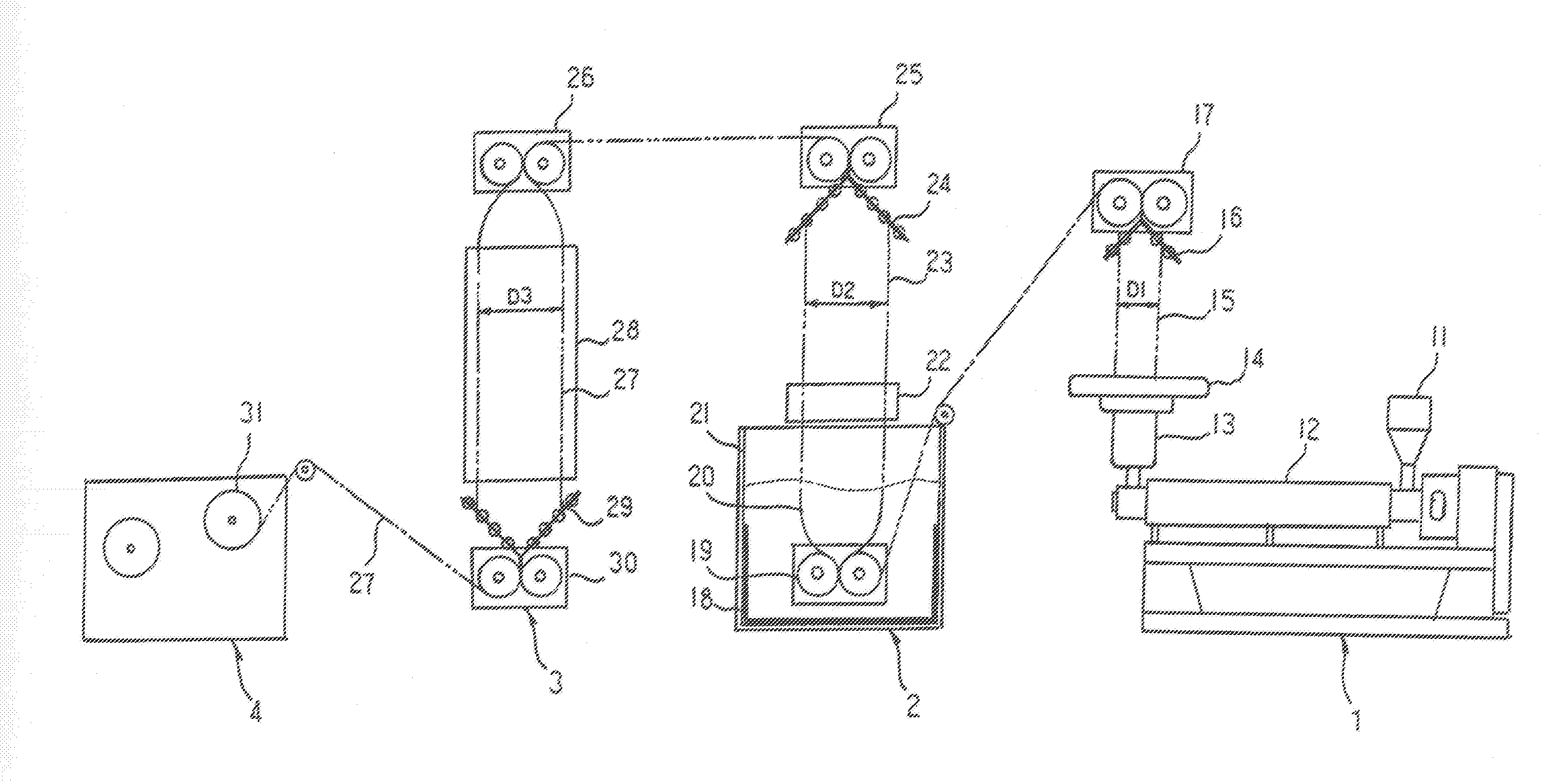

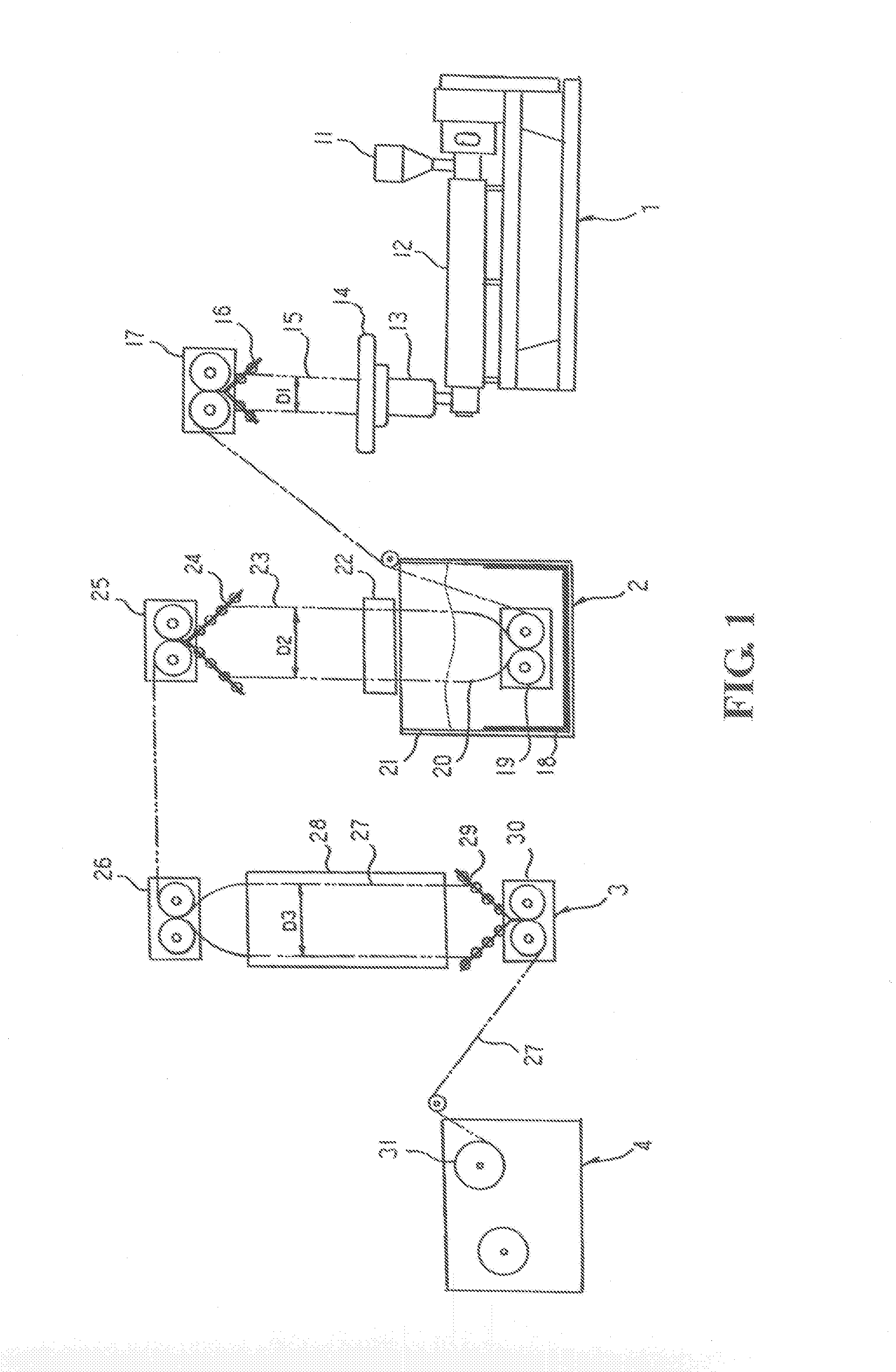

Method and apparatus for producing polystyrene tubular shrink film via film blow molding

InactiveUS20080143024A1Complicate and big machineIncrease investment costFilament/thread formingCoatingsBlow moldingPlastic materials

In a method and apparatus for producing polystyrene tubular shrink film via film blow molding, a polystyrene plastic material is extruded into a circular tubular film, which is cooled and then uniformly heated in a special hot water tank to become softened. Hot air is then blown into the softened tubular film, and two sequentially arranged speed-controlled pressure guide roller sets are set to two different operating speeds, so that the softened tubular film is transversely and longitudinally stretched and thinned to form a stretched tubular film, which is then passed through a setting treatment system to form a thermally set tubular film and be finally wound in a take-up system into a roll for storage. The method and apparatus is simple, low cost, and easy to operate, and the product thereof is environment friendly to help in economic development.

Owner:YUNG CHIH PLASTIC PROCESSING

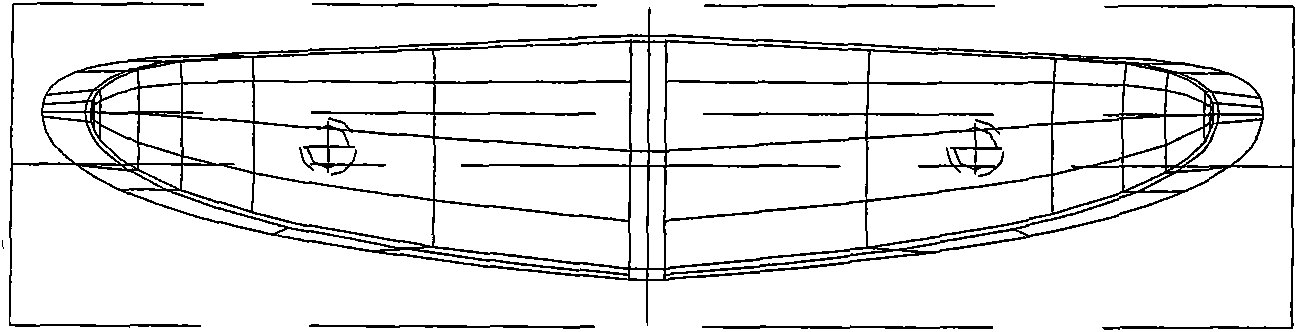

Laser additive manufacturing forming method of titanium alloy thin-walled component

InactiveCN106513675AHigh scrap rateCasting quality is not easy to controlAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufactured form

The invention relates to a laser additive manufacturing forming method of a titanium alloy thin-walled component, in particular to a preparing method of a multi-branch thin-walled titanium alloy structure and belongs to the technical field of titanium alloy structural machining and molding. The preparing method is the structural preparing method based on a selective laser melting forming and laser cladding technology. According to the thin wall, the titanium alloy structure with the thickness of the titanium alloy not larger than 5mm and particularly the wall thickness ranging from 2 mm to 4 mm is formed. The titanium alloy complex thin-walled component obtained through the method has the 4mm wall thickness, and the 0.1mm / 100mm size precision, and the manufacturing period is shortened by 50%.

Owner:BEIJING SATELLITE MFG FACTORY

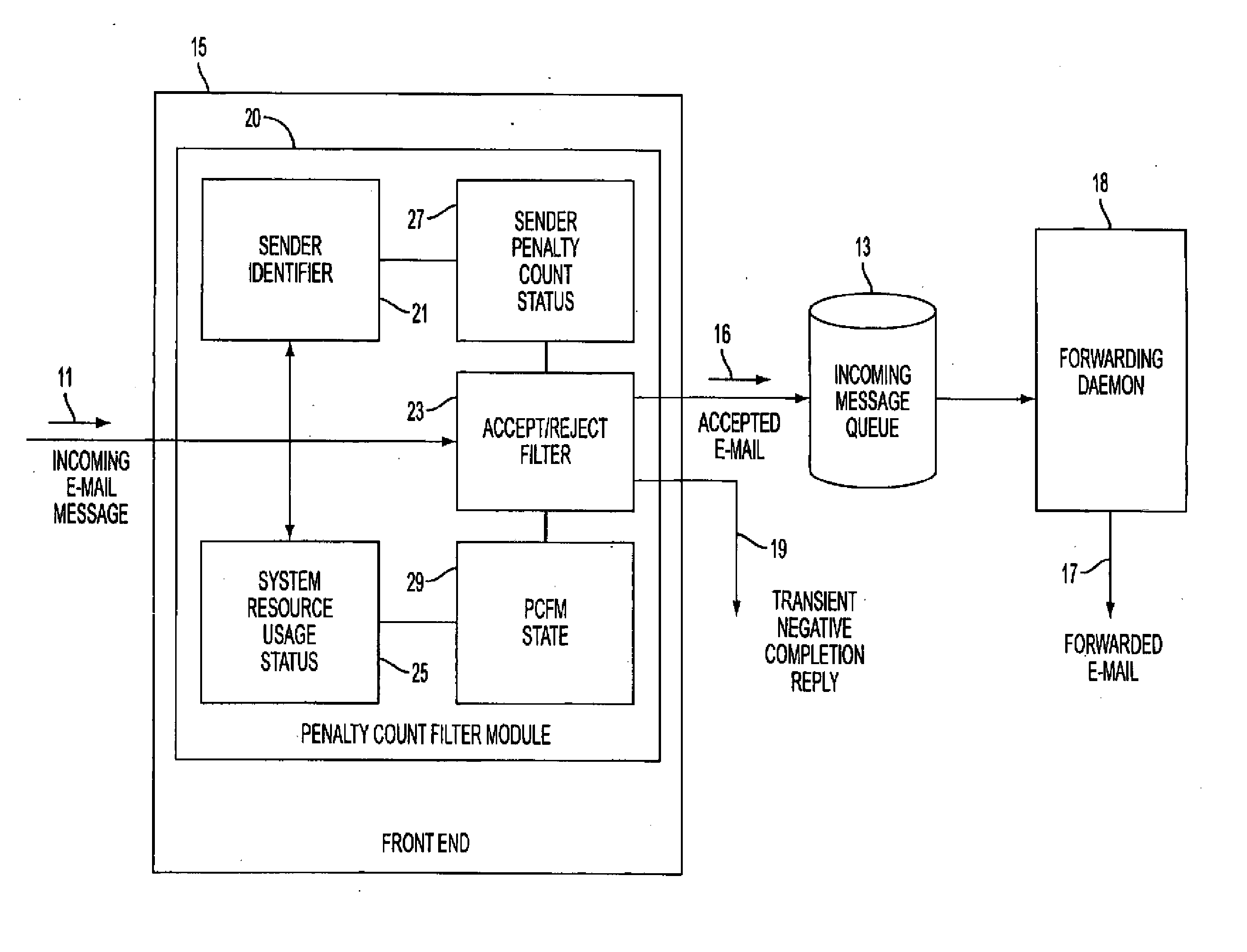

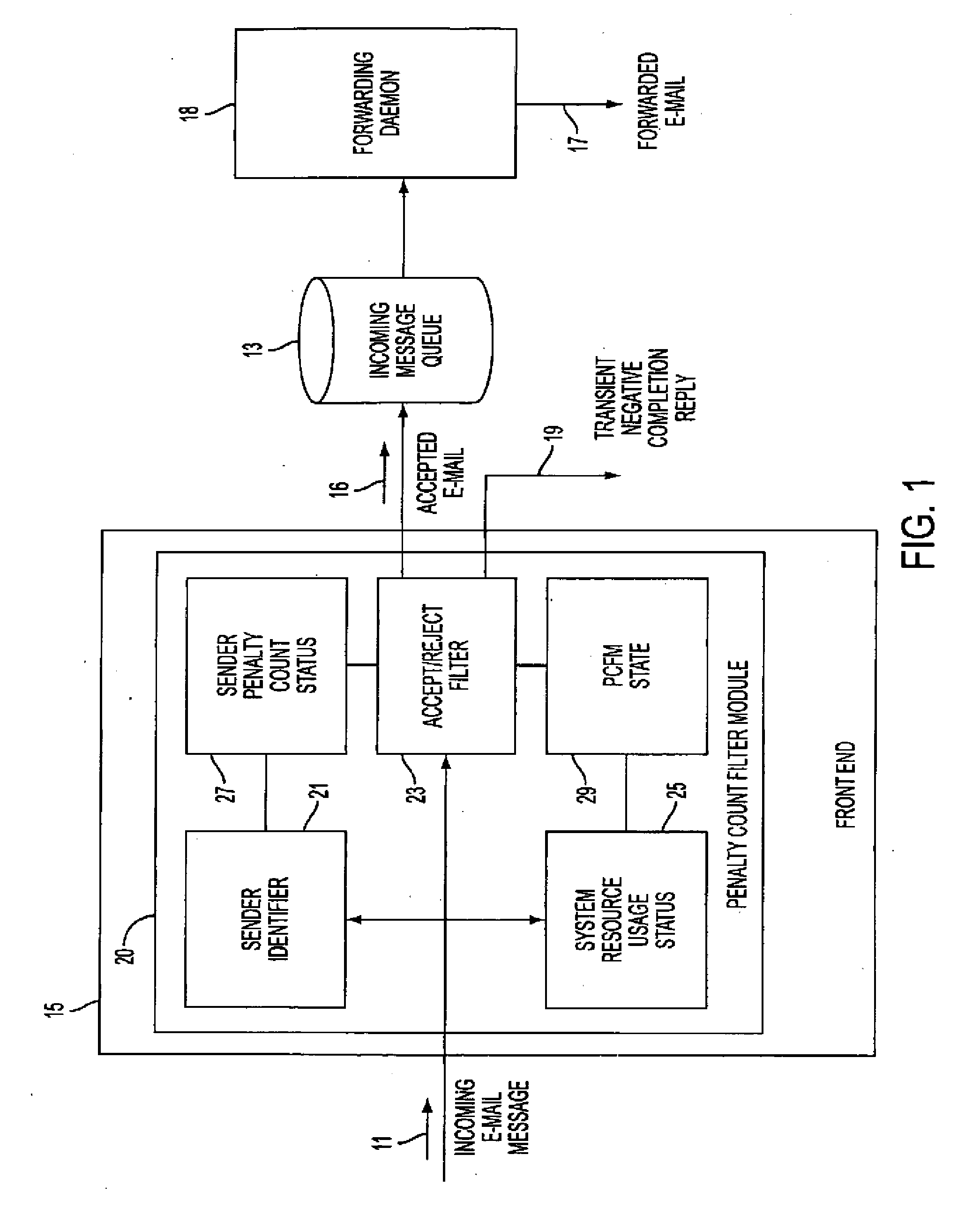

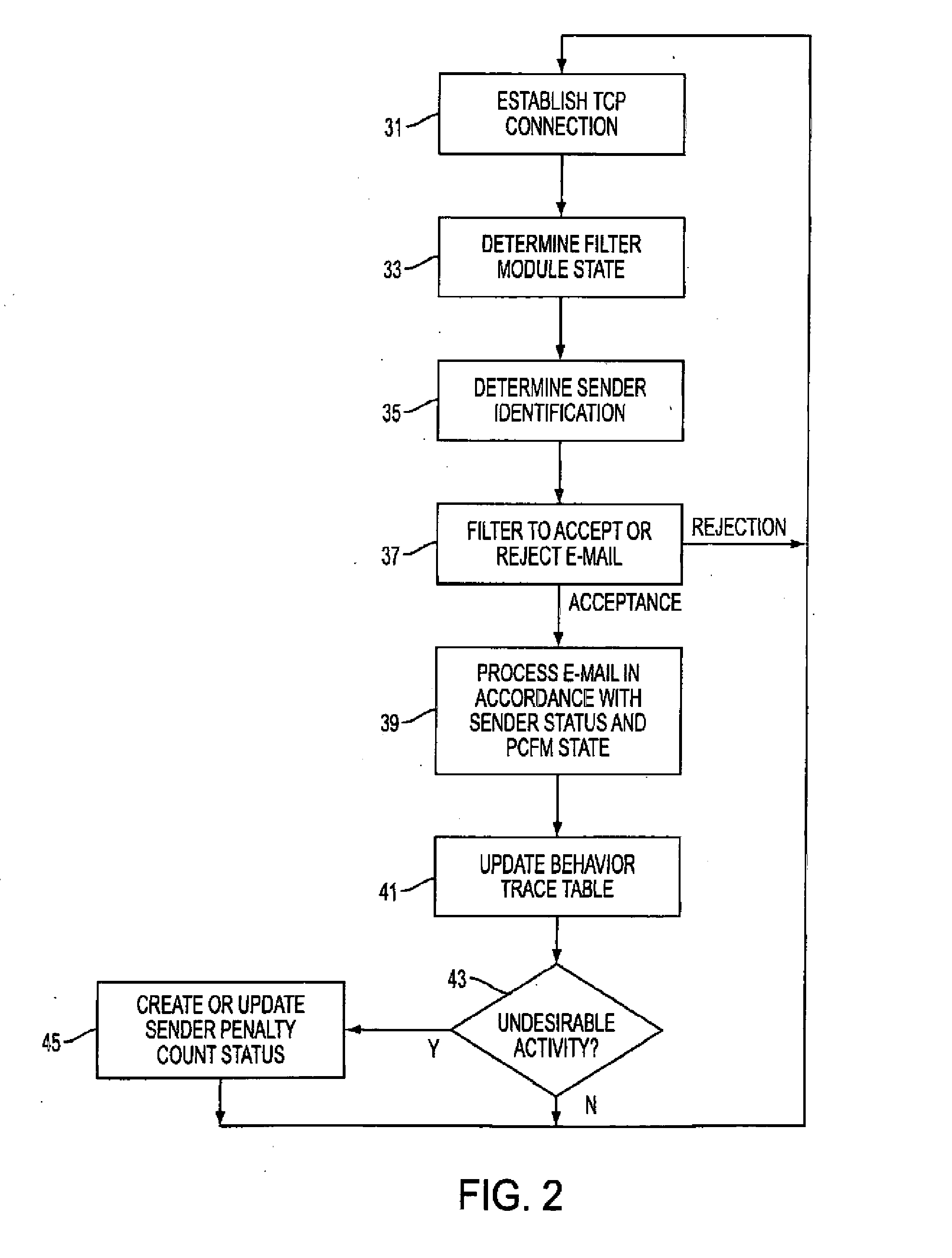

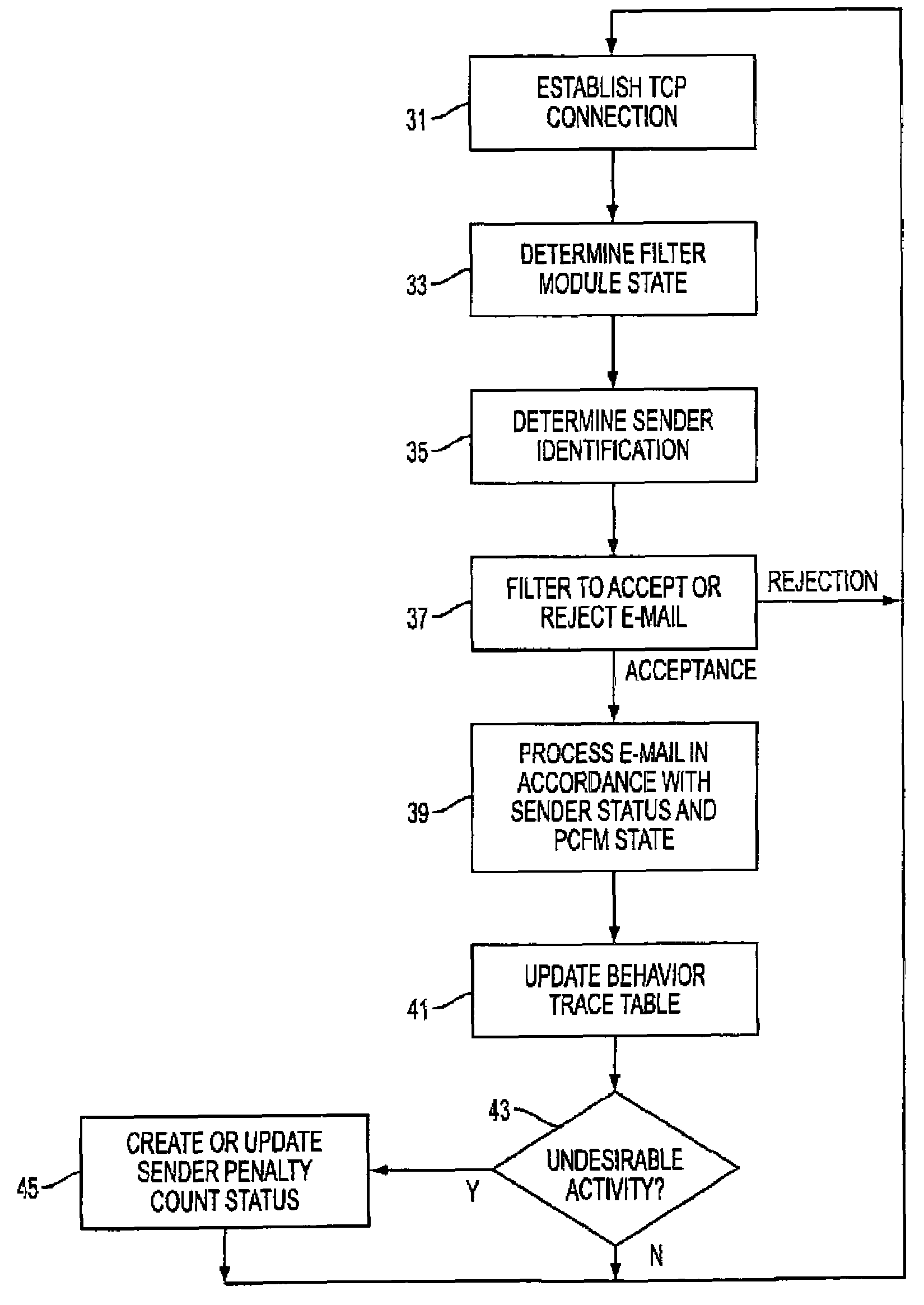

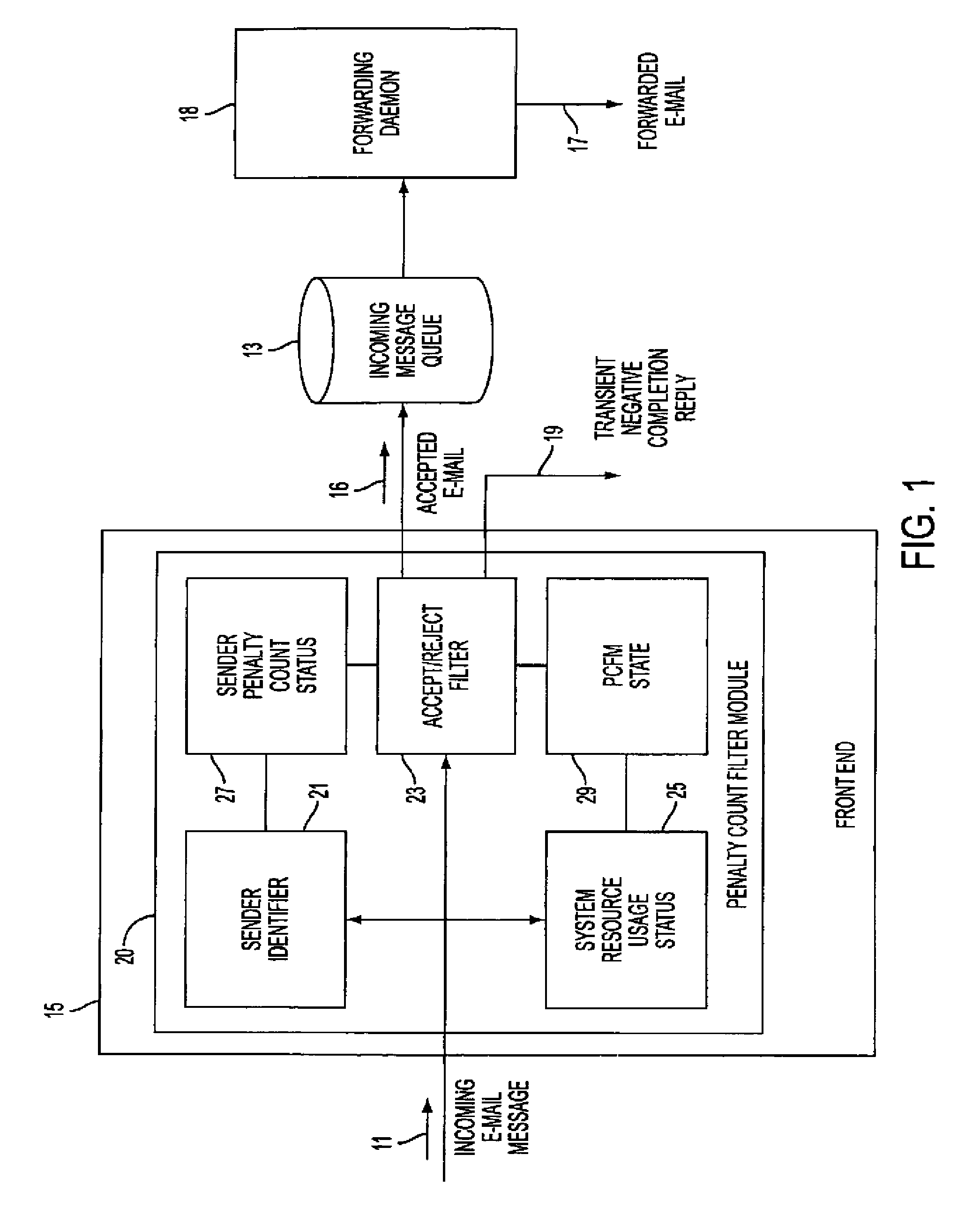

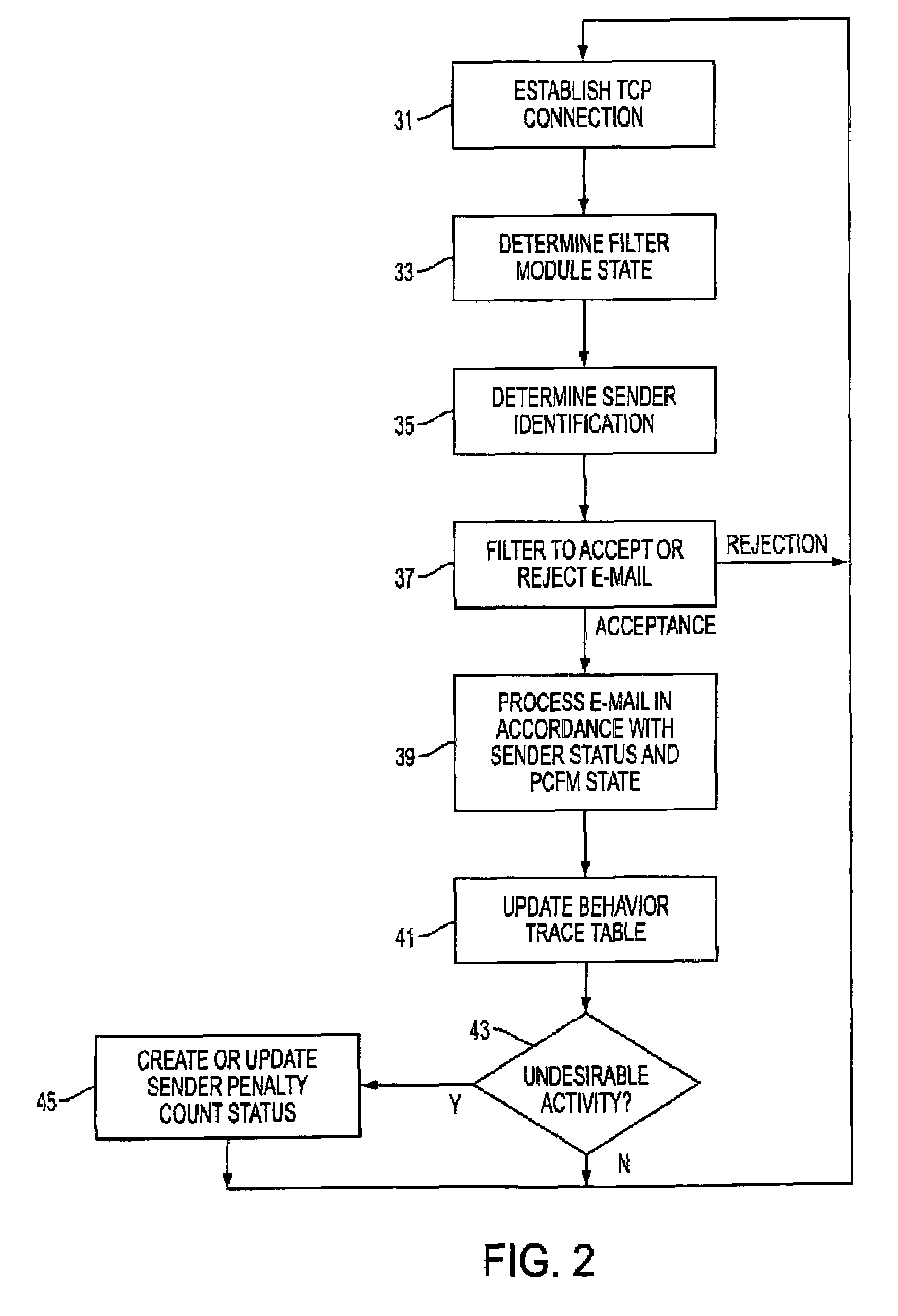

Apparatus and Method for Handling Electronic Mail

InactiveUS20080040439A1Reduce disruptionHigh scrap rateMultiple digital computer combinationsData switching networksCommunications systemRejection rate

A mail transfer agent adapted for determining the disposition of incoming e-mail from a sender includes a penalty count filter module (20 which functions on the basis of current communication system resource usage, such as the number of concurrent TCP connections being maintained, and penalty counts assigned for cumulative undesirable sender activity such as sending large e-mail files. The penalty count filter module can operate in a selective-rejection state accepting e-mail from senders without a penalty count and randomly accepting other e-mail, and in a random-rejection state rejecting all e-mail from senders with a penalty count and randomly rejecting other e-mail. The rejection rates can be increased or decreased in response to a detected increase or decrease in the usage of system resources.

Owner:NOKIA TECH OY

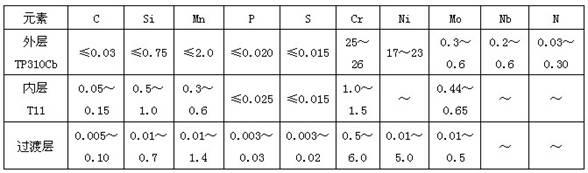

Centrifugally cast TP310Cb/T11 bimetal composite tube blank and method for producing same

InactiveCN102581250ABrittleAvoid ingredients that are out of toleranceStress concentrationHeat resistance

The invention discloses a centrifugally cast TP310Cb / T11 bimetal composite tube blank and a method for producing the same, which belong to the field of casting of tube blanks. The centrifugally cast TP301Cb / T11 bimetal composite tube blank comprises a tube blank inner layer, a tube blank outer layer and a tube blank transitional layer. The method includes controlling components of the inner layer, the outer layer and the transitional layer by means of controlling selection of a tube blank raw material at first; pouring the outer layer; then pouring the transitional layer; and finally pouring the inner layer. The transitional layer is fused with the outer layer, the inner layer is fused with the transitional layer, difference between the components of the outer layer and the components of the outer layer are relieved by the aid of the transitional layer, the purpose of completely fusing is achieved simultaneously, accordingly, interface stress between the inner layer and the outer layer is greatly relieved, stress concentration of interfaces of the inner layer and the outer layer is avoided, and the service life of the centrifugally cast TP310Cb / T11 bimetal composite tube blank is greatly prolonged. Simultaneously, conduction heat resistance of the inner layer and the outer layer is reduced by the aid of metallurgical fusion of the inner layer and the outer layer, and accordingly heat conduction efficiency of a bimetal tube is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

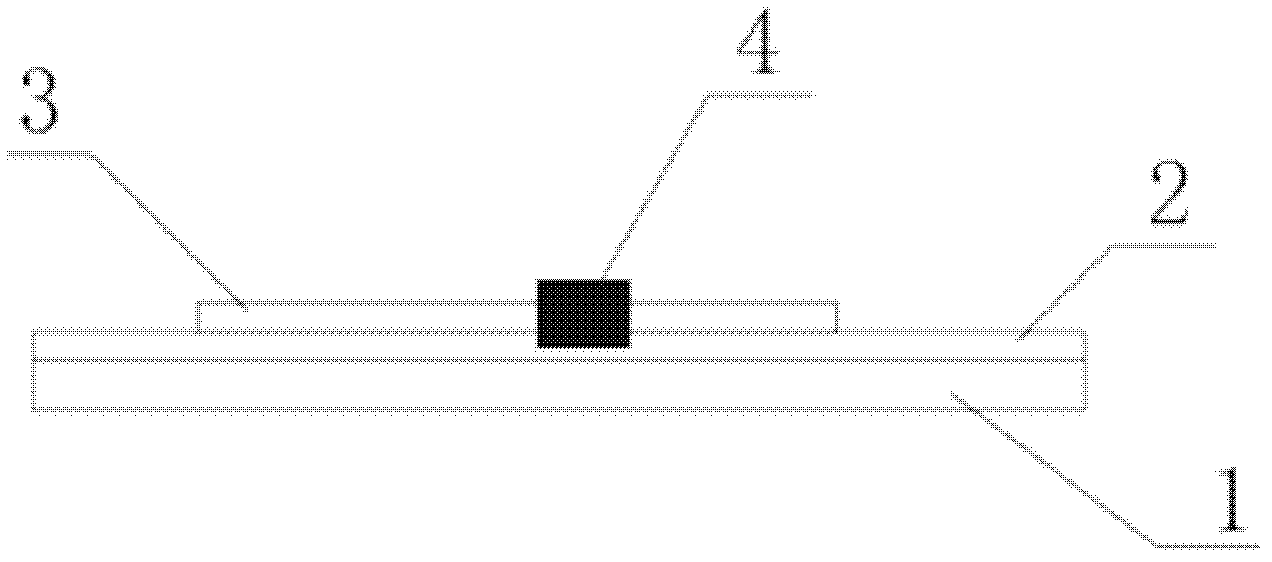

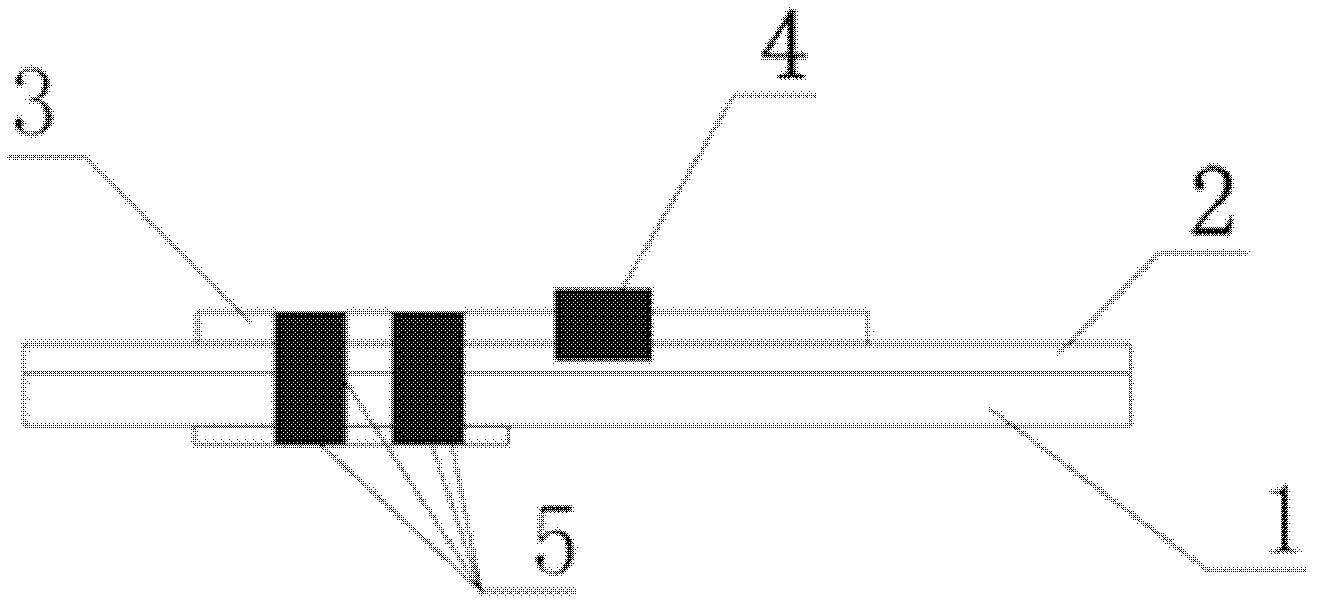

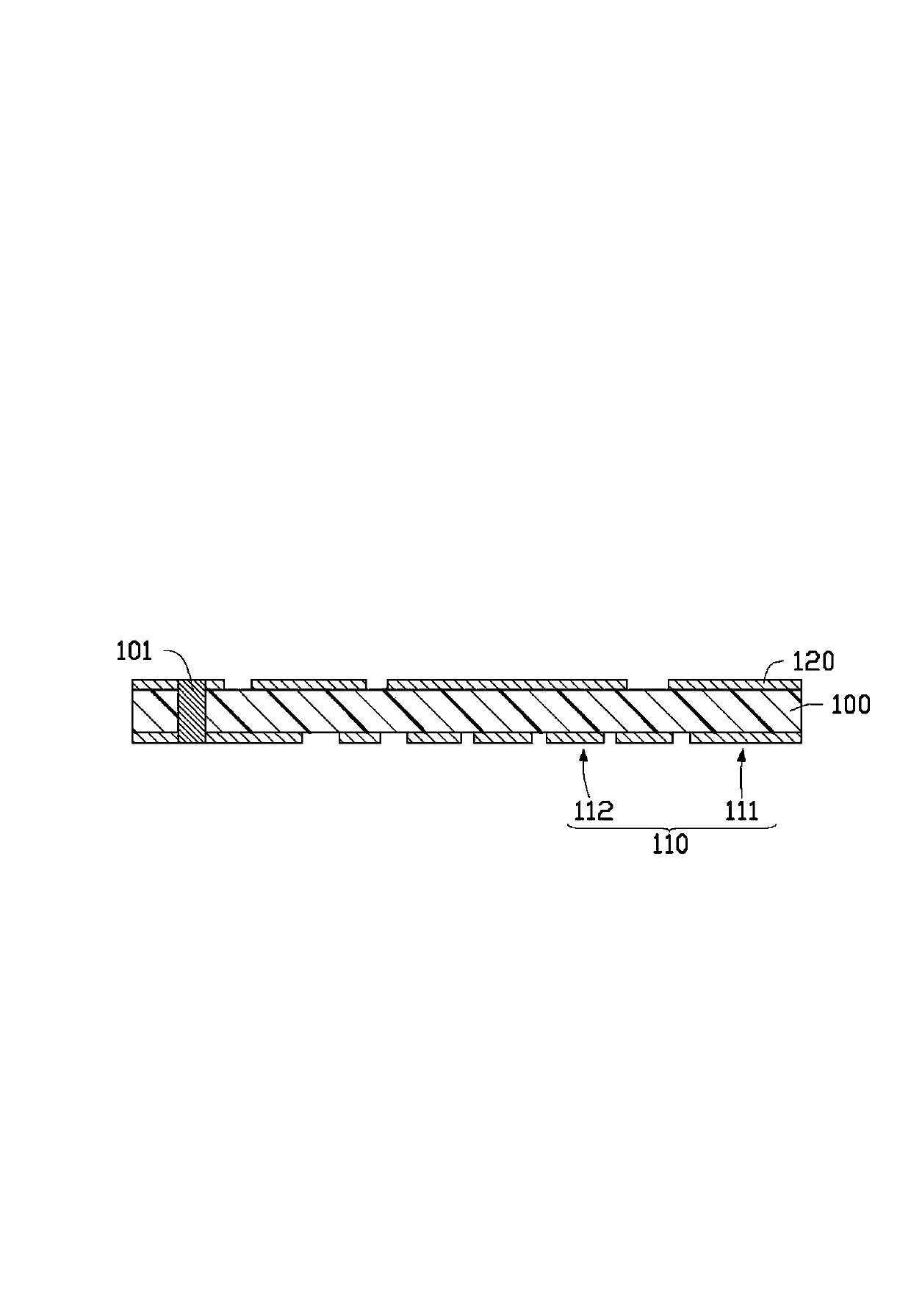

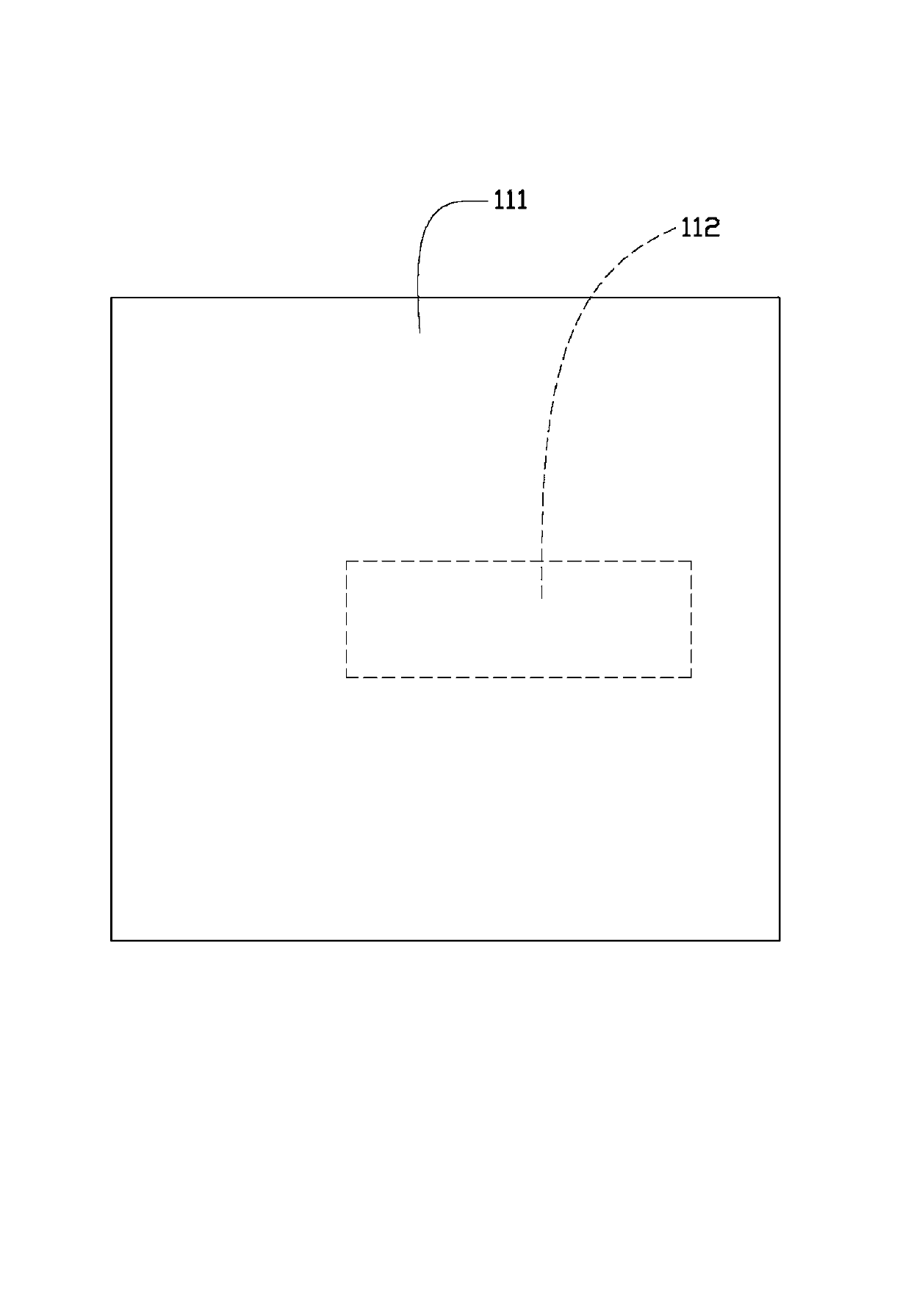

Radio frequency identification tag having diversion-proof function and manufacturing method thereof

ActiveCN102982364APrevent looseningAvoid breakingRecord carriers used with machinesEngineeringElectrical and Electronics engineering

The present invention provides a radio frequency identification tag having a diversion-proof function and a manufacturing method thereof. The radio frequency identification tag having a diversion-proof function is formed of a support layer, a release layer, antennas and a chip; the release layer is attached to one side of the support layer, the antennas are attached to the other side of the release layer, or, the antennas are attached to two sides of the support layer and the release layer, and connected through overbridge points on the antennas, and the overbridge points run through the support layer and the release layer so that antennas at two sides are switched into conduction; and the chip is bonded onto the antennas. When the diversion-proof RFID tag is stripped or diverted, the physical structure thereof is damaged, information contained therein cannot be read, so as to achieve the purpose of being incapable of reuse. At the same time, a thermally curable resin is organically combined according to the fabrication process of the RFID tag, so that high bonding fastness is provided between the bonding point of the chip as well as the overbridge points and the support layer, it is uneasy for the chip to drop off due to the release layer, the overbridge effect is better, and the yield of the diversion-proof RFID tag may be greatly improved.

Owner:SHANGHAI TECHSUN ANTI COUNTERFEITING TECH HLDG +1

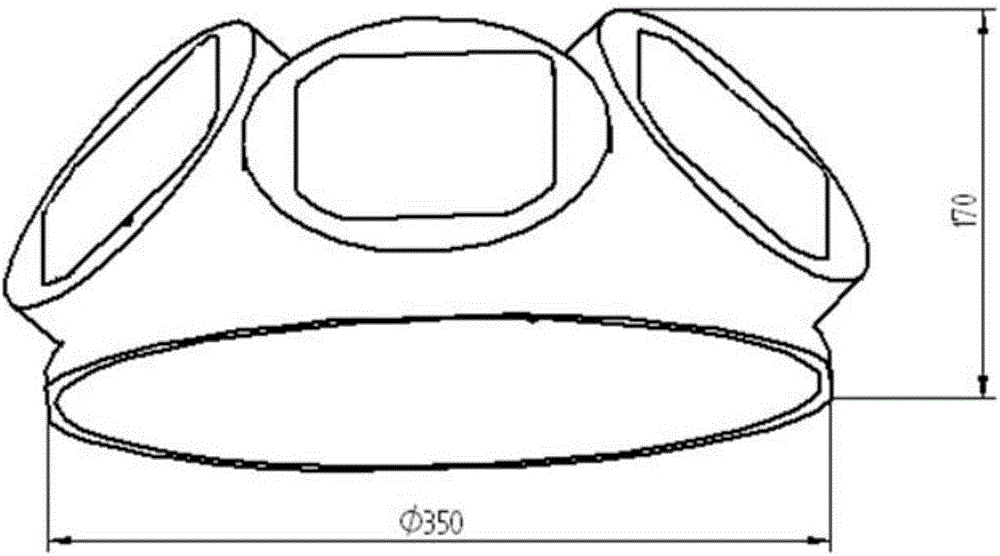

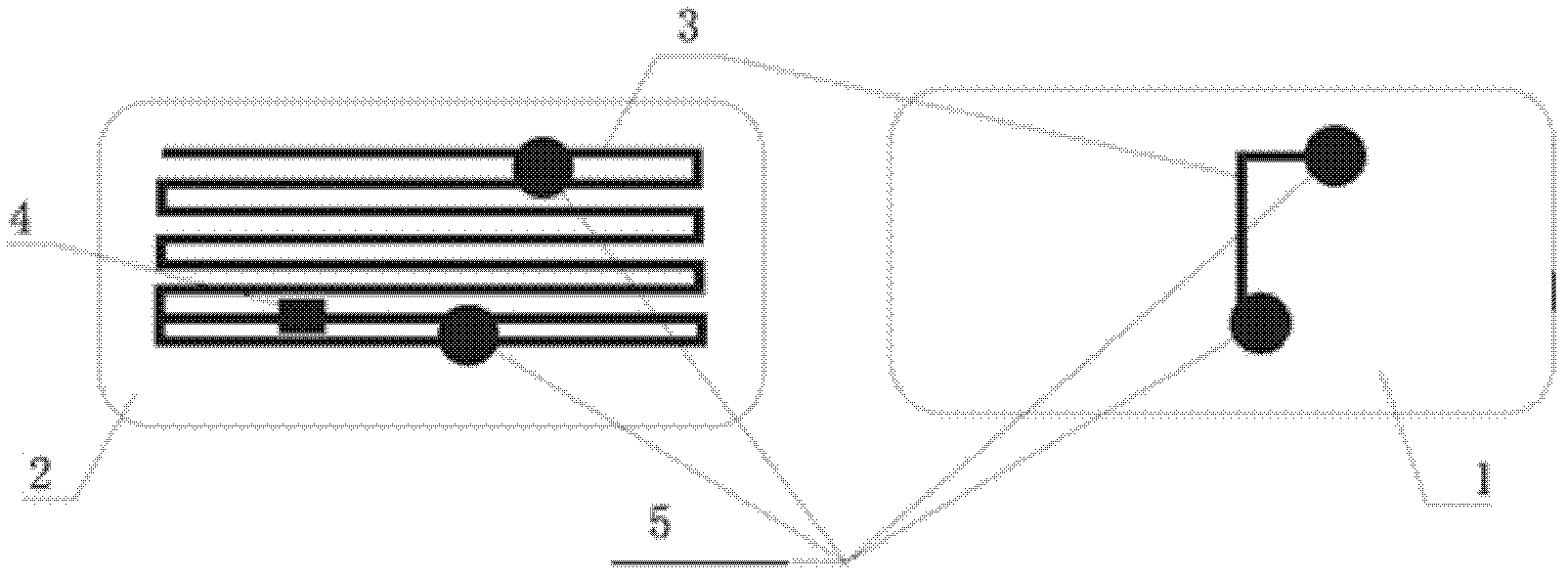

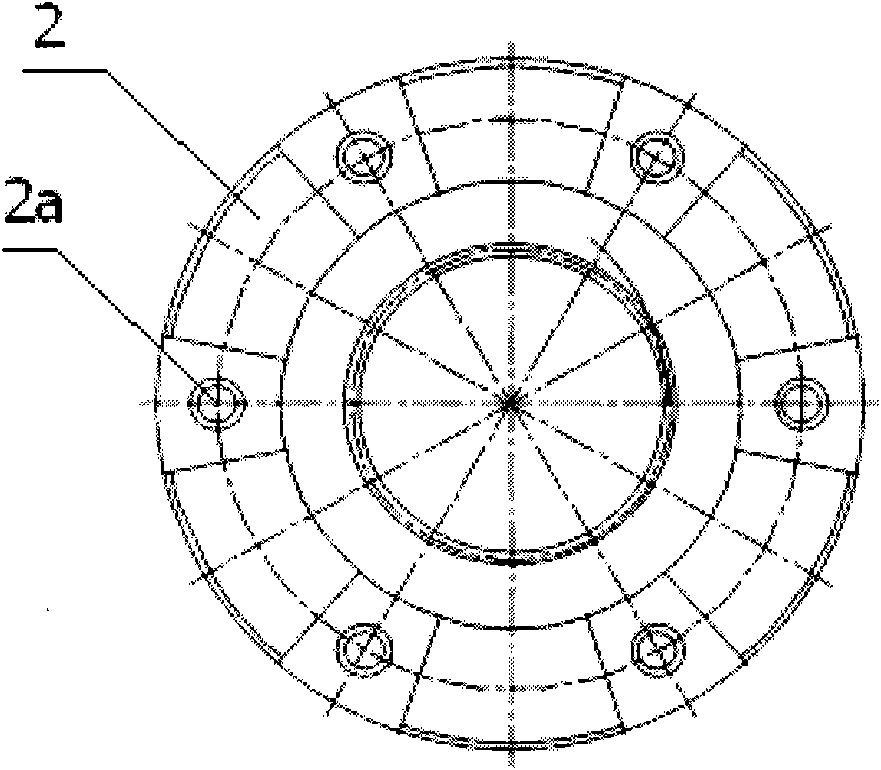

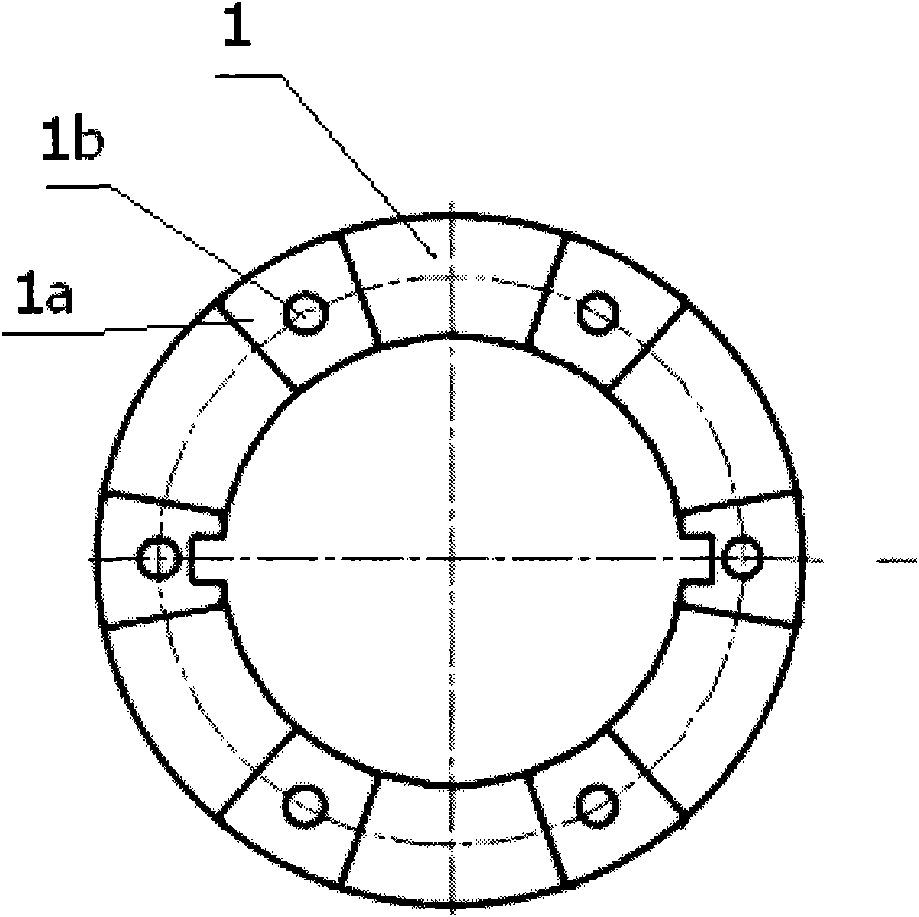

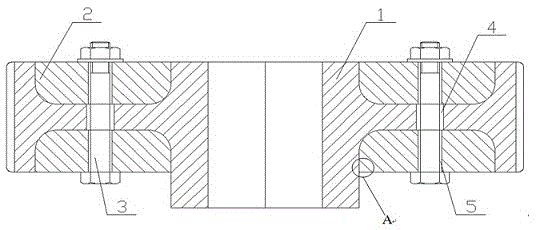

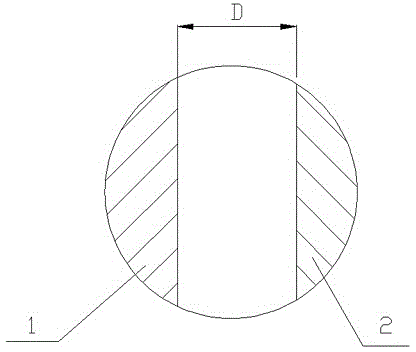

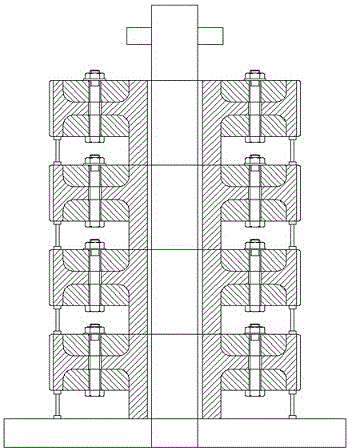

Sintering and brazing technology of powder metallurgical planet carrier assembly

InactiveCN101618482AImprove productivityHigh scrap rateWelding/cutting media/materialsSoldering mediaMetallurgyMaterials science

The invention provides a sintering and brazing technology of a powder metallurgical planet carrier assembly, which comprises the following concrete steps: 1. pressing a planet carrier and a planetary gear carrier blank, wherein the planetary gear carrier blank (2) is provided with a solder placing hole (2a) corresponding to a claw of the planet carrier; 2. correspondingly placing the solder placing hole (2a) on the planetary gear carrier blank (2) with a claw (1a) of the planet carrier (1), and putting a solder (3) into the solder placing hole (2a), so as to prepare a planet carrier assembly sintered blank; and 3. putting the planet carrier assembly sintered blank prepared in the step 2 into a sintering and brazing furnace for sintering and brazing simultaneously; sequentially and continuously sintering and brazing in the sintering and brazing furnace for presintering, sintering and cooling, and once finishing the sintering process and the brazing process in the furnace simultaneously to finish manufacturing the assembly. The sintering process and the brazing process are carried out simultaneously and conform to the requirement of the technological parameter in the sintering and brazing furnace.

Owner:DONGFENG MOTOR CO LTD

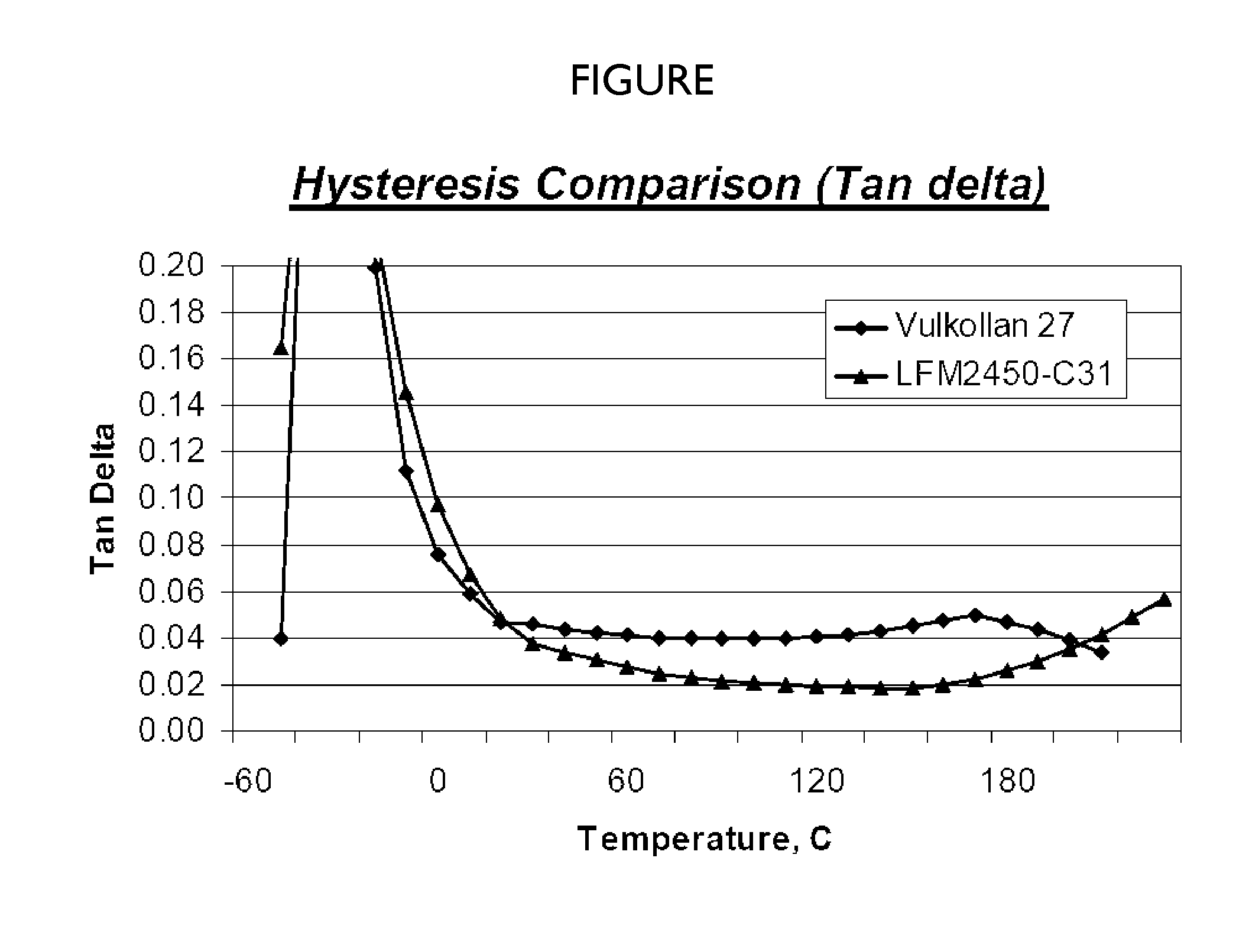

Polyurethane elastomer articles from low free diphenylmethane diisocyanate prepolymers

InactiveUS20090110894A1High scrap rateExtension of timeSynthetic resin layered productsNon-inflatable tyresPrepolymerPolyester

Polyurethane elastomer articles formed from prepolymer mixtures having free diphenylmethane diisocyanate (MDI) content from 2.0 to 5.0 wt %, based on the weight of the prepolymer mixture. The prepolymer mixtures comprise a polyester, polyether, or polycaprolactone (PCL) prepolymer and MDI. The polyurethane elastomer articles are formed by curing the prepolymer mixture with a chain extender, such as a curative comprising a methylenedianiline-sodium chloride complex. The articles have good physical properties that may weigh over 225 kg, and have a three-axis thickness greater than 10.2 cm.

Owner:CHEMTURA CORP

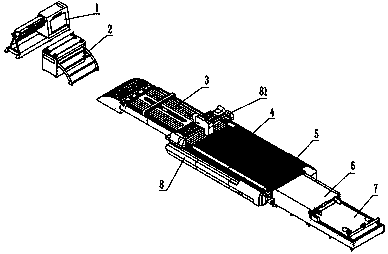

Laser cutting device

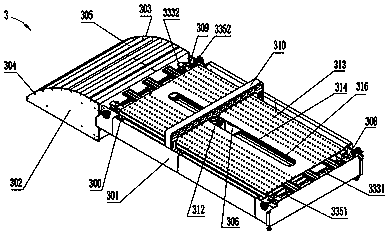

PendingCN110170752APrecise cutting and automatic unloadingReduce biasLaser beam welding apparatusStops deviceLaser cutting

The invention belongs to the technical field of metal plate production equipment, and particularly relates to a laser cutting device. The laser cutting device is provided with a main lathe bed (8), afeeding machine (3), a clean material cutting area (4) and a rotary workbench (5), wherein the feeding machine (3), the clean material cutting area (4) and the rotary workbench (5) are arranged from back to front; the feeding machine (3) is provided with a feeding rail (314), a feeding crossbeam (310) and a floating clamp (312); the clean material cutting area (4) is provided with a clean materialcutting support bar (41), a clean material cutting servo motor (42) and a stop device; and the rotary workbench (5) is provided with a rotary support bar (51), a rotary servo motor (52), a chain support rail (53) and a supporting bracket (54). According to the laser cutting machine, the feeding machine can achieve high-precision positioning and automatic deviation rectifying through plate limiting and can achieve automatic feeding; a plate is accurately positioned by the clean material cutting area so to be cleaned and cut and is then conveyed to the rotary workbench to be cut into a workpiece; and laser cutting based on automatic feeding and discharging is achieved, and the production efficiency is improved.

Owner:河南力锋科技有限公司 +1

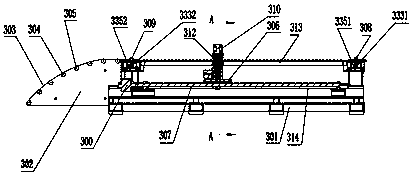

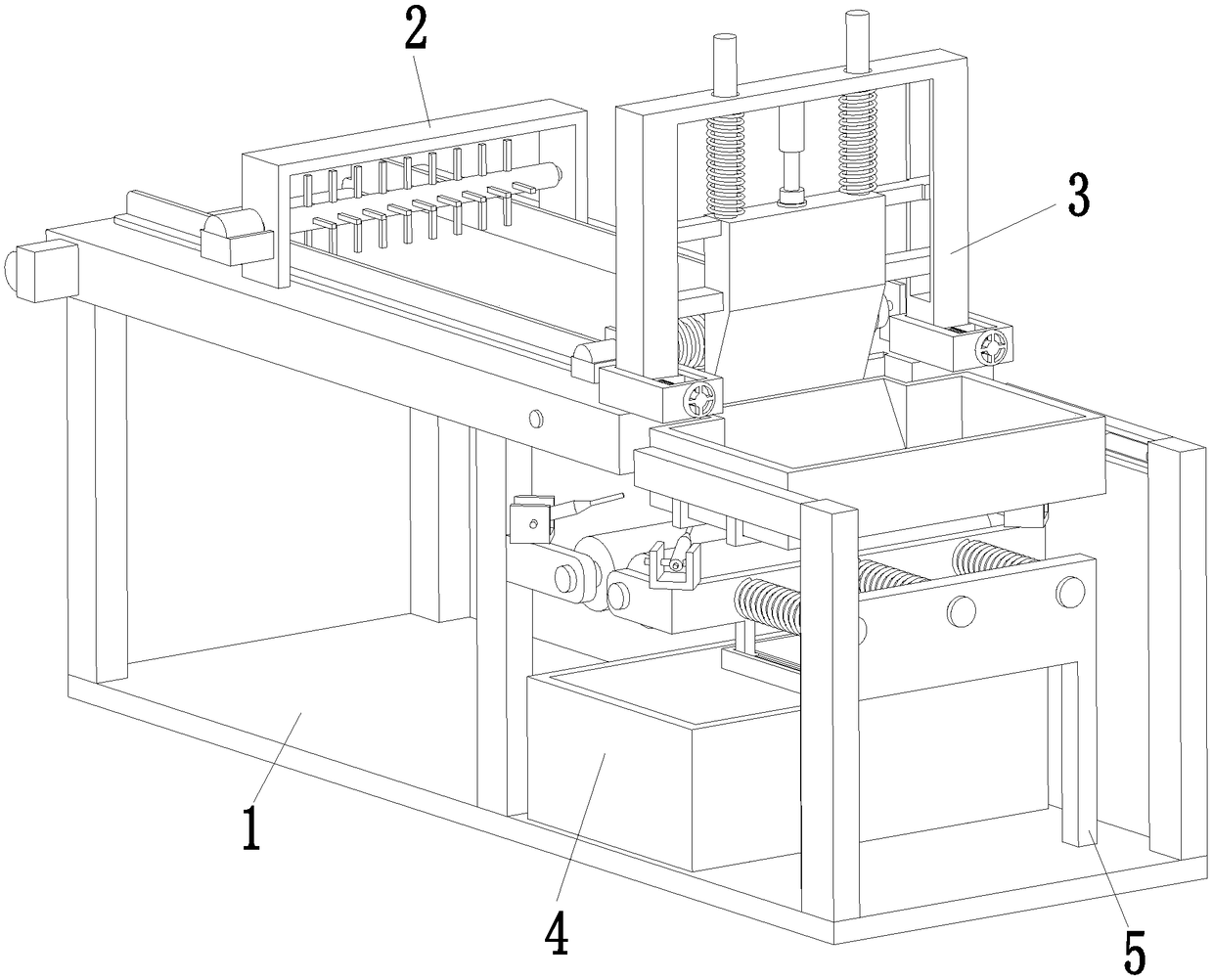

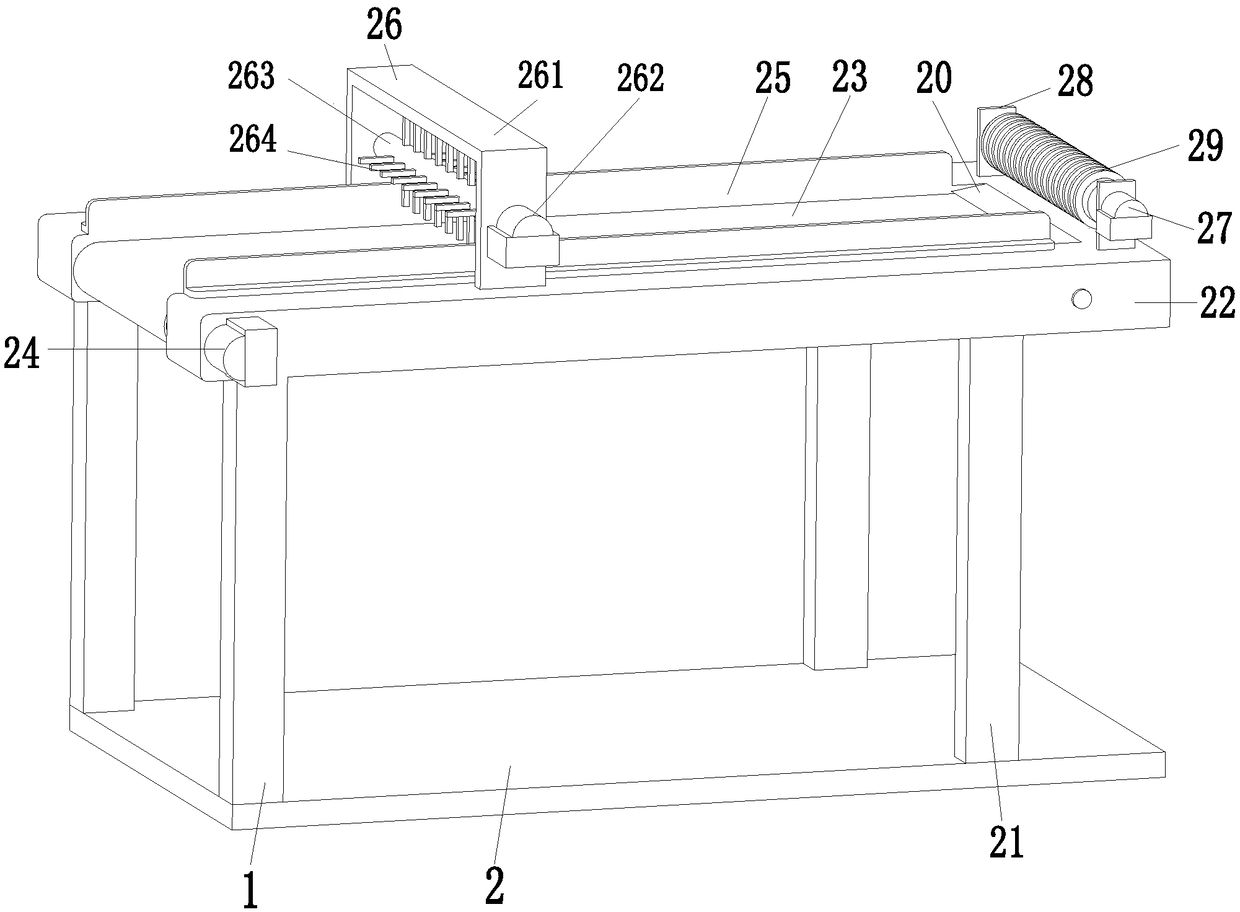

Medicinal material cutting equipment for traditional Chinese medicine decoction piece manufacturing

ActiveCN109278078AEasy to transport and cutReduce manual labor intensityMetal working apparatusEngineeringChinese herbology

The invention relates to medicinal material cutting equipment for traditional Chinese medicine decoction piece manufacturing. The medicinal material cutting equipment comprises a bottom plate, a conveying device, a cutting device, a cleaning device and a material collecting device. The conveying device is arranged on the left side of the upper end of the bottom plate. The cutting device is arranged at the right end of the conveying device. The right side of the upper end of the bottom plate is provided with the material collecting device. The material collecting device is located on the rightside of the cutting device. The cleaning device is arranged at the upper end of the bottom plate. The cleaning device is located below the cutting device and the material collecting device. The medicinal material cutting equipment can solve the problems that during medicinal material cutting at present, a manual manner is commonly used for conveying and cutting, manual cutting safety is low, the effect is poor, the rejection rate is high, and the cutting length, size and thickness are not uniform; and when fiber and starch containing medicinal materials or medicinal materials containing more sticky liquid and saccharides are cut, residues on the surface of a cutting blade cannot be cleaned, the later cutting effect is influenced, the cut medicinal materials are manually collected, and thelabor intensity of manual work is increased.

Owner:江西一方天江药业有限公司

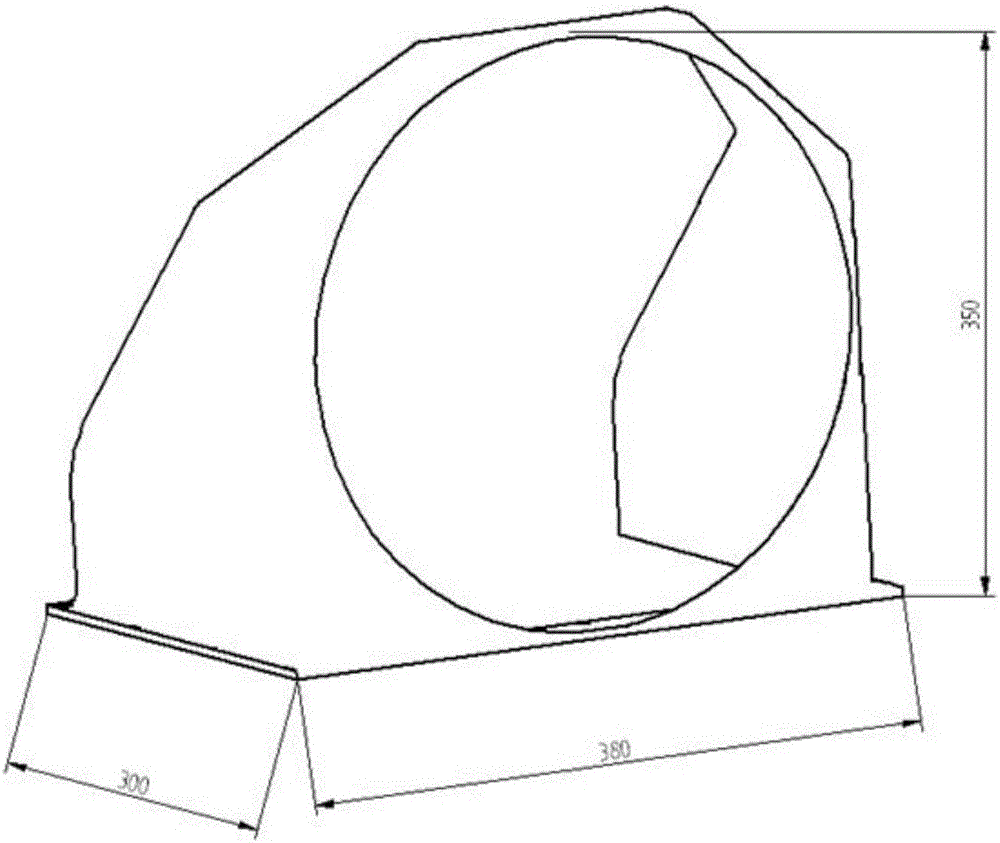

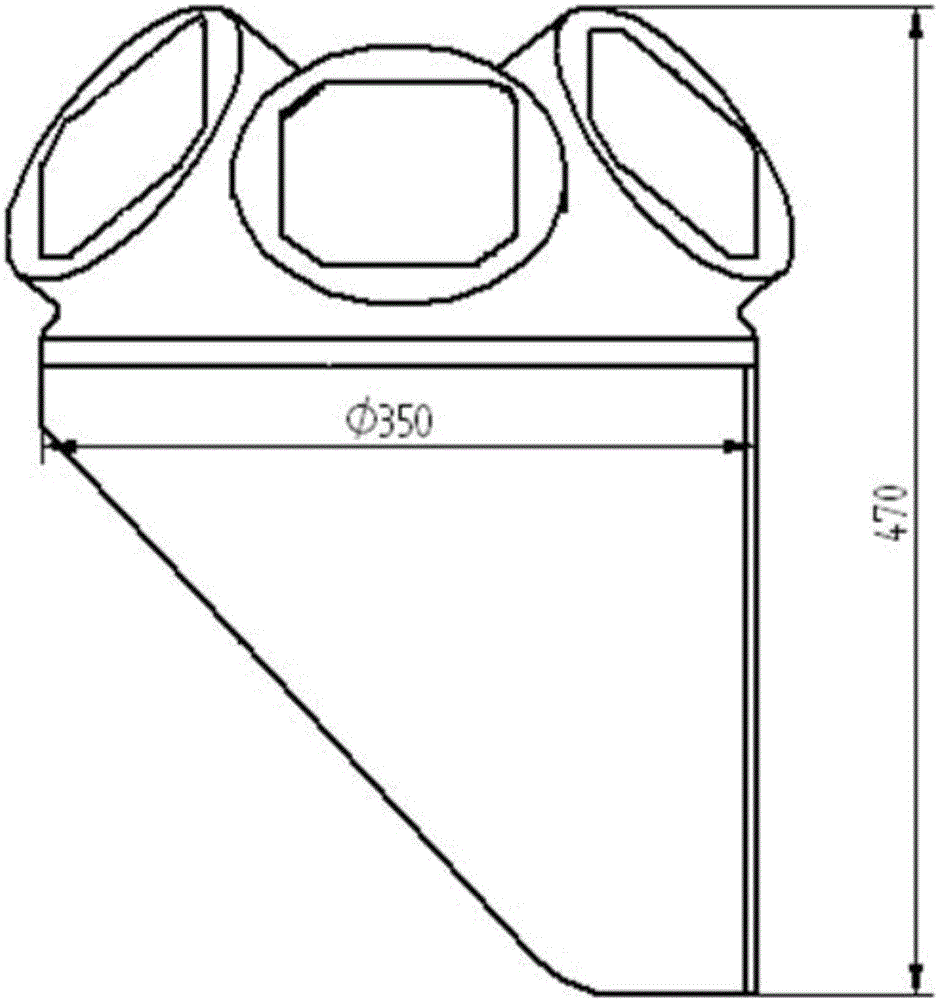

Semicircular plate used for oil drilling platform leg and manufacture process thereof

ActiveCN101576197AReduce manufacturing costUniform and stable performanceArtificial islandsSheets/panelsOil drillingMolten steel

The invention discloses a process for manufacturing an oil drilling platform leg, comprising the following steps of: continuously casting a molten steel with the composition complying with the requirement into a solid tube blank; processing the tube blank as a seamless steel pipe; and finally sawing the seamless steel pipe into the semicircular plate by longitudinal sawing operation. The invention also discloses a semicircular plate used for the oil drilling platform leg. The process directly changes the existing technology of pressing semicircular plate by steel plate, adopts the mode of a formed steel pipe to segment and manufacture the semicircular plate and leads the process forming way to be different from the original type; the processing technology route is firstly created in the field; and the manufacture cost is greatly reduced as large-tonnage presses are not adopted.

Owner:CHINA NAT OFFSHORE OIL CORP +1

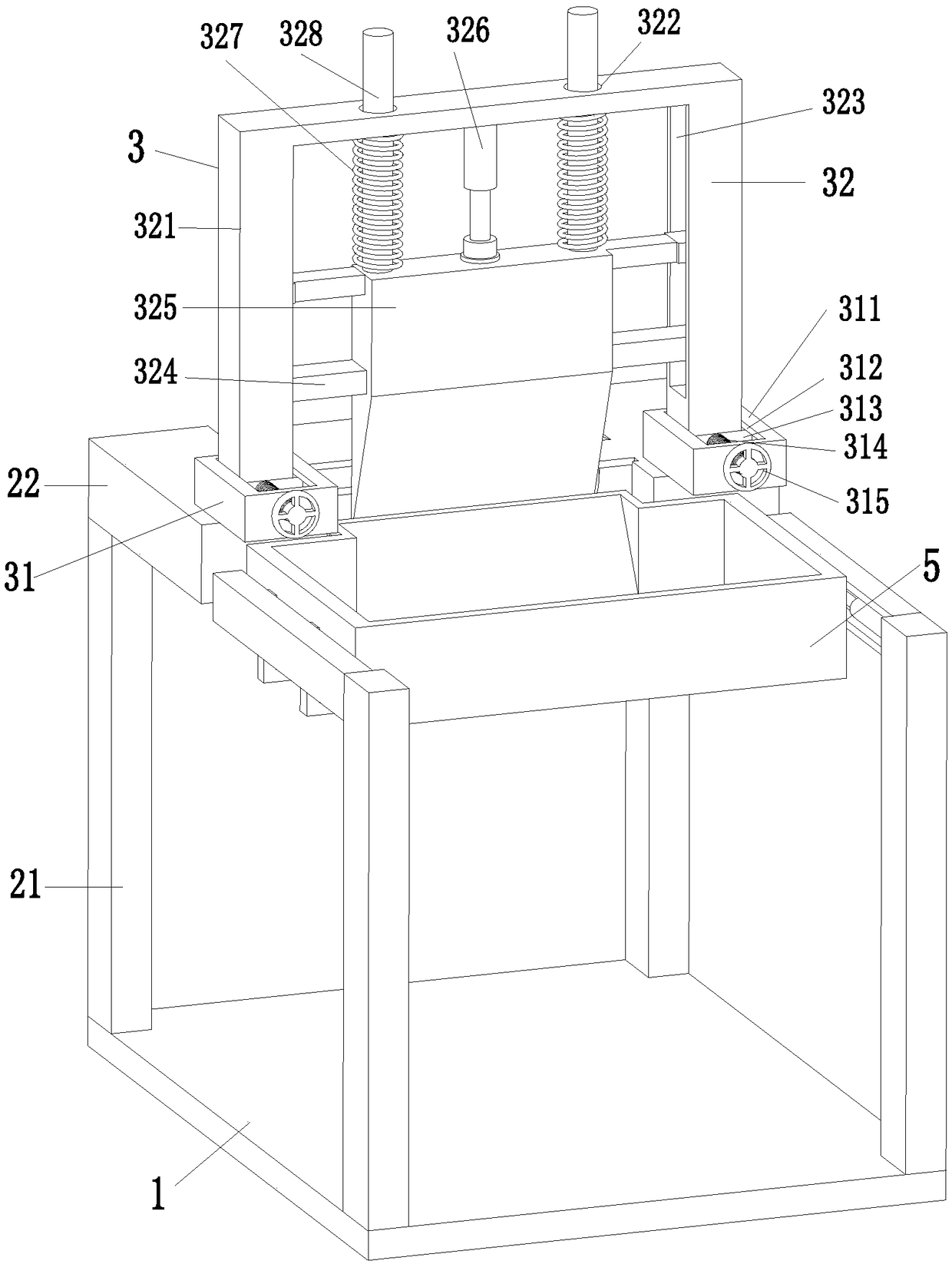

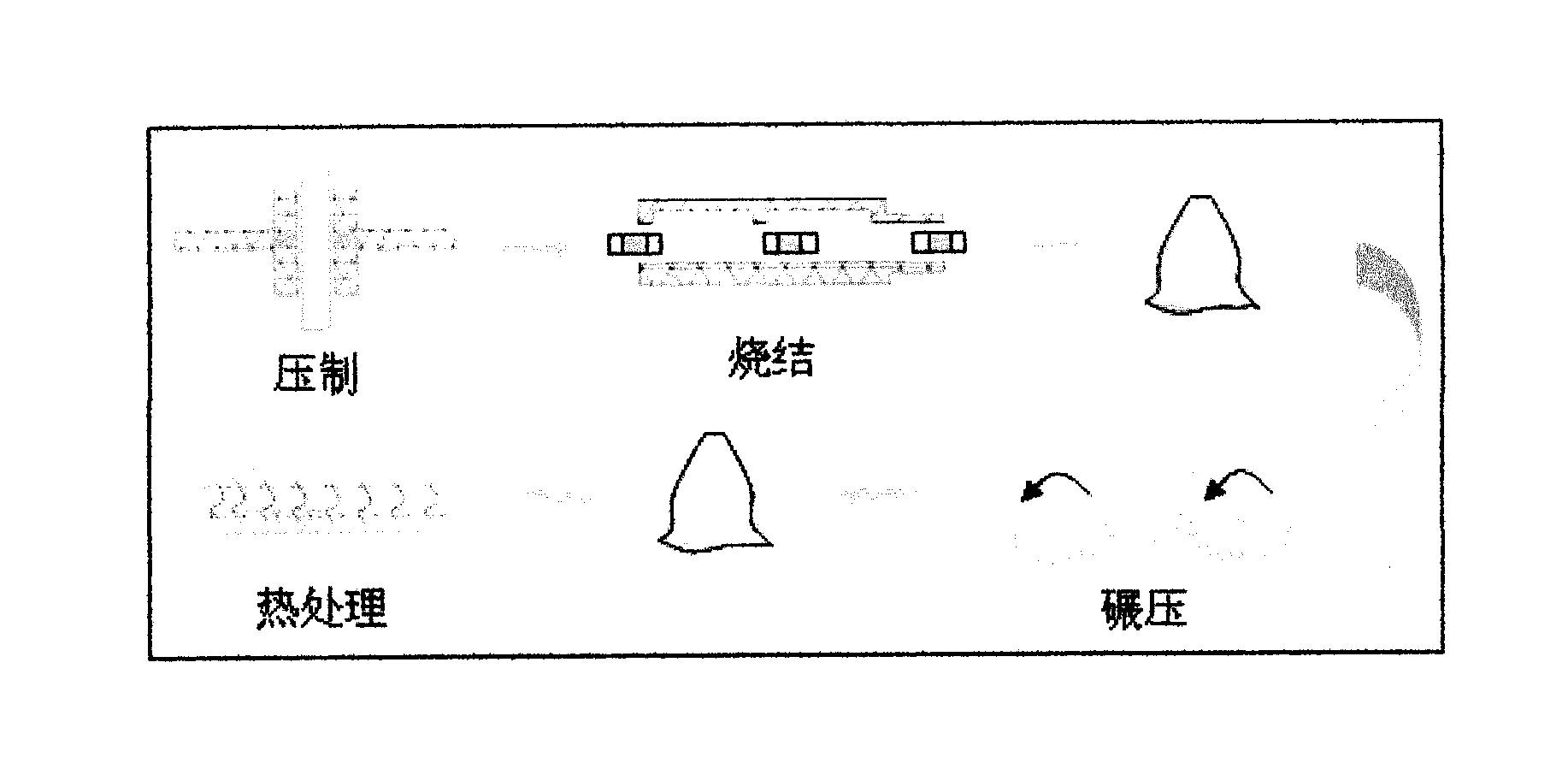

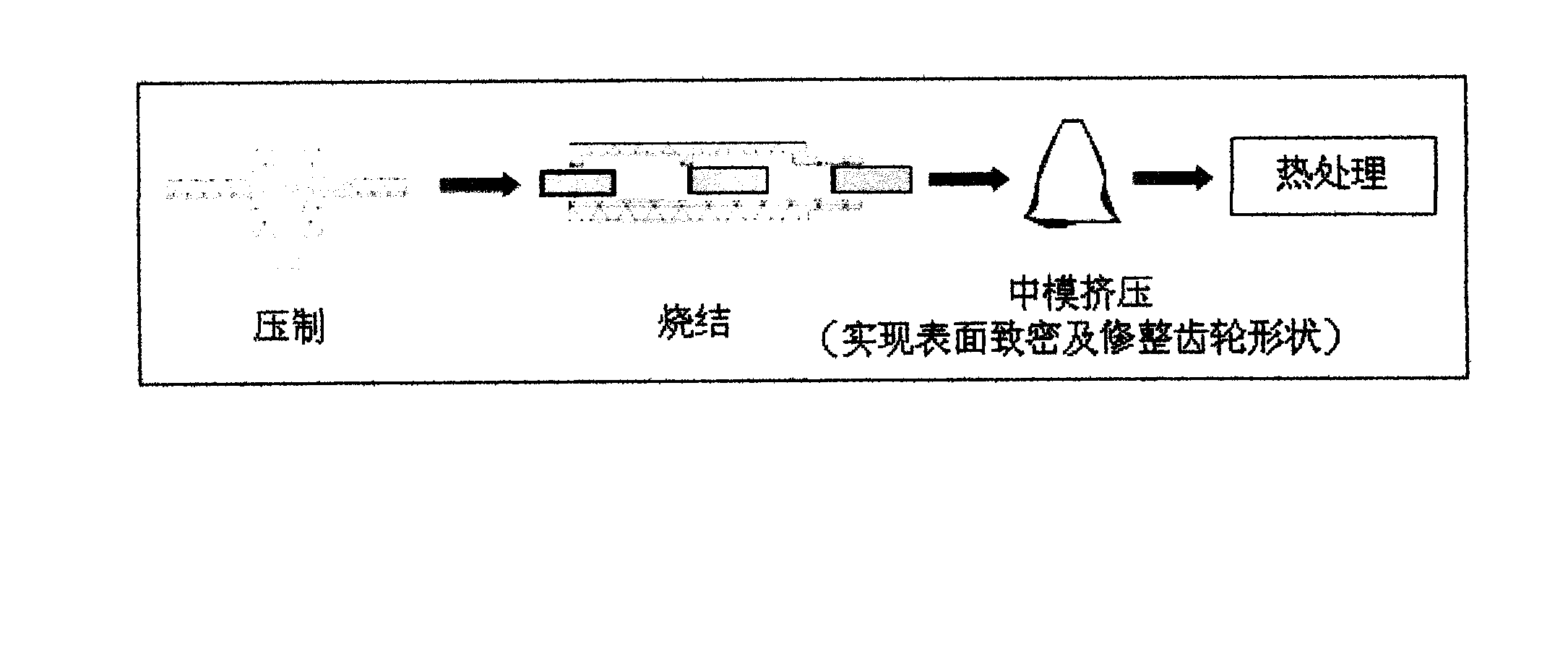

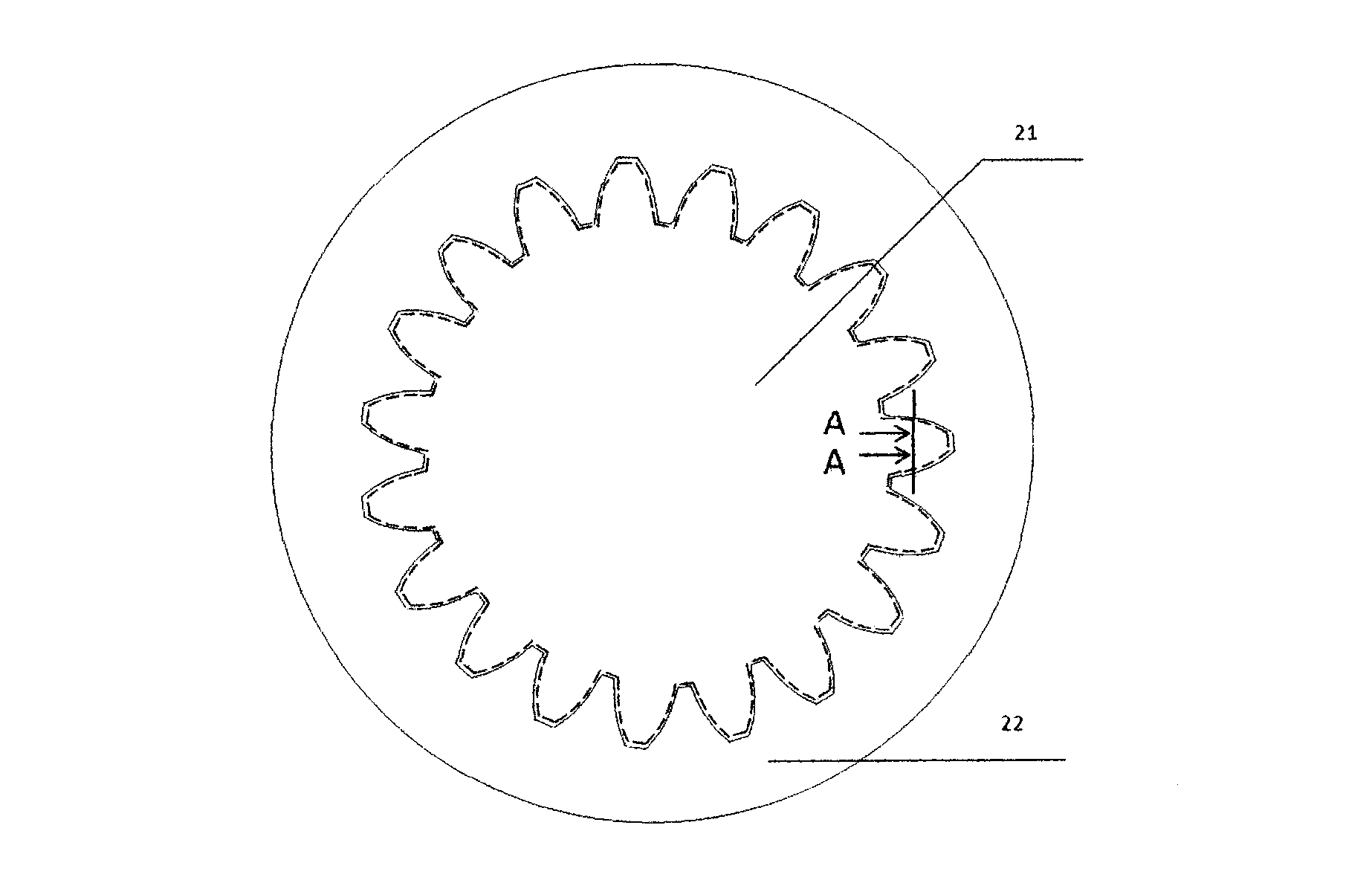

Method for producing surface-densified powder metallurgic gear

The invention relates to a method for producing a surface-densified powder metallurgic gear. The method comprises the following steps of material mixing, powder pressing, sintering, peening, shaping, heat treatment and quality inspection. The gear processed by the method has the advantages that the surface porosity is avoided, the densification degree of the surface can be easily controlled, the number of adjusting times is reduced, the size precision is high, the fatigue-resistance and abrasion-resistance capabilities are improved, the defective rate is greatly reduced, the production cost is reduced, and meanwhile, the performance and the quality are improved.

Owner:SHANDONG XINYI POWDER METALLURGY CO LTD +1

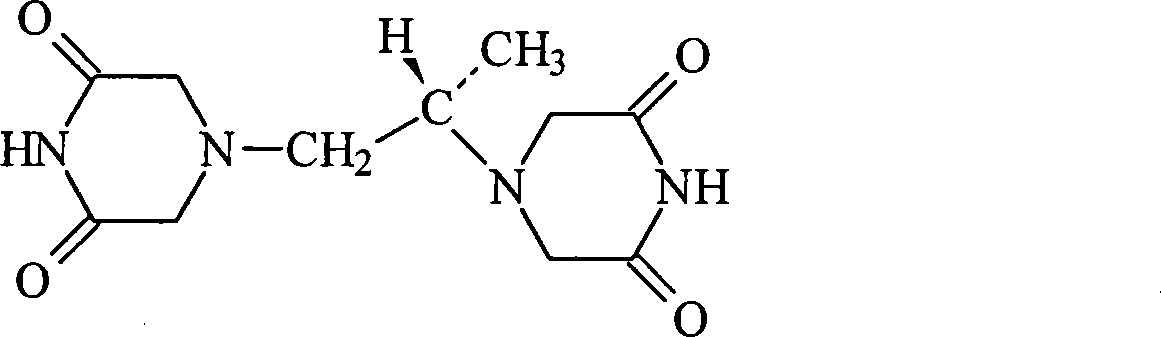

Dexrazoxane freezing-dried powder injection and preparation method thereof

InactiveCN101143134AFix stability issuesFreeze-dried wellOrganic active ingredientsPowder deliveryMicropore FilterFreeze-drying

The invention relates to a dexrazoxane freeze-dried powder injection and the preparation method. The preparation is used for resisting the cardiac toxicity which is induced by the cumulate quantity of adriamycin. The dexrazoxane freeze-dried powder injection contains the active components of the dexrazoxane and hydrochloric acid, the weight proportion of which is 1 to 0.05 to 0.5, and the preferential proportion is 1 to 0.2 to 0.5. The preparation method is that the hydrochloric acid is put into an aseptic vessel; the water for injecting is added till 80 percent of the preparation quantity, and the temperature is reduced and kept at 2 to 6 DEG C; the dexrazoxane is added to be mixed, and the hydrochloric acid of 1.0mol / L is dripped slowly into the solution to be solved while mixing the solution; the water for injecting is added till the full quantity; active carbon of 0.3 percent is added for absorbing for thirty minutes, and then the solution is decarbonized; after the medium body content is mensurated as being eligible, the solution is filtered by a 0.22 micron-micropore filtering filer; the filtrate is filled into a 25ml cillin bottle according to the filling quantity of 10ml each bottle, and the bottles are partially plugged by buna plugs and filled onto a plate to be sent into a freeze-drying box; a temperature probe is inserted, and the box door is closed; the filtrate is warmed, sublimed and dried be stages; nitrogen is puffed; the plugs are pressed; the filtrate is taken out from the box for rolling the openings, detecting the quality and packaging and the preparation can be obtained.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

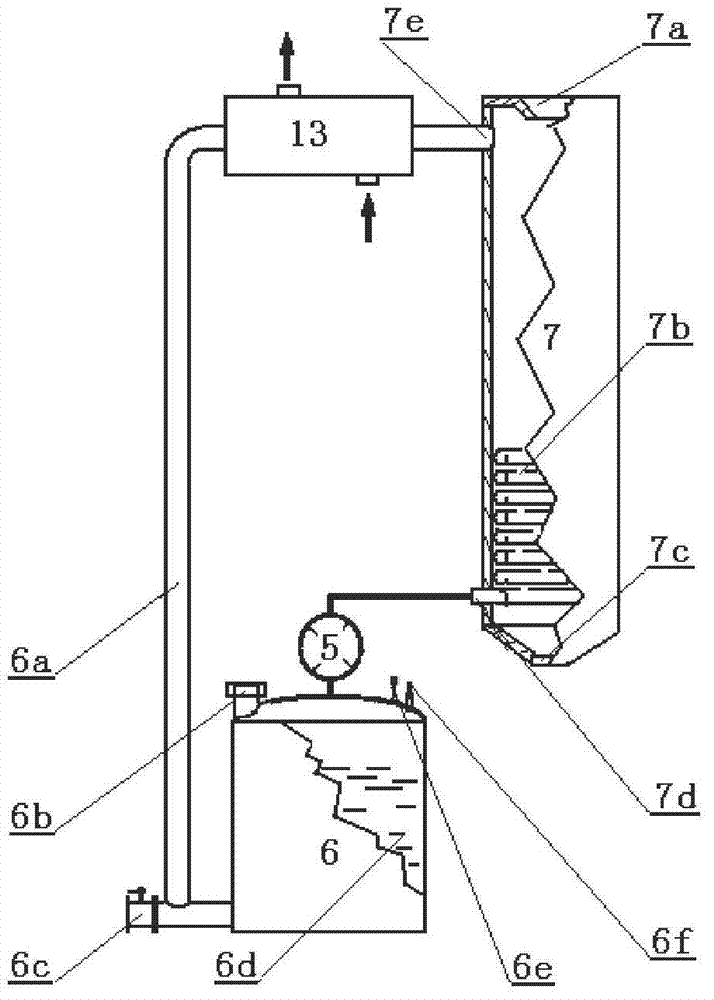

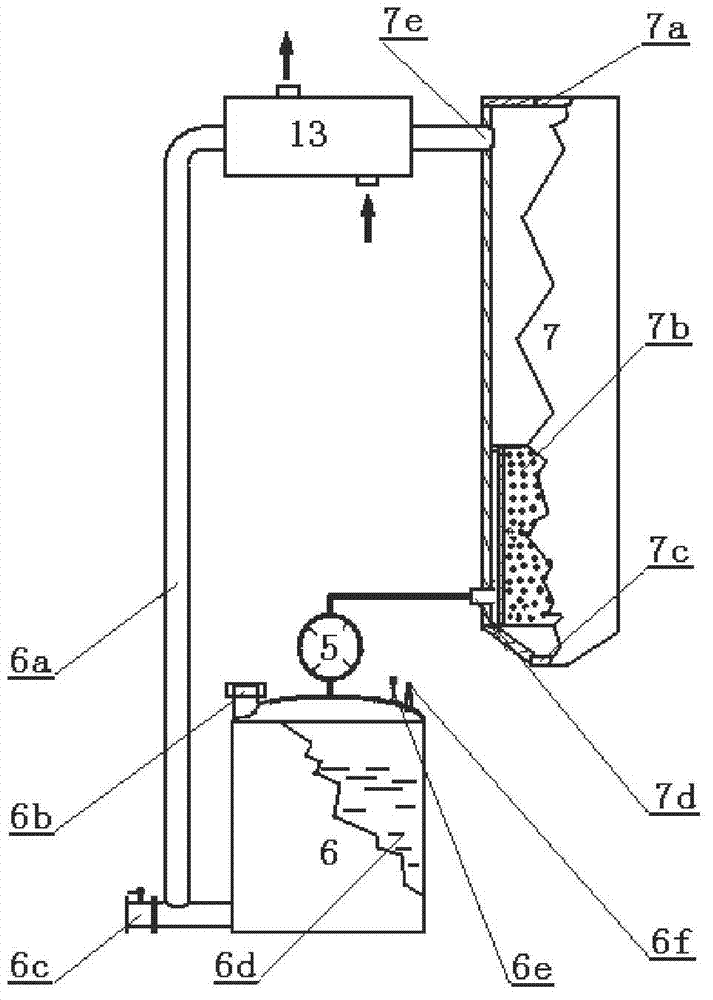

Thin vermicelli and/or vermicelli vertical cooler

ActiveCN102726784AImprove flexibilityHigh strengthFood shapingFood preparationCold airEconomic benefits

The invention discloses a thin vermicelli and / or vermicelli vertical cooler, which is provided with a cold air blower, a cooling tank, a cooler and a heat exchanger, wherein the cooler is provided with an air distributor, a bean vermicelli inlet, a bean vermicelli outlet, a cooling air inlet and a cooling air outlet, wherein the air distributor is arranged at the lower end of the cooler, and is adisk circular tube provided with even air distribution holes, or an air distribution card provided with even air outlet holes; the upper and lower ends of the air distribution card are welded with the cooler; the cooling air outlet is arranged at the upper end of the cooler; the top part of the cold air blower is provided with an exhaust opening, a liquid feeding opening, a vacuum meter and a thermometer; an air pipe and a cooling liquid are arranged at the lower end of the cooling tank; and the cooler, the cold air blower, the cooling tank and the heat exchanger are circularly connected in turn. With the adoption of the vertical cooler, the bean vermicelli is cooled in time, the flexibility and strength of the bean vermicelli are enhanced due to vertical stretching; a frequency modulation variable speed motor is automatically controlled by a computer, so that the operation is easy, the safety is high, the apparatus failure rate is low, the production efficiency and the product quality thin vermicelli and / or vermicelli are enhanced, and the thin vermicelli and / or vermicelli vertical cooler is suitable for industrial production, and has high economic benefit.

Owner:广西崇左天赐生物科技有限公司

Carburizing and quenching deformation control method for gears of large-sized heavy-load locomotive

ActiveCN104651857AEasy wayUniform sizeSolid state diffusion coatingFurnace typesEngineeringHeavy load

The invention provides a carburizing and quenching deformation control method for gears of a large-sized heavy-load locomotive. The method comprises the steps of laminating two steel plates with the same shapes with spoke plates of gears to sunken parts on two sides of the spoke plates of the gears by virtue of a compensation method, penetrating lightening holes in the spoke plates of the gears by bolts to fix the upper and lower steel plates and avoid relative displacement, sequentially charging the gears of the heavy-load locomotive into a furnace according to design requirements of a conventional process, and carrying out carburizing and quenching. According to the method, two sides of the spoke plates of the gears are clamped and compressed by the upper and lower steel plates, so that the bending of the spoke plates is avoided, the temperature differences among parts of the gears are uniformed, the large thermal stress and the large structural stress caused due to different sectional dimensions are reduced, and therefore, the deformation of the gears is reduced; furthermore, the carburization can be effectively prevented, the manufacturing cost for coating a seepage-proofing agent and maintaining machining allowance is lowered, the production cycle is shortened, and the production efficiency is improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

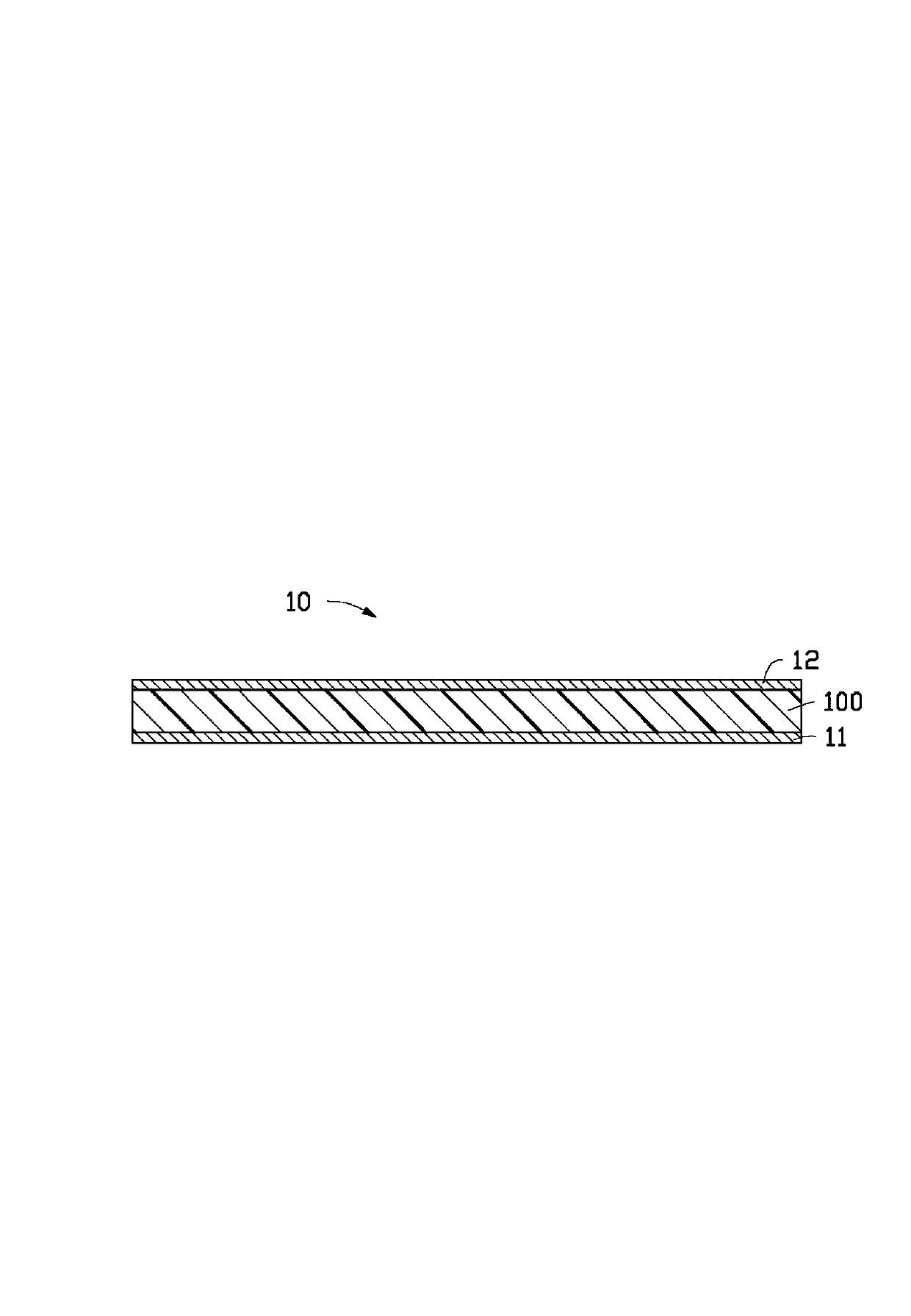

Multilayer circuit board and manufacturing method thereof

ActiveCN103379749AImprove qualityHigh scrap ratePrinted circuit detailsMultilayer circuit manufactureSolder maskCopper foil

The invention provides a manufacturing method of a multilayer circuit board. The manufacturing method includes: (1) providing a circuit substrate, wherein the circuit substrate comprises a substrate body and a first copper foil layer attached to the surface of the substrate body, (2) manufacturing the first copper foil layer into a first conductive line layer, wherein the first conductive line layer is provided with a first exposed zone and a first pressing zone, (3) setting a first solder mask layer in the first exposed zone, (4) pressing a first alkali developable resin layer and a third copper foil layer on one side of the first conductive line layer of the circuit substrate, (5) forming a first opening corresponding to the first exposed zone in the third copper foil layer so as to expose the first alkali developable resin layer corresponding to the first exposed zone, (6) exposing the first alkali developable resin layer exposed out of the first opening, and (7) dissolving the exposed first alkali developable resin layer through an alkali developing solution so as to form a groove, wherein the first solder mask layer is exposed in the groove. The invention further provides the multilayer circuit board manufactured by means of the manufacturing method.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

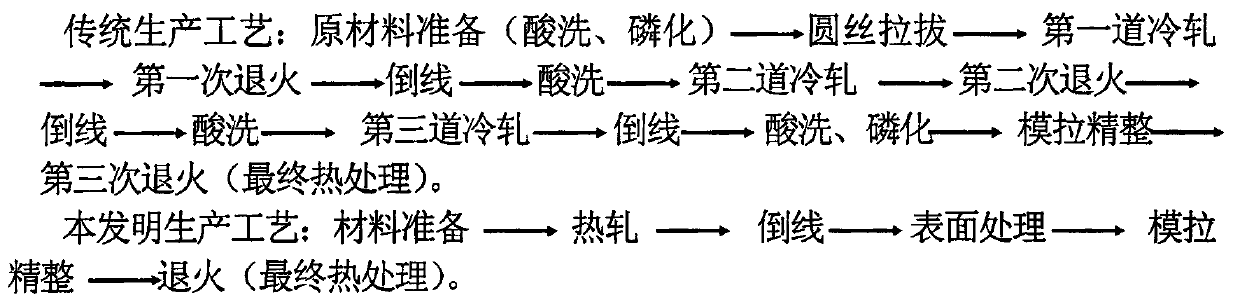

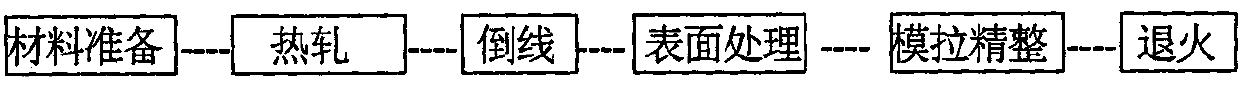

Processing method for flat wire used for tensioning wheel of engine

InactiveCN103357695AImprove productivityHigh scrap rateFurnace typesMetal rolling arrangementsWire rodEngineering

The invention discloses a processing method for a flat wire used for a tensioning wheel of an engine. The processing method comprises the following steps of drawing a carbon steel wire rod or an alloy steel wire rod with the diameter of 11.0-12.0 mm into roulette wounded wire with the diameter of 10.0-10.8 mm; heating the steel wire to a temperature of 900-1,100 DEG C at a heating speed of 6.0-12.0 m / s by power-on heating; rolling the roulette wounded wire to the thickness of 3.4-4.5 mm and the width of 16.5-17.0 mm through a rolling mill once; performing pickling and phosphating surface treatment on the hot-roll flat wire; drawing the wire into the size of a product; winding the wire by a detachable roulette; removing the roulette; and carrying out annealing treatment at a temperature of 650-720 DEG C and keeping the temperature for 2-5 h. The production process can roll the wire into required size once, is high in production efficiency and stable in product quality, can save energy consumption, overcomes the disadvantages of a conventional production process, and omits tedious backwinding and pickling processes.

Owner:SINOSTEEL ZHENGZHOU AOWEI STEEL WIRE TECH

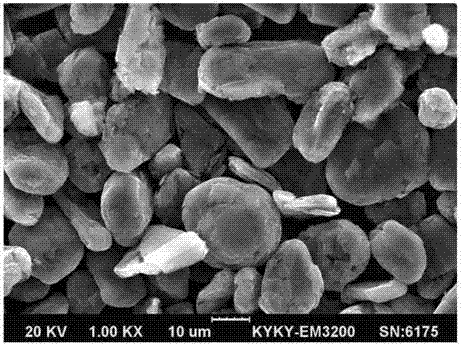

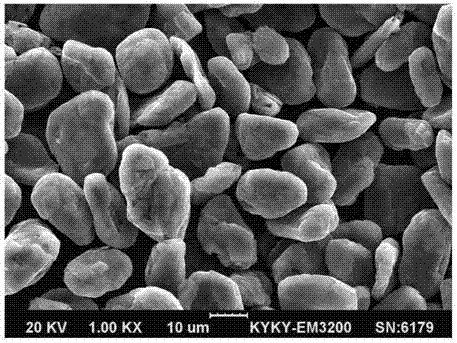

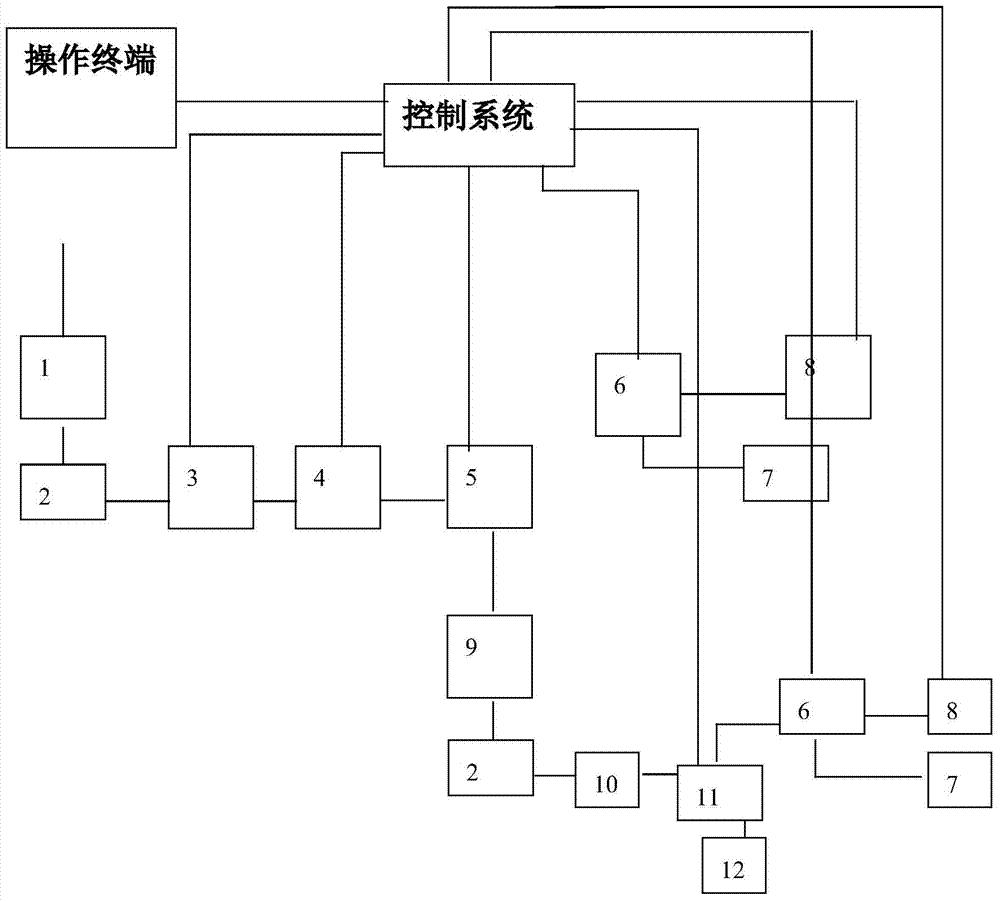

Lithium ion battery carbon negative electrode material grinding shaping technological process and production system thereof

ActiveCN103904302AHigh degree of automationIncrease productivityElectrode manufacturing processesCarbon compoundsElectrical batteryPulverizer

The invention provides a lithium ion battery carbon negative electrode material grinding shaping technological process. The process comprises the following steps: step one, feeding graphite in an inner grading ultra-fine grinding pulverizer, wherein particles with qualified sizes automatically flow out along with airflow under the rotation of an inner grading turbine, and coarse particles fall in a pulverizing area for continuous pulverizing until the particle sizes are qualified; and step two, enabling graphite powder with qualified particle diameters obtained in the step one to flow in a centrifugal classifier along with the airflow, wherein the powder with the particle size of smaller than 35 microns is discharged to a cyclone batcher from an airflow classifier material exhaust hole for collection, and coarse powder is discharged out from a return feeding hole. The ultra-fine grinding pulverizer with an inner grading device is adopted for replacing a plurality of airflow pulverizers to realize ultra-fine grinding, so that qualified fine powder is classified and extracted in time, over crushing is prevented, the product yield is improved, and the production yield is more than 90%.

Owner:ZHANJIANG JUXIN NEW ENERGY +1

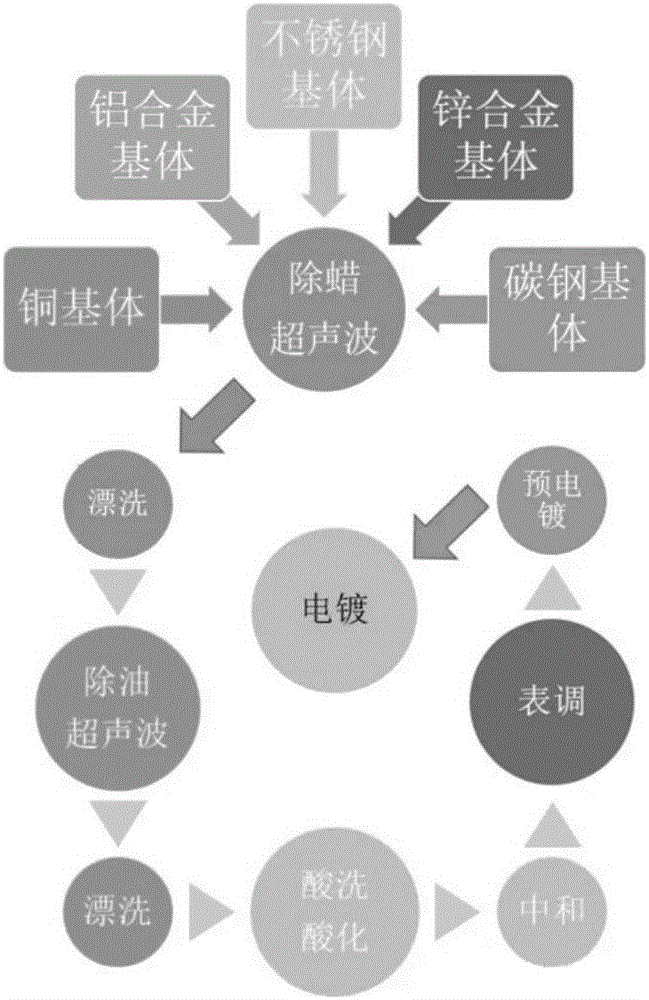

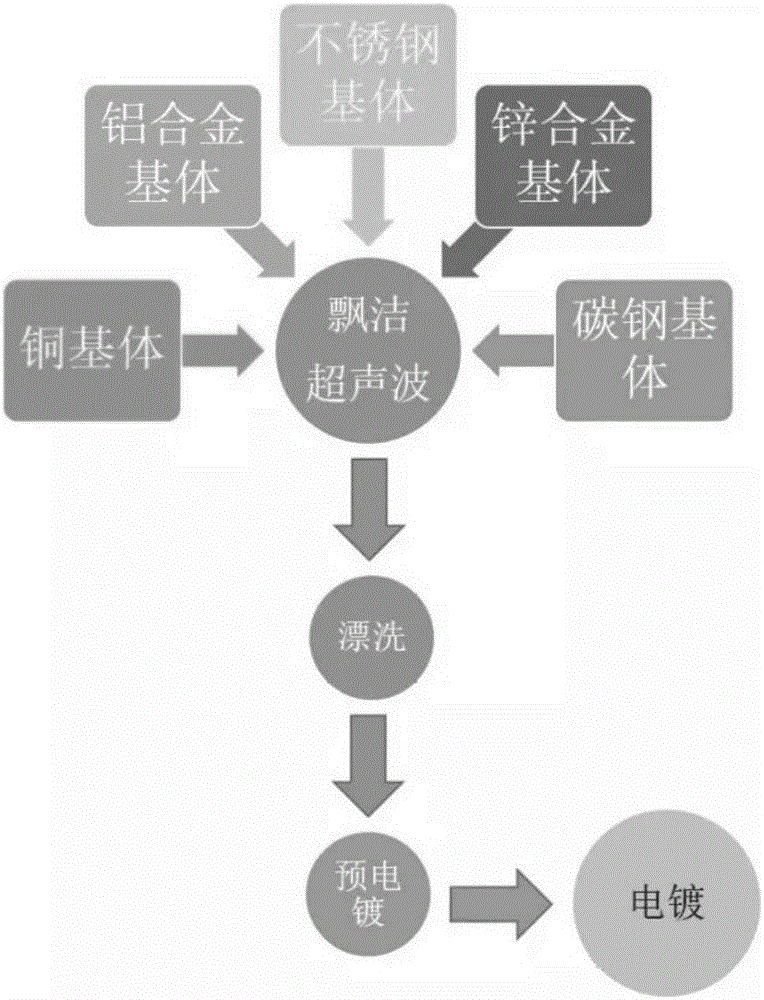

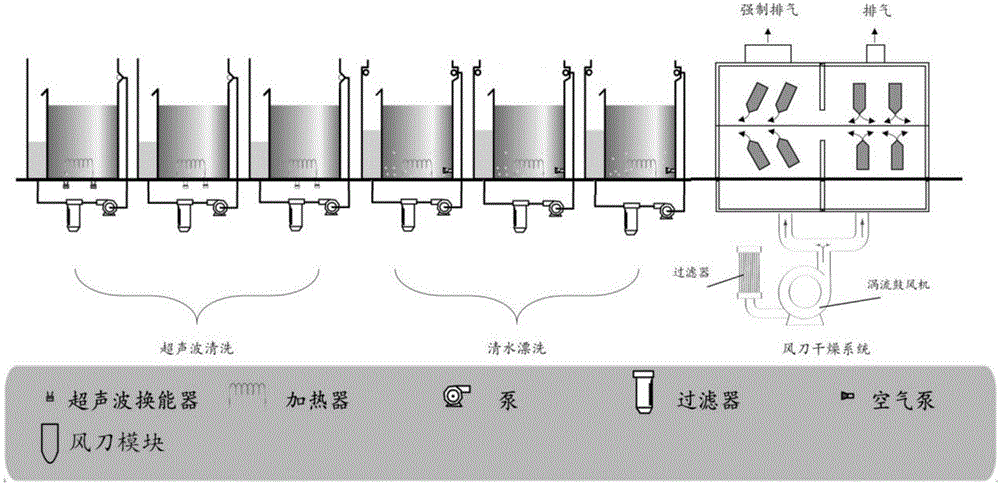

Water-soluble biodegradable cleaning agent and cleaning application method thereof

The invention discloses a water-soluble biodegradable cleaning agent and a cleaning application method of the water-soluble biodegradable cleaning agent. The water-soluble biodegradable cleaning agent comprises, by weight, 1%-15% of organic acid, 5%-20% of a surface active agent, 0.5%-1% of a stabilizer and 78%-79.5% of water. According to the cleaning application method of the water-soluble biodegradable cleaning agent, cleaning liquid containing the water-soluble biodegradable cleaning agent is used for ultrasonic cleaning of parts to be cleaned. According to the water-soluble biodegradable cleaning agent and the cleaning application method of the water-soluble biodegradable cleaning agent, the non-toxic food-grade biodegradable non-strong acid is adopted, the wetting performance, the permeability, the emulsibility, the dispersity, the capacity-increasing performance and the like of the water-soluble biodegradable cleaning agent are utilized, corresponding ultrasonic cleaning equipment is adopted in cooperation, under the mutual synergistic interaction of chemistry and machines, rust, oxides, polishing paste and all kinds of oil stains attached to the surfaces of metal, plastics and ceramics are washed away in a one-off manner; and in this way, traditional acid pickling technologies and the cleaning concept that oil removal, wax removal and oxide removal are executed separately are broken through, the cleaning process is shortened, time and energy are saved, cost is reduced, the safety of the environment and the safety of operators are guaranteed, and the effect of environment-friendly, efficient, energy-saving and safe enterprise production is achieved in real sense.

Owner:上海赛敏环保科技有限公司

Foamed core process for large cross-sections of grab handles

InactiveUS7235200B2Speed up the processLess expensiveButtonsVehicle arrangementsStructural elementElectrical and Electronics engineering

A plastic product for particular use as grab handles, door closure handles, and other trim and component products. A foam core, either structural or non-structural, is over-molded with a hard or soft plastic shell or skin. Structural members for heat staking, mechanical fastenings, and the like, are integrally formed on the ends of the handles in order to affix the handles to a door pillar, door panel, or the like.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

Apparatus and method for handling electronic mail

InactiveUS7624154B2Reduce disruptionHigh scrap rateMultiple digital computer combinationsData switching networksCommunications systemRejection rate

A mail transfer agent adapted for determining the disposition of incoming e-mail from a sender includes a penalty count filter module (20 which functions on the basis of current communication system resource usage, such as the number of concurrent TCP connections being maintained, and penalty counts assigned for cumulative undesirable sender activity such as sending large e-mail files. The penalty count filter module can operate in a selective-rejection state accepting e-mail from senders without a penalty count and randomly accepting other e-mail, and in a random-rejection state rejecting all e-mail from senders with a penalty count and randomly rejecting other e-mail. The rejection rates can be increased or decreased in response to a detected increase or decrease in the usage of system resources.

Owner:NOKIA TECH OY

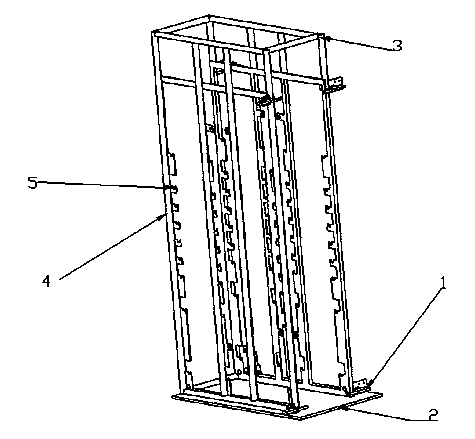

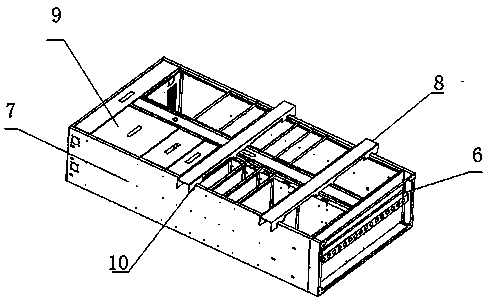

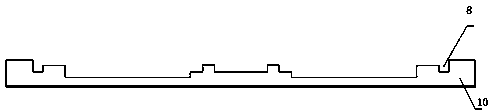

Assembling installing method for express cabinet

ActiveCN104384785AHigh welding technology requirementsLabor intensiveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses an assembling installing method for an express cabinet. According to the method, firstly, express cabinet plates are integrally assembled and spliced together, and then, connecting parts between the plates are welded. The assembling installing method has the advantages that the production and installing mode has low requirements on the welding skill of workers, the work intensity of the workers is reduced, the assembling and welding efficiency is improved under the condition of ensuring the assembling and welding precision, and further, the production efficiency of the finished product of the express cabinet is improved.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

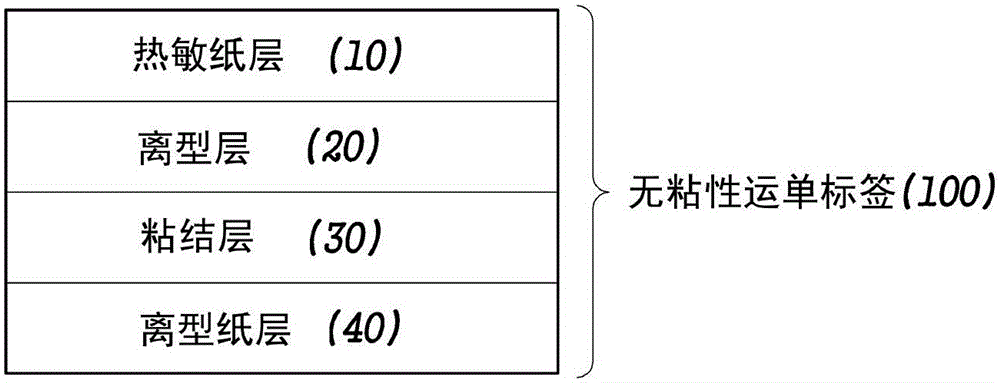

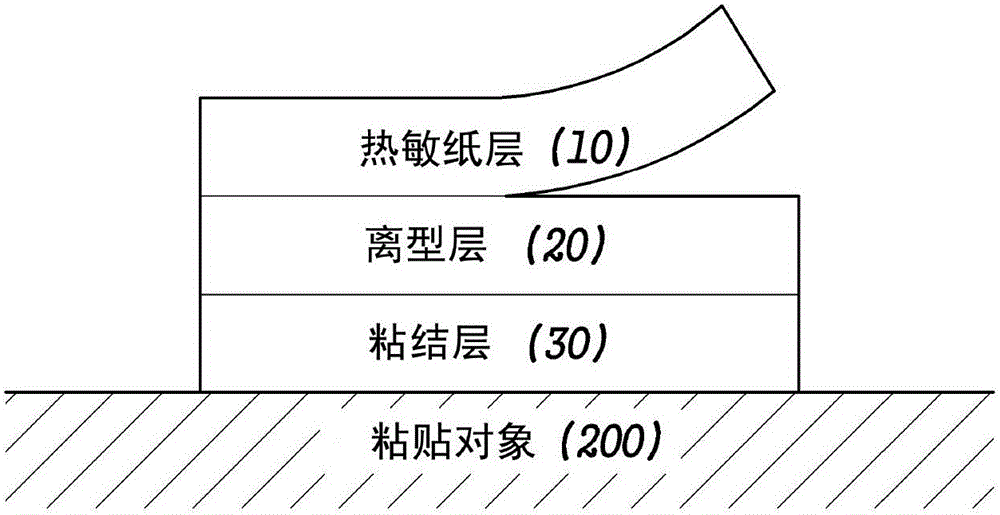

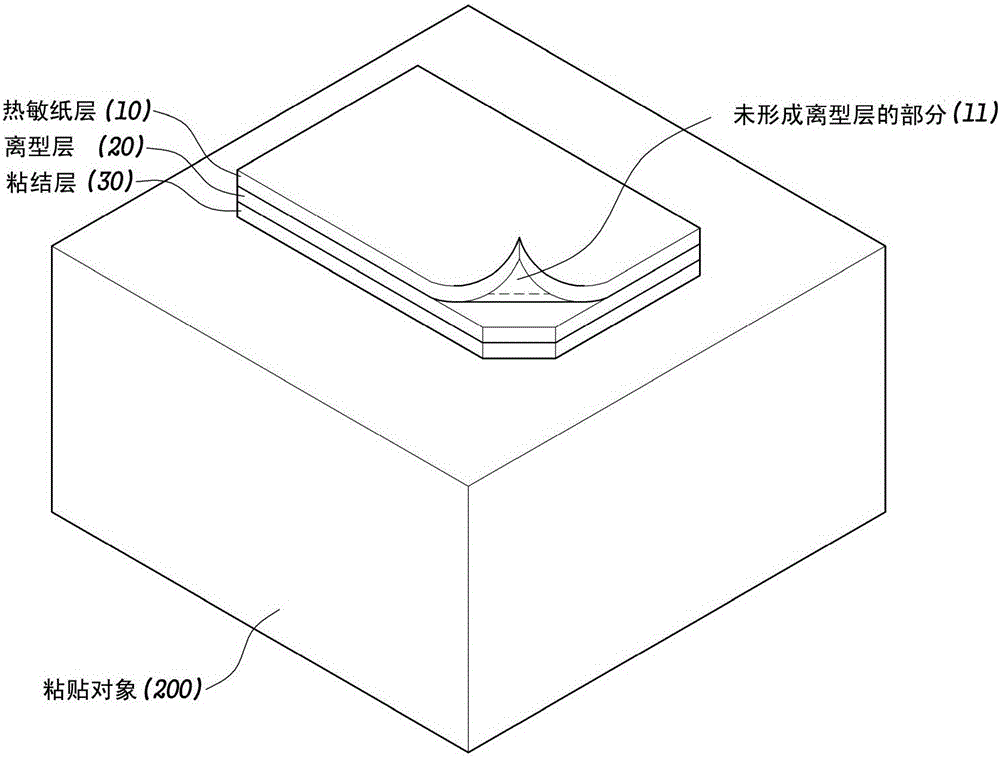

Non-sticking invoice label and manufacturing method thereof

InactiveCN105985744AStickiness will not haveProper adhesionFilm/foil adhesivesPolyether coatingsBiochemical engineeringInvoice

The invention relates to a non-sticking invoice label and a manufacturing method thereof, particularly an invoice label used for express delivery including a surface printable thermo-sensitive paper layer, a sticking layer formed on the back of the thermo-sensitive paper layer, and a release paper layer stuck to the back of the sticking layer. The non-sticking invoice label also comprises a release layer. The release layer is between the back of the thermo-sensitive paper layer and the surface of the sticking layer and is formed by coating a release liquid consisting polyethylene glycol, polyethylene, an emulsifier and water. The release layer is separated from the back of the thermo-sensitive paper layer when the thermo-sensitive paper layer is removed and is left over the surface of the sticking layer, and the part left over the surface of the sticking layer is non-sticking.

Owner:金银铁

Casting-molded large-scale nitride-combined silicon carbide product

ActiveCN103936437AIncrease contact areaFavorable for high temperature nitriding reactionSilicon nitrideAluminium

The invention relates to a casting-molded large-scale nitride-combined silicon carbide product. The product employs silicon carbide particles and powder, silicon carbide micro powder, silicon dioxide micro powder, alumina micro powder, active magnesium oxide and a water reducer as powder materials, employs silica sol as a binder and is molded by employing vibration casting. A molded blank is subjected to maintenance, drying, and high-temperature nitridation processing in nitrogent, so that the nitride-combined silicon carbide product is prepared. By reacting silicon dioxide and silicon carbide in the materials with nitrogen at the conditions of high temperature and nitrogen, silicon nitride is generated and other nitrides are further generated, and thus the combination strength is generated. The products helps to solve the problems and the disadvantages that conventional nitride-combined silicon carbide products generated through nitridation of silicon powder is high in cost and relatively easily have residual silicon, large-scale products cannot be produced, and the like. According to the technical scheme, the large-scale nitride-combined silicon carbide product can be produced and has the advantages of low cost, excellent performances and the like, the prepared silicon carbide product is capable of replacing conventional Si3N4-combined, Si2N2O-combined and Sialon-combined silicon carbide and being applied to fields of steel industry blast furnace air ports and blast furnace cooling wall cast-in bricks, nonferrous metals industry aluminium electrolytic tanks and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com