Sintering and brazing technology of powder metallurgical planet carrier assembly

A powder metallurgy and brazing technology, applied in the development field of automatic transmission planet carrier assembly, can solve problems such as difficulty in forming, and achieve the effects of increasing productivity, reducing costs and enhancing market competitiveness

Inactive Publication Date: 2010-01-06

DONGFENG MOTOR CO LTD

View PDF0 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Due to the presence of transverse grooves, the shape of the planet carrier is difficult to form by traditional processing methods and forming methods, and it is usually processed into two pieces and then welded together

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0059] parameters

[0060]

Embodiment 2

[0062]

Embodiment 3

[0064]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

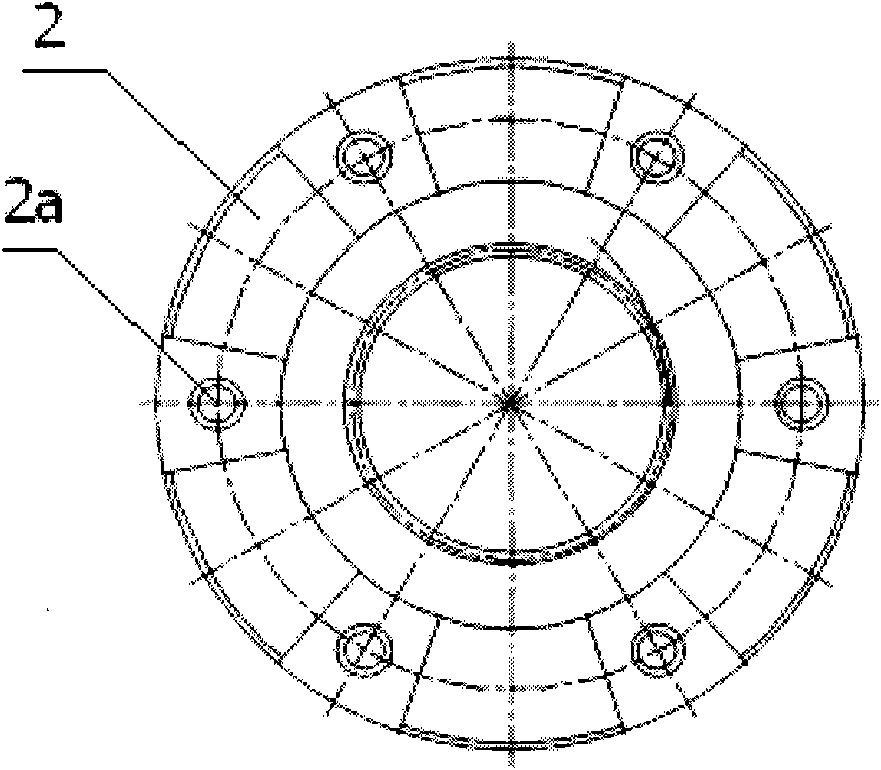

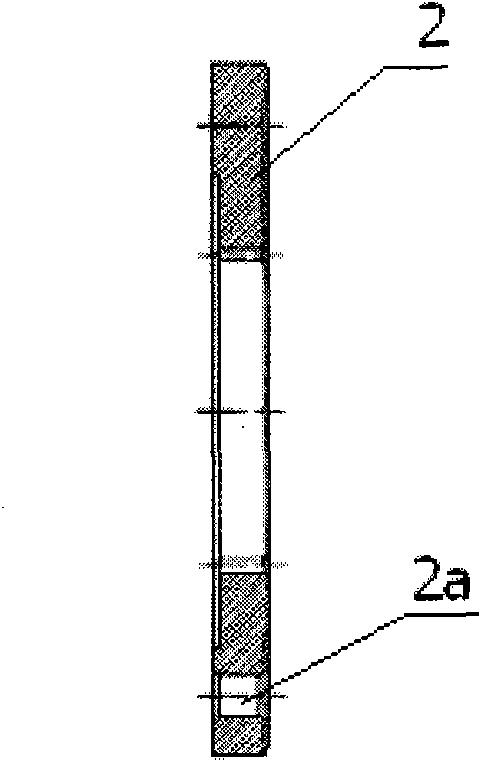

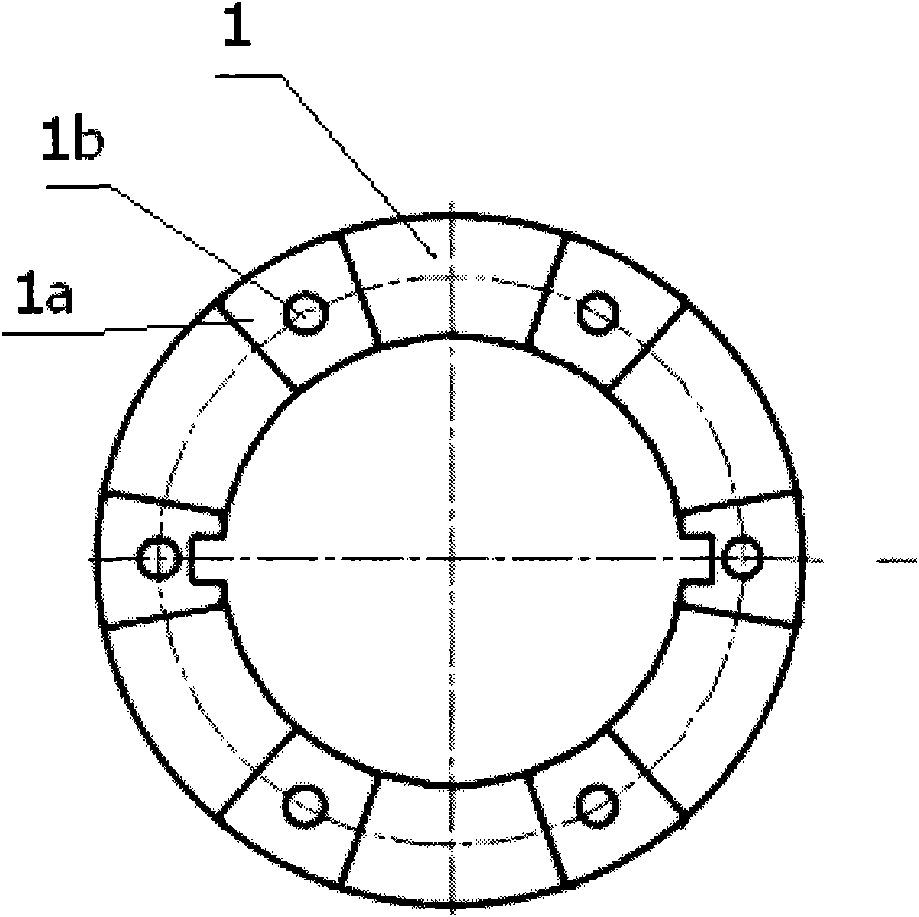

The invention provides a sintering and brazing technology of a powder metallurgical planet carrier assembly, which comprises the following concrete steps: 1. pressing a planet carrier and a planetary gear carrier blank, wherein the planetary gear carrier blank (2) is provided with a solder placing hole (2a) corresponding to a claw of the planet carrier; 2. correspondingly placing the solder placing hole (2a) on the planetary gear carrier blank (2) with a claw (1a) of the planet carrier (1), and putting a solder (3) into the solder placing hole (2a), so as to prepare a planet carrier assembly sintered blank; and 3. putting the planet carrier assembly sintered blank prepared in the step 2 into a sintering and brazing furnace for sintering and brazing simultaneously; sequentially and continuously sintering and brazing in the sintering and brazing furnace for presintering, sintering and cooling, and once finishing the sintering process and the brazing process in the furnace simultaneously to finish manufacturing the assembly. The sintering process and the brazing process are carried out simultaneously and conform to the requirement of the technological parameter in the sintering and brazing furnace.

Description

technical field [0001] The invention relates to a powder metallurgy planetary frame assembly sintering and brazing process, which belongs to the development of the powder metallurgy assembly sintering brazing technology applied to the automatic transmission planetary frame assembly. Background technique [0002] The planet carrier assembly structure, the component planet carrier is a relatively flat plate with holes, and the planet gear carrier is a leg with a plate and extending transversely from the plate. The planetary carrier assembly is the core part of the gear set of the gearbox and transfer case planetary gear mechanism. Its traditional manufacturing mode is that the steel parts are machined and welded together, and then a large amount of machining is added to complete the main process of the part; domestic inquiries have found that two planetary gear frames that match the bracket components are cold-formed using powder metallurgy technology, and welded The planetar...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K28/00B23K1/00B23K35/362B22F3/16

Inventor 华建杰裴学宏孙正军庞羽张明辉

Owner DONGFENG MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com