Water-soluble biodegradable cleaning agent and cleaning application method thereof

A technology of biodegradation and cleaning agents, applied in the field of water-soluble biodegradable cleaning agents, to achieve the effects of saving energy and cleaning costs, shortening the cleaning process, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0047] Embodiments 1-3 respectively provide a water-soluble biodegradable cleaning agent, and the components and contents are shown in Table 1:

[0048]

[0049] The comparison between the products shown in the above-mentioned examples 1-3 and the products of a certain domestic company is shown in Table 2:

[0050] Surface conditions of aluminum, copper, stainless steel, and iron after cleaning and related instructions Example 3 It is ideal for degreasing and deoxidizing the surface of aluminum, copper, stainless steel, iron, etc. a product The oxide layer on the metal surface cannot be completely removed, and there are still oxidation residues

Embodiment 4

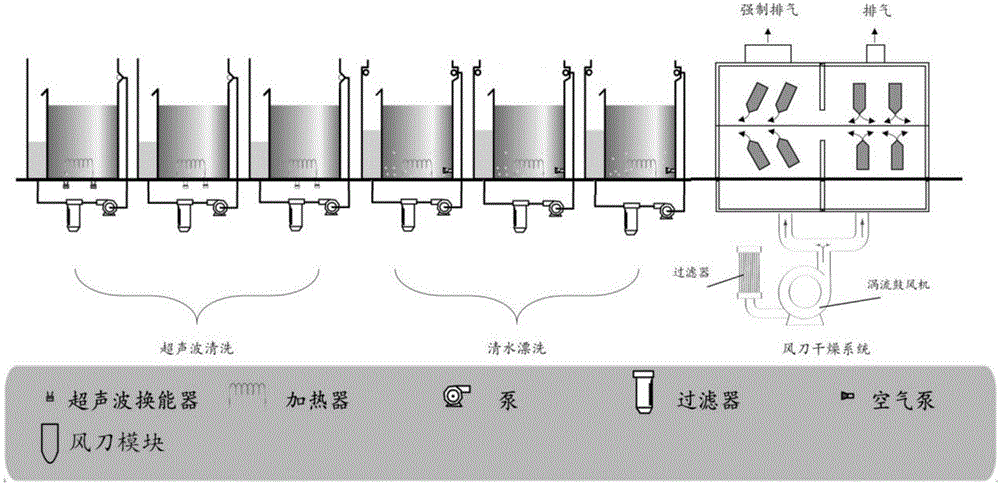

[0052] Based on the water-soluble biodegradable cleaning agent provided in Example 3, this Example 4 provides a cleaning application method (see image 3 ), comprising the steps of: adopting the cleaning solution containing the cleaning agent of embodiment 3 to carry out ultrasonic cleaning on the parts to be cleaned, and then rinsing and drying the parts; the parameters involved are specifically as follows:

[0053] (1) In the cleaning solution, the volume concentration of the cleaning agent is 5%, and the balance is water.

[0054] (2) In the ultrasonic cleaning, the number of ultrasonic cleaning tanks is 3; the ultrasonic wave uses a 25K vibrating head; the volume power per liter is 30W; the cleaning temperature is 45°C; Filtration treatment removes oil and impurities in the cleaning solution, and then returns to the cleaning tank through the water pump for continued use.

[0055] (3) During rinsing, the rinsing liquid used is water, and the rinsing temperature is 45°C; af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com