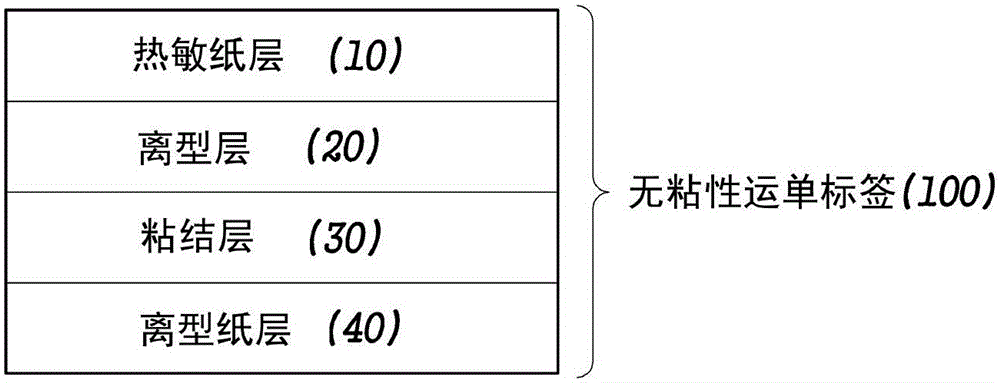

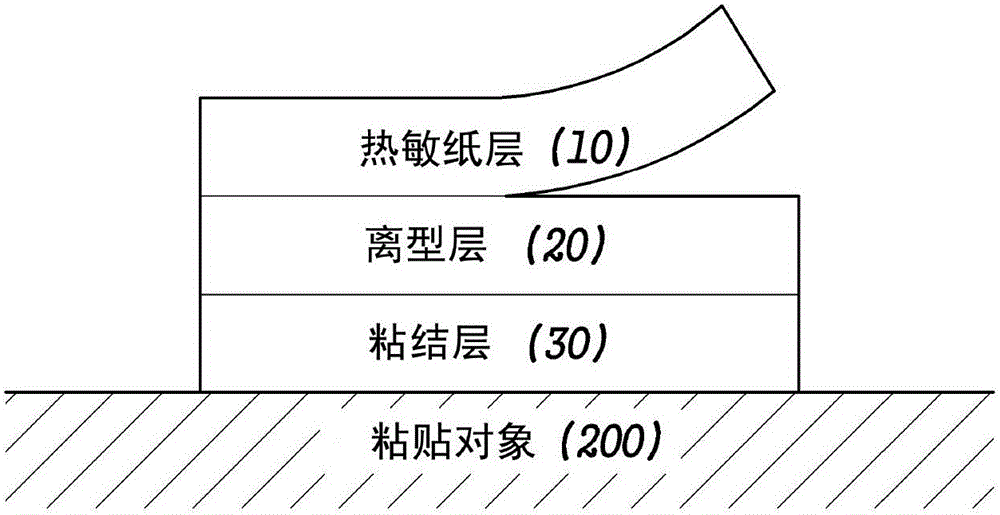

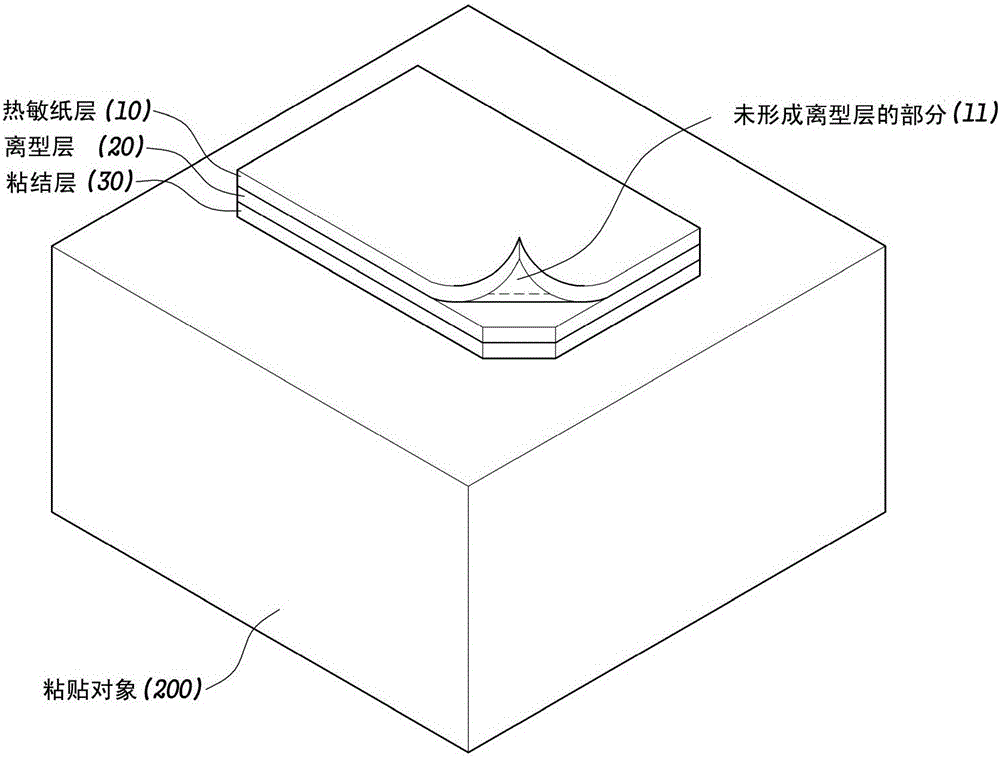

Non-sticking invoice label and manufacturing method thereof

A production method and non-stick technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problem of reducing the production cost and reject rate, to simplify the complex structure and production process, excellent non-stickiness, and reduce the reject rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Mix 40.00% by weight of distilled water and 3.00% by weight of emulsifier in a reactor, and while maintaining a temperature of 70°C, take out polyethylene glycol with a molecular weight of 2,000 to 150,000 and stir to prepare stable polyethylene glycol alcohol solution. A stable polyethylene aqueous solution was prepared by mixing 1.89% by weight of polyethylene having a molecular weight of 300˜10000 and 0.21% by weight of an emulsifier into 4.90% by weight of water. Add 7.00% by weight of the polyethylene glycol aqueous solution to 93.00% by weight of the polyethylene glycol aqueous solution, and keep stirring for 30 minutes to complete the release coating solution. The release layer 20 is formed between the thermal paper layer 10 and the adhesive layer 30 using the release coating liquid 21 having the above composition.

Embodiment 2

[0062] Mix 40.50% by weight of distilled water and 0.50% by weight of emulsifier in a reactor, and while maintaining a temperature of 70°C, take out 58.00% by weight of polyethylene glycol with a molecular weight of 2,000 to 150,000 and stir to prepare a stable aqueous polyethylene glycol solution. 0.27% by weight of polyethylene having a molecular weight of 300˜10000 and 0.03% by weight of an emulsifier were mixed into 0.70% by weight of water, thereby preparing a stable polyethylene aqueous solution. Add 1.00% by weight of the polyethylene glycol aqueous solution to 99.00% by weight of the polyethylene glycol aqueous solution, and keep stirring for 30 minutes to complete the release coating solution. The release layer 20 is formed between the thermal paper layer 10 and the adhesive layer 30 using the release coating liquid 21 having the above composition.

Embodiment 3

[0064] Mix 26.86% by weight of distilled water and 3.14% by weight of emulsifier in a reactor, and while maintaining a temperature of 70°C, take out 30.00% by weight of polyethylene glycol with a molecular weight of 2,000 to 150,000 and stir to prepare a stable aqueous polyethylene glycol solution. A stable polyethylene aqueous solution was prepared by mixing 10.80% by weight of polyethylene having a molecular weight of 300˜10000 and 1.20% by weight of an emulsifier into 28.00% by weight of water. Add 40.00% by weight of the polyethylene glycol aqueous solution to 60.00% by weight of the polyethylene glycol aqueous solution, and keep stirring for 30 minutes to complete the release coating solution. The release layer 20 is formed between the thermal paper layer 10 and the adhesive layer 30 using the release coating liquid 21 having the above composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com