Laser additive manufacturing forming method of titanium alloy thin-walled component

A thin-walled component and laser additive technology, applied in the directions of additive manufacturing, additive processing, and process efficiency improvement, can solve the problems of limited casting precision, long development cycle, and difficult control of casting quality, and achieve a shortened manufacturing cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

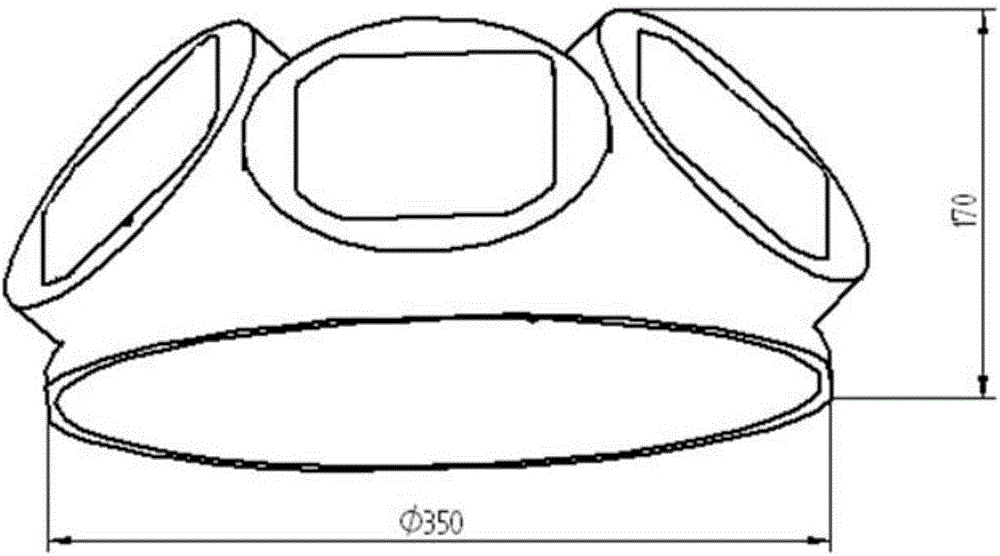

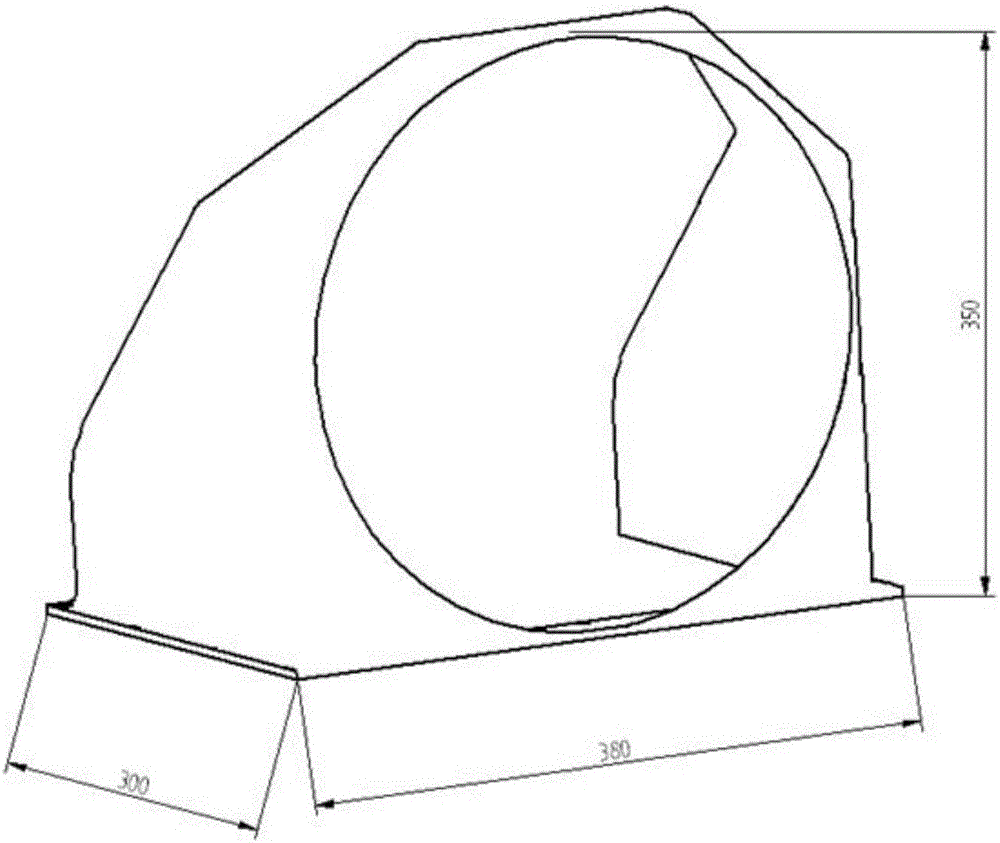

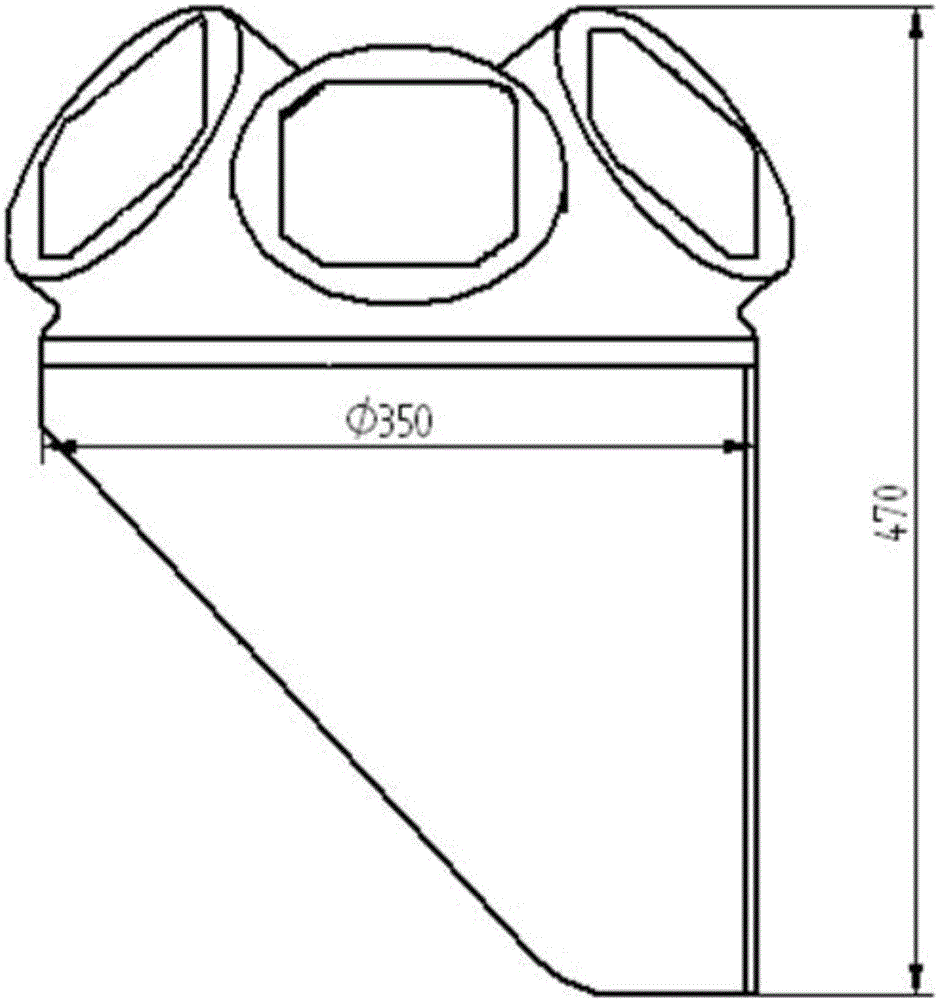

[0030] A laser additive manufacturing forming method for titanium alloy thin-walled components, such as Figure 1~3 As shown, the titanium alloy thin-walled member includes a support cylinder composed of three cylinders and a plate-shaped bottom bracket. The steps of the method include:

[0031] (1) The bottom bracket and the support cylinder are respectively formed by the method of laser selective melting and forming. The process parameters during forming are: laser power is 350W, spot diameter is 0.08mm, scanning speed is 1100mm / s, and powder coating thickness is 0.03mm ;

[0032] (2) Carry out heat treatment on the bottom bracket with base plate and support and support tube with base plate and support at the same time. The process parameters of heat treatment are: temperature is 800°C, holding time is 2.5h, working pressure is 1×10 -3 Pa, cooling with the furnace after the heat preservation is over;

[0033] (3) Carry out wire cutting to the heat-treated bottom bracket an...

Embodiment 2

[0038] (1) The bottom bracket and the support cylinder are respectively formed by laser selective melting and forming. The process parameters during forming are: laser power 360W, spot diameter 0.07mm, scanning speed 1200mm / s, powder coating thickness 0.04mm ;

[0039] (2) Carry out heat treatment on the bottom bracket with base plate and support and the support cylinder with base plate and support at the same time. The process parameters of heat treatment are: temperature is 810°C, holding time is 2h, working pressure is 1×10 -3 Pa, cooling with the furnace after the heat preservation is over;

[0040] (3) Carry out wire cutting to the heat-treated bottom bracket and the support tube, remove the substrate, and obtain only the bottom bracket and the support tube with support;

[0041] (4) remove the support of the bottom bracket and the support cylinder, obtain the bottom bracket and the support cylinder, and polish and sandblast the surface of the bottom bracket and the supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com