Thin vermicelli and/or vermicelli vertical cooler

A technology of cooler and vermicelli, applied in the field of vermicelli vertical cooler and vermicelli, can solve the problems of unstable product quality, low production efficiency, high rejection rate, and achieve improved production efficiency and product quality, low equipment failure rate, and economical The effect of producing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

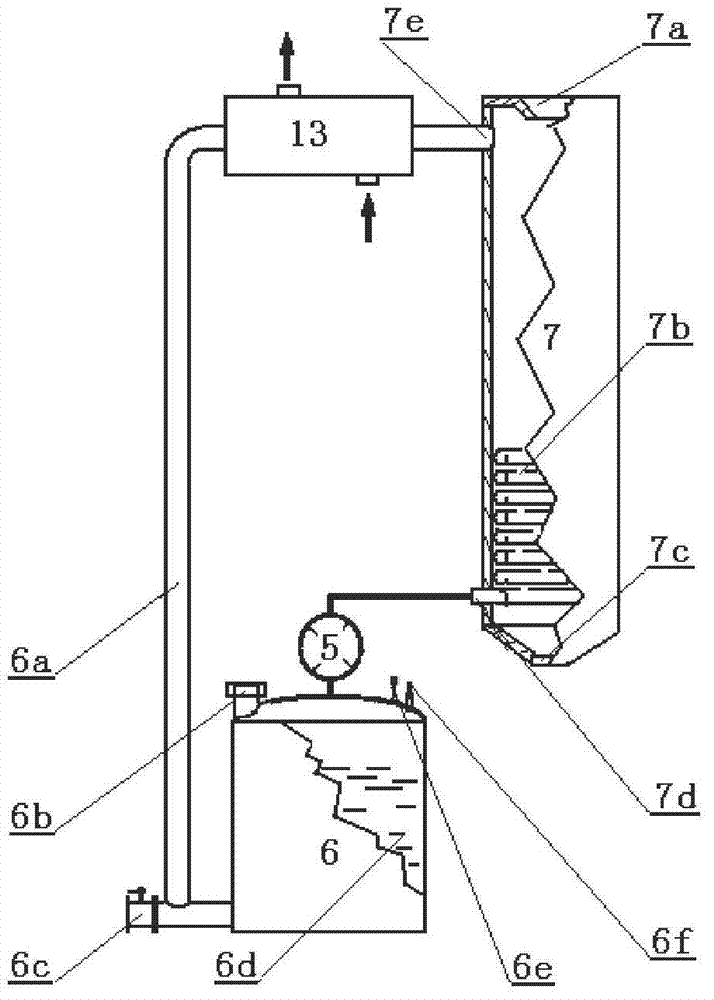

[0023] The vertical cooler for vermicelli and vermicelli is equipped with air cooler 5, cooling tank 6, cooler 7 and heat exchanger 13. The cooler 7 is provided with an air distributor 7b, a thread inlet 7a, a thread outlet 7c, a cooling air inlet 7d, and a cooling air outlet 7e. The outer shell of the cooler 7 is set as a cylindrical stainless steel cylinder, the wire inlet 7a of the cooler 7 is set as a circular outer horn, and the wire outlet 7c is set as a circular inner horn. The air distributor 7b is provided with a coil pipe with evenly distributed air holes, and is fixed in the lower section of the cooler 7. The cooling air outlet 7e is provided at the upper end of the cooler 7. The cooler 7, the air cooler 5, the cooling tank 6 and the heat exchanger 13 are cyclically connected in sequence. Cooling tank 6 is provided with air pipe 6a, liquid filling port 6b, valve 6c, cooling liquid 6d, vacuum gauge 6e and thermometer 6f, valve 6c is provided at the lower end of cool...

Embodiment 2

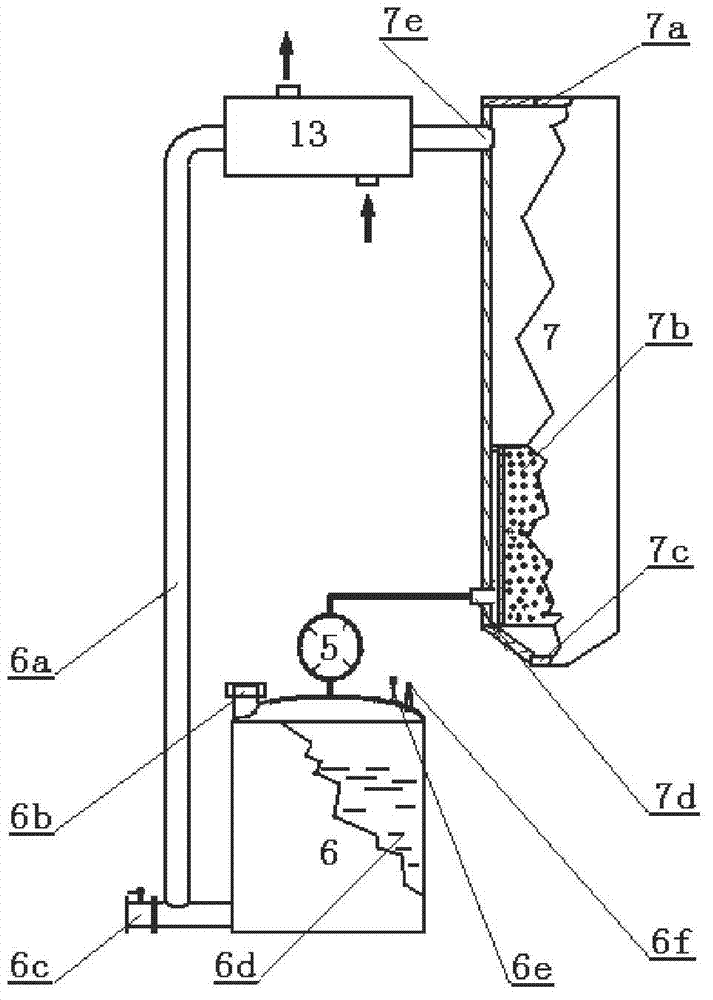

[0026] The vertical cooler for vermicelli and vermicelli is equipped with air cooler 5, cooling tank 6, cooler 7 and heat exchanger 13. The cooler 7 is provided with an air distributor 7b, a thread inlet 7a, a thread outlet 7c, a cooling air inlet 7d, and a cooling air outlet 7e. The outer shell of the cooler 7 is set as a square cylindrical stainless steel cylinder, the wire inlet 7a of the cooler 7 is set as a square flat opening; the wire outlet 7c is set as a square inner horn. The air distributor 7b is provided with a square cloth air pattern plate with evenly distributed air holes, and the upper and lower ends of the square cloth air pattern plate are welded with the outer shell of the cooler 7. The cooling air outlet 7e is provided at the upper end of the cooler 7. The cooler 7, the air cooler 5, the cooling tank 6 and the heat exchanger 13 are cyclically connected in sequence. Cooling tank 6 is provided with air pipe 6a, liquid filling port 6b, valve 6c, cooling liqui...

Embodiment 3

[0029] The vertical cooler for vermicelli and vermicelli is equipped with air cooler 5, cooling tank 6, cooler 7 and heat exchanger 13. The cooler 7 is provided with an air distributor 7b, a thread inlet 7a, a thread outlet 7c, a cooling air inlet 7d, and a cooling air outlet 7e. The outer shell of the cooler 7 is set as a rectangular plastic cylinder, the wire inlet 7a of the cooler 7 is set as a rectangular outer bell mouth; the wire outlet 7c is set as a rectangular inner bell mouth. The air distributor 7b is provided with rectangular plastic cloth air pattern plates with uniform vents, and the upper and lower ends of the rectangular plastic cloth air pattern plates are welded to the outer shell of the rectangular plastic cylinder cooler 7. The cooling air outlet 7e is provided at the upper end of the cooler 7. The cooler 7, the air cooler 5, the cooling tank 6 and the heat exchanger 13 are cyclically connected in sequence. Cooling tank 6 is provided with air pipe 6a, liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com