Processing method for flat wire used for tensioning wheel of engine

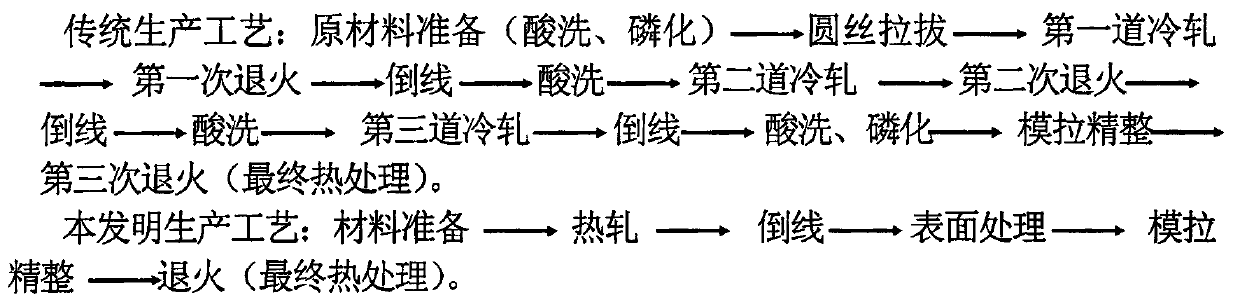

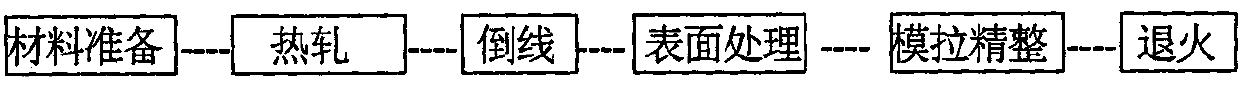

A processing method and tensioning wheel technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of uncontrollable flat steel wire width, long production cycle, low productivity, etc., and reduce the tedious line down and pickling process. , energy saving, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The thickness of the flat steel wire for the engine tensioner described in this embodiment is 3.2 ± 0.04 × 16.0 ± 0.08mm, and both sides are flat steel wires with free arcs. The processing method comprises the following steps:

[0028] (1) Material preparation. The 60Si2Mn alloy steel wire rod with a diameter of 11.0mm is pickled and phosphating treated, drawn to a diameter of 10.2±0.02mm, and the wire is taken up by the roulette. Among them, pickling and phosphating are conventional processes in the production of metal products; drawing is carried out on a known 1 / 900 horizontal dry drawing machine, and the drawing speed is 40m / min. During the drawing process, the water cooling of the mold box and the reel is sufficient, the mold is well cooled, and the head and tail of the whole steel wire are within the tolerance range, that is, not out of tolerance; the straightness of the drawn steel wire is good, so that the steel wire can smoothly enter the rolling mill guide dur...

Embodiment 2

[0035] The thickness of the flat steel wire for the engine tensioner described in this embodiment is 3.9 ± 0.04 × 16.0 ± 0.08mm, and both sides are flat steel wires with free circular arcs. The processing method comprises the following steps:

[0036] (1) Material preparation: pickling and phosphating the 60Si2Mn alloy steel wire rod with a diameter of 12.0mm, drawing it to a diameter of 10.8±0.02mm, and taking it up on the roulette. Among them, pickling and phosphating are conventional processes in the production of metal products; drawing is carried out on a known 1 / 900 horizontal dry drawing machine, and the drawing speed is 40m / min. During the drawing process, the water cooling of the mold box and the reel is sufficient, the mold is well cooled, and the head and tail of the whole steel wire are within the tolerance range, that is, not out of tolerance; the straightness of the drawn steel wire is good, so that the steel wire can smoothly enter the rolling mill guide during h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com