Circular rubber pad cutting device

A rubber pad and circular technology, which is applied in the field of circular rubber pad interception devices, can solve the problems of slow rubber pad interception, rubber pad stuck in the mold, rubber sheet cannot be delivered on time, etc., to improve Utilization rate and the effect of reducing leftovers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

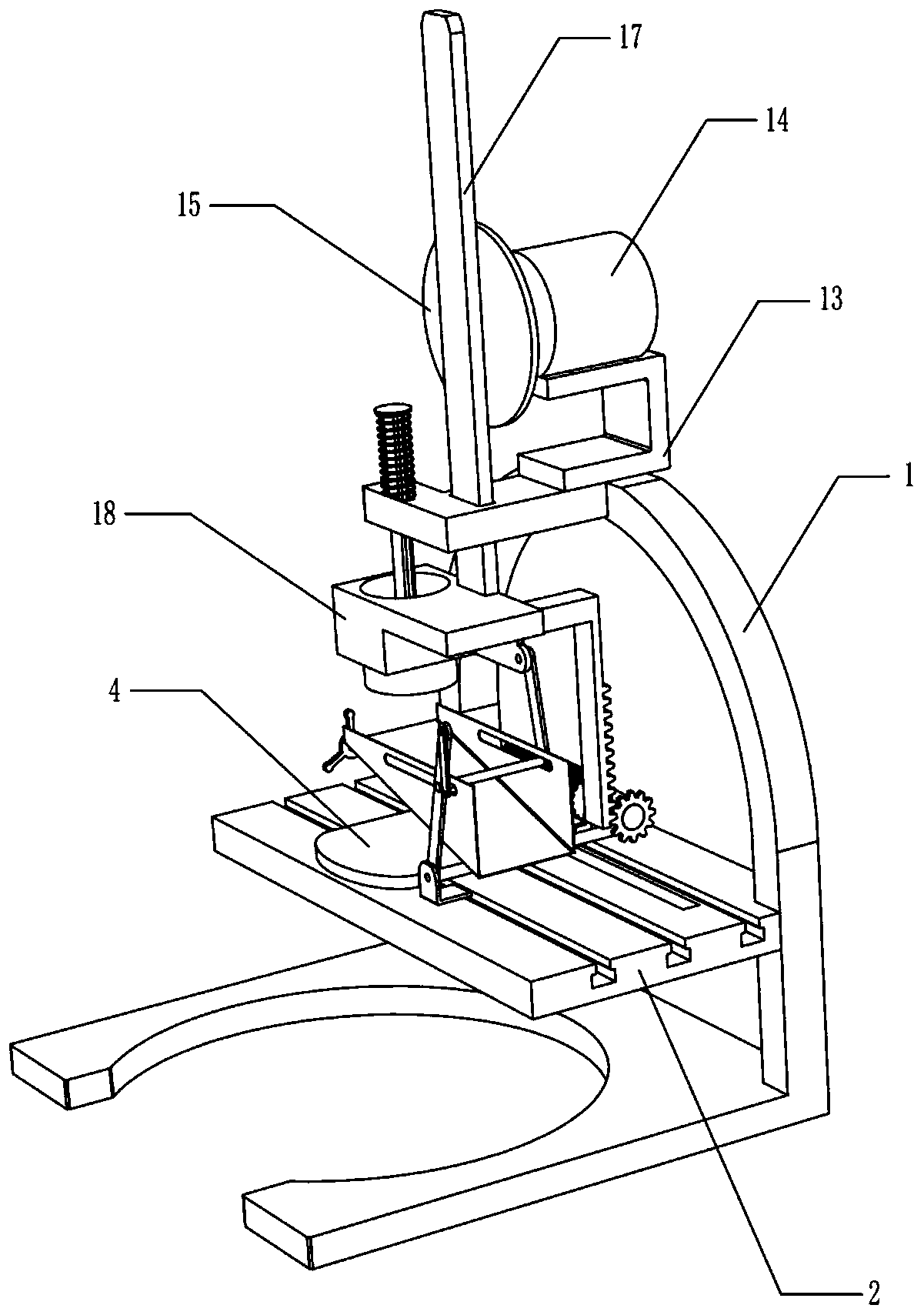

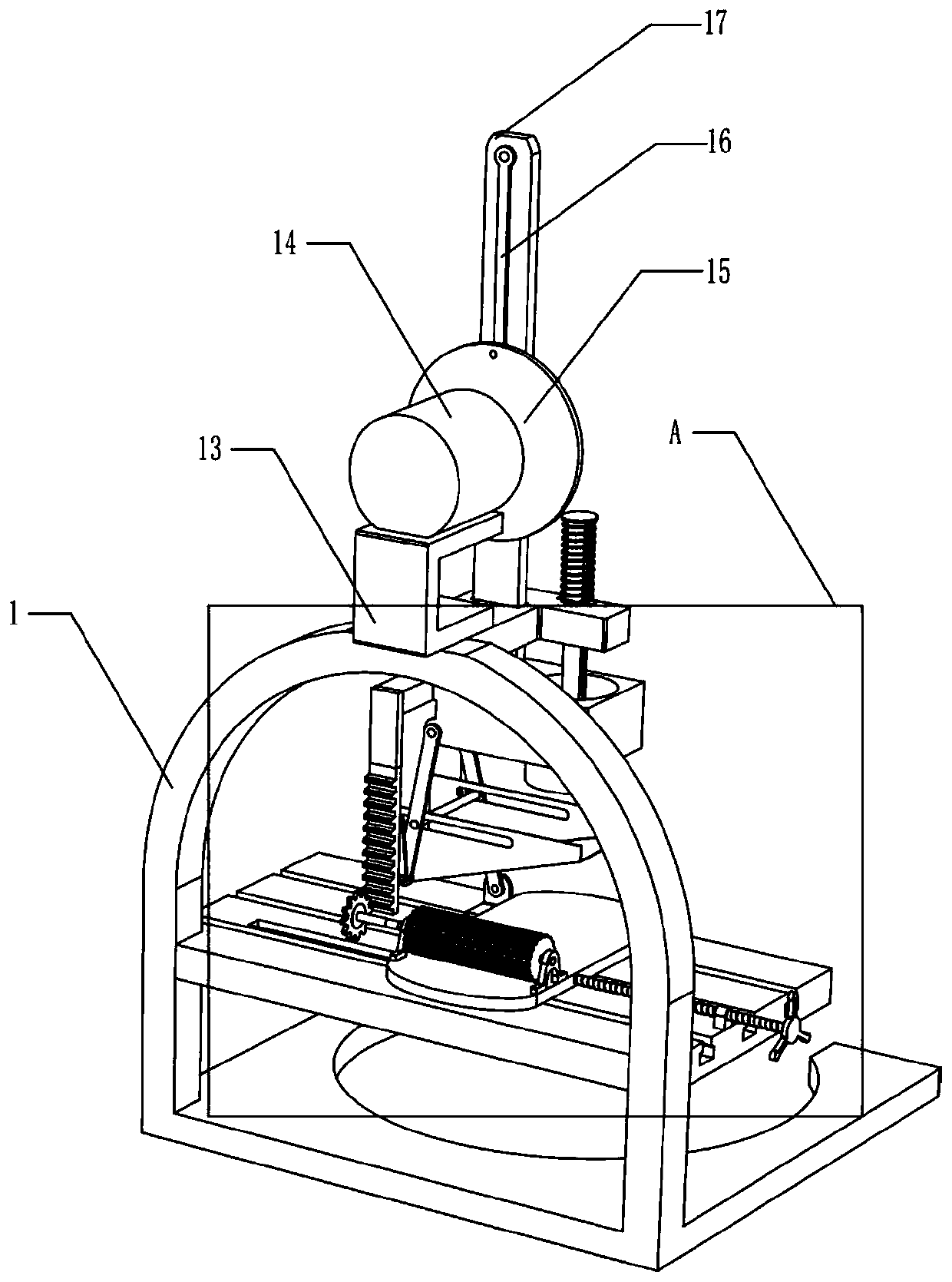

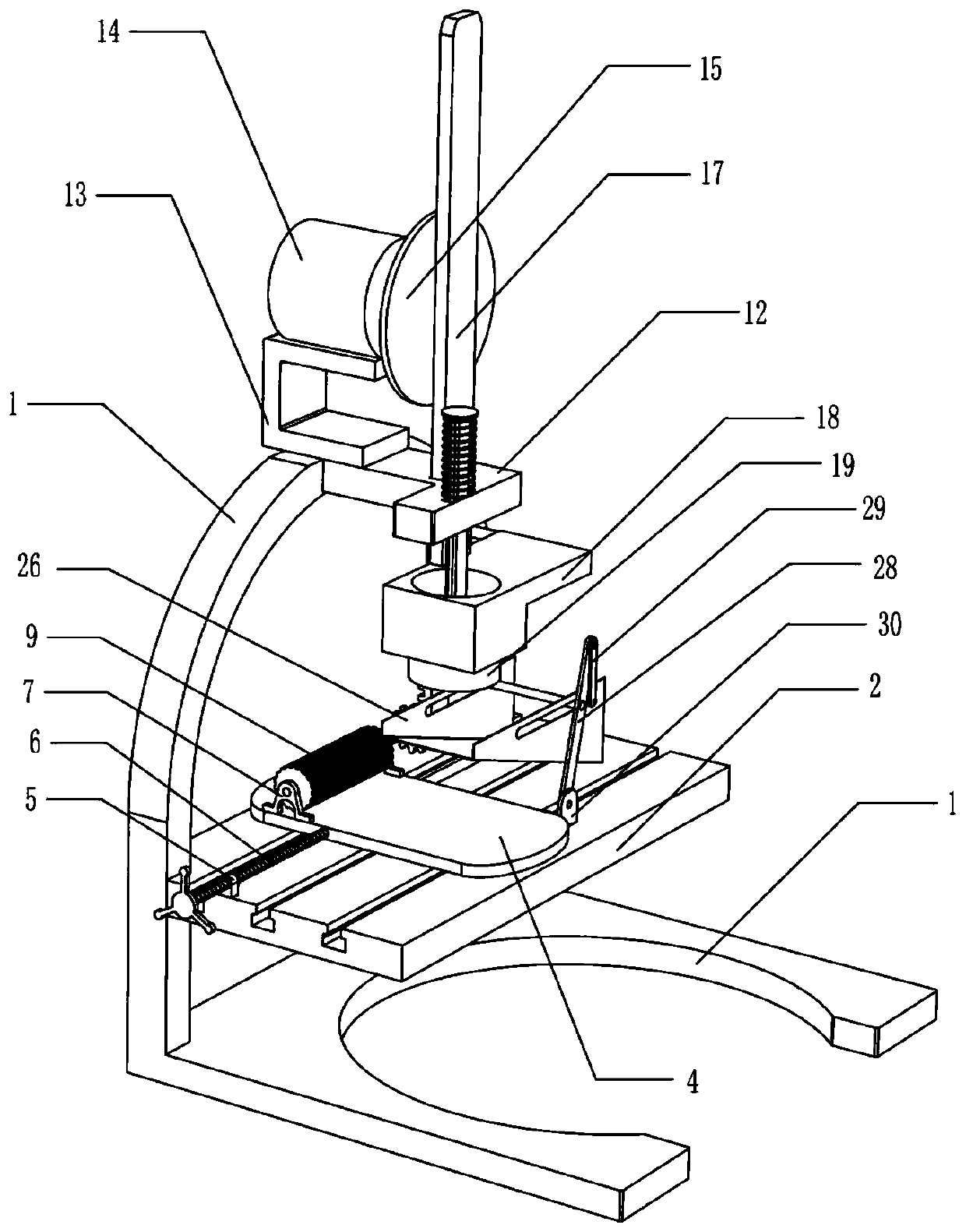

[0023] A circular rubber mat intercepting device such as Figure 1-7 As shown, it includes outrigger 1, slide rail 2, slider 3, support plate 4, fixed seat 7, fixed plate 12, support seat 13, motor 14, turntable 15, transmission connecting rod 16, guide rod 17, hollow Plate 18, circular cutter 19, rack 20, adjustment mechanism and transmission mechanism, the slide rail 2 is fixedly installed on the leg 1 and has three slideways, and the three slide blocks 3 are slidably installed on the slide On the rail 2, the support plate 4 used to place the raw material of the rubber sheet is fixedly installed on the slider 3, and the two fixed seats 7 are fixedly installed on the upper side of the support plate 4, and are arranged symmetrically. The fixed plate 12 The rear end is fixedly installed on the front side of the leg 1 and above the support plate 4, the support seat 13 which plays a supporting role is fixedly installed on the leg 1 and is located on the upper side of the fixed pl...

Embodiment 2

[0025] On the basis of Example 1, such as Figure 1-7 As shown, the adjustment mechanism includes a nut 5 and a screw rod 6, the nut 5 is fixedly installed on the slide rail 2 and is located on the left side of the support plate 4, the screw rod 6 is sleeved in the nut 5, and the right end of the screw rod 6 is connected to the support plate The left side of the plate 4 is rotationally connected, and the operator can adjust the position of the support plate 4 by rotating the screw 6 .

[0026] After the work of cutting a circular rubber pad is completed, the transmission mechanism that can transmit the raw material of the rubber sheet forward includes a rotating shaft 8, a transmission wheel 9, an overrunning clutch 10 and a gear 11. The rotating shaft 8 is rotatably installed on two fixed On the seat 7, and the right end of the rotating shaft 8 passes through the fixed seat 7 close to the rack 20, and the transmission wheel 9, which plays the role of transmitting the raw mate...

specific Embodiment approach

[0029] Specific implementation method: when it is necessary to cut a whole piece of rubber sheet into several circular rubber pads, first place the rubber sheet on the support plate 4 manually, and adjust the position of the support plate 4 through the adjustment device to make the rubber sheet move to the right To the circular cutter 19 below.

[0030]Then manually turn on the motor 14 to rotate clockwise, which drives the rotating disk 15 to rotate clockwise. Under the action of the transmission connecting rod 16, the guide rod one 17 is moved downward, and the hollow plate 18 fixedly connected with the guide rod one 17 lower ends also moves downward. , the circular cutter 19 moves downward with the hollow plate 18, and at the same time the rack 20 fixedly connected to the rear side of the hollow plate 18 moves downward, and the gear 11 meshing with the rack 20 rotates counterclockwise, but when the overrunning clutch 10 Under action, gear 11 can not drive transmission wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com