Automatic molding device

A molding and mold technology, applied in the field of automatic molding equipment, can solve the problems of non-recyclable, increased production funds, material damage, etc., and achieve the effect of saving funds, improving utilization rate, and saving leftover materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with specific examples.

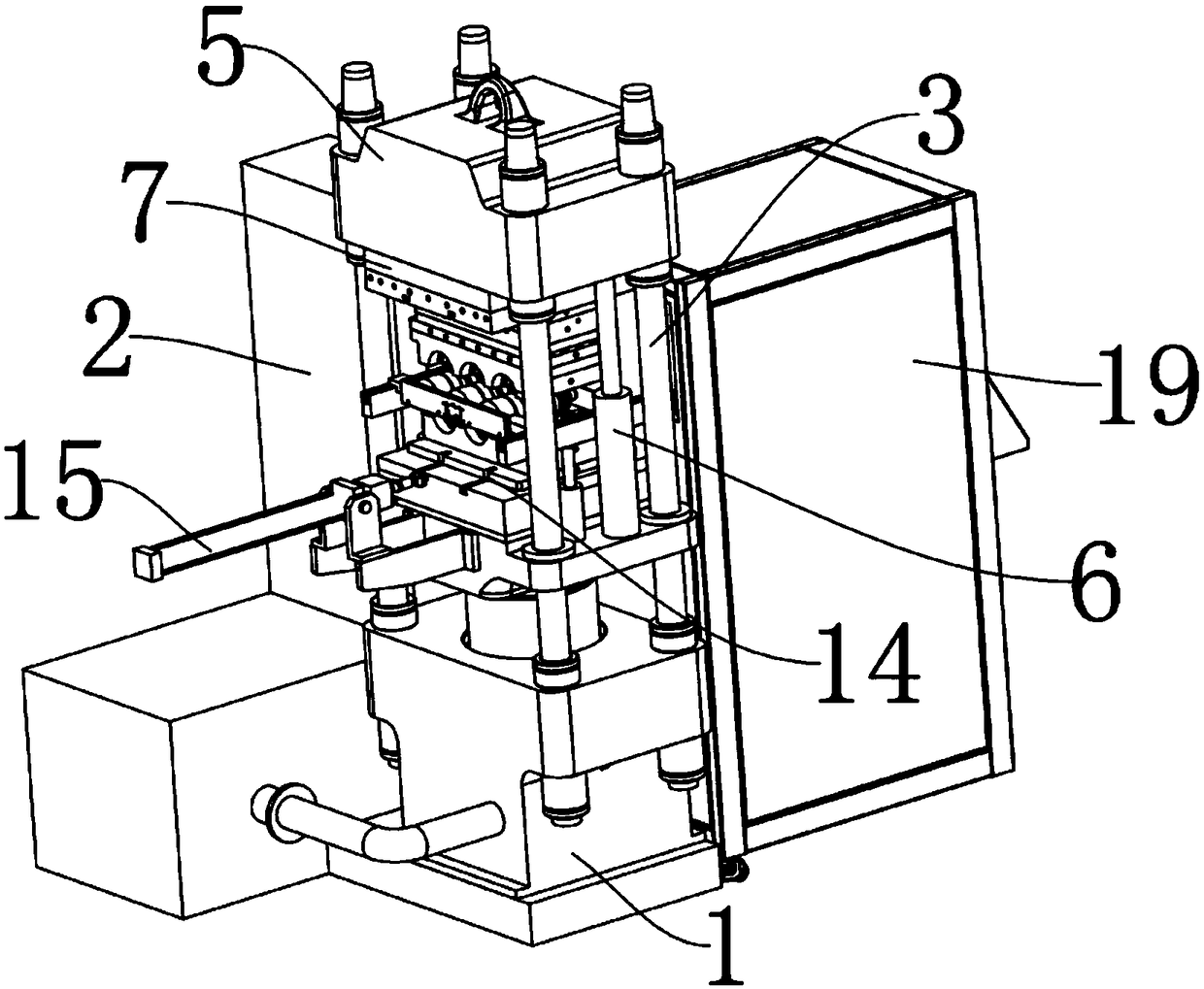

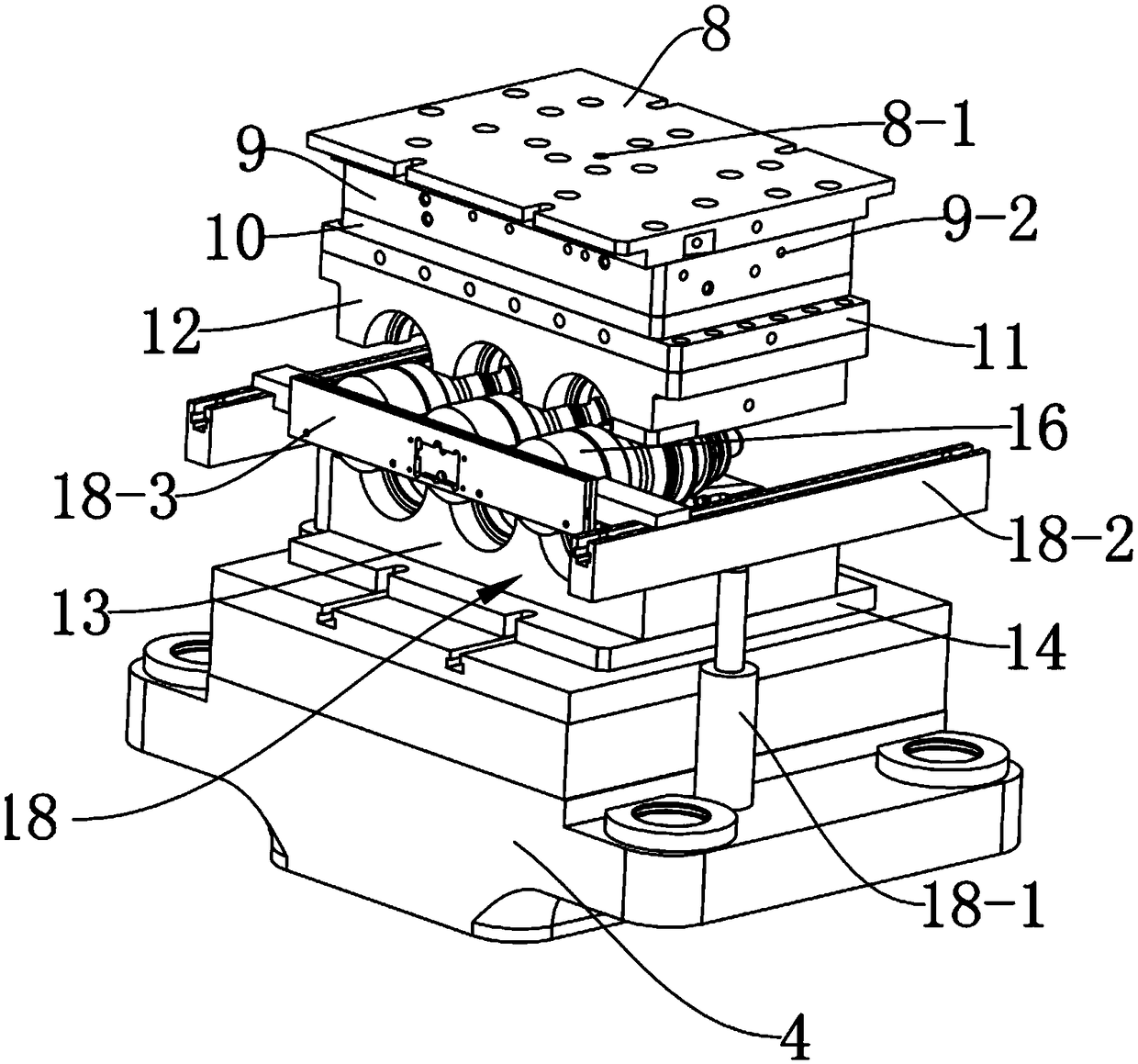

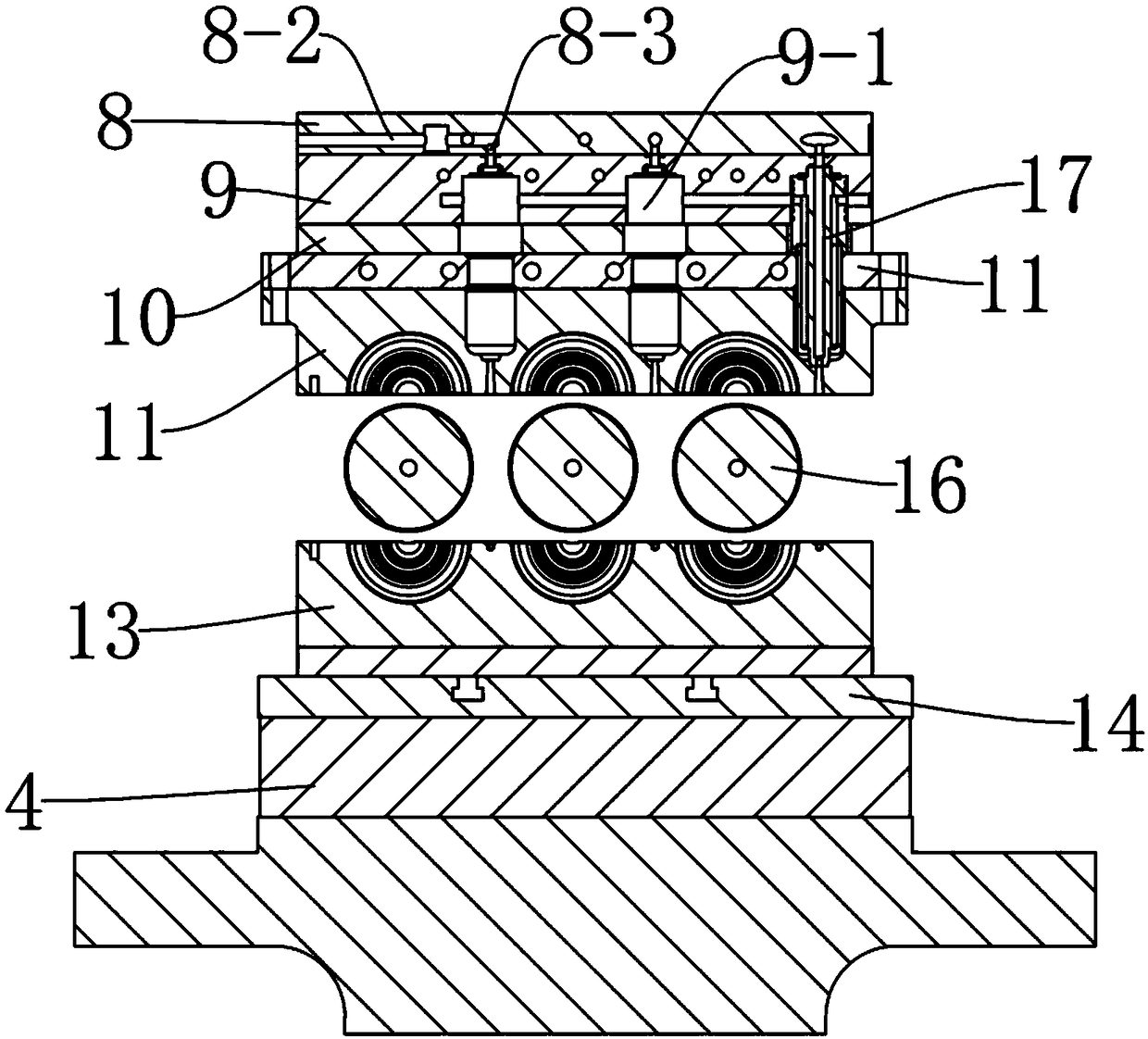

[0039] Such as figure 1 As shown, an automatic molding device includes a body 1, a control box 2 is arranged beside the body 1, the control box 2 is equipped with a PLC control system, a base 4 is arranged on the body 1, a guide column 3 is arranged on the body 1, and a guide column 3 is arranged on the body 1. There are four pillars 3 , the four guide pillars 3 are respectively arranged on the four corners of the base 4 , and the four guide pillars 3 all run through the base 4 . The upper mold beam 5 is slidably arranged on the guide pillar 3, and the upper mold beam 5 is provided with a sliding sleeve 23-2 which can slide on the guide pillar 3. The base 4 is provided with a first lifting part 6 connected to the upper mold beam 5, the first lifting part 6 is set as the first driving cylinder, and the first driving cylinder is set to two, and the two first driving cylinders are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com