Mandrel structure of circular saw machine for preferably cutting timber in longitudinal direction

A circular saw machine and saw shaft technology, applied in the field of wood processing, can solve the problems of inability to optimize, high labor intensity, waste of raw material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

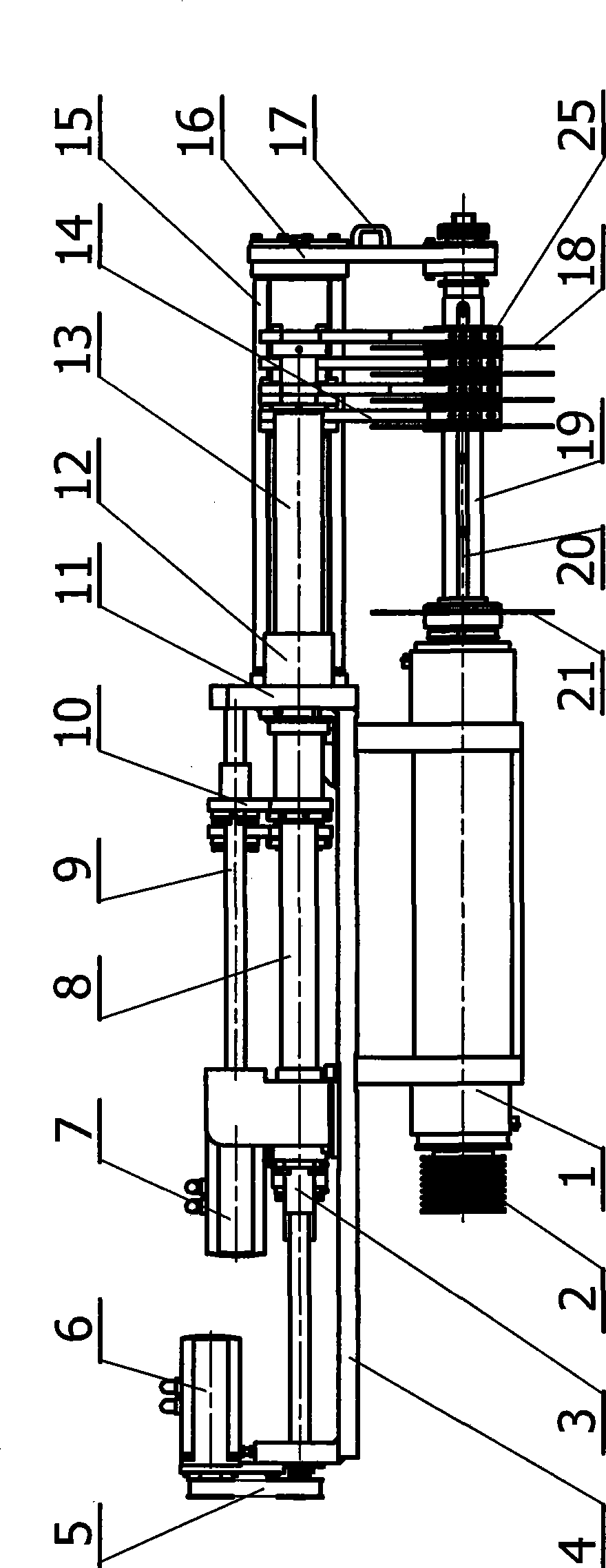

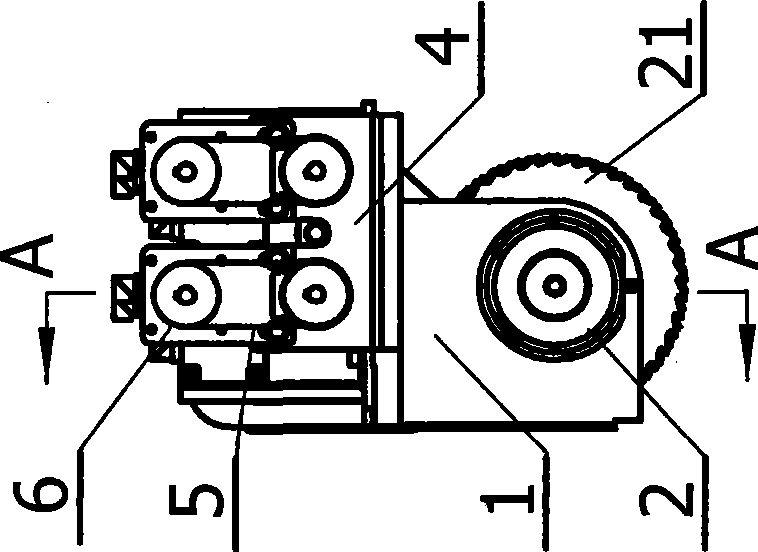

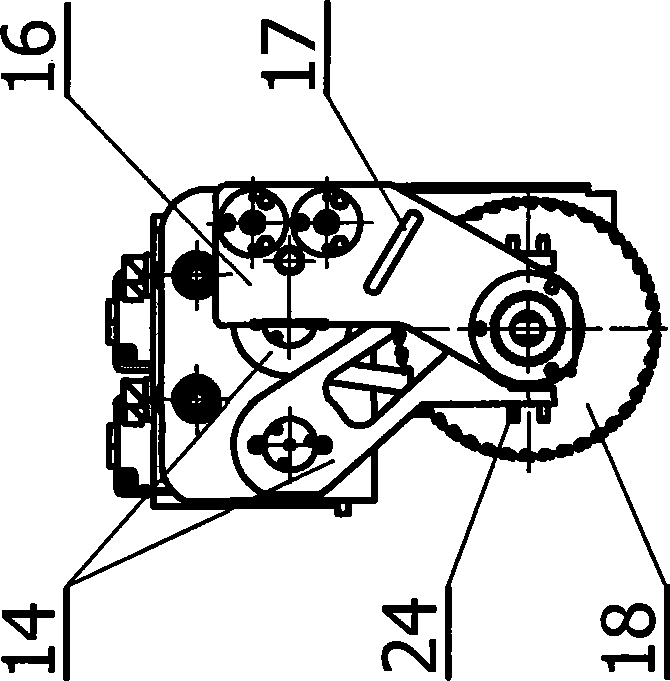

[0018] exist figure 1 , figure 2 and image 3 In the shown saw shaft structure, the saw shaft 19 is supported by rolling bearings on the saw shaft support 1, and the saw shaft support 1 is supported on the frame of the circular saw machine. One end of saw shaft 19 is equipped with saw shaft pulley 2, and saw shaft pulley 2 is connected with saw shaft drive motor transmission, on the other protruding end of saw shaft 19 and saw shaft pulley 2 assembly end relative, successively is equipped with A piece of fixed circular saw blade 21 and four saw blade sliding sleeves 25, fixed circular saw blade 21 can only do rotary sawing with saw shaft. The shaft surface of the saw shaft 19 is symmetrically provided with two saw shaft sliding keys 20 along the length direction, and the saw shaft sliding keys 20 are slidingly matched with two sliding key slots in the shaft hole of the saw blade sliding sleeve 25 . A moving circular saw blade 18 is housed on each saw blade sliding sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com