Vulcanizing system of brominated butyl rubber/ polypropylene thermoplastic elastomer sealing material and preparation method for sealing material

A technology of brominated butyl rubber and thermoplastic elastomer, which is applied in the field of vulcanization system and its preparation, can solve the problems of low double bond content in the main chain of brominated butyl rubber, loss of thermoplasticity of leftover materials, slow vulcanization speed of models, etc., and achieve easy The effects of weighing and calculation, high tensile strength, and easy control of production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

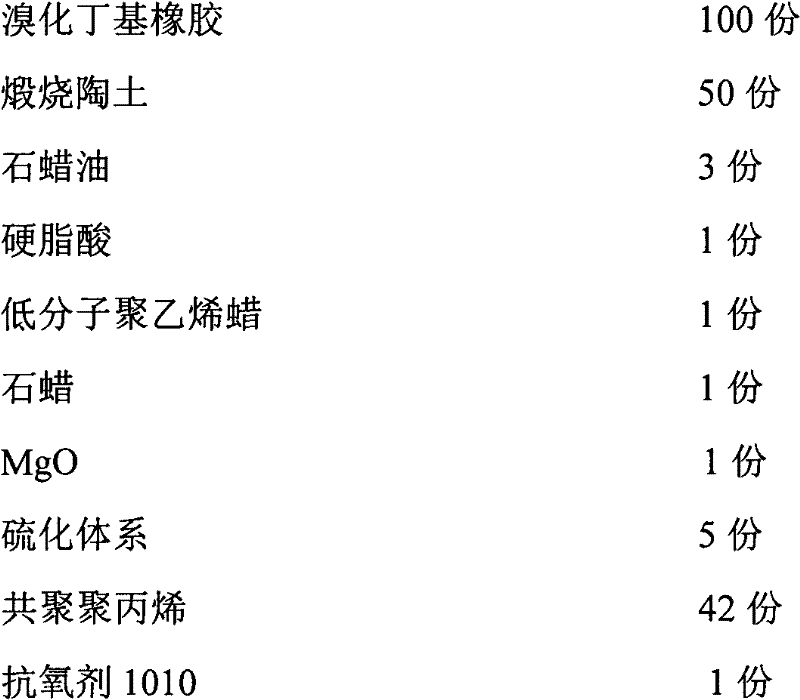

[0029] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0030]

[0031] Process as follows:

[0032] (1) Under the open mill at room temperature, add IIR, heat-reactive alkylphenolic resin, and zinc oxide in sequence to obtain a vulcanization system; at a temperature of 40°C, add bromobutyl rubber, calcined clay, and paraffin in sequence Oil and processing aids were blended for 10 minutes in a double-roller kneading machine to obtain a rubber compound.

[0033] (2) Under the condition that the rotor speed of the internal mixer is 70rpm and the blending temperature is 180°C, add polypropylene and additives, plasticize for 2 minutes, then add the prepared mixed rubber, blend for 4 minutes, and then add the vulcanization system, The bromobutyl rubber / polypropylene thermoplastic elastomer was prepared by dynamic vulcanization and blending for 6 minutes. In the open mill, the flakes are made into sheets.

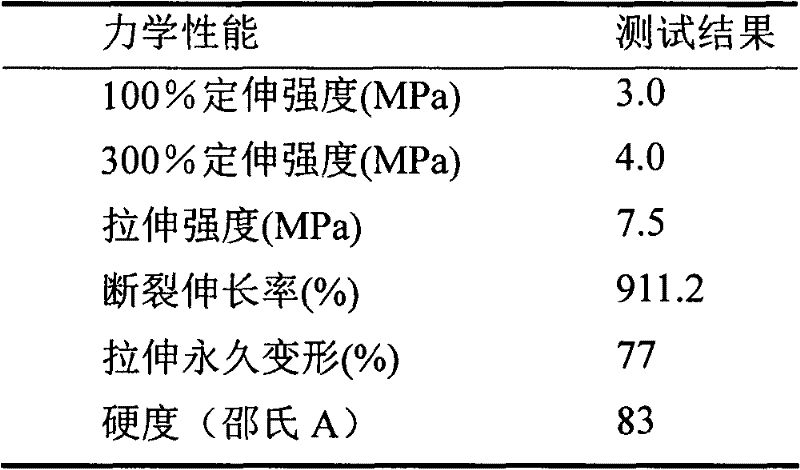

[0034] The the...

Embodiment 2

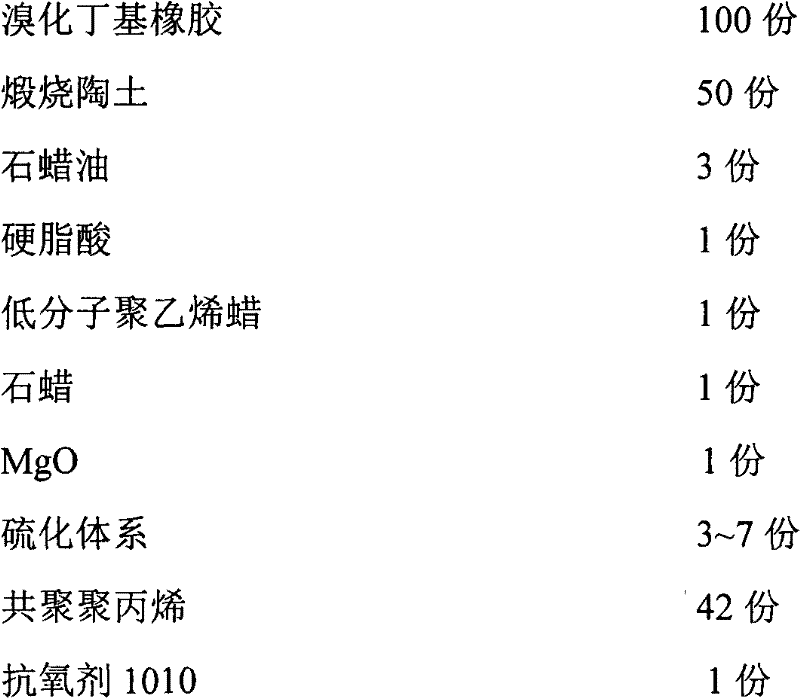

[0038] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0039]

[0040] Above each formula is processed according to the following process method:

[0041] (1) Under the open mill at room temperature, add IIR, heat-reactive alkylphenolic resin, and zinc oxide in sequence to make a vulcanization system; at a temperature of 40°C, add bromobutyl rubber and reinforcing filler in sequence , Processing aids were blended for 10 minutes in a double-roller kneading machine to obtain a mixed rubber.

[0042] (2) Under the condition that the rotor speed of the internal mixer is 70rpm and the blending temperature is 180°C, add polypropylene and additives, plasticize for 2 minutes, then add the prepared mixed rubber, blend for 4 minutes, and then add the vulcanization system, The bromobutyl rubber / polypropylene hydrocarbon thermoplastic elastomer was prepared by dynamic vulcanization and blending for 6 minutes. In the open mill, ...

Embodiment 3

[0047] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0048]

[0049] Process as follows:

[0050] (1) Under the open mill at room temperature, add IIR, heat-reactive alkylphenolic resin, and zinc oxide in sequence to make a vulcanization system; at a temperature of 40°C, add bromobutyl rubber and reinforcing filler in sequence , Processing aids were blended for 10 minutes in a double-roller kneading machine to obtain a mixed rubber.

[0051] (2) Under the condition that the rotor speed of the internal mixer is 70rpm and the blending temperature is 180°C, add polypropylene and additives, plasticize for 2 minutes, then add the prepared mixed rubber, blend for 4 minutes, and then add the vulcanization system, The bromobutyl rubber / polypropylene hydrocarbon thermoplastic elastomer was prepared by dynamic vulcanization and blending for 6 minutes. In the open mill, the flakes are made into sheets.

[0052] The thermopl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com