Spiral pushing type cow feed pushing robot and feed pushing method

A pusher robot and screw pusher technology are applied in applications, animal feeding devices, animal husbandry, etc., which can solve the problems of slow manual work, increased labor, and out-of-reach of cattle, and achieve easy installation and maintenance, Save manpower and material resources, simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

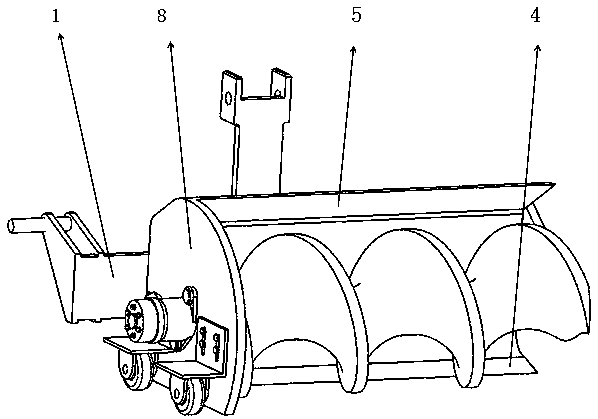

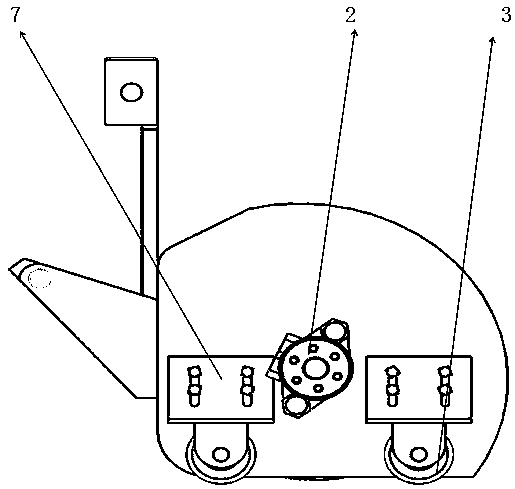

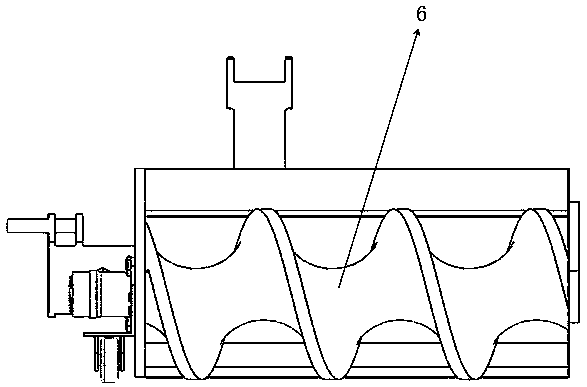

[0023] In order to clearly illustrate the technical features of this solution, the following will describe this solution through specific implementation methods in conjunction with the accompanying drawings in the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, and not only limitative in this technical solution.

[0024] The machine includes a screw pushing auger, a hydraulic motor part, a body casing, a pushing plate located at the lower part of the body casing, auxiliary wheels and a connecting device with a tractor. When working, the whole machine is placed on the front or back of the tractor, and the whole machine is driven by the tractor. The machine part is driven by the hydraulic motor on the left side of the fuselage to rotate the screw pusher auger to push the far feed to the cow trough, which is convenient for the cows to eat. The push plate at the bottom of the fuselage is made of rubber material to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com