Method and equipment for forming roof board

A molding equipment and molding method technology, applied in molding tools, metal processing equipment, feeding devices, etc., can solve the problems of troublesome operation, low production efficiency, and many processes, and achieve the reduction of scraps, high production efficiency, and simple processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

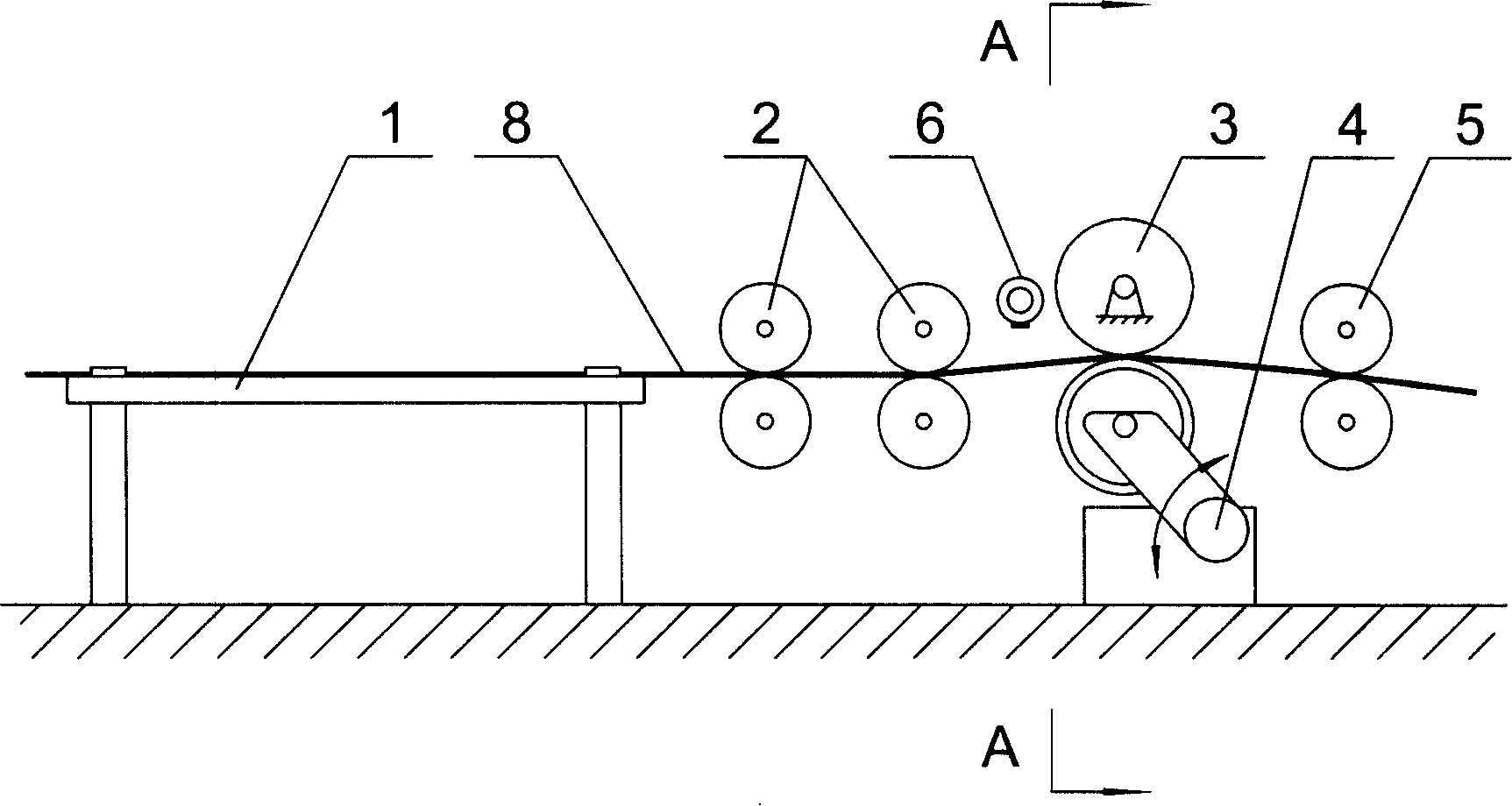

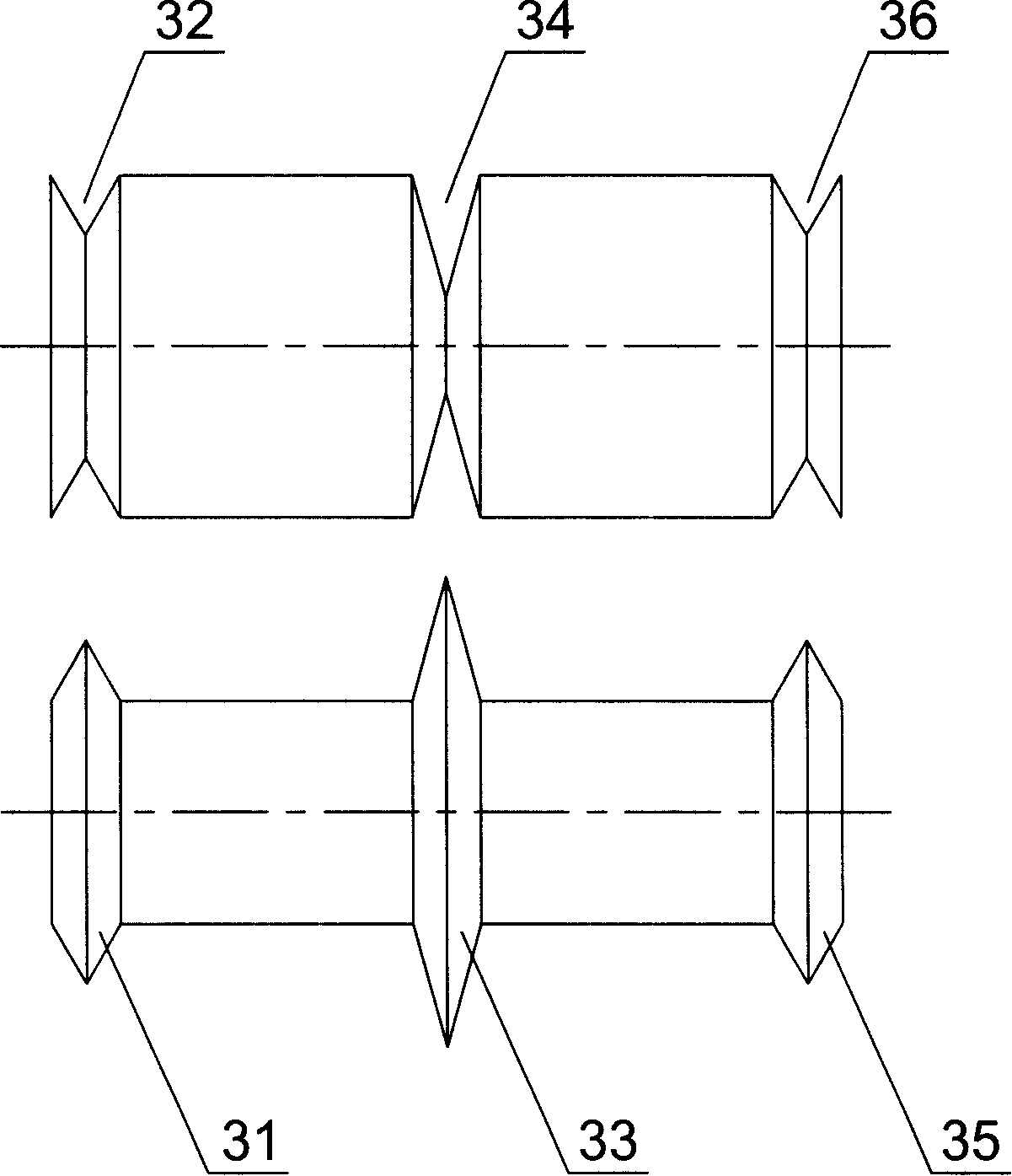

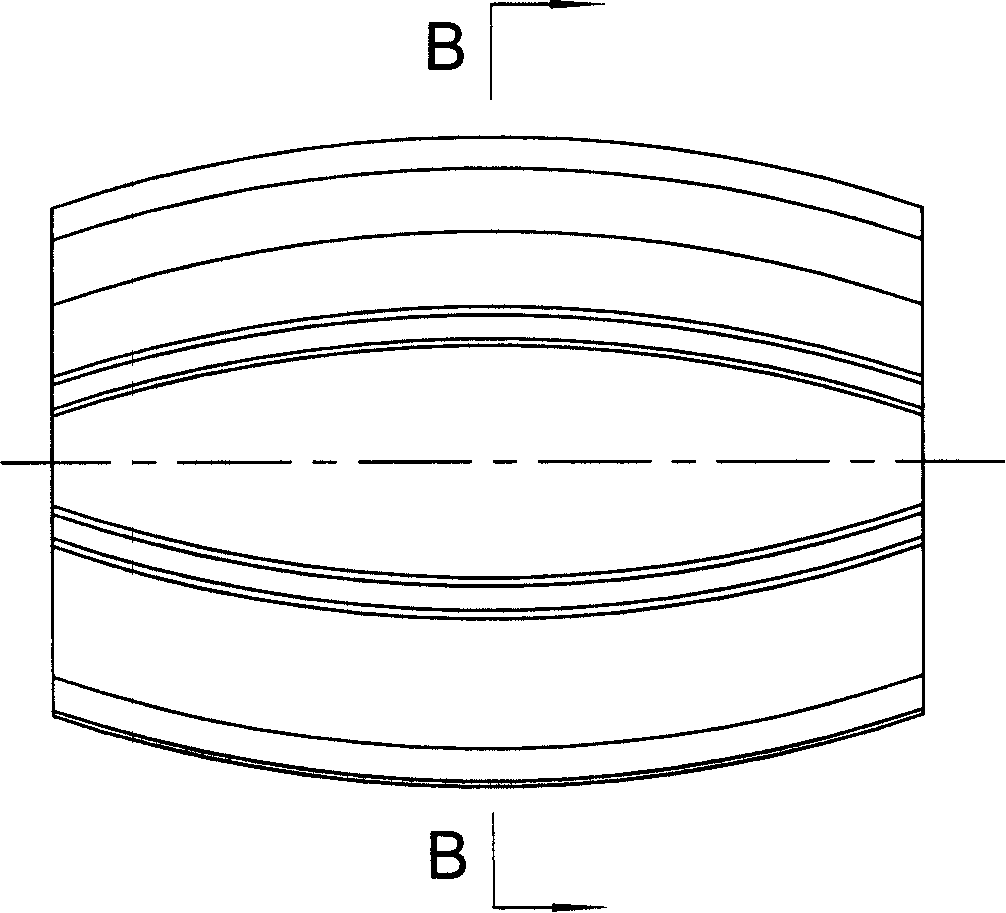

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the forming equipment of the roof panel of the present invention includes a positioning platform 1, a feeding roller group 2, a forming roller group 3, a forming roller lifting device 4, a numerical control device for controlling the forming roller lifting device 4, and a discharging roller group 5 , reader 6, described forming roller group 3 comprises upper roller, lower roller, and described forming roller lifting device 4 is connected with described lower roller, and described lower roller comprises three forming wheels 31,33,35, three The outer diameters of the forming wheels 31, 33, 35 are not completely the same, wherein the two forming wheels 31, 35 on both sides have the same radius, and the radius of the forming wheel 33 in the middle is larger than that of the two forming wheels 33 on both sides. The radii of the forming wheels 31, 35 are large, and the roller shaft of the upper roller is fixed, ...

Embodiment 2

[0032] Such as figure 1 , Figure 5 , Figure 6 , Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the forming wheel 33 in the middle of the forming equipment of the roof panel in this embodiment has the same radius as the forming wheel 35 on the right side, and the radius of the forming wheel 35 on the left side is the same. The radius of the forming wheel 31 is larger than that of the two forming wheels 33, 35 in the middle and the right side.

[0033] The structure of the roof panel manufactured by the forming equipment and method of the roof panel of this embodiment is as follows: Figure 6 , Figure 7 As shown, that is, the horizontal dimension of the roof panel is unchanged, but it is curved in the length direction.

Embodiment 3

[0035] Such as figure 1 , Figure 8 , Figure 9 , Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the two forming wheels 31 and 35 on both sides of the forming equipment of the roof panel in this embodiment have the same radius, and the radius of the forming wheel 33 in the middle is the same. The radius is smaller than the radius of the two said forming wheels 31 , 35 on both sides.

[0036] The structure of the roof panel manufactured by the forming equipment and method of the roof panel of this embodiment is as follows: Figure 9 , Figure 10 As shown, that is, the transverse dimension of the roof panel gradually increases from the middle to both ends.

[0037] In the same way, changing the outer diameters, wheel bases, and lifting tracks of the three forming wheels 31, 33, and 35 also has other different combination methods, and different combination methods can produce metal plates with different arcs and curvatures. The examples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com