Resin insulation dry type transformer with three-dimensional roll iron core

A three-dimensional wound iron core and dry-type transformer technology, which is applied in the field of transformers, can solve the problems of excitation current, increased no-load loss, excessive silicon steel sheet corners, and low core filling factor, etc., to achieve reduced no-load loss , Beautiful appearance, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

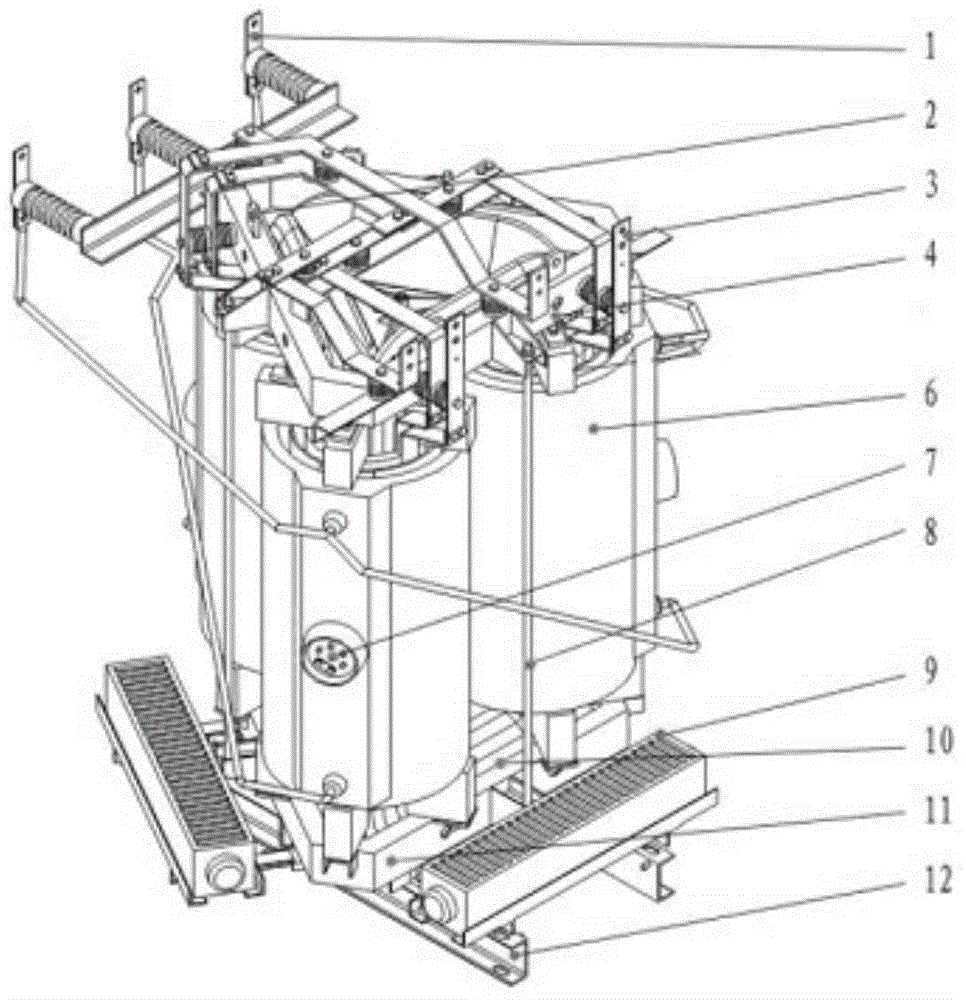

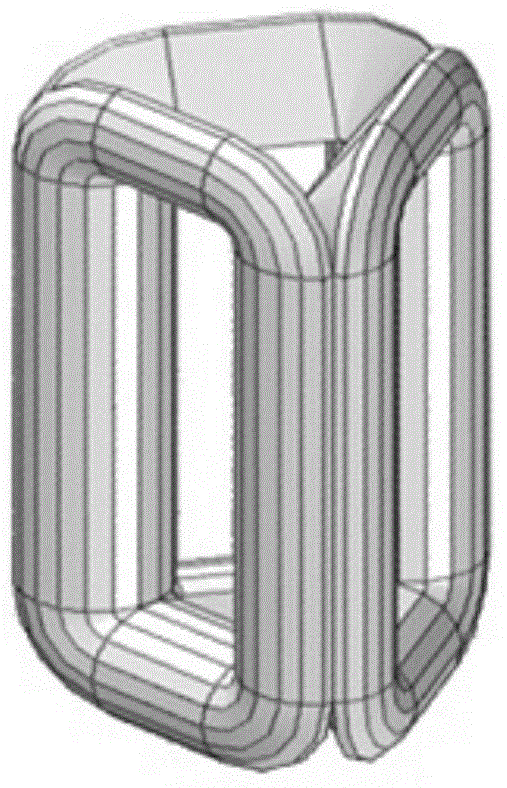

[0027] see figure 1 and figure 2 The three-dimensional wound iron core resin insulated dry-type transformer of the present invention includes a transformer base 12, an upper clamp 4 and a lower clamp 11 that are arranged on the transformer base 12 up and down correspondingly, and are clamped on the upper clamp 4 and the lower clamp 11. Between the three-dimensional wound core 10, the three-dimensional wound core 10 includes three single frames with a hollowed out middle part and a rounded rectangular structure, and the three single frames are assembled together in an equilateral triangular three-dimensional arrangement , each of the single frames is formed by successively winding several silicon steel trapezoidal strips, and coils 6 are respectively wound at the joints of the two single frames, and each of the coils 6 is poured with curin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com