Method for manufacturing filled formed sound insulation pad for automobile

A production method and technology for sound insulation pads, which are applied in the production field of filling and molding sound insulation pads for automobiles, can solve the problems that the shape cannot be completely in place, cannot achieve the same degree of softness and hardness, and achieve the effect of saving materials, reducing scraps and good molding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for making a filling-molded sound-insulating pad for automobiles. The method adopts the air-flow mixing filling molding method, uses the filling system to fill the fiber material into the mesh mold according to the thickness of each part, and then molds it, and finally water-cuts the edge material get the product. Specifically include the following steps:

[0024] (1) Put 70kg of cloth flowers, 25kg of molten fiber and 5kg of sponge particles into the hair mixing box for mixing, and send them into the hair storage box at the filling port after mixing evenly;

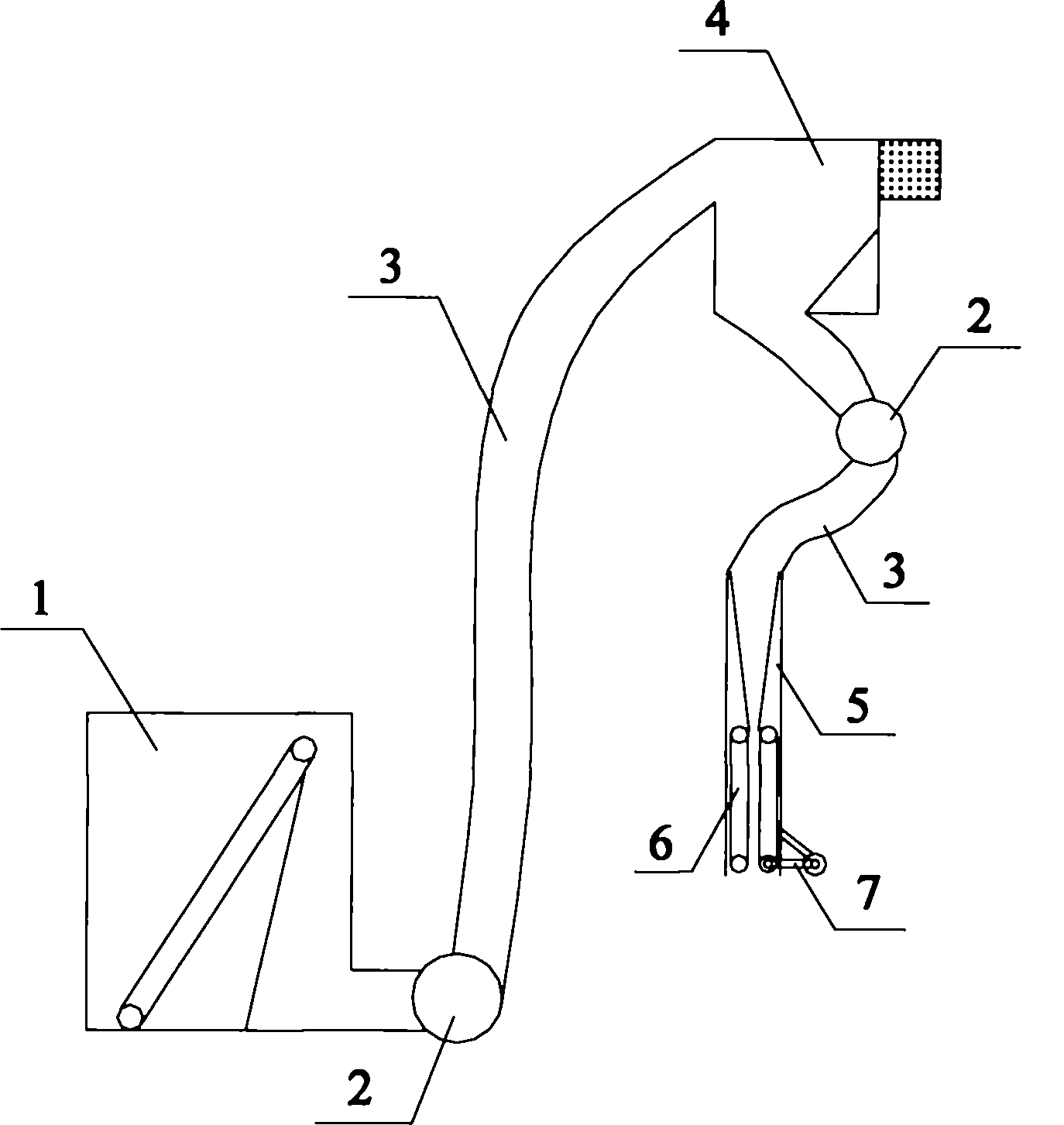

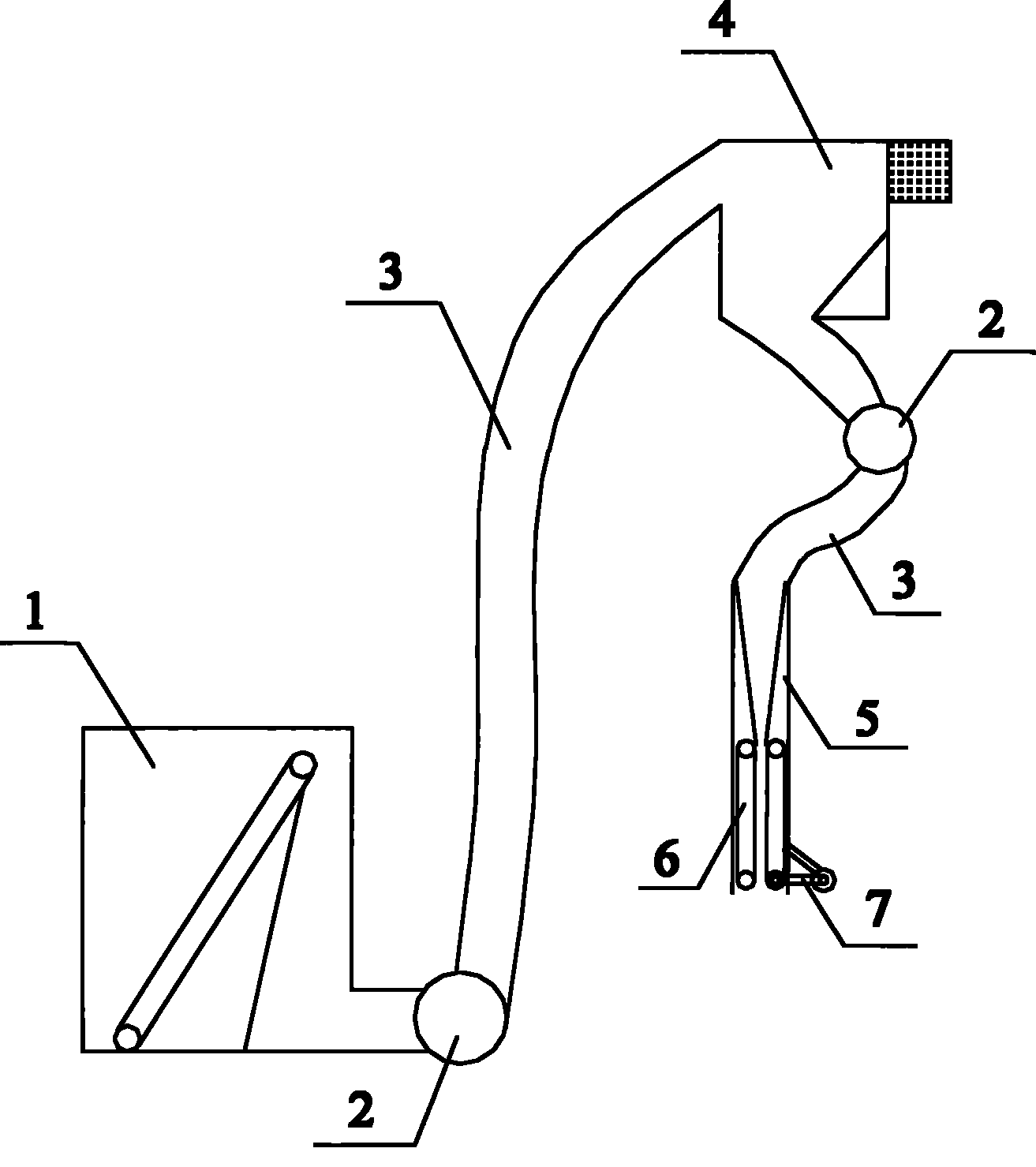

[0025] (2) Use the filling system to drive the uniformly mixed materials in the hair storage box into the molding mold through the filling port according to the thickness requirements of the parts; the structure of the filling system is as follows: figure 1 As shown, it consists of a cotton storage box 1, a fan 2, a hose 3, a second cotton storage box 4 and a cotton bin 5. The cotton storage box 1 is con...

Embodiment 2

[0030] A method for making a filling and forming sound insulation pad for automobiles. The method adopts the air-flow mixing filling and molding method, and uses the filling system to fill the fiber material into the mesh mold according to the thickness of each part, and then molds it, and finally water-cuts the edge material get the product. Specifically include the following steps:

[0031] (1) Put 65kg of cloth flowers, 30kg of molten fiber and 5kg of sponge particles into the hair storage box for mixing, and send them into the hair storage box at the filling port after mixing evenly;

[0032] (2) Use the filling system to drive the uniformly mixed materials in the hair storage box into the forming mold through the filling port according to the thickness requirements of the parts;

[0033] (3) On the lower mold of the forming mold filled with materials, the fiber web is laid as a whole, and the laying amount of the fiber web is 800g / m 2 ;

[0034] (4) Clamp the upper and...

Embodiment 3

[0037] A method for making a filling and forming sound insulation pad for automobiles. The method adopts the air-flow mixing filling and molding method, and uses the filling system to fill the fiber material into the mesh mold according to the thickness of each part, and then molds it, and finally water-cuts the edge material get the product. Specifically include the following steps:

[0038] (1) Put 77kg of cloth flowers, 20kg of molten fiber and 3kg of sponge particles into the hair storage box for mixing, and send them into the hair storage box at the filling port after mixing evenly;

[0039] (2) Use the filling system to drive the uniformly mixed materials in the hair storage box into the forming mold through the filling port according to the thickness requirements of the parts;

[0040] (3) On the lower mold of the forming mold filled with materials, lay the fiber net as a whole, and the laying amount of the fiber net is 1000g / m 2 ;

[0041] (4) Clamp the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com