Manufacturing method for decorated eyeglass frame or eyeglass leg

A production method and technology of ornaments, applied to frames, other home appliances, home appliances, etc., can solve the problems of cumbersome production process, high production cost, and low processing efficiency, so as to reduce manpower and material resources, improve product quality, and install Strong and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

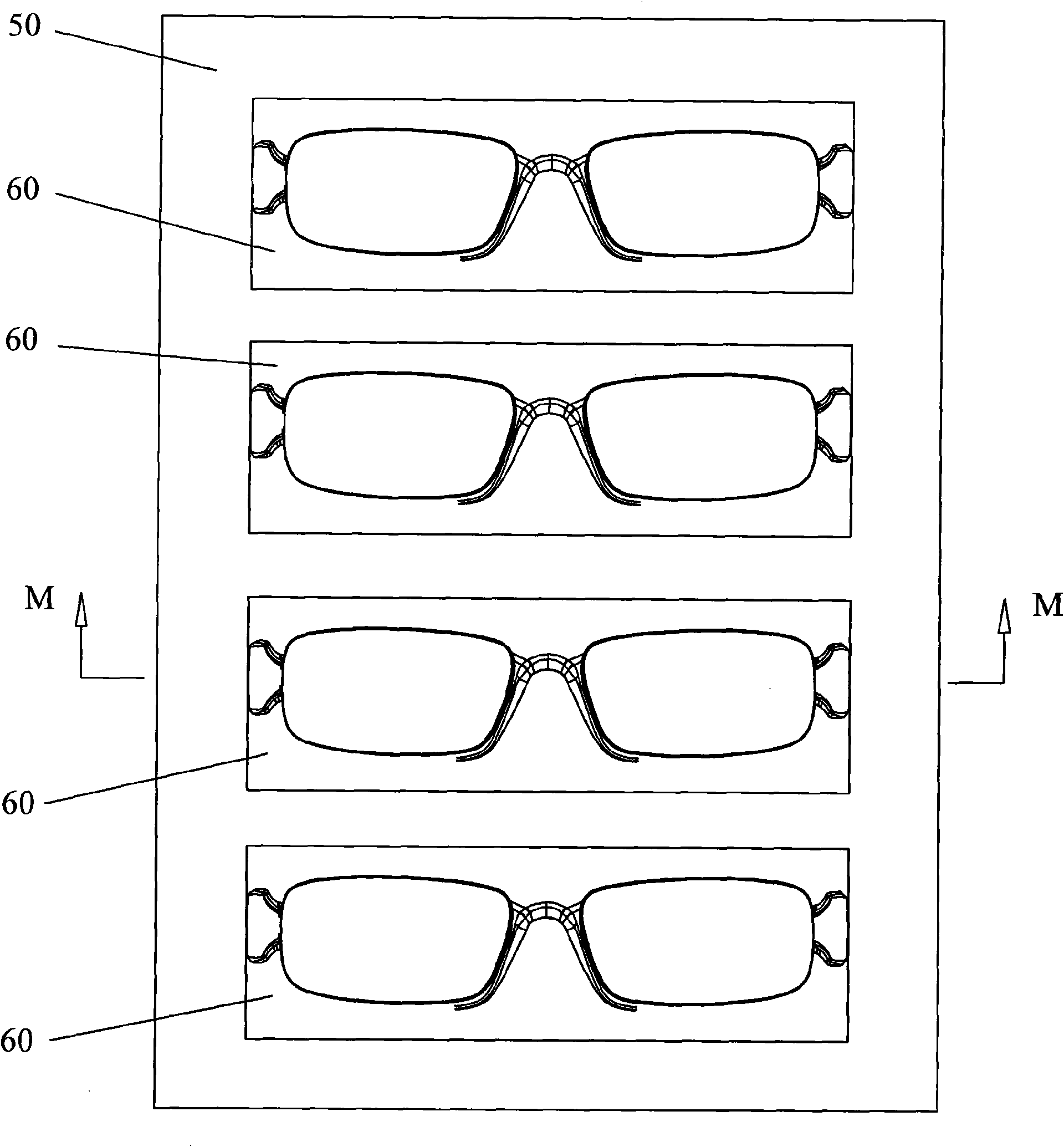

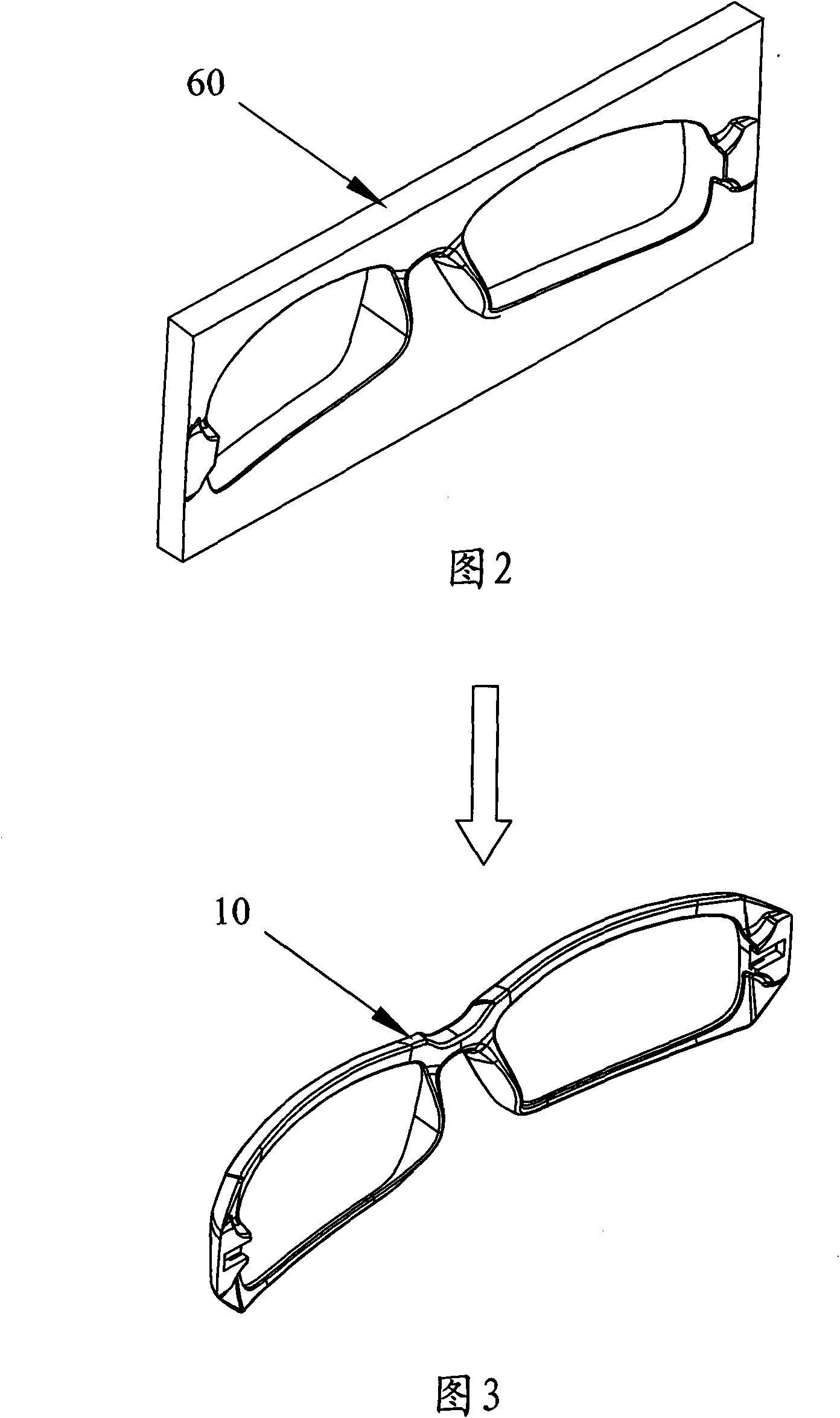

[0041] First, please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the first embodiment of the present invention. This embodiment takes the manufacturing process of a spectacle frame 10 as an example to describe in detail. The process of making the spectacle frame 10 mainly includes molding and processing two steps.

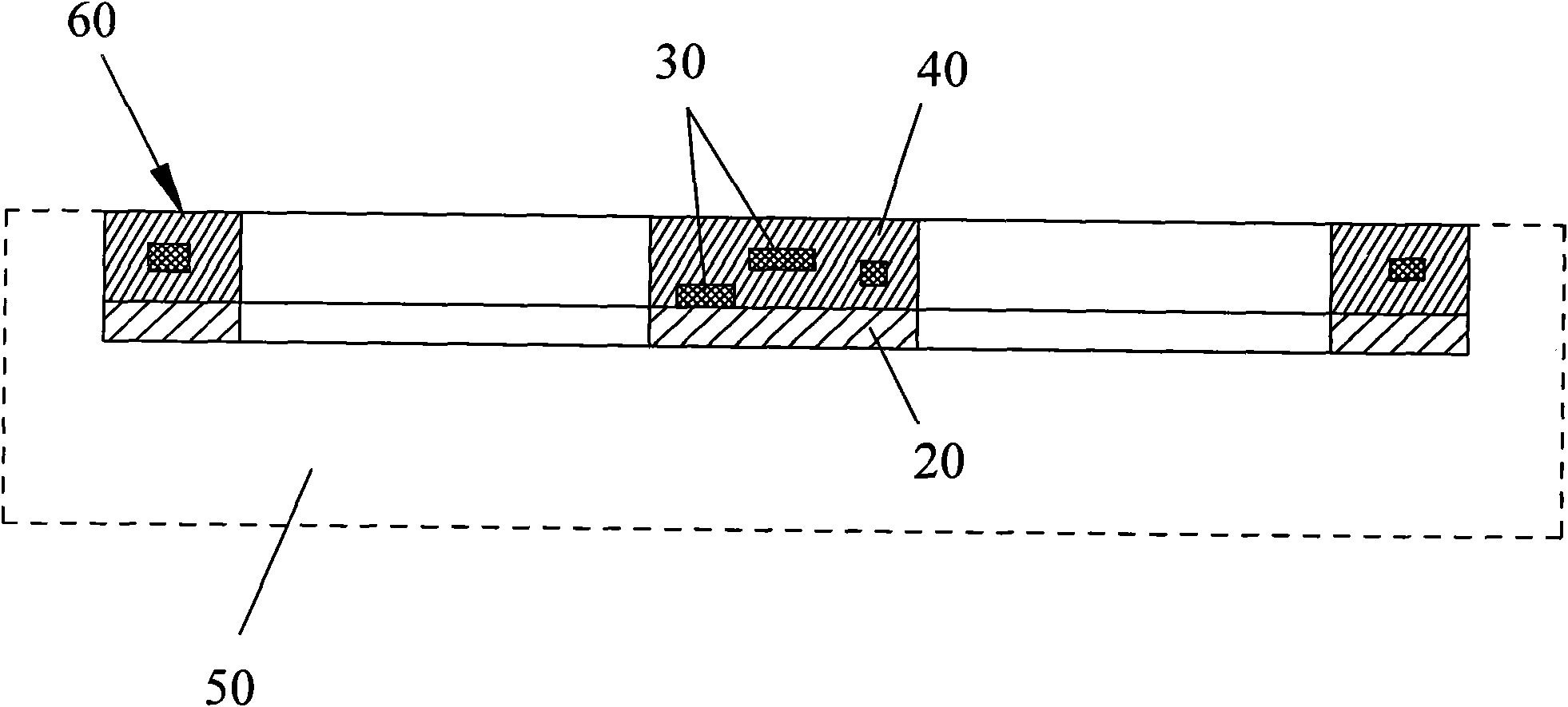

[0042] Specifically, the molding step is to put the acetate fiber (CA) plate 20, the ornament 30 and the plastic material 40 into a mold cavity of the die-casting mold 50 in an appropriate position and order, and press the mold under certain pressure and temperature conditions. , a rigid frame substrate 60 is formed by one-time die-casting, so that the ornament 30 is mounted inside the spectacle frame 10 .

[0043] Wherein, the ornament 30 in the picture frame 10 of the present embodiment is a plurality of small shells, and the acetate fiber (CA) plate 20 is used to make the structural lines of the product molding more clear, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com