Halogen-free flame-retardant nitrile rubber/nylon thermoplastic elastomer and preparation method thereof

A technology of thermoplastic elastomer and flame-retardant nitrile, which is applied in the field of thermoplastic elastomers, can solve the problems of poor flame-retardant performance and poor mechanical properties, and achieve the effect of easy repeated processing, easy processing and good flame-retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

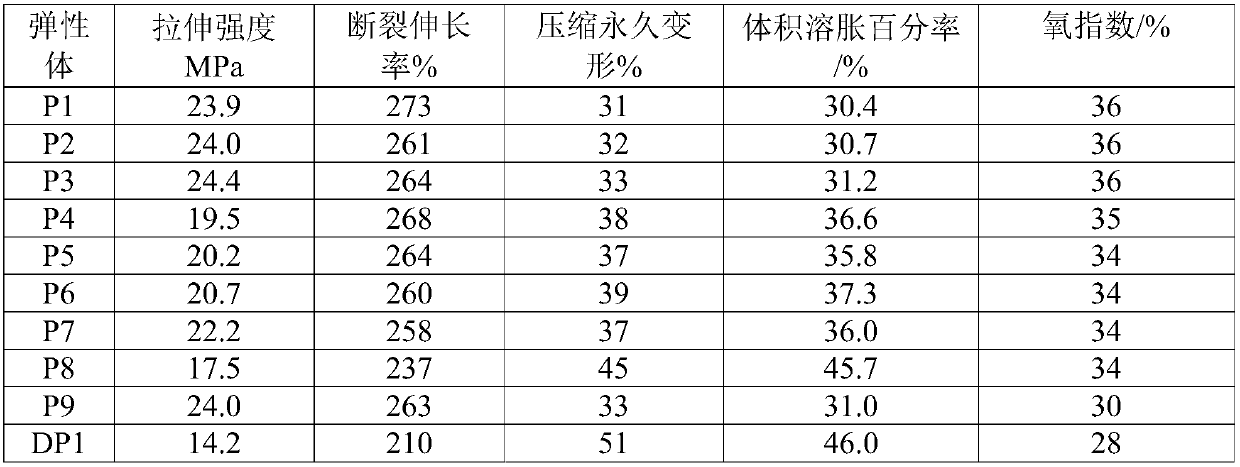

Examples

preparation example Construction

[0026] In order to make the halogen-free flame-retardant nitrile rubber / nylon thermoplastic elastomer of the present invention have more excellent tensile strength, abrasion resistance, excellent solvent resistance and flame retardant properties, the present invention provides the second aspect as described above. The preferred preparation method prepares the halogen-free flame-retardant nitrile rubber / nylon thermoplastic elastomer of the present invention, and the method comprises:

[0027] (1) Component A containing nitrile rubber, anti-aging agent and auxiliary agent is carried out first mixing to obtain masterbatch;

[0028] (2) extruding and granulating the masterbatch to obtain masterbatch particles;

[0029] (3) Dynamic vulcanization and granulation of the masterbatch particles and component B containing nylon, antioxidant, vulcanizing agent and flame retardant.

[0030] The dosage of each component involved in the second aspect of the present invention is the same as ...

Embodiment 1

[0043] According to the formula shown in Table 1, the following processing method was performed to obtain the elastomer P1.

[0044](1) at 40 ℃, sequentially add nitrile rubber, antioxidant RD, auxiliary (liquid paraffin and stearic acid, and the weight ratio of liquid paraffin and stearic acid is 1:0.2) into the internal mixer, dense The rotor speed of the mill is 70 rpm, and the mixing is performed for 10 minutes to obtain a masterbatch;

[0045] (2) at a screw speed of 100 rpm and an extrusion temperature of 180° C., extruding and granulating the masterbatch through a single-screw extruder to obtain masterbatch particles;

[0046] (3) A co-rotating intermeshing twin-screw extruder is used, the screw speed is 100 rpm, the main feeding speed is 40 rpm, the temperature of the head is 180 ℃, the temperature of the screw feeding section is 150 ℃, and the temperature of the melting and kneading section is 180 ℃, Add the masterbatch particles obtained in step (2) and nylon, antio...

Embodiment 2

[0048] According to the formula shown in Table 1, the following processing method was performed to obtain the elastomer P2.

[0049] (1) At 45°C, add nitrile rubber, antioxidant MB, auxiliary (liquid paraffin and stearic acid, and the weight ratio of liquid paraffin and stearic acid is 1:0.2) into the internal mixer in turn, densely The rotor speed of the mill is 60 rpm, and the blending is performed for 8 minutes to obtain a masterbatch;

[0050] (2) at a screw speed of 80 rpm and an extrusion temperature of 160° C., extruding and granulating the masterbatch through a single-screw extruder to obtain masterbatch particles;

[0051] (3) A co-rotating intermeshing twin-screw extruder is used, the screw speed is 80 rpm, the main feeding speed is 30 rpm, the temperature of the head is 200 ℃, the temperature of the screw feeding section is 120 ℃, and the temperature of the melt-kneading section is 200 ℃, Add the masterbatch particles obtained in step (2) and nylon, antioxidant 101...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compression set | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com