Extrusion abrasive flow machining medium single-double circulation supply device and working method thereof

A technology for processing medium and supplying device, applied in abrasive feeding device, abrasive, metal processing equipment, etc., can solve the problems of high viscosity, reduced processing efficiency, unable to realize one-way cyclic processing, etc., to speed up the collection rate, The effect of improving processing efficiency and reducing development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

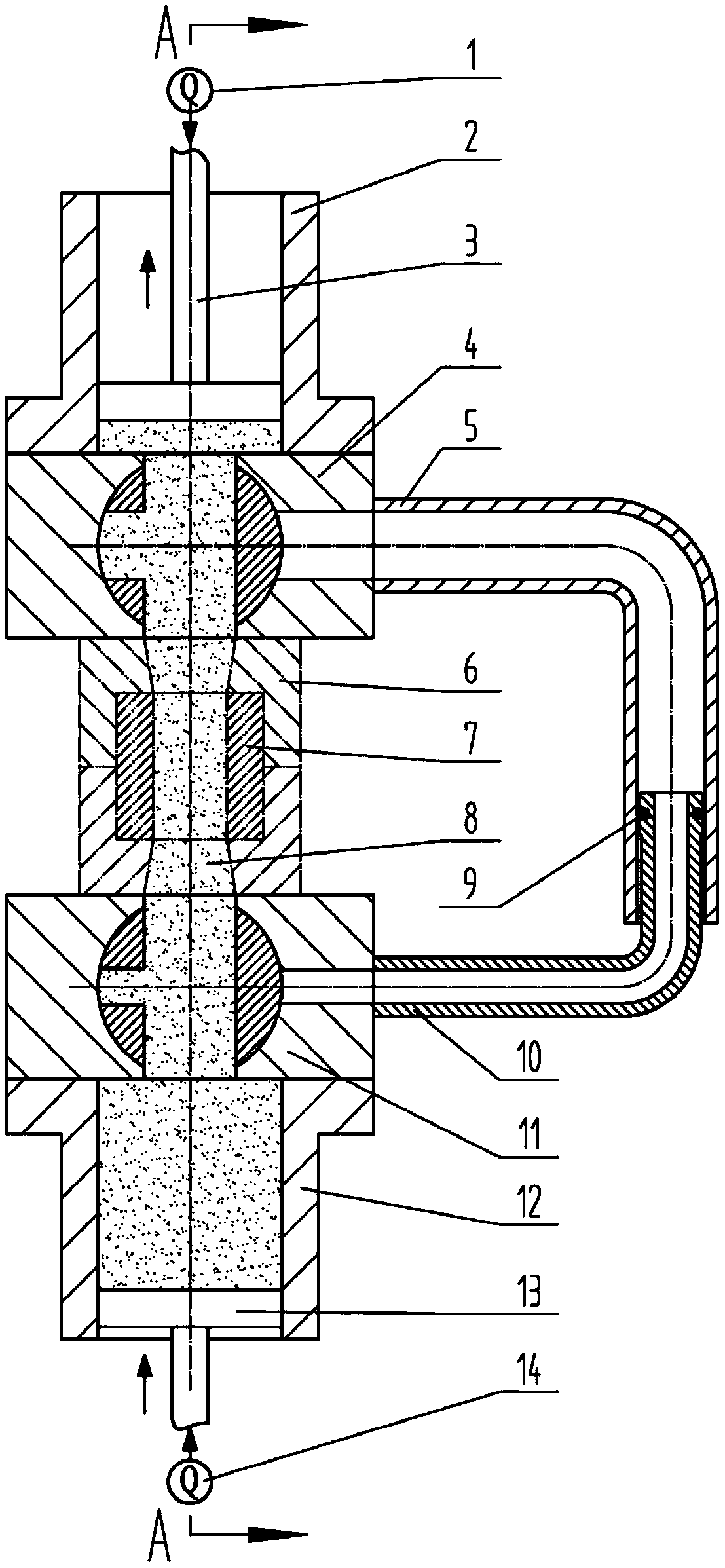

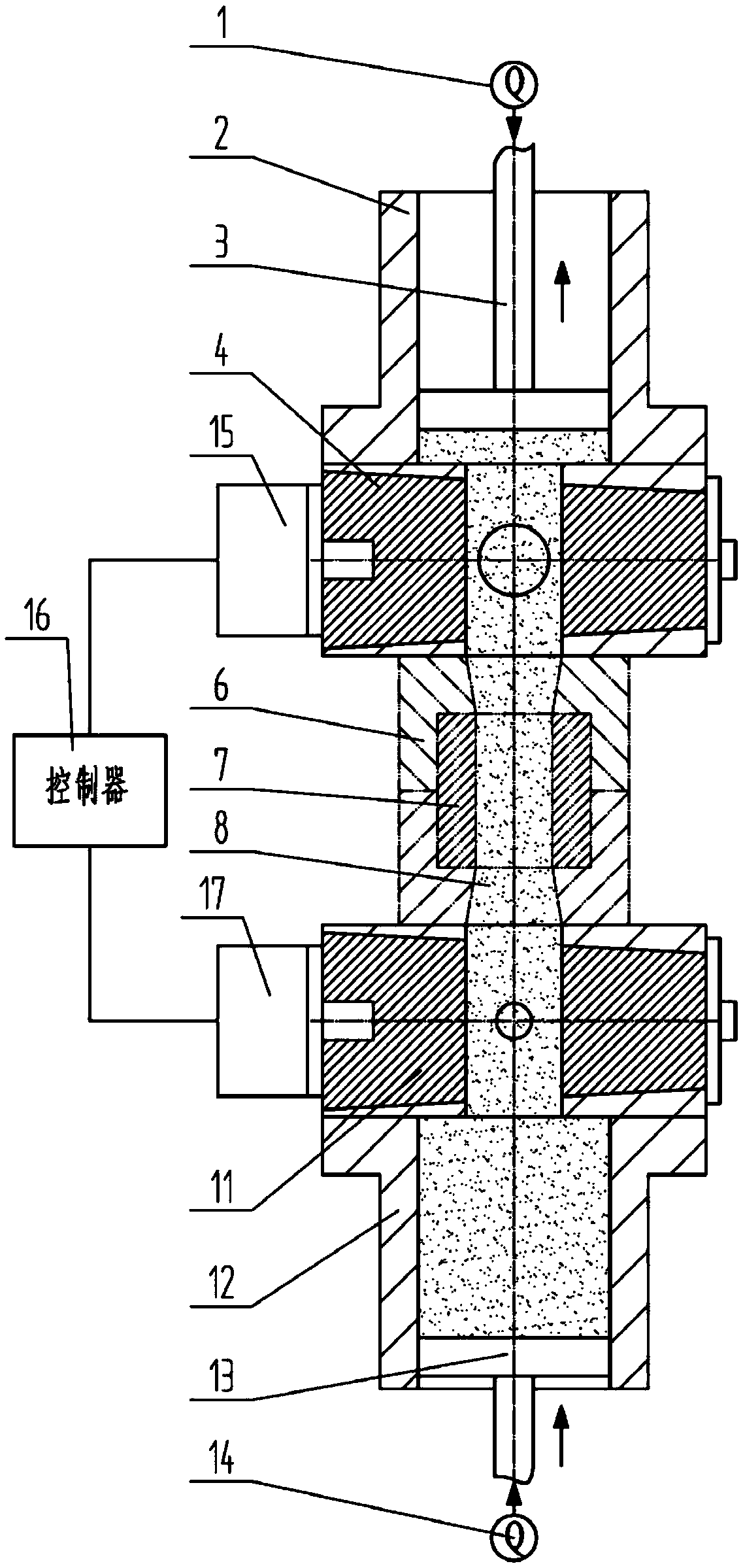

[0047] The specific implementation manners of the present invention will be further described below in combination with technical solutions, specific embodiments and accompanying drawings.

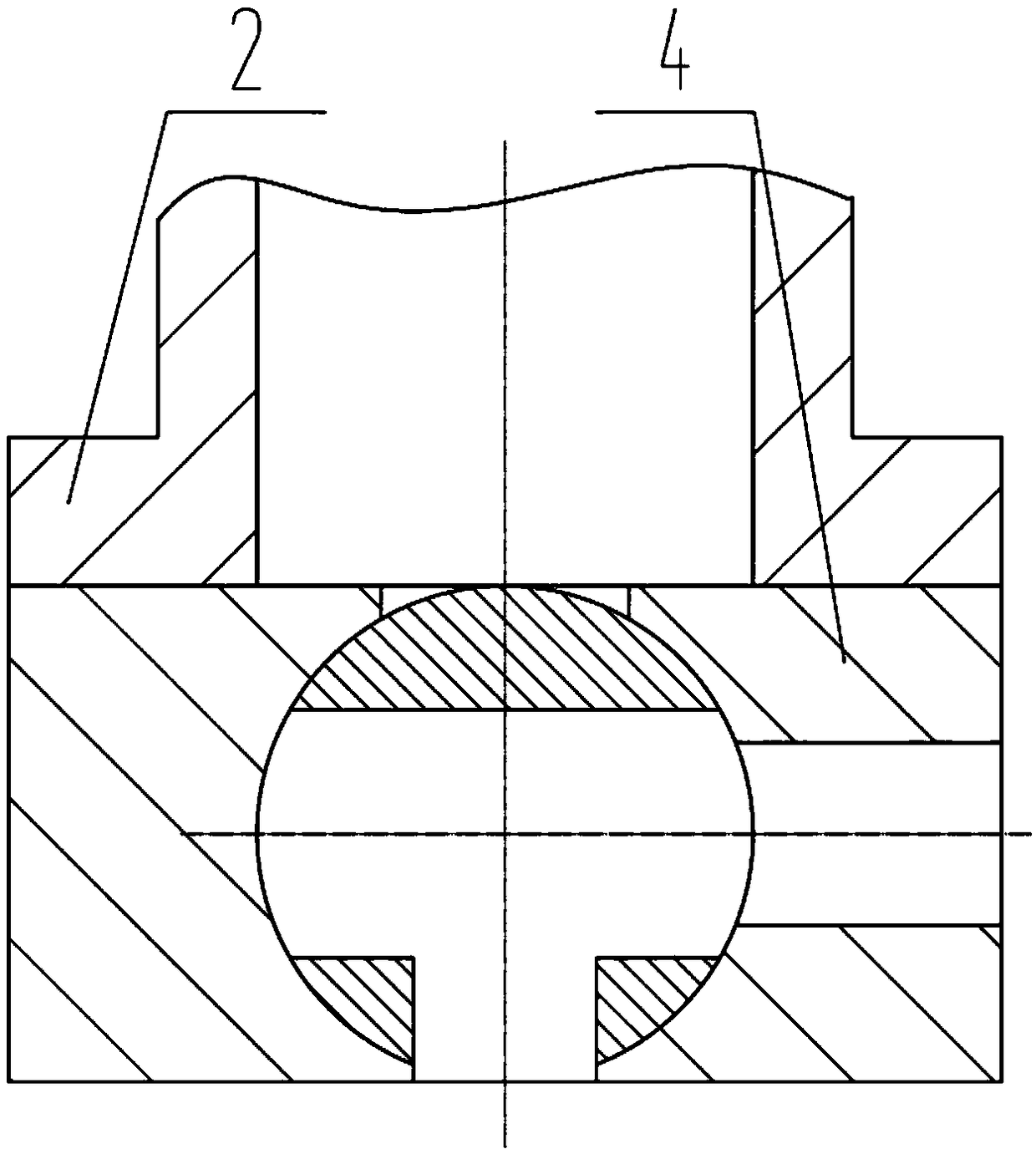

[0048] Such as Figure 1-6 As shown, a single and double circulation supply device for extruded abrasive flow processing medium, including a pushing device A, a pushing device B and an abrasive medium circulation device;

[0049] The pushing device A is composed of a material cylinder A2, a piston A3 and a piston driving mechanism A1, the piston A3 is located inside the material cylinder A2, the piston driving mechanism A1 acts on the piston A3, and the driving piston A3 performs a reciprocating linear motion in the material cylinder A2 ;

[0050] The pushing device B is composed of a material cylinder B12, a piston B13 and a piston driving mechanism B14, the piston B13 is located inside the material cylinder B12, the piston driving mechanism B14 acts on the piston B13, and the driving pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com