Metallized porous conductive polymer composite material, preparation method and application thereof

A polymer material, porous conductive technology, applied in conductive materials dispersed in non-conductive inorganic materials, electrical components, magnetic field/electric field shielding, etc., can solve problems such as high weight and limit the application range of composite materials, and achieve large contact area, increase the multiple reflection loss, and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

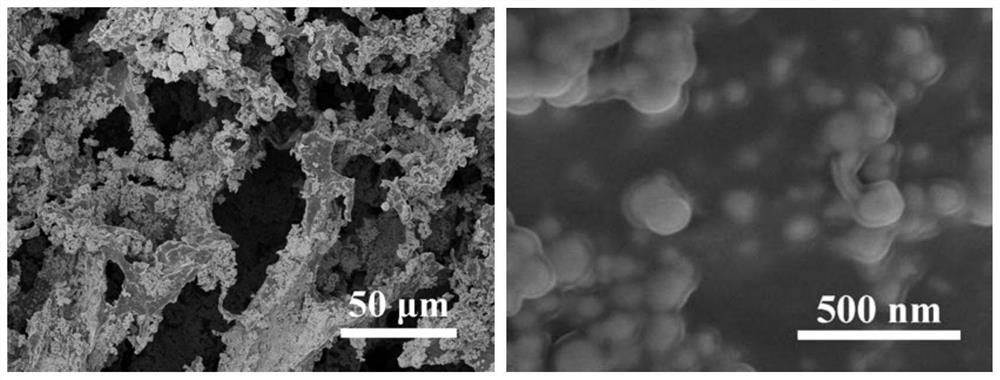

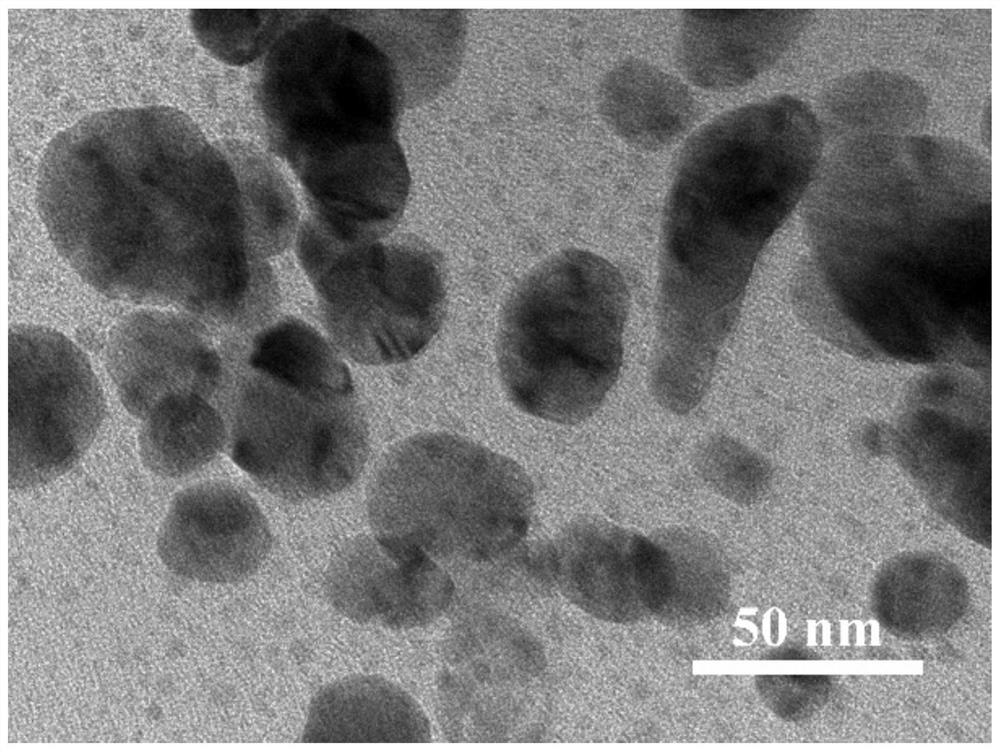

[0046] Embodiment 1 carbon nanotube / styrene-butadiene-styrene triblock copolymer metallization method

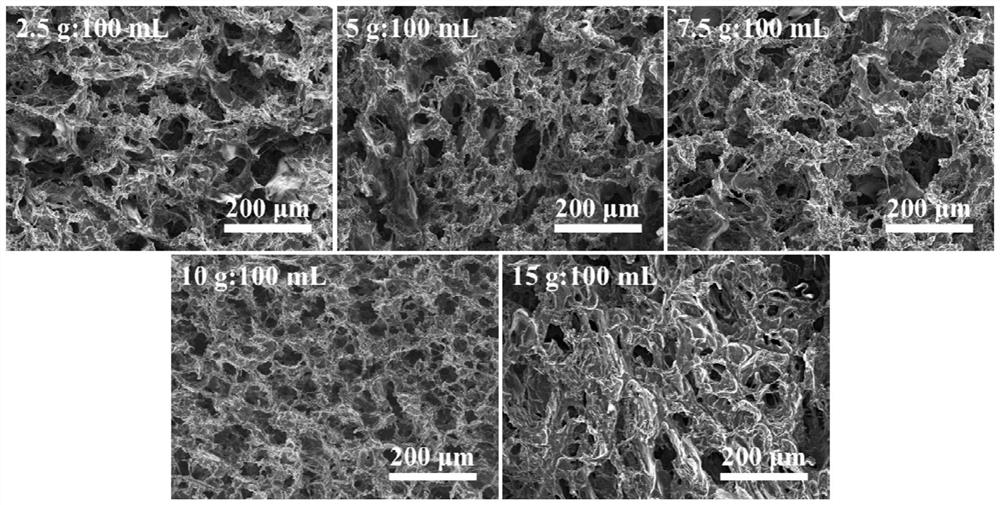

[0047] (1) Conductive filler solution: add 20 grams of SBS to 100 milliliters of 1,4-dioxane solution, add 1 gram of CNTs powder after the SBS is completely dissolved, and mix well to obtain a CNT / SBS mixed solution;

[0048] (2) Porous polymer material: put the CNTs / SBS mixed solution in an environment of 0°C, and after it is completely solidified, put it into a freeze-drying box for freeze-drying to obtain a porous CNTs / SBS foam material;

[0049] (3) Metallization of porous conductive polymers: soak the CNTs / SBS foam in a 10wt.% silver trifluoroacetate ethanol solution, place it in a vacuum box for 30 minutes of adsorption, then take out the CNTs / SBS foam and dry it at room temperature for 1 h. Subsequently, the CNTs / SBS foam was placed in an ethanol solution of hydrazine hydrate and reacted in a vacuum box for 5 minutes, and the CNTs / SBS foam was taken out and dried at r...

Embodiment 2

[0052] Embodiment 2 carbon fiber / hydrogenated styrene-butadiene block copolymer metallization method

[0053] (1) Conductive filler solution: Add 15 grams of SEBS to 100 milliliters of 3-pentanone solution, add 5 grams of CF powder after SEBS is completely dissolved, and mix well to obtain a CF / SEBS mixed solution;

[0054] (2) Porous polymer material: place the CF / SEBS mixed solution in an environment of -50°C, and after it is completely solidified, put it into a freeze-drying box for freeze-drying to obtain a porous CF / SEBS foam material;

[0055] (3) Metallization of porous conductive polymers: immerse the CF / SEBS foam in an ethanol solution of 20wt.% copper trifluoroacetate, place it in a vacuum box for adsorption for 30 minutes, then take out the CF / SEBS foam and dry it at room temperature for 1 h. Subsequently, the CF / SEBS foam was placed in an ethanol solution of phenylhydrazine, and placed in a vacuum box to react for 5 minutes. The CF / SEBS foam was taken out and dried...

Embodiment 3

[0057] Embodiment 3 silver nanowire / styrene-isoprene-styrene block copolymer metallization method

[0058] (1) Conductive filler solution: add 10 grams of SIS to 100 milliliters of chloroform solution, add 2 grams of AgNW powder after the SIS is completely dissolved, and mix well to obtain an AgNW / SIS mixed solution;

[0059] (2) Porous polymer material: place the AgNW / SIS mixed solution in an environment of -196°C, and after it is completely solidified, put it into a freeze-drying oven for freeze-drying to obtain a porous AgNW / SIS foam material;

[0060] (3) Metallization of porous conductive polymers: The AgNW / SIS foam was immersed in a 15wt.% silver trifluoroacetate ethanol solution, placed in a vacuum box for 30 minutes of adsorption, and the AgNW / SIS foam was taken out and dried at room temperature for 1 h. Then the AgNW / SIS foam was placed in the ethanol solution of phenylhydrazine, and placed in a vacuum box for 5 minutes to react, the AgNW / SIS foam was taken out and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com