Fe2O3 (iron oxide)-based photocatalysis composite material and preparation method thereof

A composite material, fe2o3 technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve excellent electronic storage capacity, mild hydrothermal reaction, and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

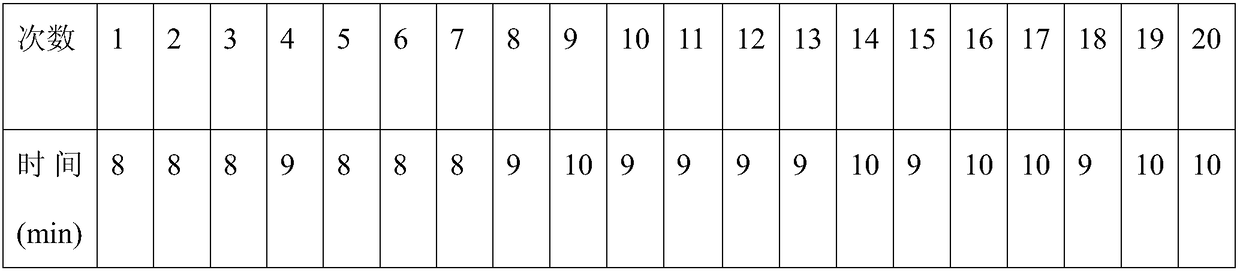

Embodiment 1

[0020] A kind of Fe 2 O 3 The preparation method of base photocatalytic composite material, the specific steps are as follows:

[0021] (1) The solid-liquid mass ratio of ferric chloride, CQDs aqueous solution, urea and water is 1g:18ml:0.4g:25ml, and the content of the carbon quantum dot aqueous solution is 5mg / ml and mixed evenly;

[0022] (2) Transfer the above solution to a reactor lined with tetrafluoroethylene for hydrothermal reaction. The specific steps of the reaction are heating up to 90°C at 4°C / min, holding for 1.5h, and then rapidly heating up to 260°C at 9°C / min ℃, keep for 50min, and finally cool to room temperature;

[0023] (3) The specific steps for post-processing the product using CQDs aqueous solution are as follows: according to the solid-to-liquid ratio of 1g:10ml, the solid product after the hydrothermal reaction is put into the CQDs aqueous solution with a content of 7mg / ml, and then vigorously stirred at 85°C for 2h .

[0024] (4) Wash the stirred product an...

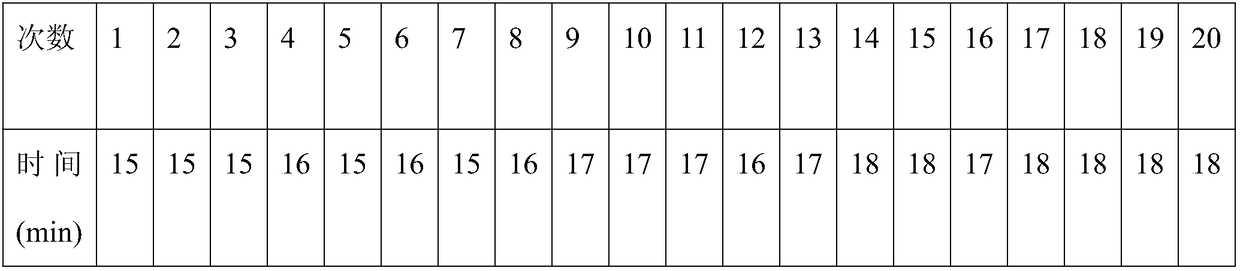

Embodiment 2

[0033] A kind of Fe 2 O 3 The preparation method of base photocatalytic composite material, the specific steps are as follows:

[0034] (1) The solid-liquid mass ratio of ferric chloride, CQDs aqueous solution, urea and water is 1g:15ml:0.2g:20ml, and the content of the carbon quantum dot aqueous solution is 1mg / ml and mixed uniformly;

[0035] (2) Transfer the above solution to a reactor lined with tetrafluoroethylene for hydrothermal reaction. The specific steps of the reaction are to raise the temperature to 80°C at 3°C / min, keep it for 1 hour, and then quickly raise the temperature to 250°C at 8°C / min , Keep for 40min, and finally cool to room temperature;

[0036] (3) The specific steps of post-processing the product with CQDs aqueous solution are as follows: according to the solid-liquid ratio of 1g:10ml, put the solid product after hydrothermal reaction into the CQDs aqueous solution with a content of 5mg / ml, and then vigorously stir at 80℃ for 1h .

[0037] (4) Wash the stirr...

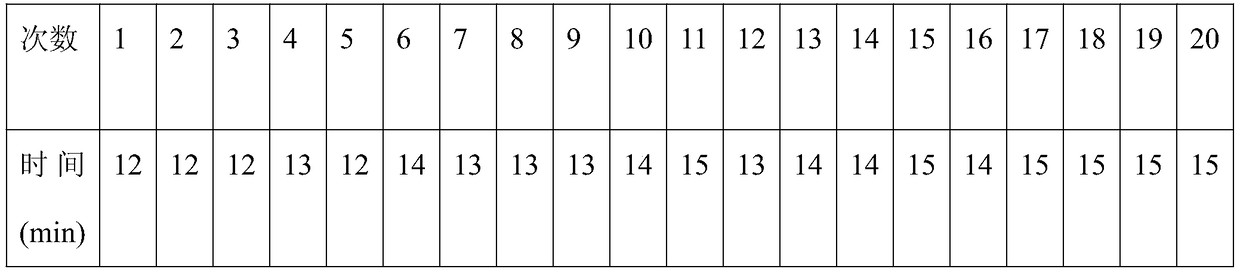

Embodiment 3

[0043] A kind of Fe 2 O 3 The preparation method of base photocatalytic composite material, the specific steps are as follows:

[0044] (1) The solid-liquid mass ratio of ferric chloride, CQDs aqueous solution, urea, and water is 1g:20ml:0.5g:30ml, and the content of the carbon quantum dot aqueous solution is 10mg / ml and mixed evenly;

[0045] (2) Transfer the above solution to a reactor lined with tetrafluoroethylene for hydrothermal reaction. The specific steps of the reaction are heating up to 100°C at 5°C / min, keeping it for 2h, and then quickly heating up to 270°C at 10°C / min , Keep for 60min, and finally cool to room temperature;

[0046] (3) The specific steps for post-processing the product using CQDs aqueous solution are as follows: according to the solid-liquid ratio of 1g:10ml, the solid product after hydrothermal reaction is put into the CQDs aqueous solution with a content of 10mg / ml, and then vigorously stirred at 90℃ for 3h .

[0047] (4) Wash the stirred product and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com