ZnO-C3N4-CQDs visible light catalytic composite material and preparation method thereof

A technology of zno-c3n4-cqds and composite materials, which is applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve problems that affect wide application and non-response to visible light, and achieve easy industrial production and excellent electronics Effect of migration and reduction of production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

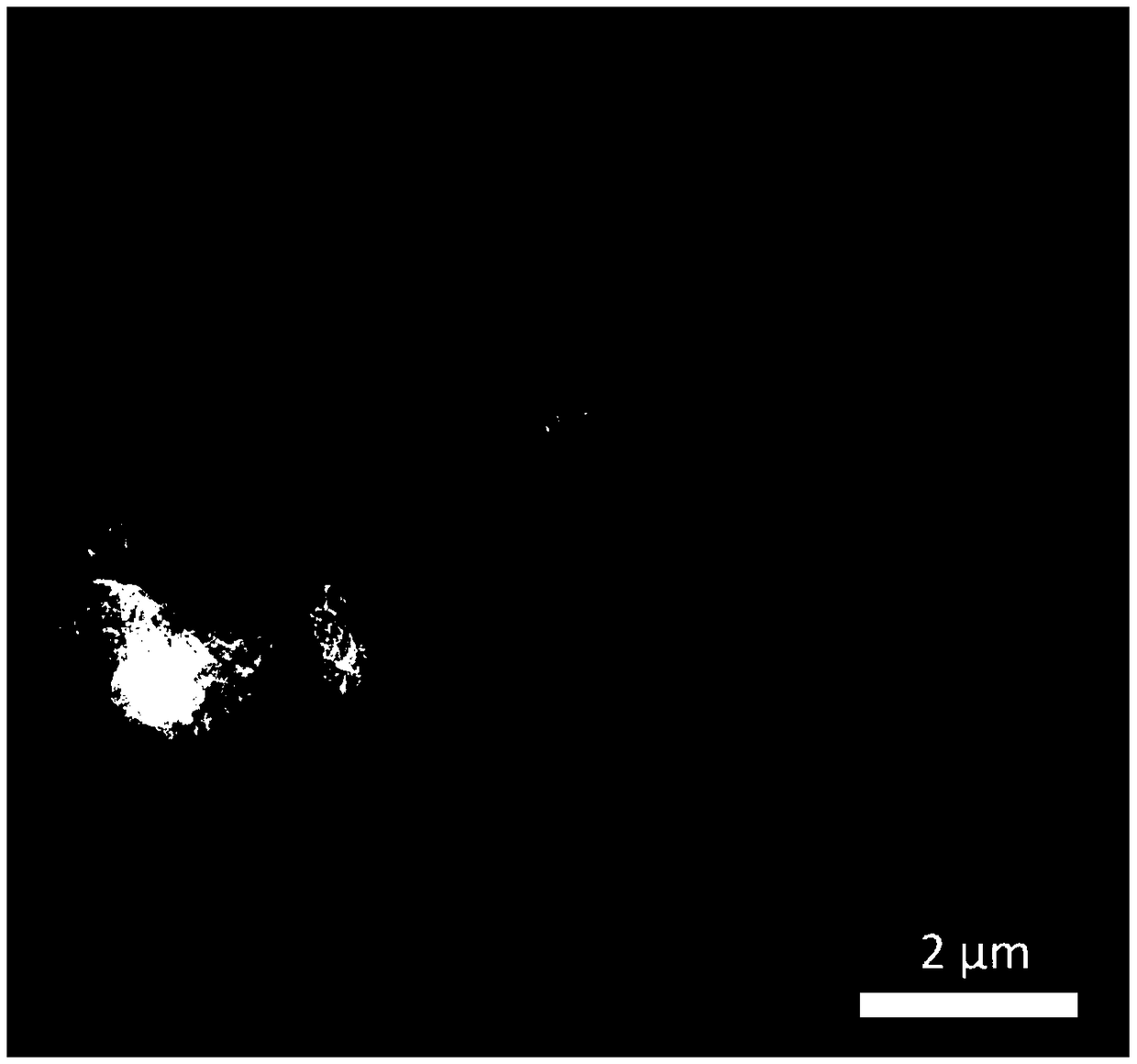

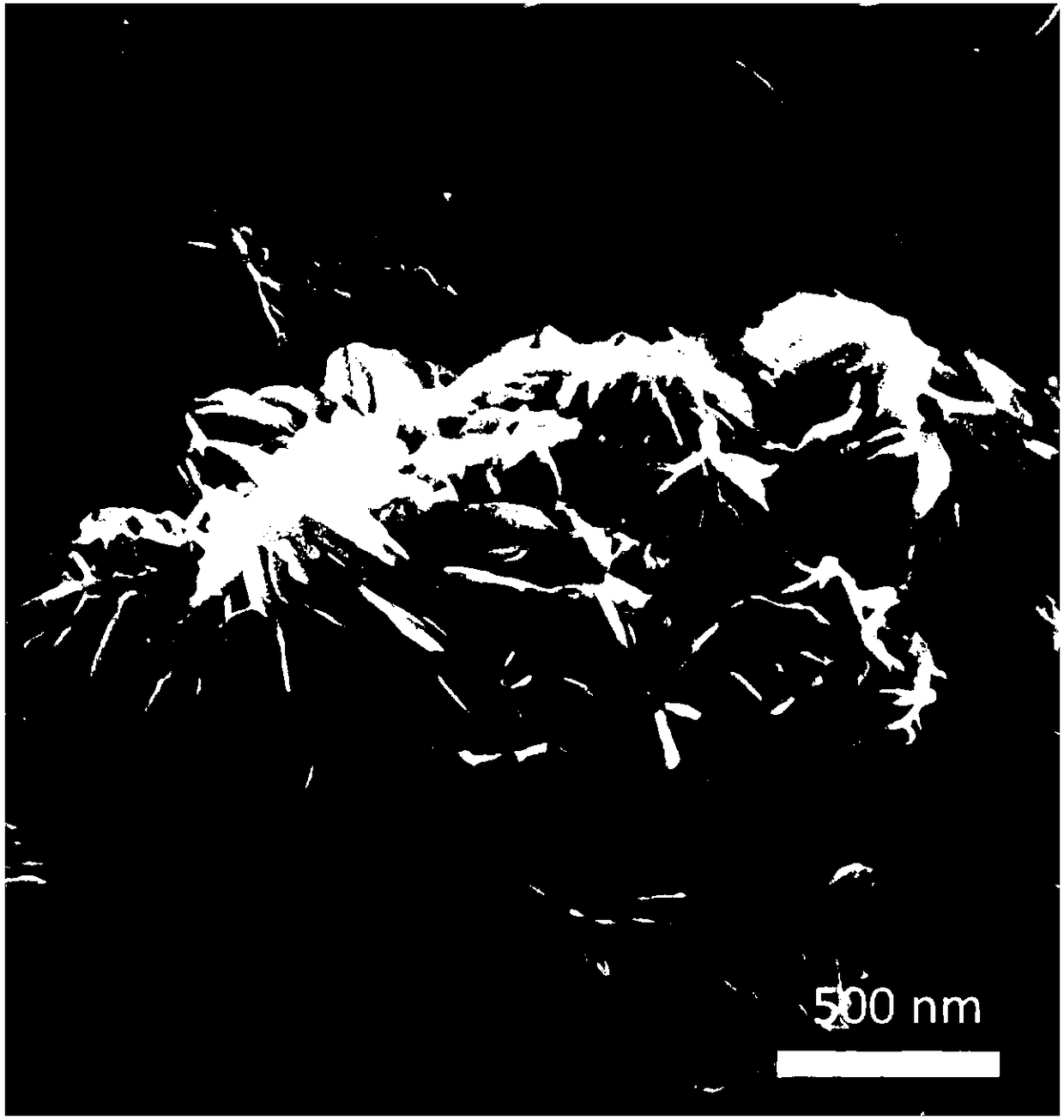

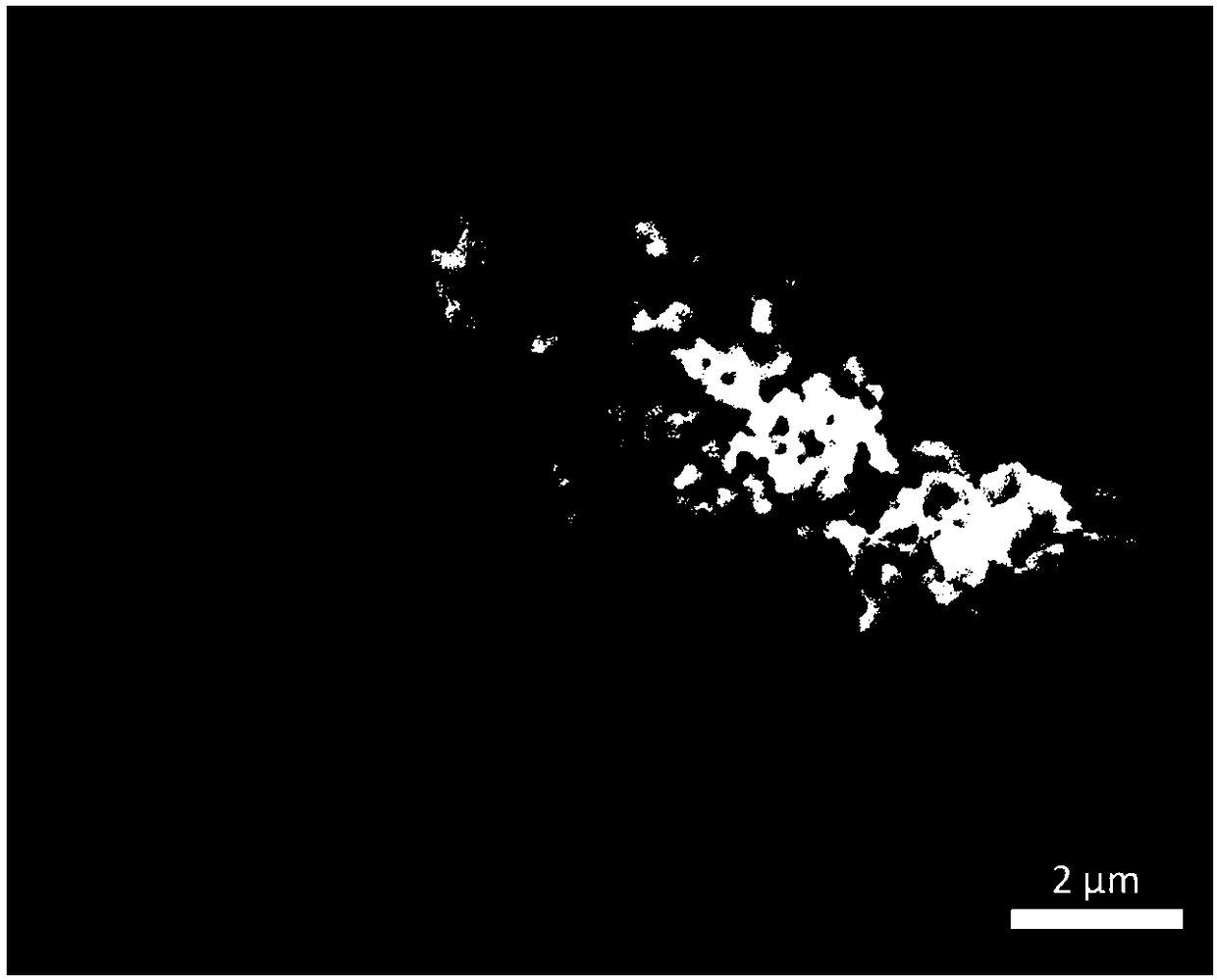

Image

Examples

Embodiment 1

[0021] A ZnO-C 3 N 4 -The preparation method of CQDs visible photocatalysis composite material, concrete steps are as follows:

[0022] (1) Stir and mix zinc nitrate, CQDs aqueous solution, melamine and water according to the solid-to-liquid mass ratio of 1g: 12ml: 0.3g: 2g: 25ml, and adjust the pH value to 11 with ammonia water. The carbon quantum dot aqueous solution content is 5mg / ml;

[0023] (2) Transfer the above solution to a reaction kettle lined with tetrafluoroethylene for hydrothermal reaction. The specific steps of the reaction are to raise the temperature to 70°C at 4°C / min, keep it for 1h, and then rapidly raise the temperature to 210°C at 9°C / min , kept for 30min, and finally cooled to room temperature;

[0024] (3) Wash and dry in vacuum at 50°C for 12 hours to obtain ZnO-C 3 N 4 -CQDs visible light photocatalytic composites.

[0025] The preparation method of the carbon quantum dots is to put graphite rods into water, conduct continuous electrolysis at 3...

Embodiment 2

[0032] A ZnO-C 3 N 4 -The preparation method of CQDs visible photocatalysis composite material, concrete steps are as follows:

[0033] (1) Stir and mix zinc nitrate, CQDs aqueous solution, melamine and water according to the solid-to-liquid mass ratio of 1g: 10ml: 0.2g: 1g: 20ml, and adjust the pH value to 11 with ammonia water. The content of the aqueous solution of carbon quantum dots is 1 mg / ml;

[0034] (2) Transfer the above solution to a reaction kettle lined with tetrafluoroethylene for hydrothermal reaction. The specific steps of the reaction are to raise the temperature to 70°C at 4°C / min, keep it for 1h, and then rapidly raise the temperature to 200°C at 9°C / min , kept for 30min, and finally cooled to room temperature;

[0035] (3) Wash and dry in vacuum at 50°C for 12 hours to obtain ZnO-C 3 N 4 -CQDs visible light photocatalytic composites.

[0036] The preparation method of the carbon quantum dots is to put graphite rods into water, conduct continuous elect...

Embodiment 3

[0039] A ZnO-C 3 N 4 -The preparation method of CQDs visible photocatalysis composite material, concrete steps are as follows:

[0040] (1) Stir and mix zinc nitrate, CQDs aqueous solution, melamine and water according to the solid-to-liquid mass ratio of 1g: 15ml: 0.5g: 4g: 30ml, and adjust the pH value to 11 with ammonia water. The content of the aqueous solution of carbon quantum dots is 10 mg / ml;

[0041] (2) Transfer the above solution to a reaction kettle lined with tetrafluoroethylene for hydrothermal reaction. The specific steps of the reaction are to raise the temperature to 70°C at 4°C / min, keep it for 1h, and then rapidly raise the temperature to 220°C at 9°C / min , kept for 30min, and finally cooled to room temperature;

[0042] (3) Wash and dry in vacuum at 50°C for 12 hours to obtain ZnO-C 3 N 4 - CQDs visible light photocatalytic composites.

[0043] The preparation method of the carbon quantum dots is to put graphite rods into water, conduct continuous ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com