Paraffin-prevention and viscosity-reduction rectifier of oil field flowing well

A rectifier and self-flowing well technology, which is applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of reduced efficiency, high difficulty, and easy problems in sealing parts, so as to reduce the viscosity of the produced fluid and reduce the The cost of oil production and the effect of reducing workover operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

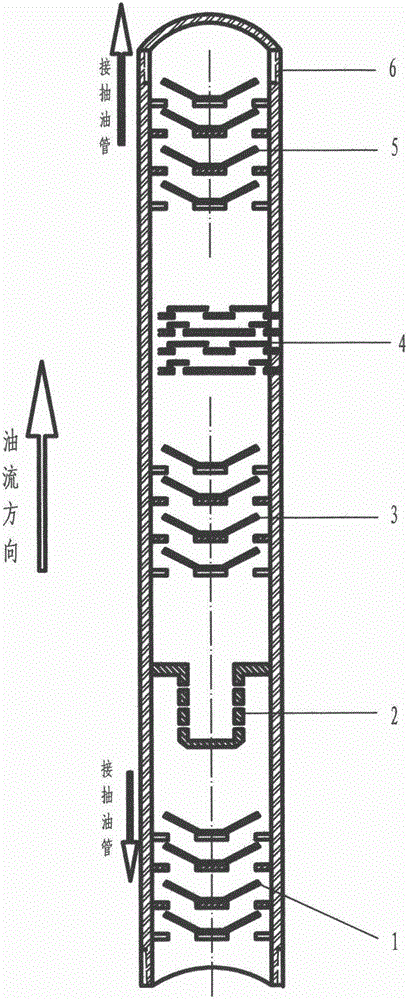

[0042] see figure 1 , In the present invention, in order to facilitate manufacture and installation, the three-section API tubing tube is used to install the components respectively, and then connect them to form a complete product. The first section of the tube is equipped with a first-stage vortex rectifier 1 and an impinging flow mixer 2; the second section of the tube is equipped with a second-stage vortex rectifier 3 and a sonic oscillator 4; the third section is equipped with a three-stage vortex rectifier 5. The three sections of pipe are connected by oilfield standard 27 / 8 inch pipe thread.

[0043] For the vortex rectifiers 1, 3, and 5 (ie, the first, second, and third stages) in the present invention, please refer to the structure Figure 5 , made of 2Cr18Ni9Ti steel; it is a circular bottom plate 18 with 6 rectangular channels 20. Above each channel, a baffle plate 19 at an angle of 30° to the central axis of the bottom plate is set, and the baffle plate is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com