Patents

Literature

269results about How to "Reduce shaping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

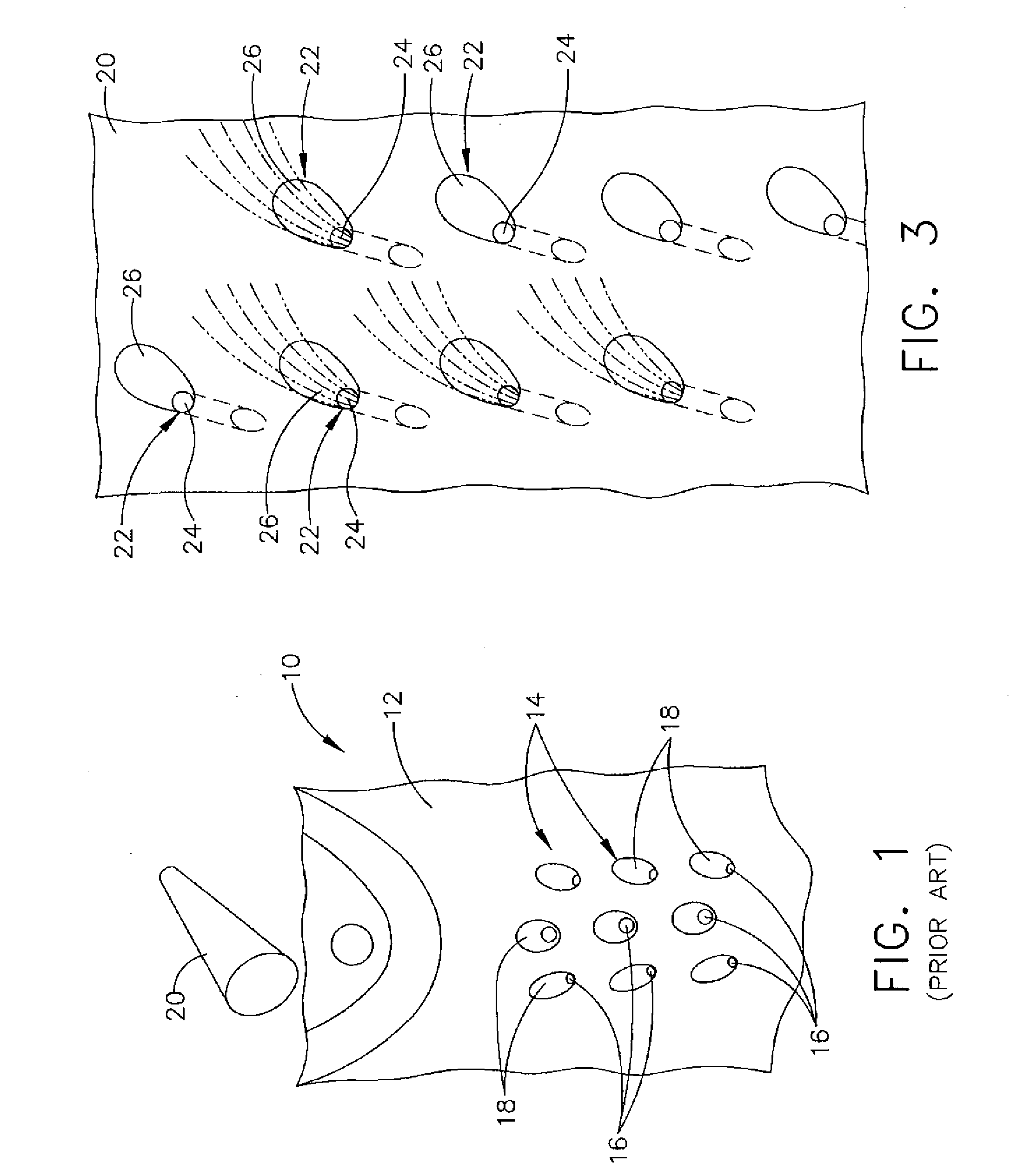

Interconnect layout method

InactiveUS20060084261A1Image degradationReduce shapingSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

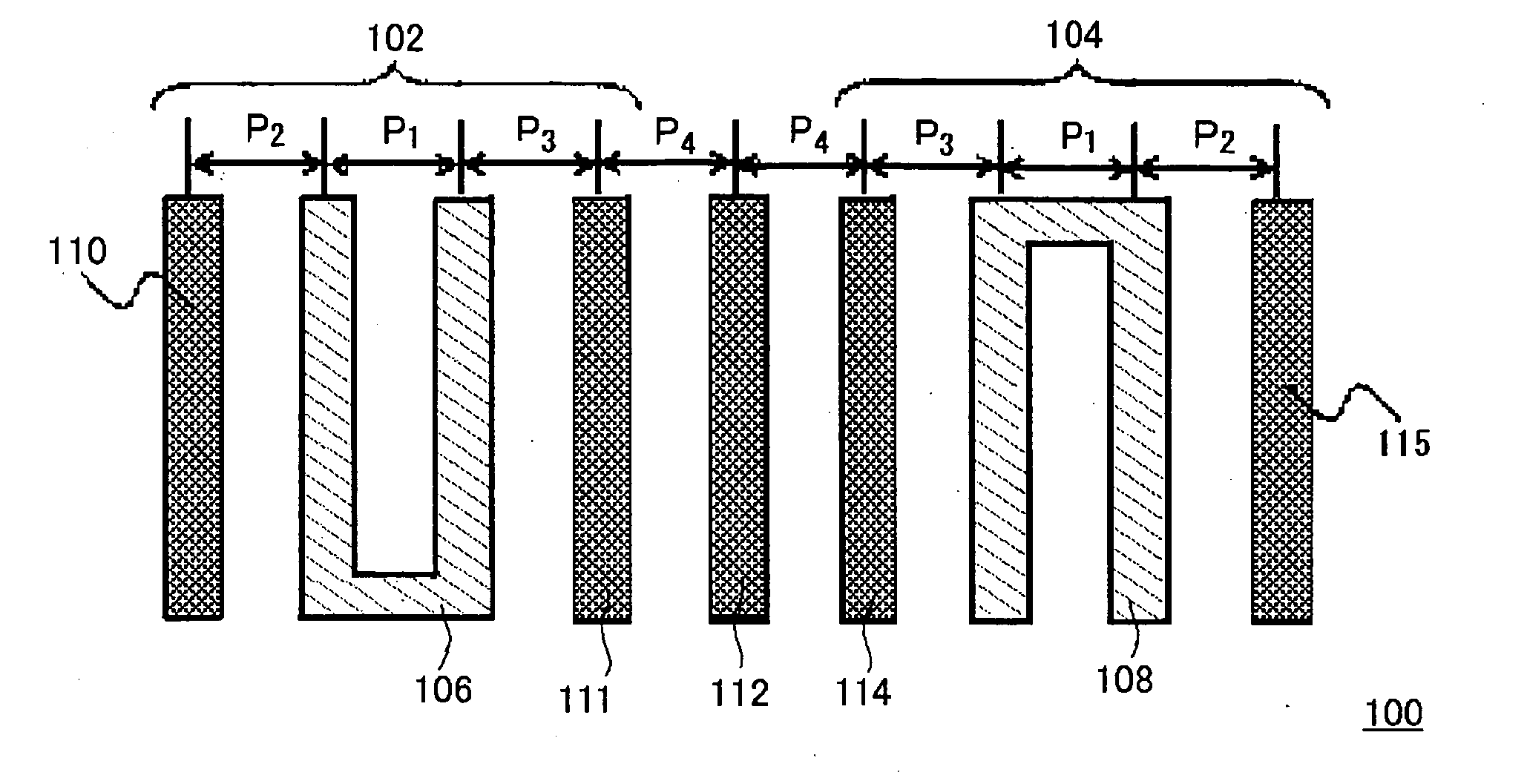

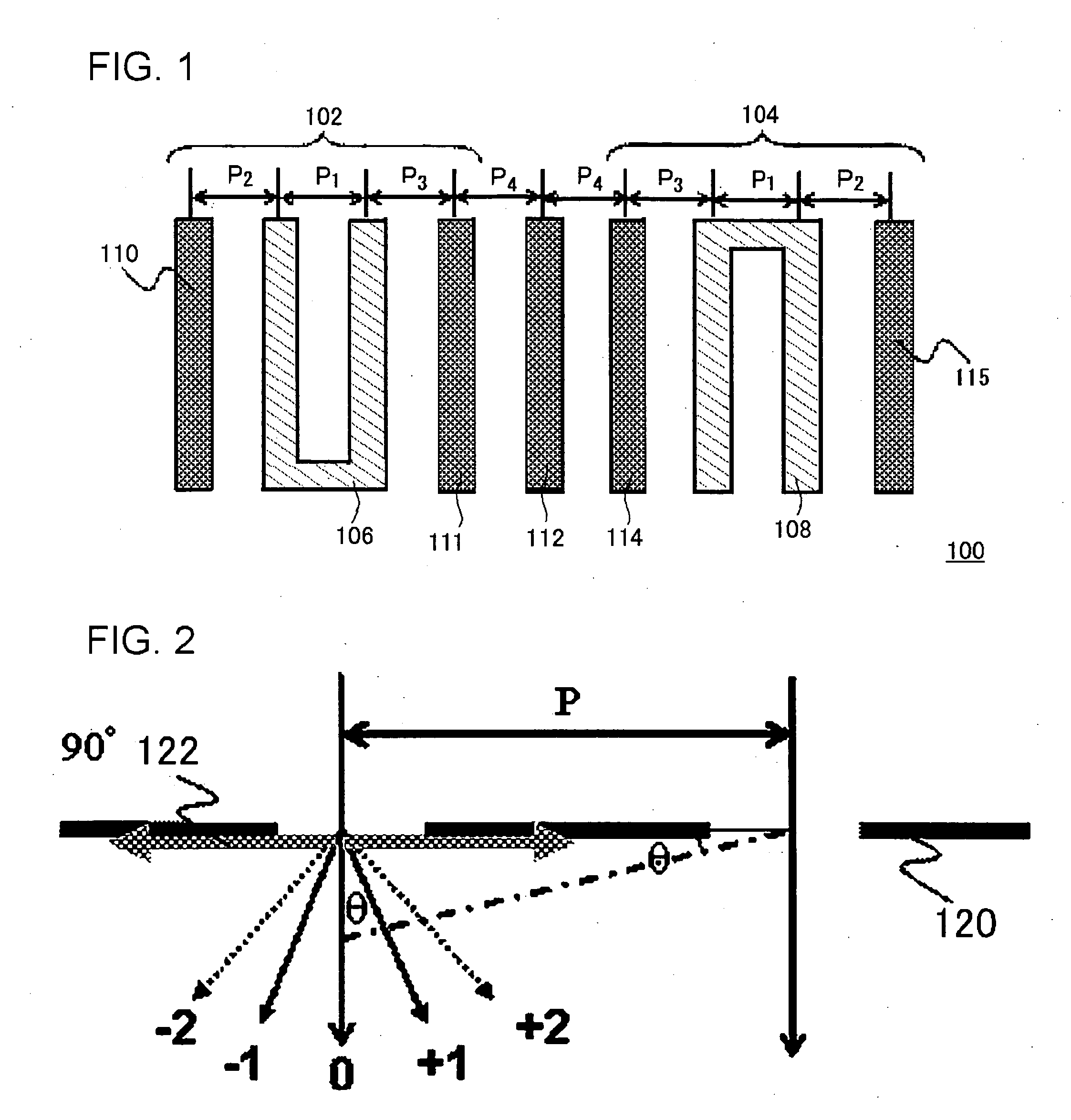

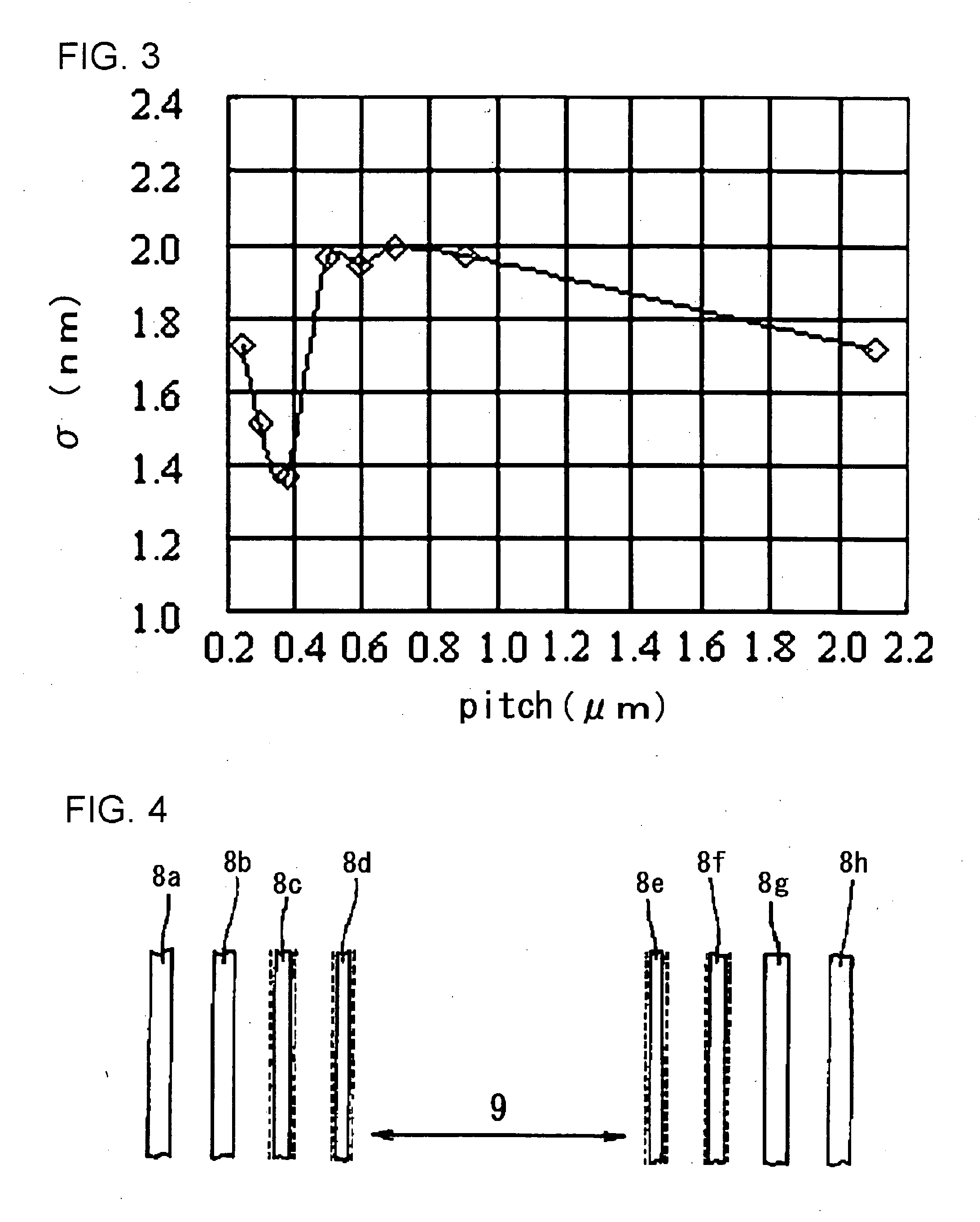

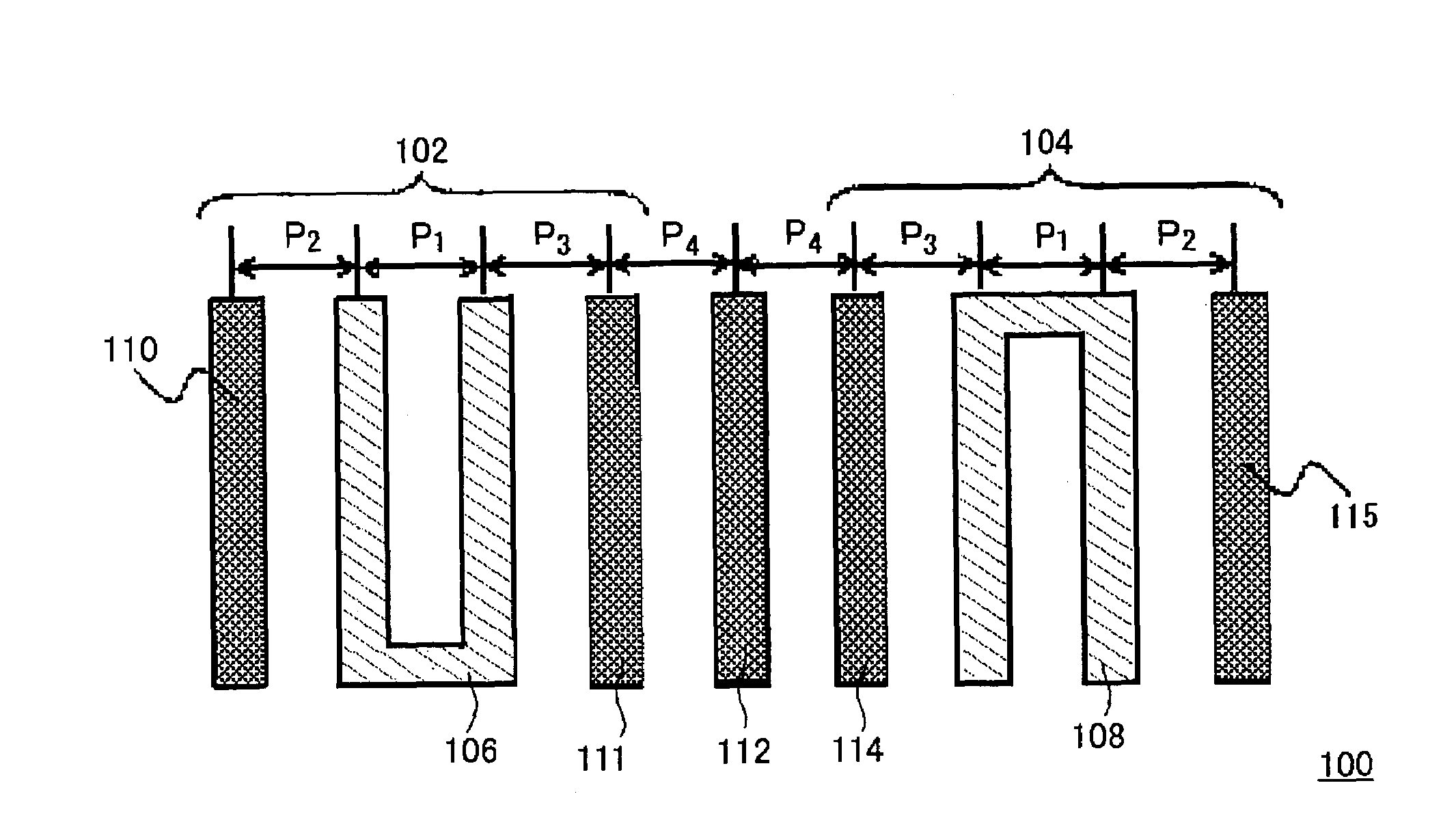

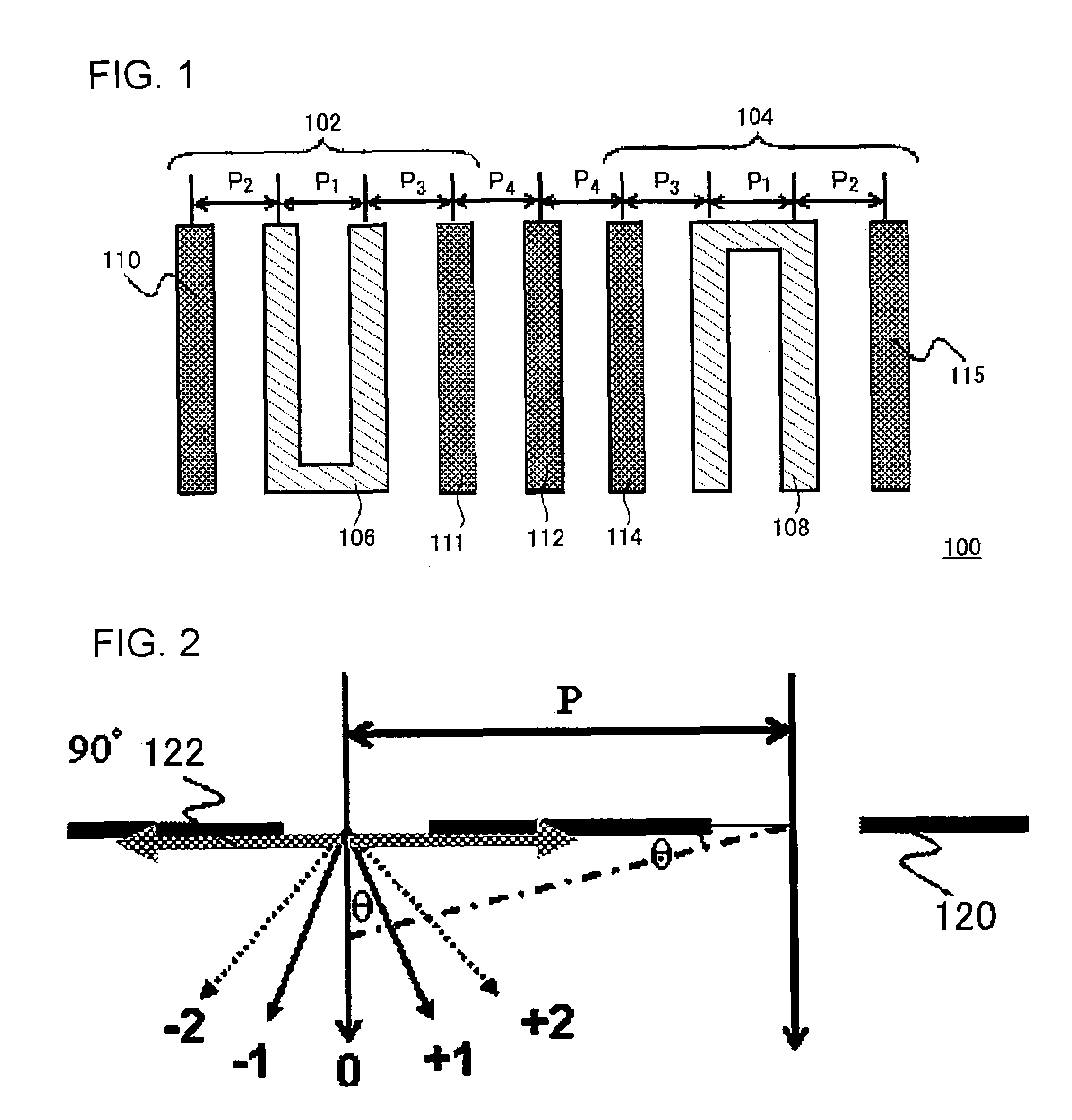

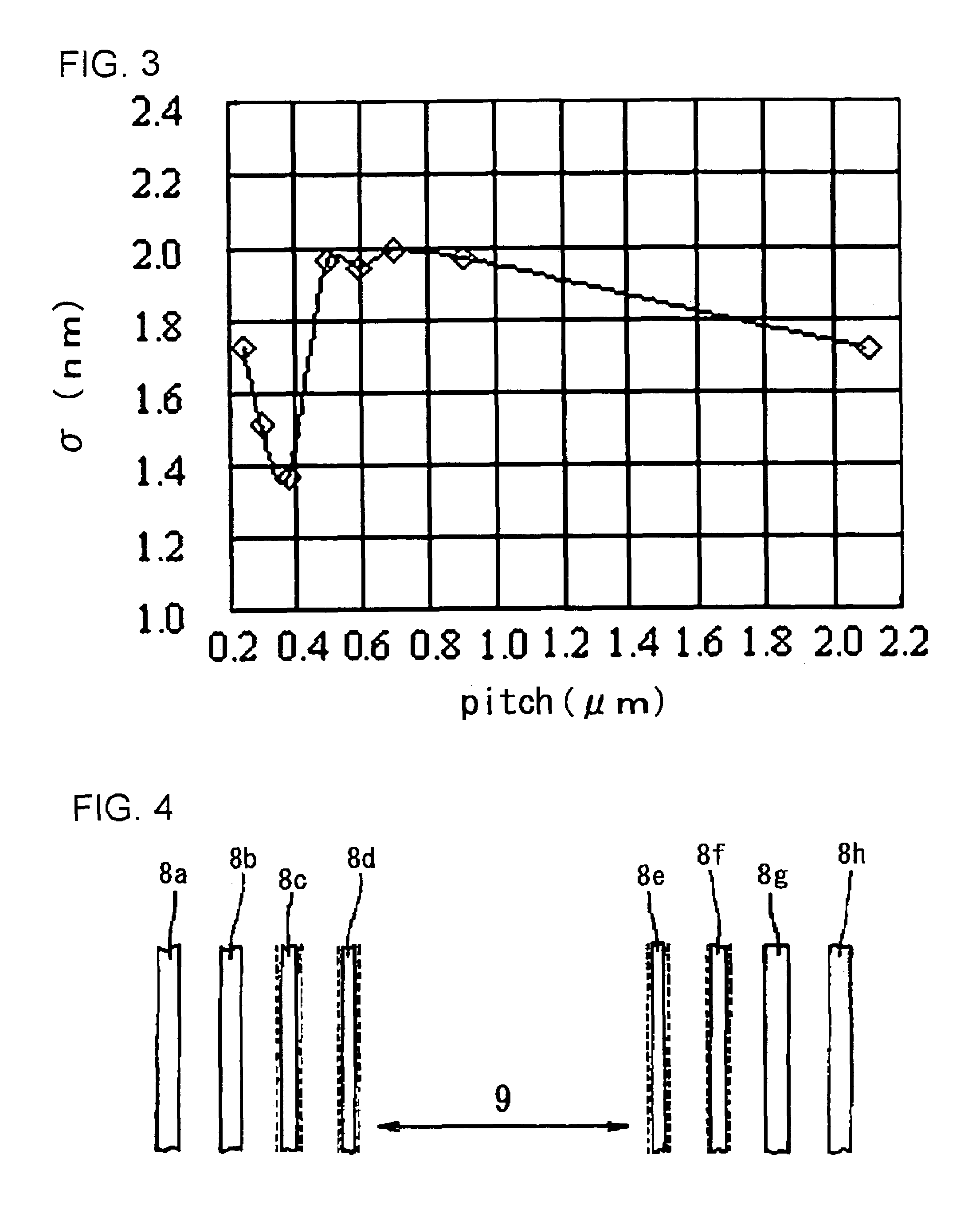

An interconnect layout method capable of reducing variations in shape of gate patterns and improving yield of a semiconductor device is provided. In an interconnect layout 100, the first gate pattern, the second gate pattern, the first dummy pattern, and the second dummy pattern are arranged so that, if a wavelength of a light used to expose the first gate pattern and the second gate pattern is λ, natural numbers are m1, m2, and m3, the first predetermined distance is P1, the second predetermined distance is P2, the third predetermined distance is P3, a design value of the first predetermined distance is P1′, a design value of the second predetermined distance is P2′, and a design value of the third predetermined distance is P3′, then the first predetermined distance satisfies relationships of P1=m1λ and P1′−0.1λ≦P1≦P1′+0.1λ, the second predetermined distance satisfies relationships of P2=m2λ and P2′−0.1λ≦P2≦P2′+0.1λ, and the third predetermined distance satisfies relationships of P3=m3λ and P3′−0.1λ≦P3≦P3′+0.1λ.

Owner:RENESAS ELECTRONICS CORP

Interconnect layout method

InactiveUS7294534B2Image degradationReduce shapingSemiconductor/solid-state device detailsSolid-state devicesLength wavePhysics

In an interconnect layout 100, the first gate pattern, the second gate pattern, the first dummy pattern, and the second dummy pattern are arranged so that, if a wavelength of a light used to expose the first gate pattern and the second gate pattern is λ, natural numbers are m1, m2, and m3, the first predetermined distance is P1, the second predetermined distance is P2, the third predetermined distance is P3, a design value of the first predetermined distance is P1′, a design value of the second predetermined distance is P2′, and a design value of the third predetermined distance is P3′, then the first predetermined distance satisfies relationships of P1=m1λ and P1′−0.1λ≦P1≦P1′+0.1λ, the second predetermined distance satisfies relationships of P2=m2λ and P2′−0.1λ≦P2≦P2′+0.1λ, and the third predetermined distance satisfies relationships of P3=m3λ and P3′−0.1λ≦P3≦P3′+0.1λ.

Owner:RENESAS ELECTRONICS CORP

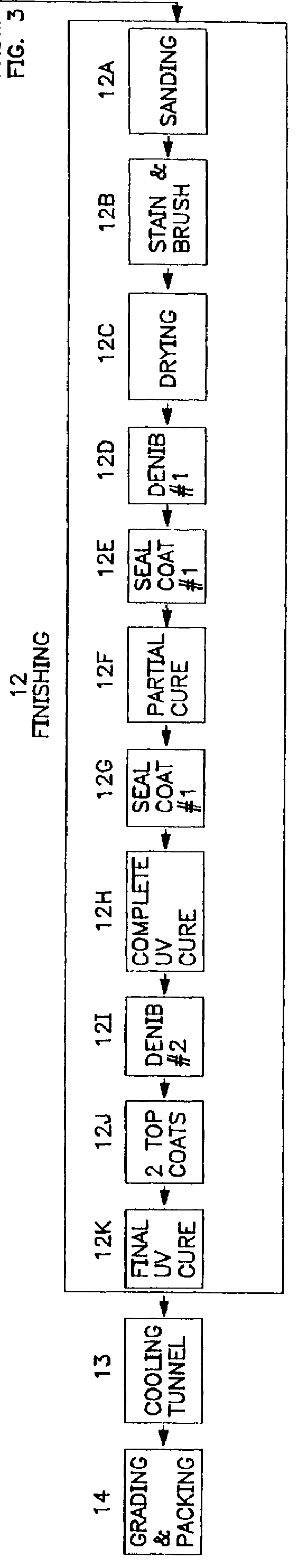

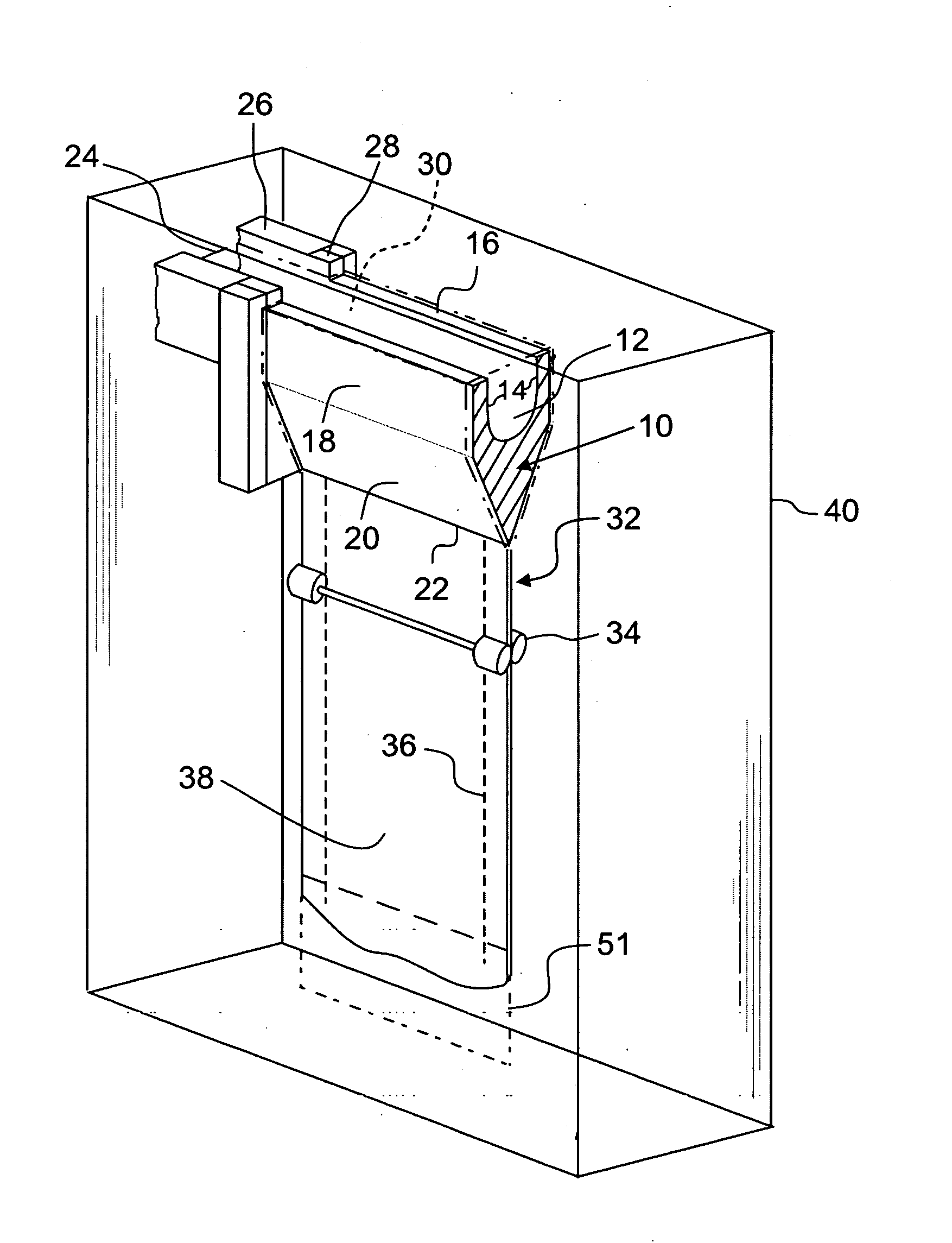

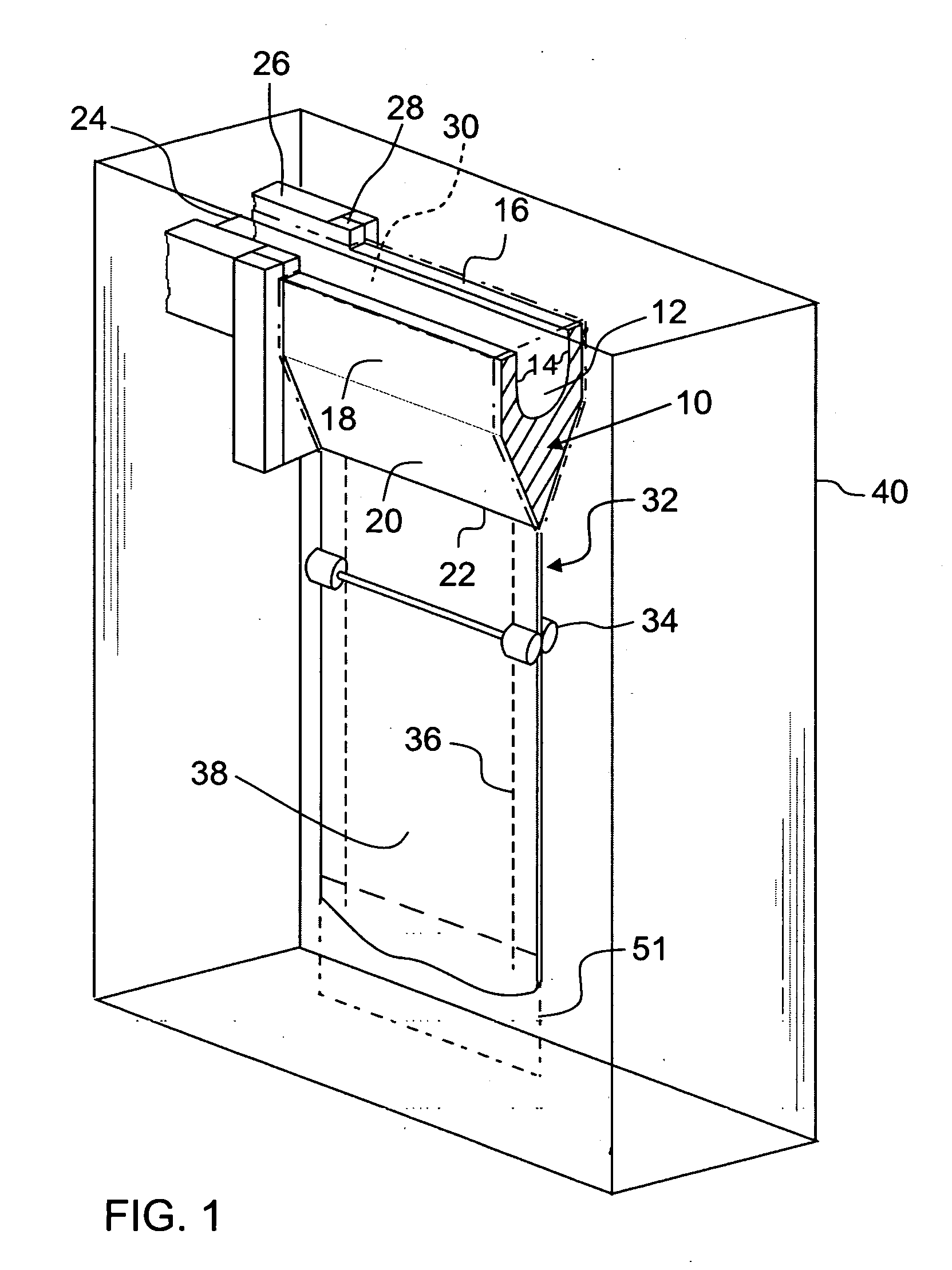

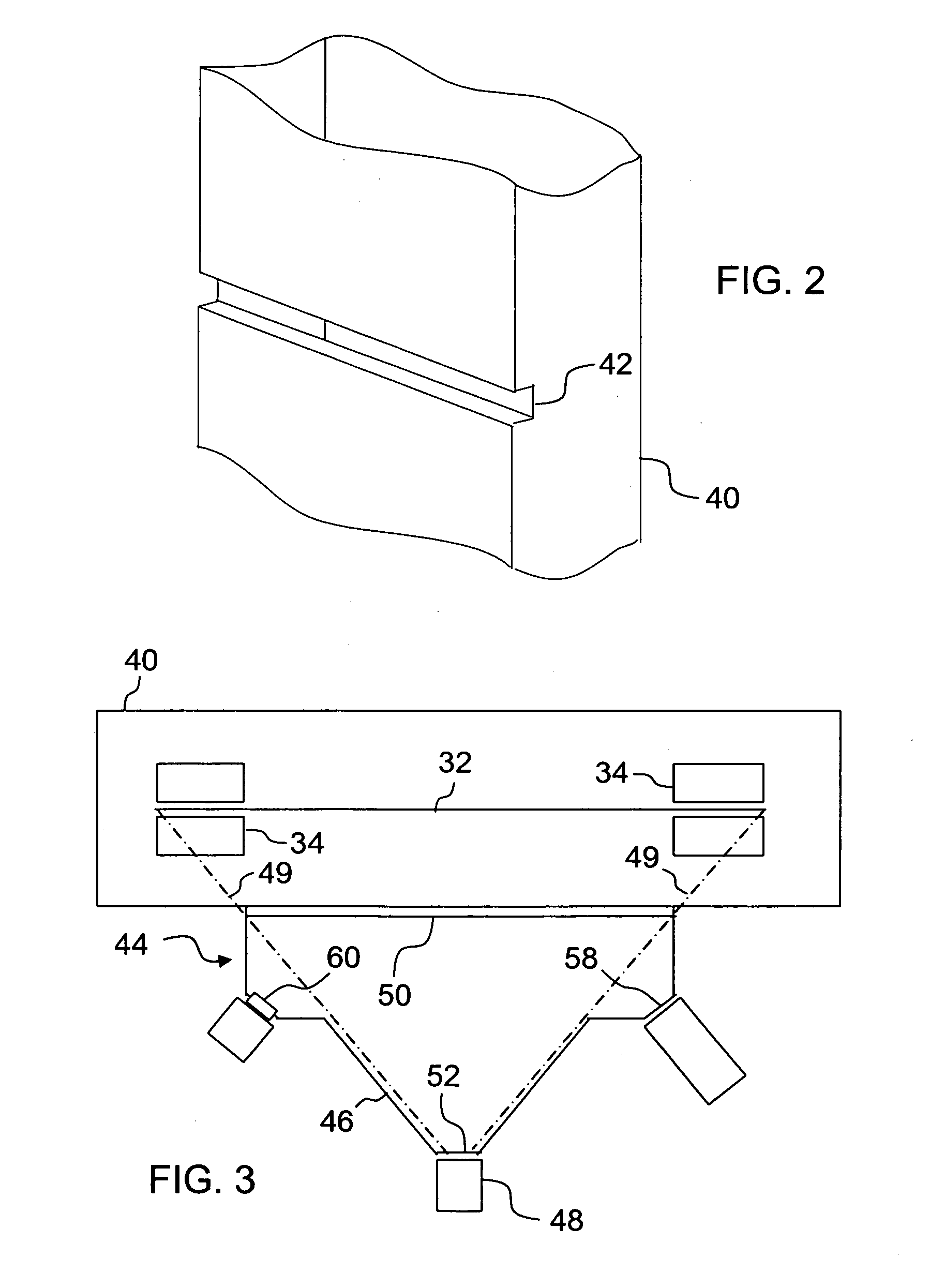

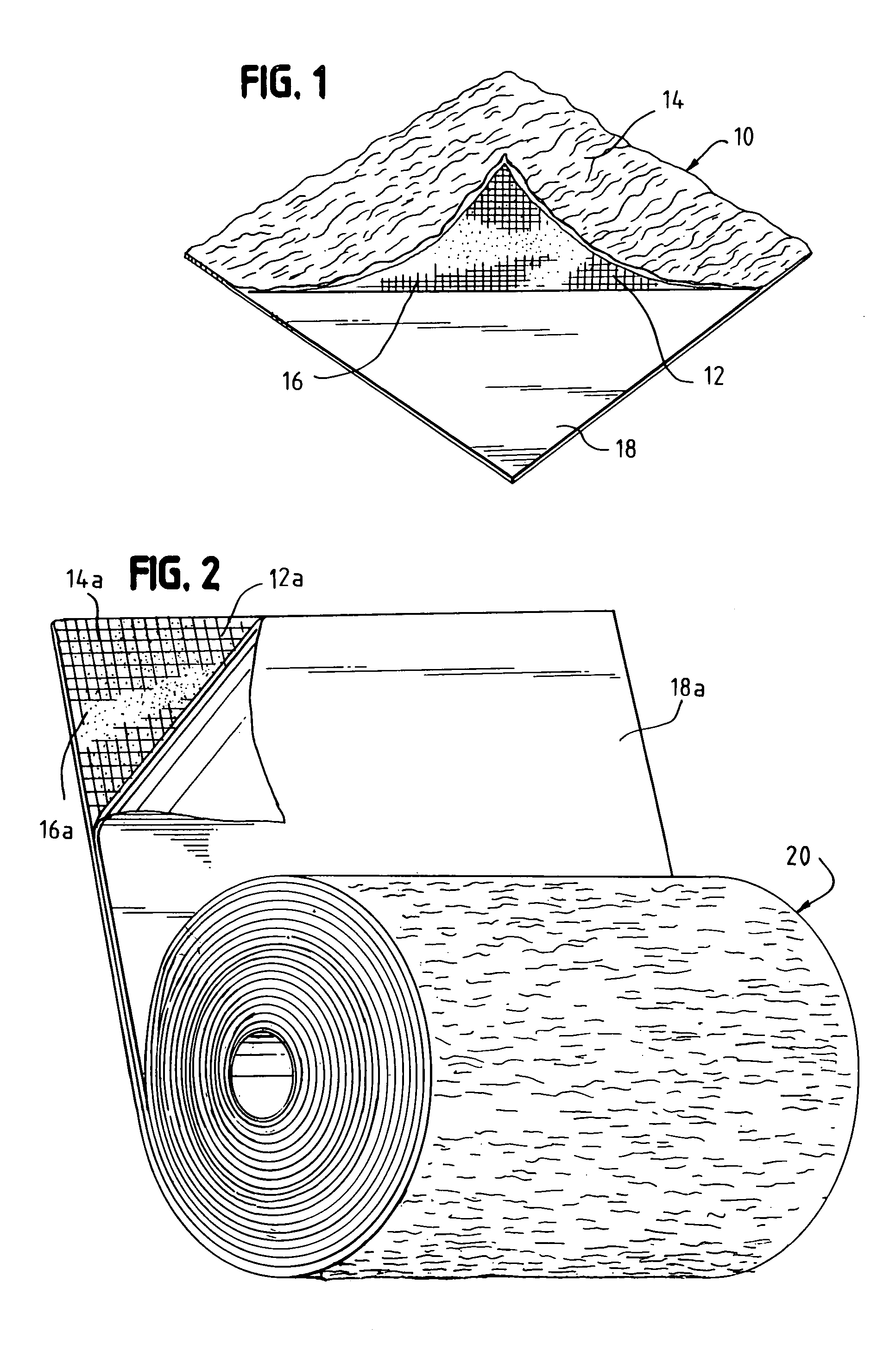

Low profile hardwood flooring strip and method of manufacture

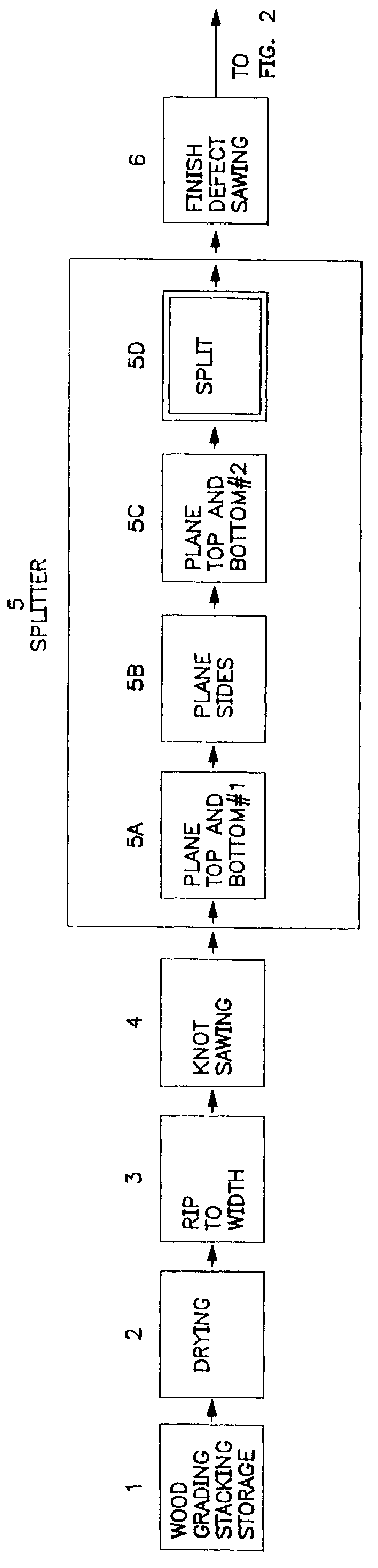

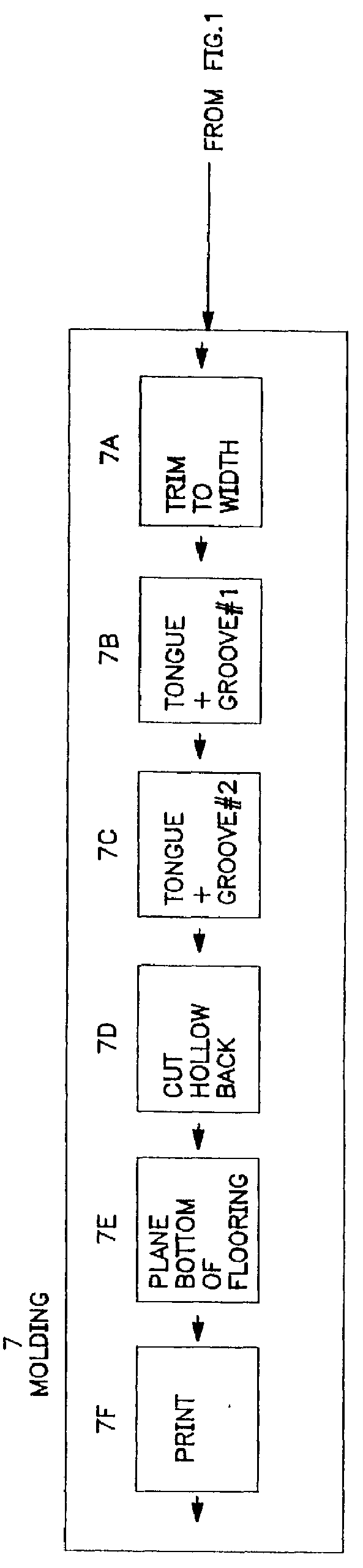

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

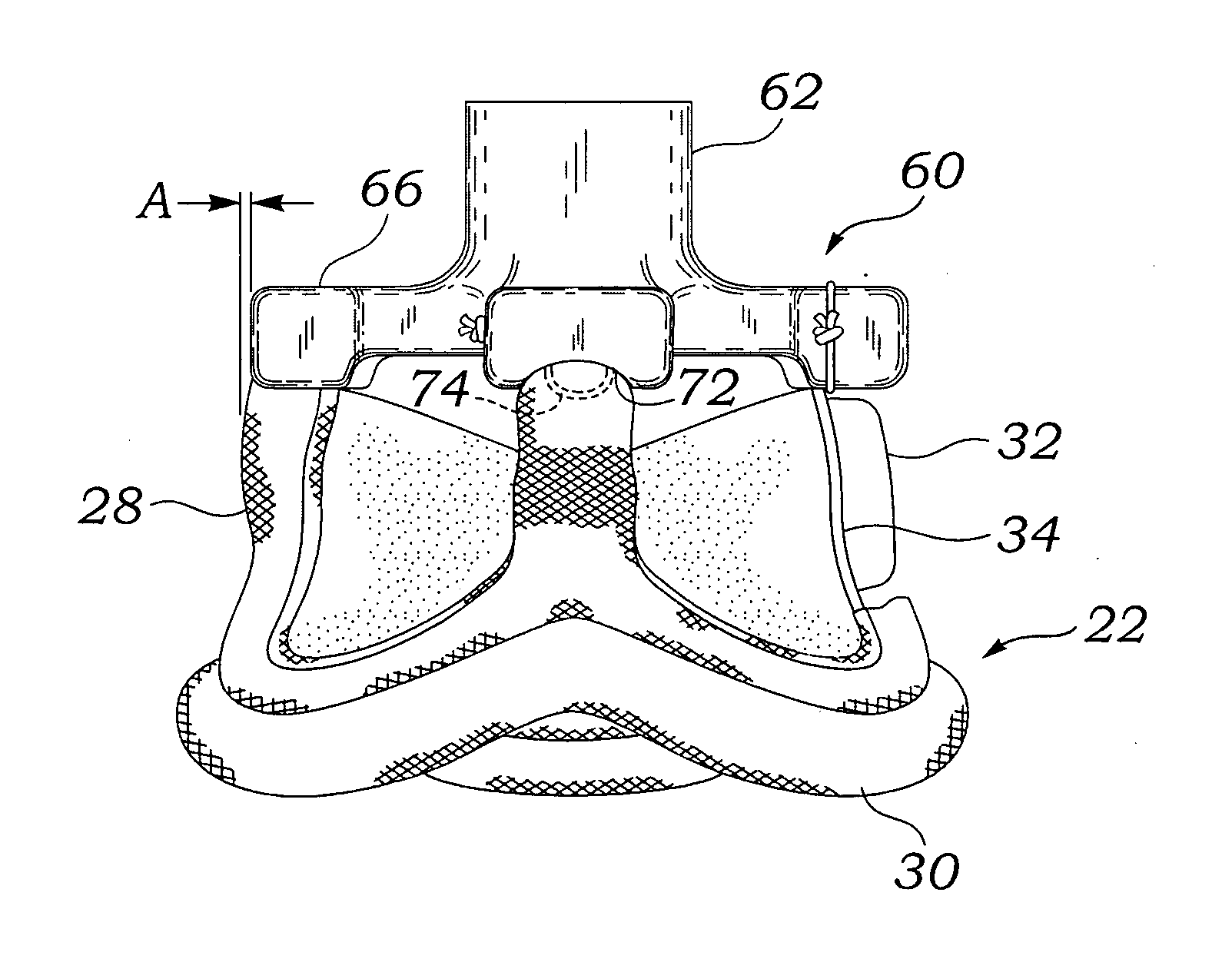

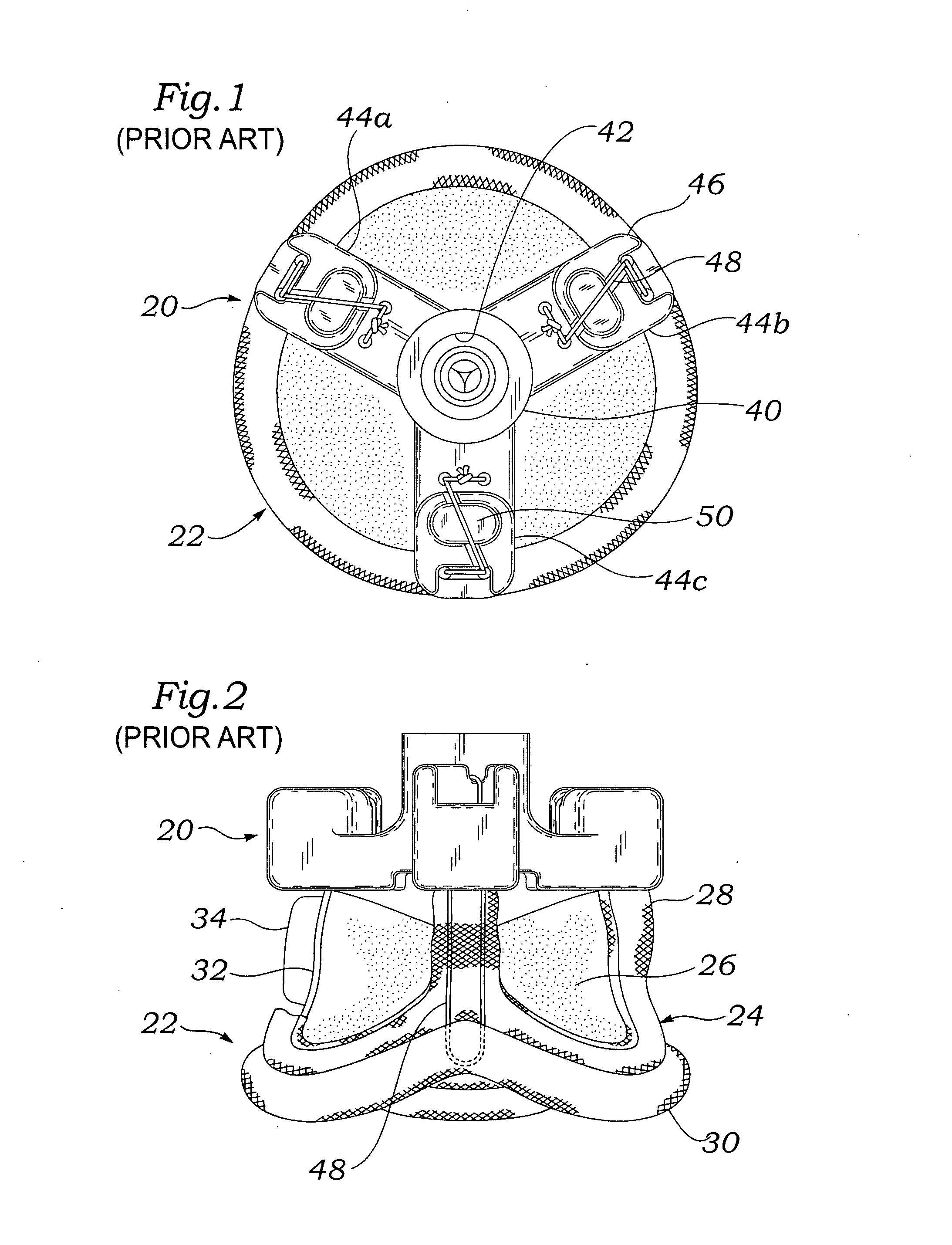

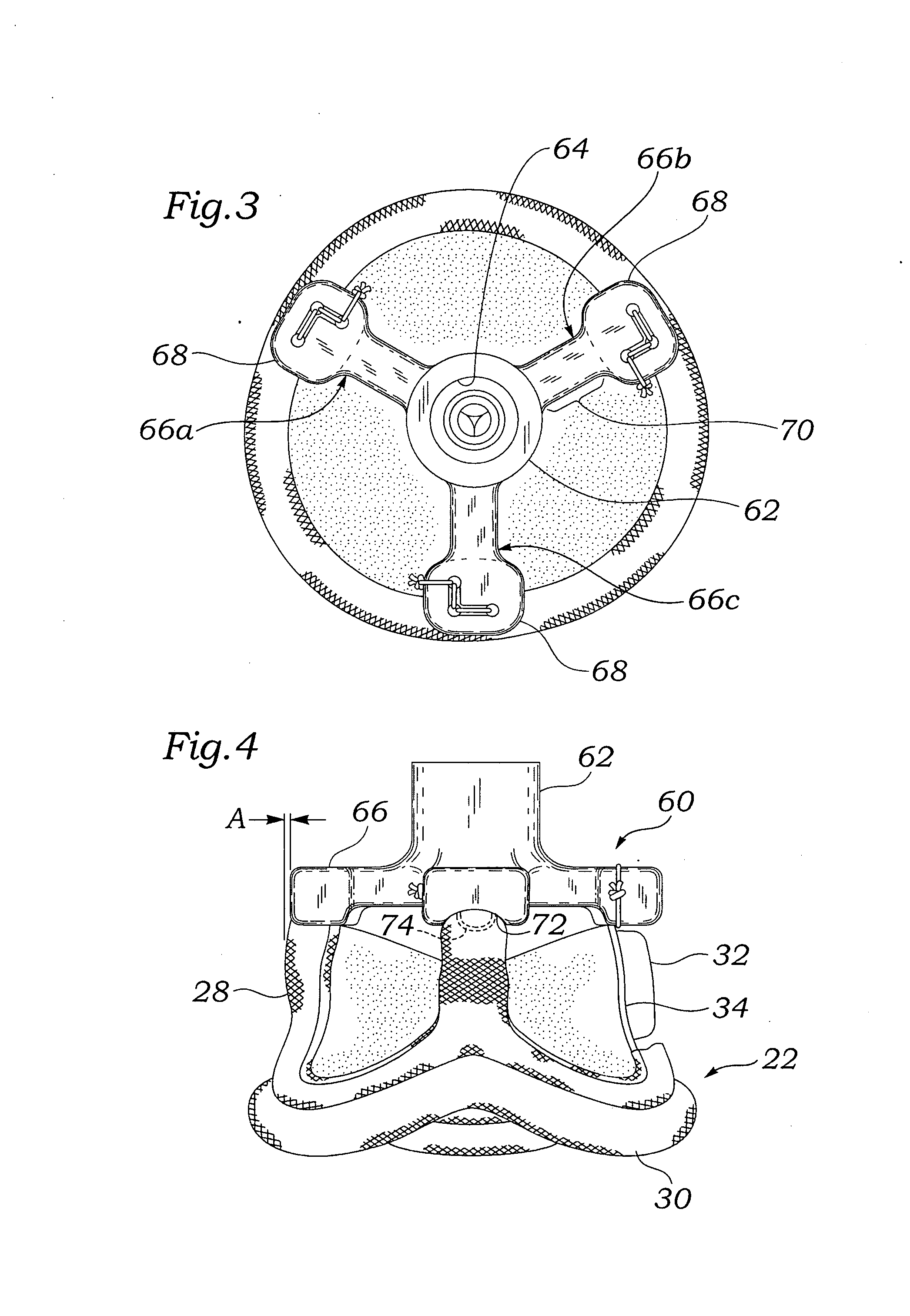

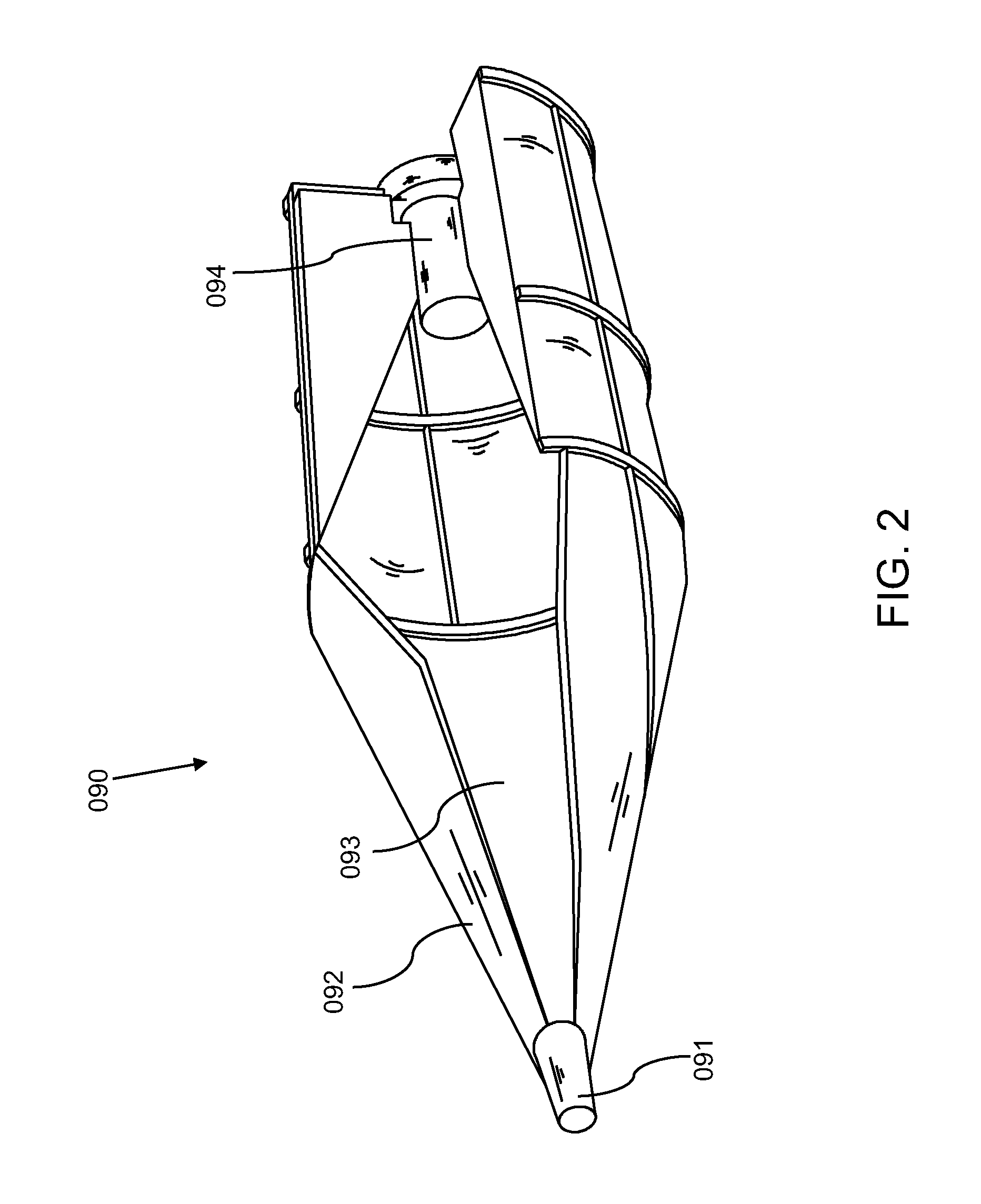

Holders for prosthetic aortic heart valves

A holder for a flexible leaflet prosthetic aortic heart valve that is less bulky than earlier holders and minimizes obstructions to vision and working space around the valve to facilitate implantation thereof. The holder may have a central hub and three outwardly extending legs that connect directly and exclusively to tips of the commissures of the aortic heart valve for better tactile feedback when parachuting and seating the valve in the annulus. The legs are sized so that they do not overlap the commissure tips and therefore afford a better view of the sewing ring adjacent the commissures. The legs may be narrow in the midsection or split into two rails to increase visibility of the valve leaflets. The hub may be vaulted axially upward relative to the outer ends of the legs to further increase visibility of the valve. A more secure engagement between the central hub and a delivery handle is also provided to ensure the holder / handle connection does not become loose during suture placement through the sewing ring and fewer handle revolutions are required to screw in and unscrew the handle from the holder.

Owner:EDWARDS LIFESCIENCES CORP

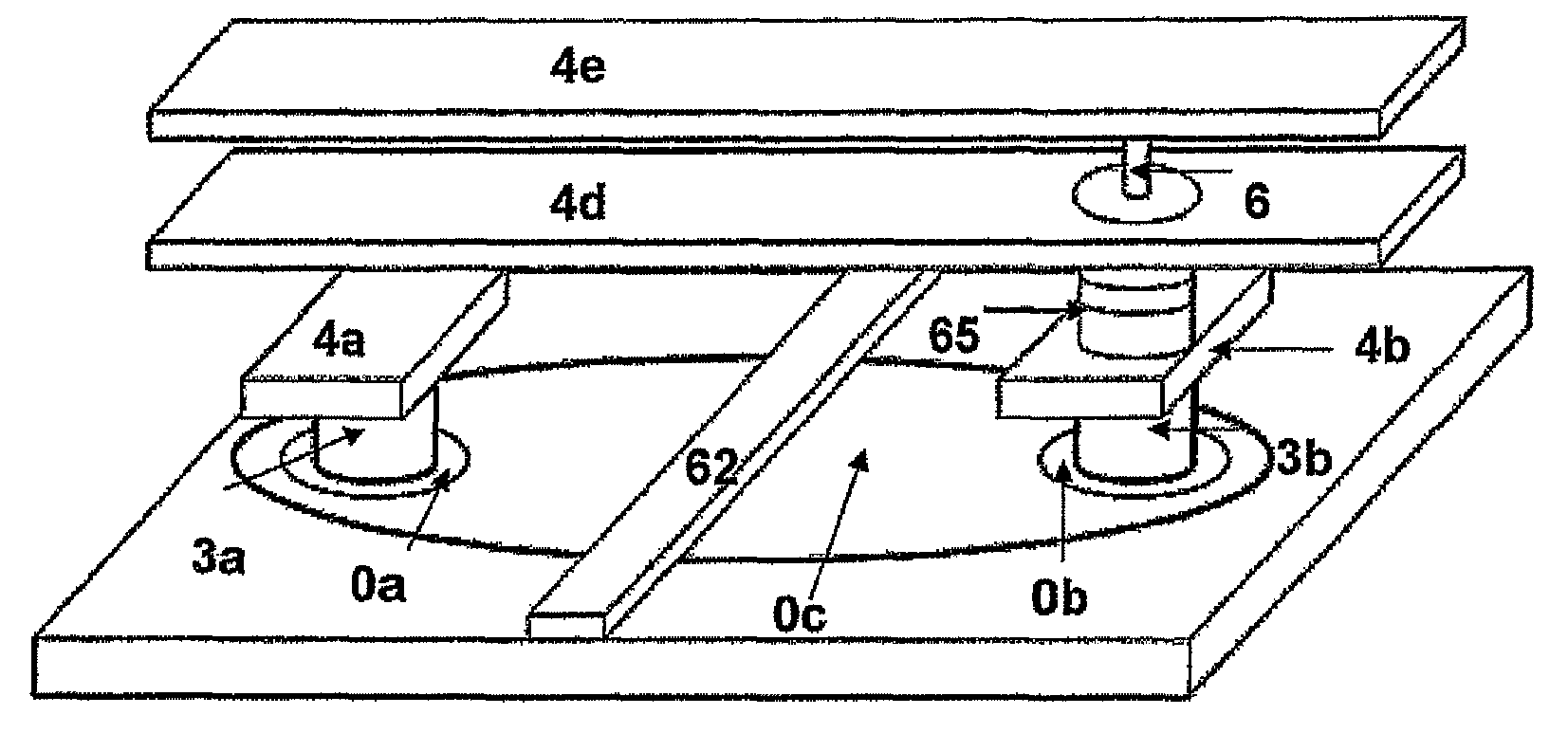

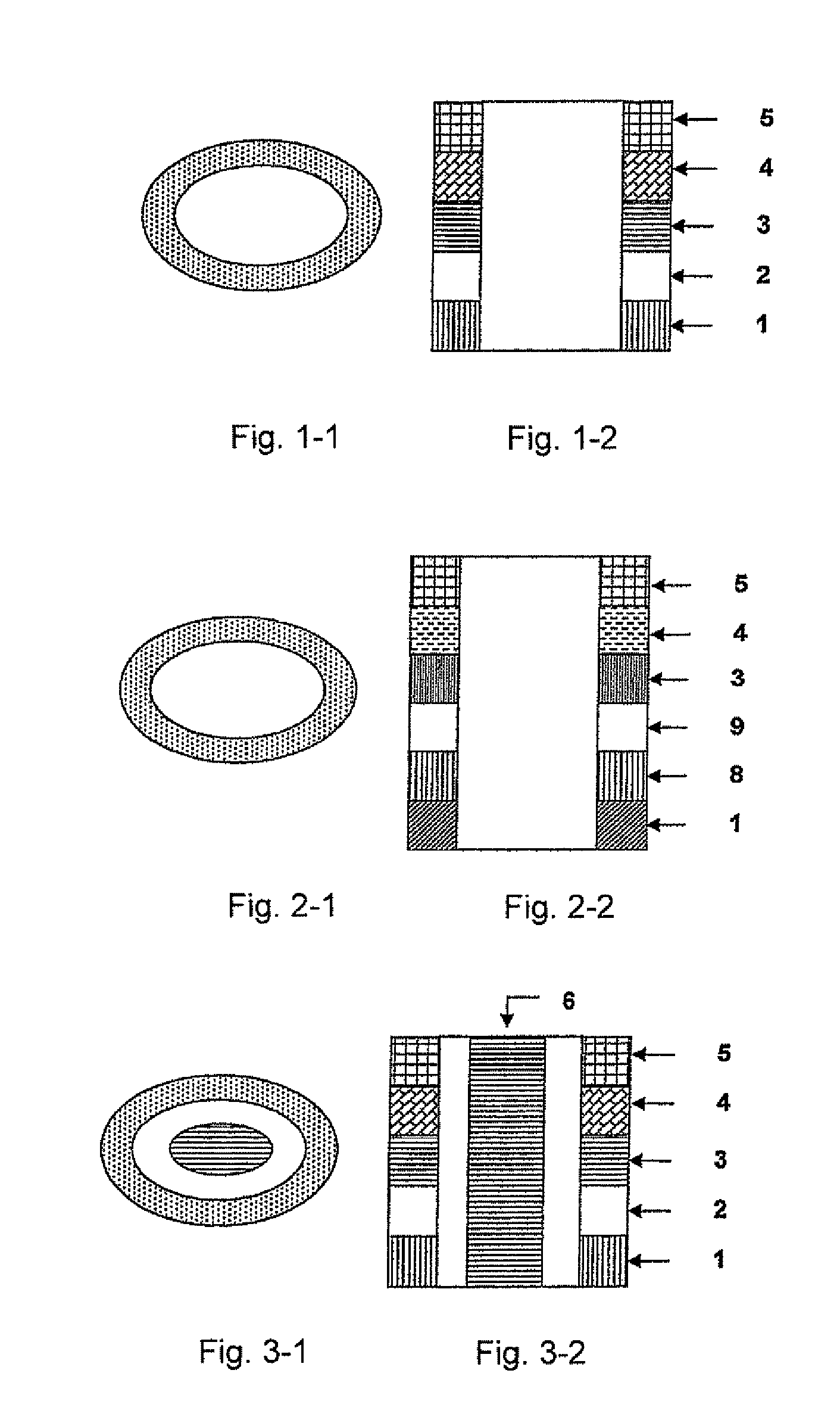

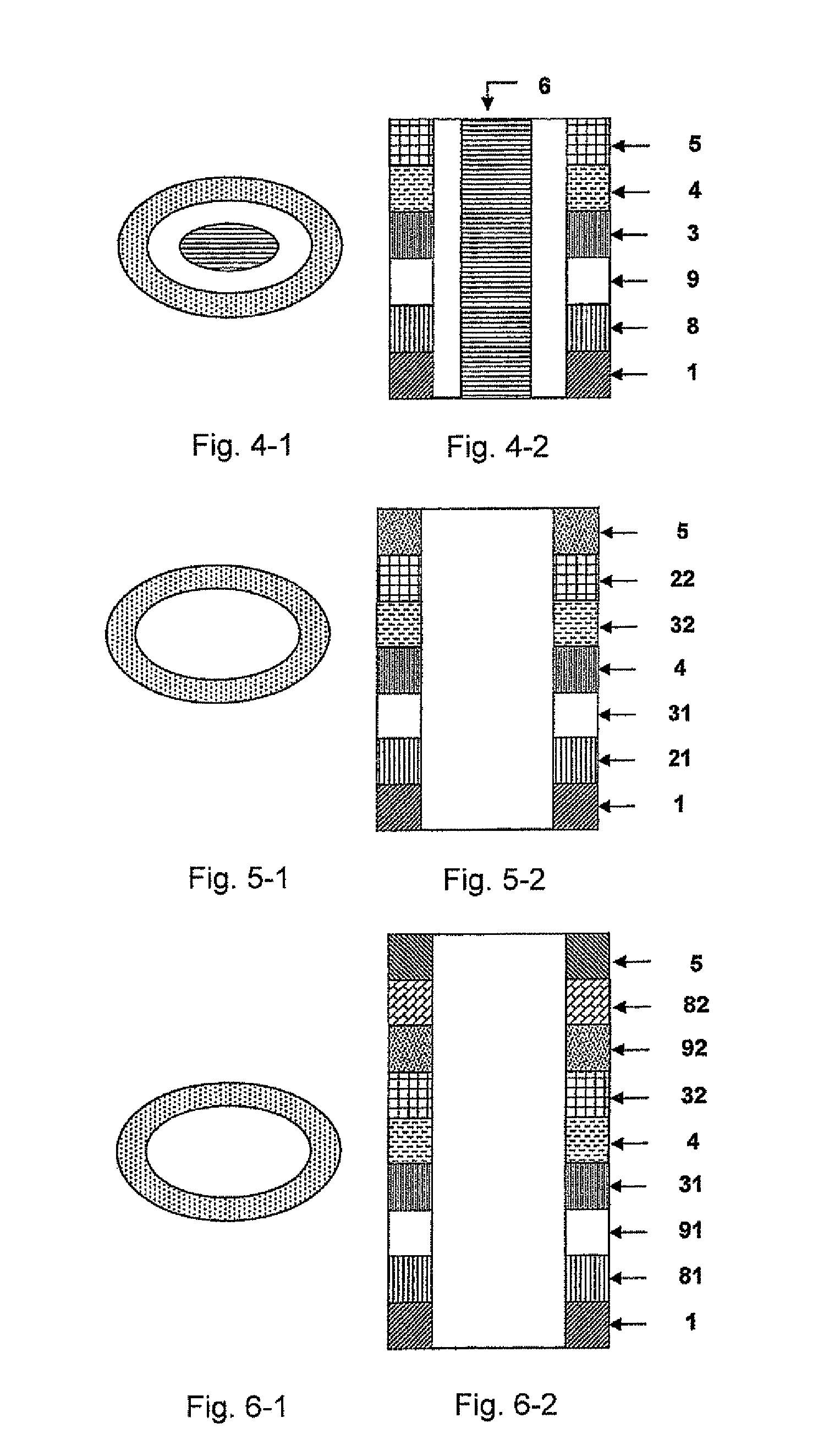

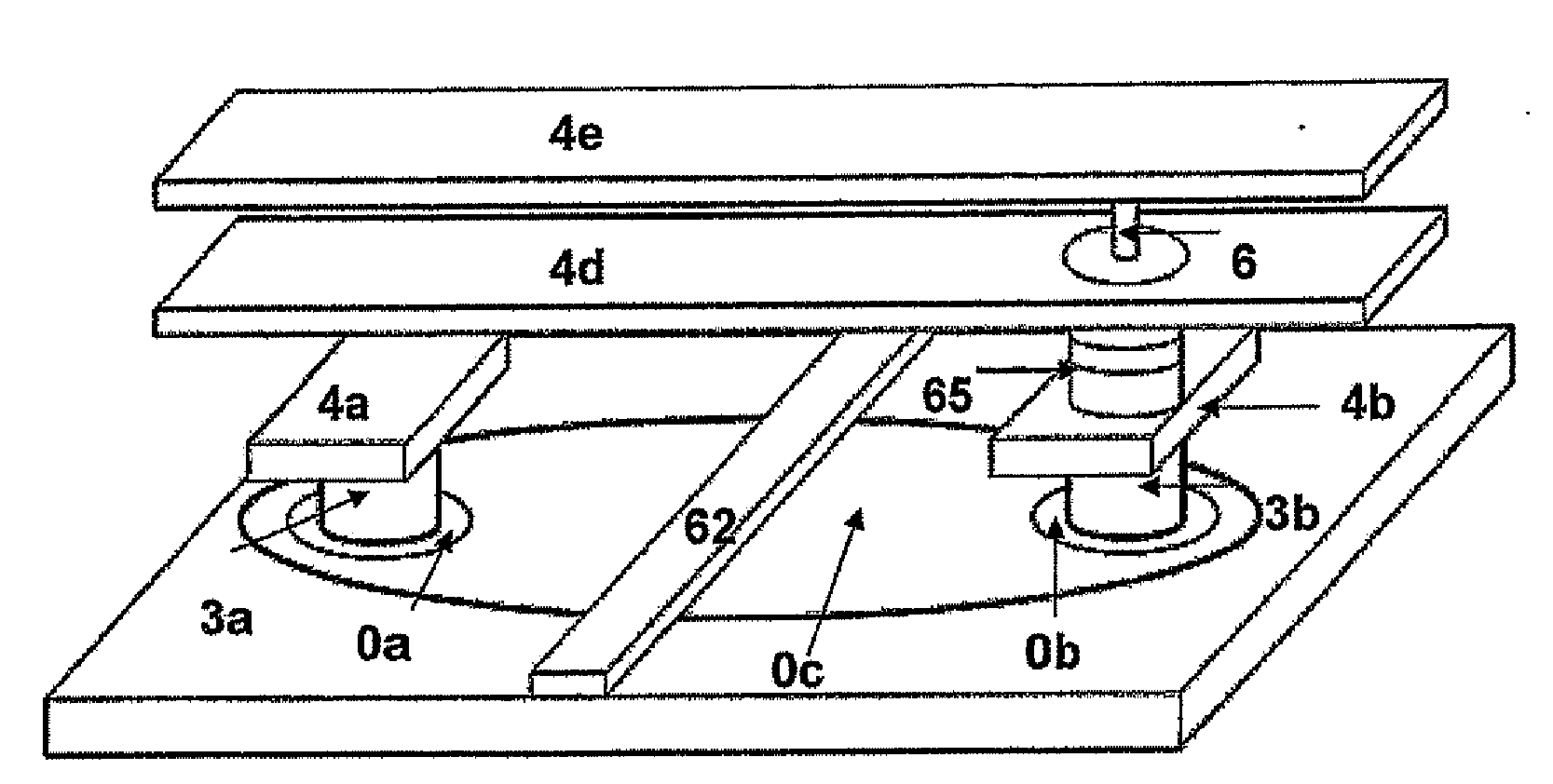

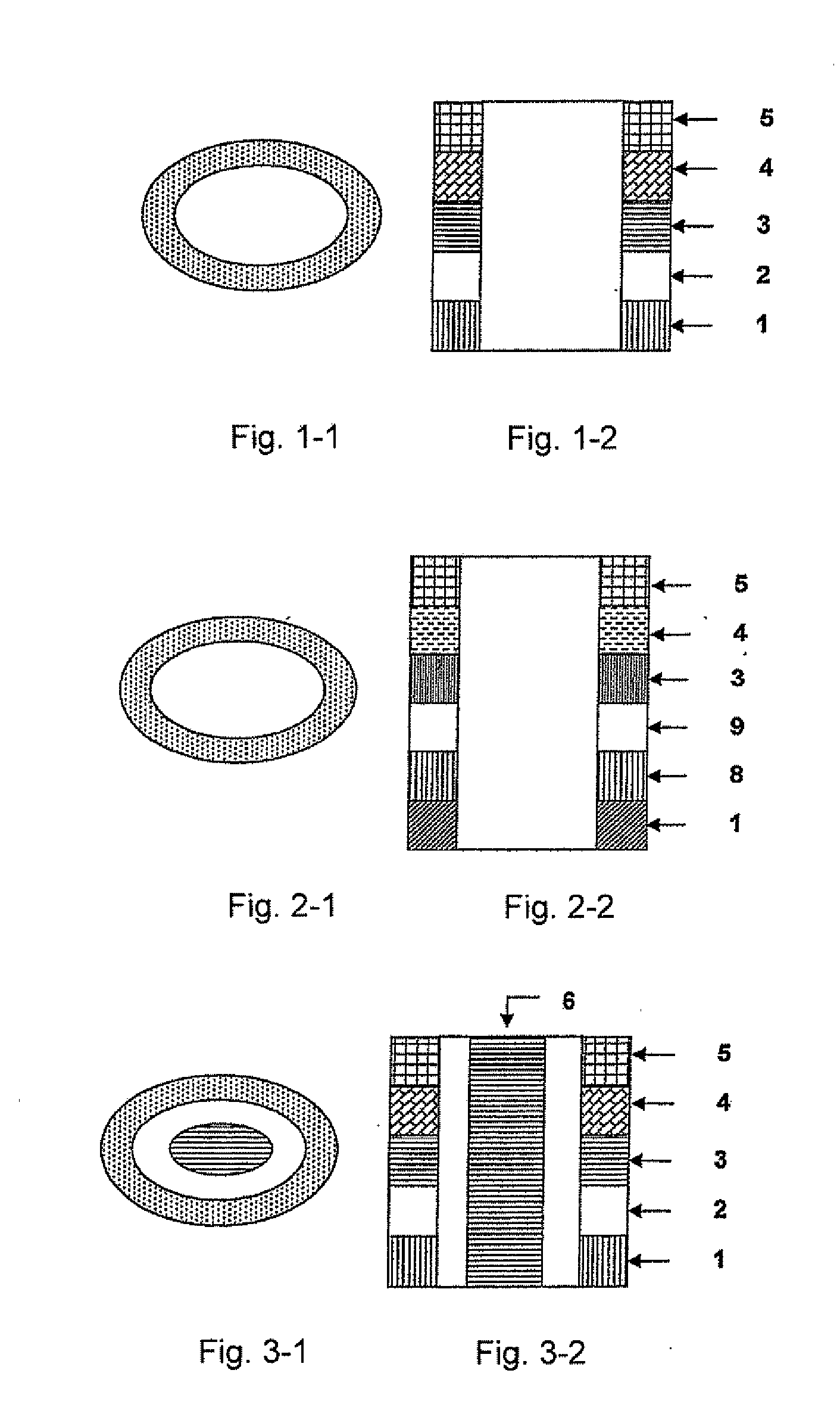

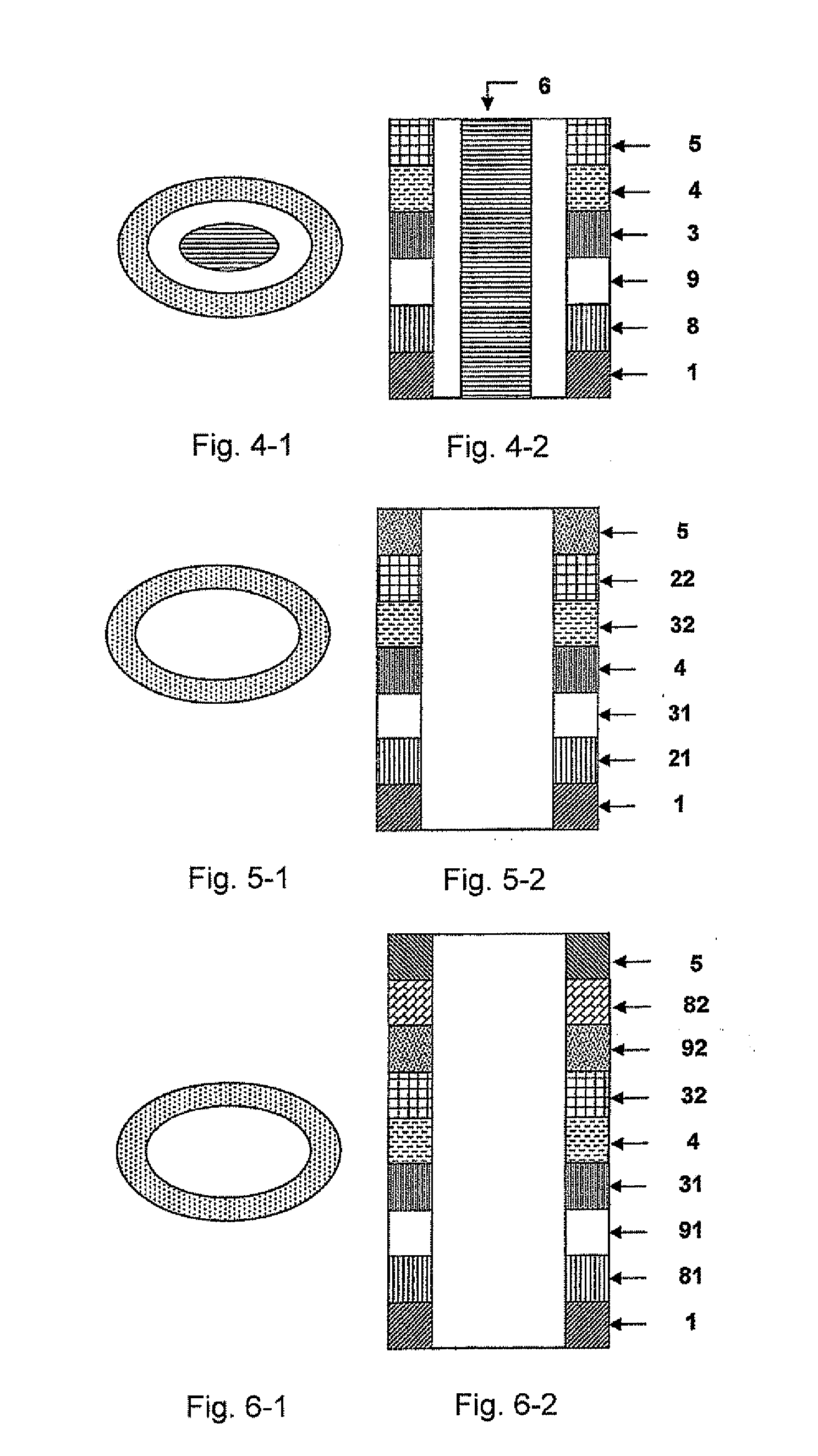

Close shaped magnetic multi-layer film comprising or not comprising a metal core and the manufacture method and the application of the same

InactiveUS7936595B2High densitySmall scaleNanomagnetismMagnetic measurementsMagnetic beadMagnetic logic

Each layer in the magnetic multilayer film is a closed ring or oval ring and the magnetic moment or flux of the ferromagnetic film in the magnetic unit is in close state either clockwise or counterclockwise. A metal core is put in the geometry center position in the close-shaped magnetic multilayer film. The cross section of the metal core is a corresponding circular or oval. A MRAM is made of the closed magnetic multilayer film with or without a metal core. The close-shaped magnetic multilayer film is formed by micro process method. The close-shaped magnetic multilayer film can be used broadly in a great variety of device that uses a magnetic multilayer film as the core, such as MRAM, magnetic bead in computer, magnetic sensitive sensor, magnetic logic device and spin transistor.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Close shaped magnetic multi-layer film comprising or not comprising a metal core and the manufacture method and the application of the same

InactiveUS20090168506A1High densitySmall scaleNanomagnetismMagnetic measurementsMagnetic beadMagnetic logic

Each layer in the magnetic multilayer film is a closed ring or oval ring and the magnetic moment or flux of the ferromagnetic film in the magnetic unit is in close state either clockwise or counterclockwise. A metal core is put in the geometry center position in the close-shaped magnetic multilayer film. The cross section of the metal core is a corresponding circular or oval. A MRAM is made of the closed magnetic multilayer film with or without a metal core. The close-shaped magnetic multilayer film is formed by micro process method. The close-shaped magnetic multilayer film can be used broadly in a great variety of device that uses a magnetic multilayer film as the core, such as MRAM, magnetic bead in computer, magnetic sensitive sensor, magnetic logic device and spin transistor.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

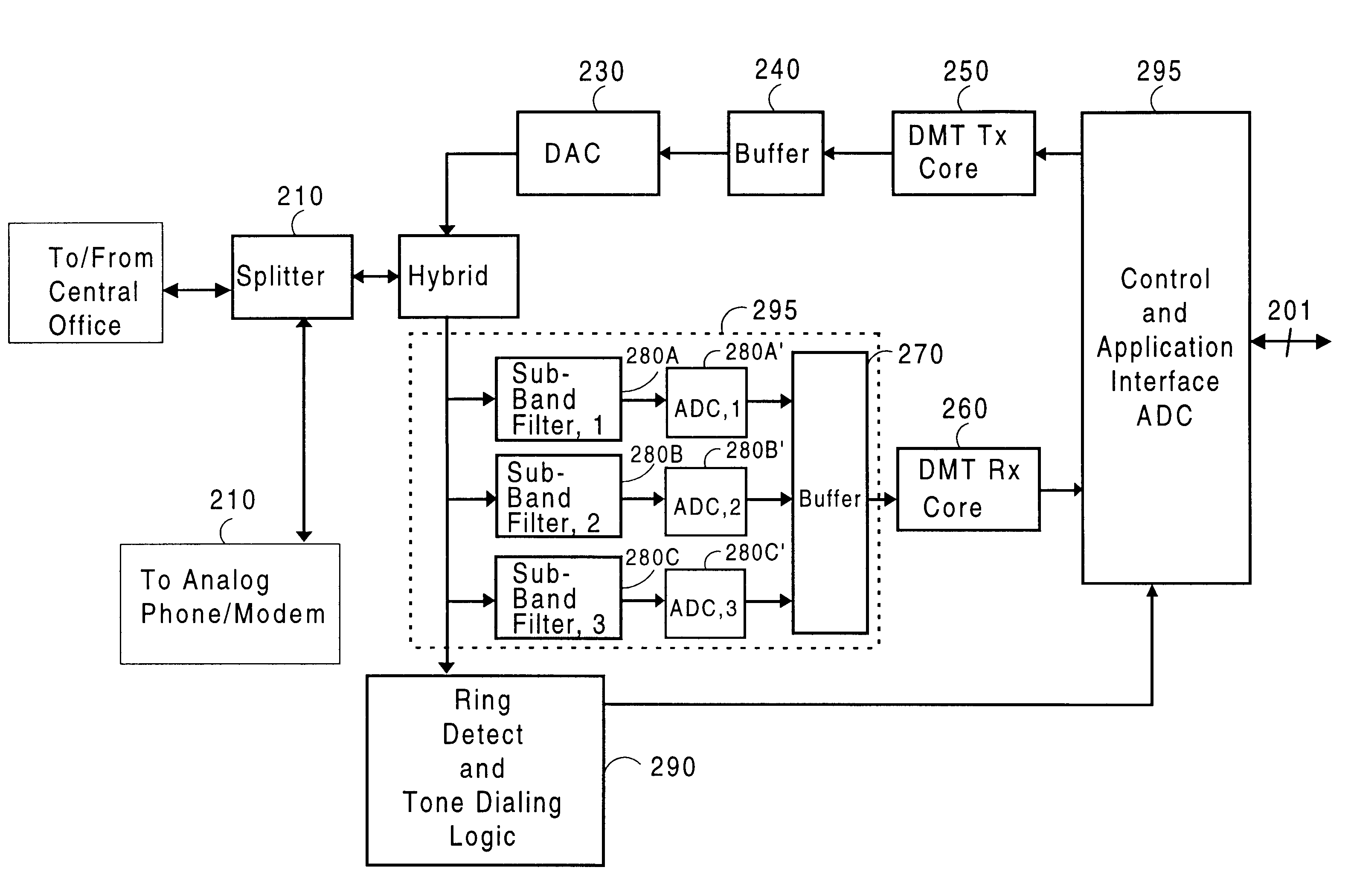

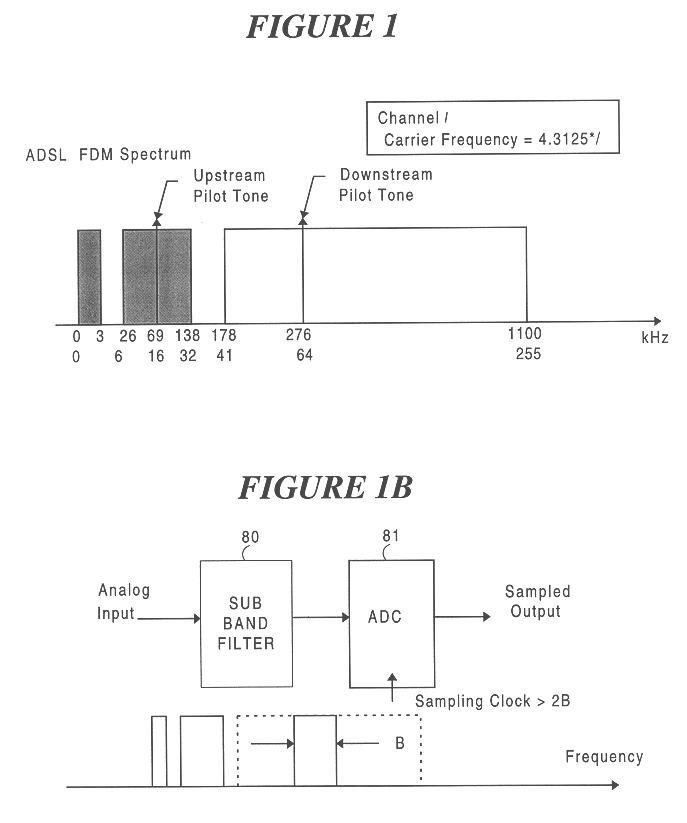

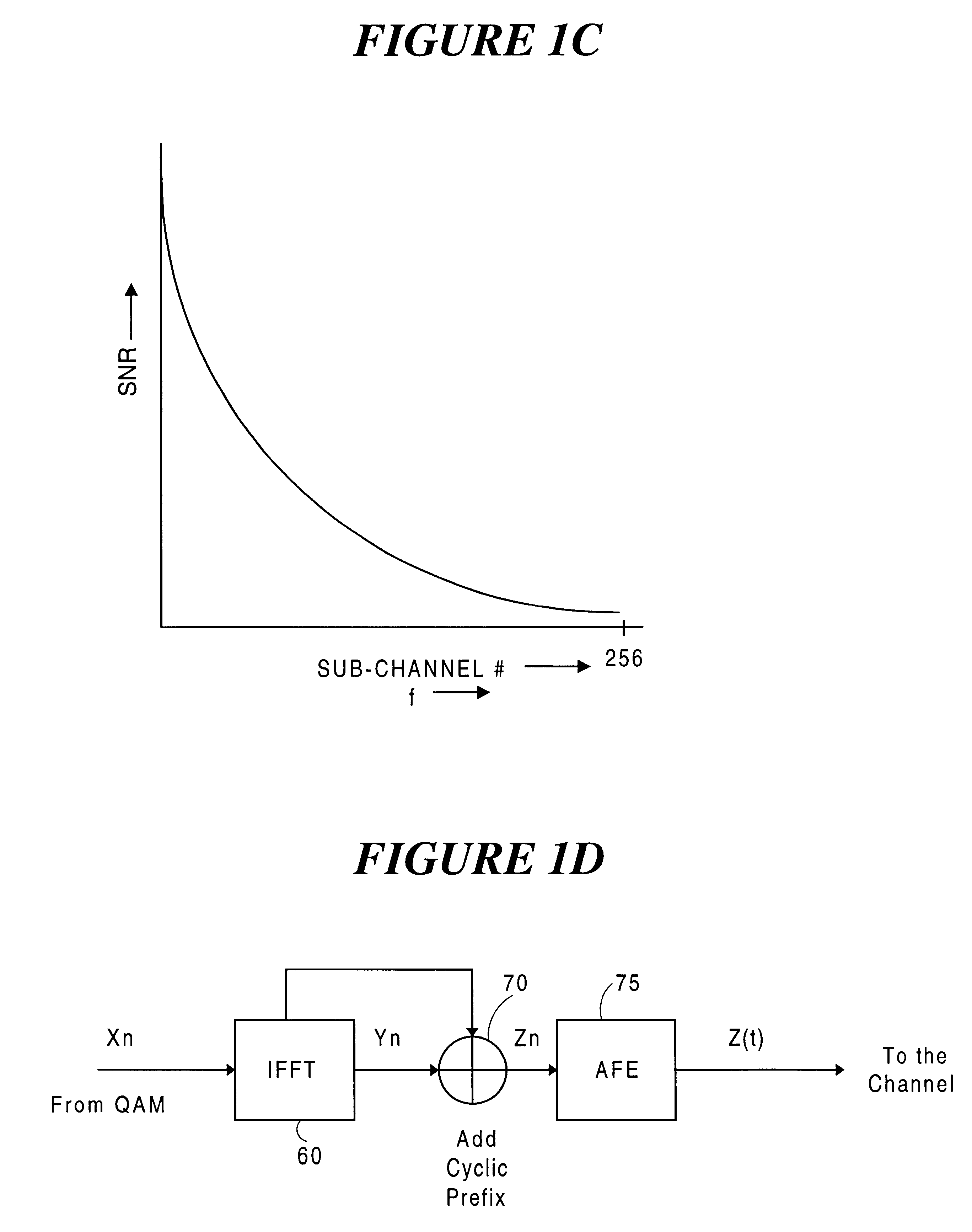

Multiple low speed sigma-delta analog front ends for full implementation of high-speed data link protocol

InactiveUS6442195B1Reduce quantization noiseReduce shapingTelephonic communicationSignal channelsModularityIntegrated circuit

An analog front end (AFE) circuit used in a high-speed communications system is presented that includes multiple stages each including a bandpass filter, base band modulator, low pass filter and Sigma-Delta modulator. Each stage processes a fractional portion of the total frequency of a wide bandwidth analog signal. The number of such AFE stages is configurable in parallel to process the entire bandwidth of the received signal. The AFEs can be incorporated in a single integrated circuit or similar suitable manner so as to be modular, and easily replaceable / upgradeable. To achieve minimum quantization noise and reduce manufacturing costs, the Sigma-Delta modulators in each AFE are made to have identical characteristics. Because the wideband signal is broken down into smaller frequency portions, the sampling rate, and thus the complexity and cost associated with the AFEs, is reduced significantly. In a preferred embodiment, a number of such AFEs are used in an ADSL modem for processing separate but roughly equal portions of the wideband ADSL signal containing data carrying DMT sub-channels. The separated portions are re-combined in a DMT receiver logic circuit to reconstruct the original data stream.

Owner:REALTEK SEMICON CORP +1

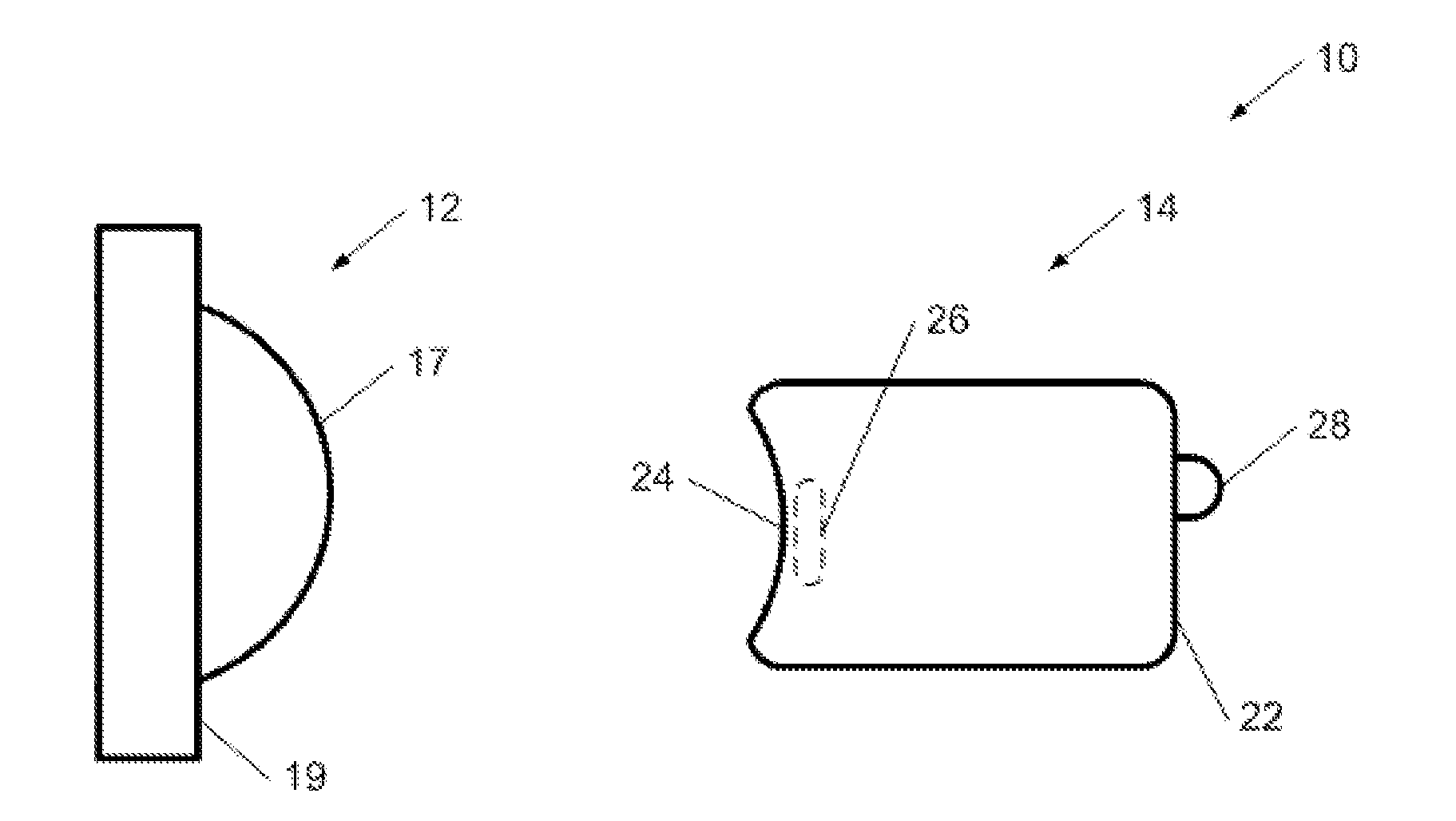

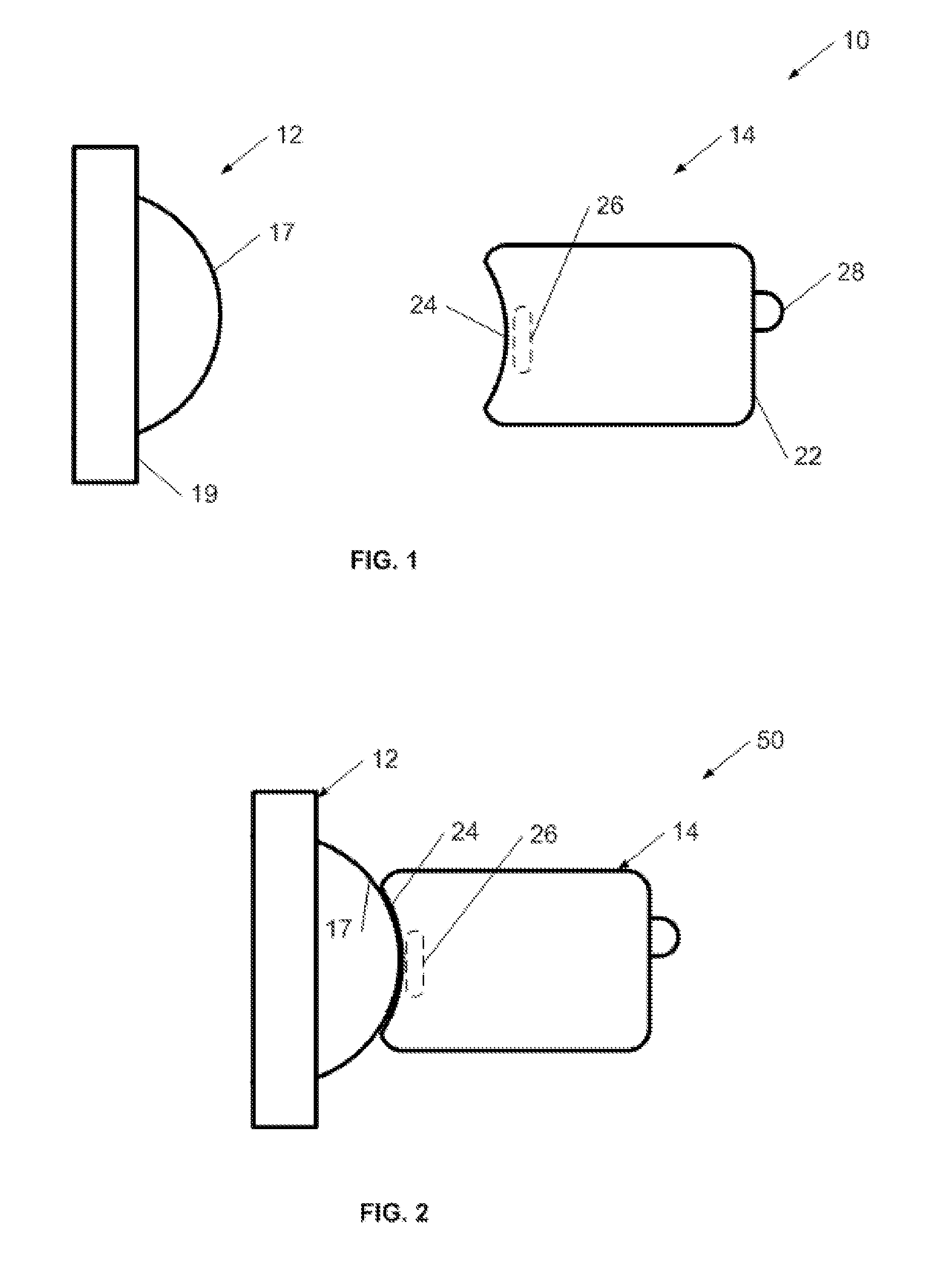

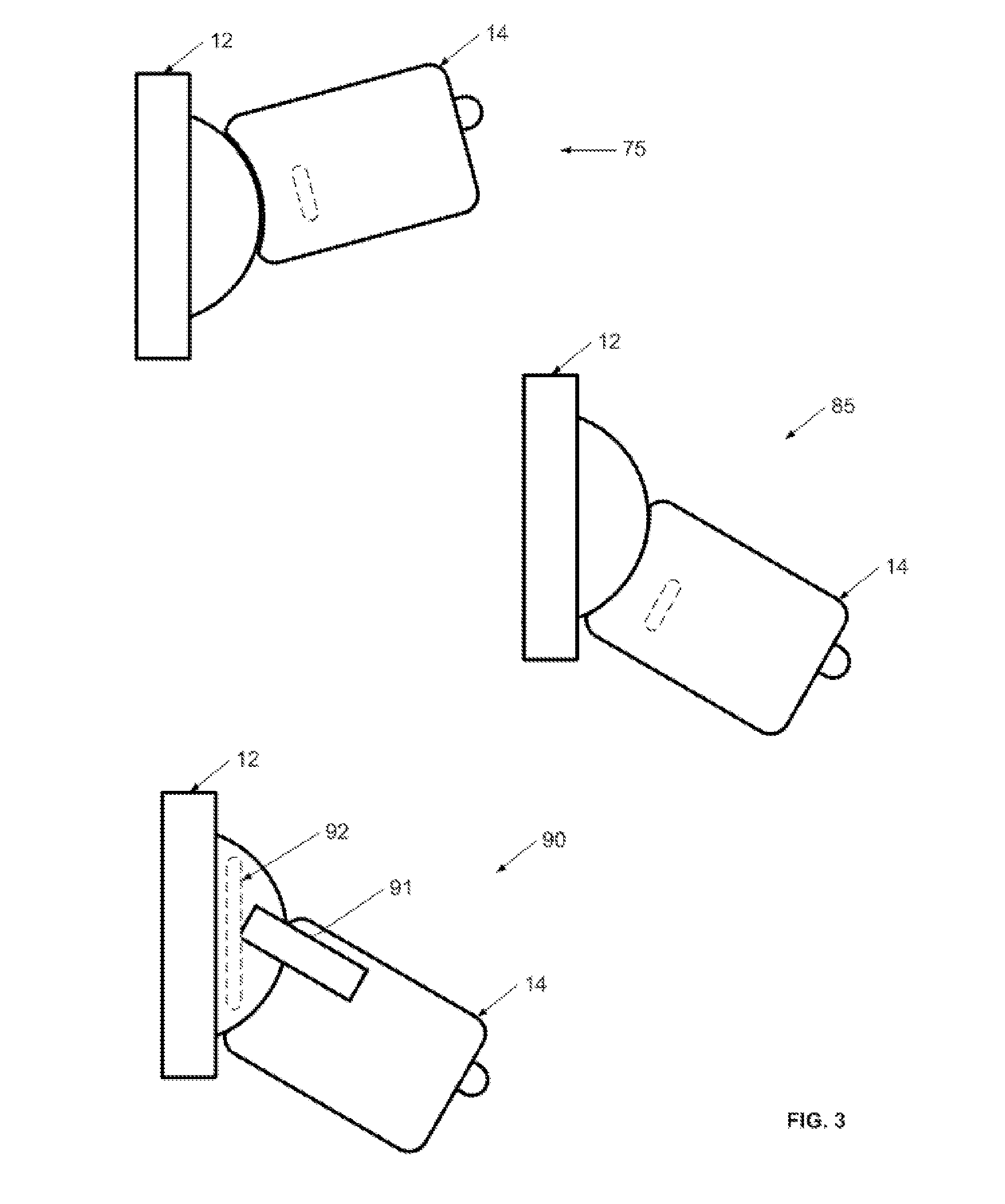

Mounting and Positioning System

InactiveUS20090196597A1Precise positioningEasy to repositionTelevision system detailsColor television detailsEngineeringGlobal Positioning System

A magnetic mount is provided for easily mounting, positioning, and orienting a camera, sensor or other directionally sensitive electronic device. In one example the magnetic mount is a camera mount. The camera mount has a camera part that has an image sensor, electronics, battery, and communication components. The housing for the camera part has a generally concave mounting surface, with a magnet positioned inside the camera housing and adjacent to the camera mounting surface. A base part has a base mounting surface that is constructed to be attracted to the magnet. In one example, the base mounting surface is dome-shaped, with a convex curvature constructed to mate with the concave curvature of the camera mounting surface. The base part is mounted to a stable support, and the camera mounting surface brought near the base counting surface. The magnetic attractive forces pull the camera part firmly to the base part, thereby securely positioning and orienting the camera. However, the camera may be readily repositioned by pushing the camera into a new position. The size and shape of the complementary mounting surfaces may be selected according to positioning requirements.

Owner:AVAAK

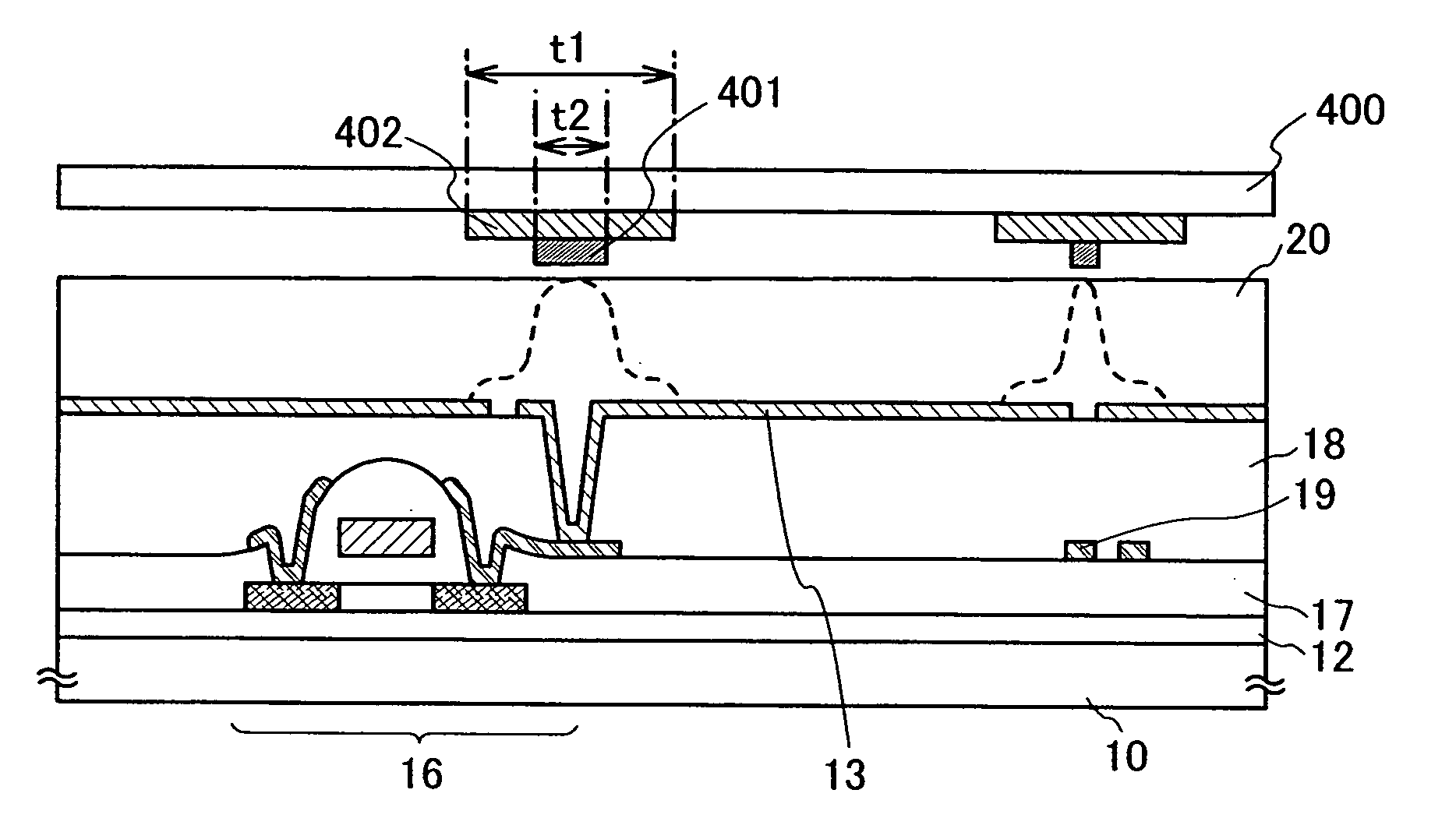

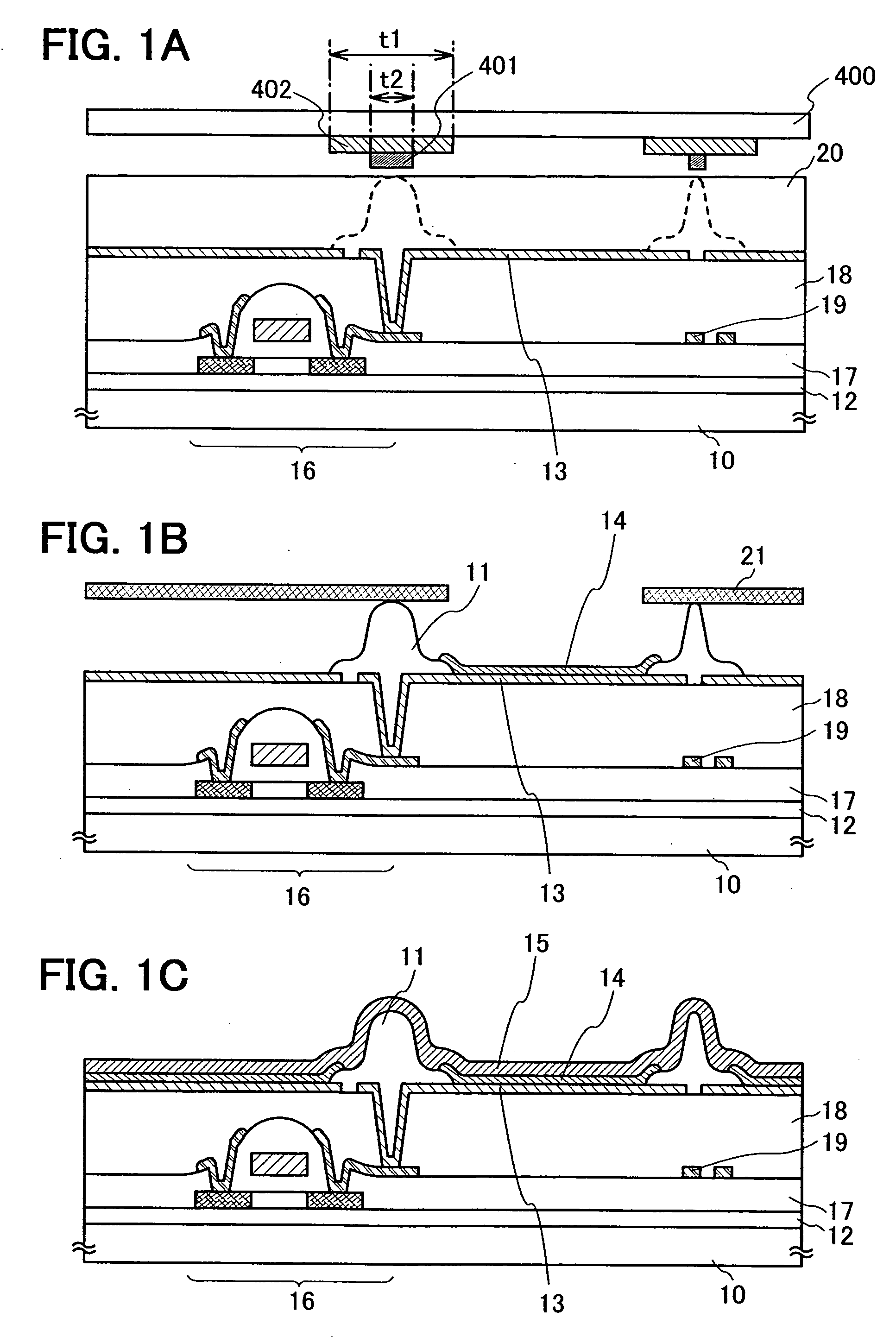

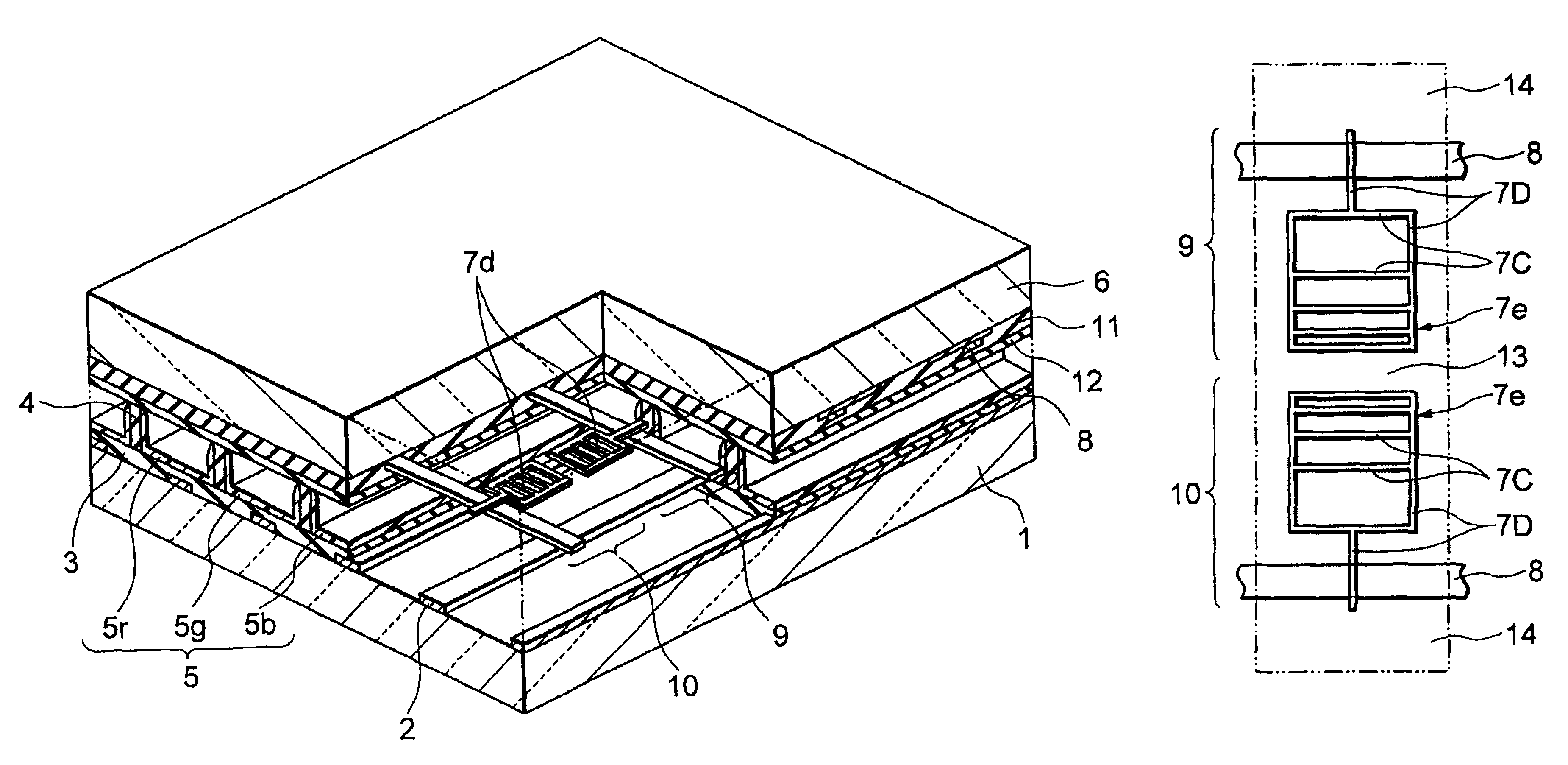

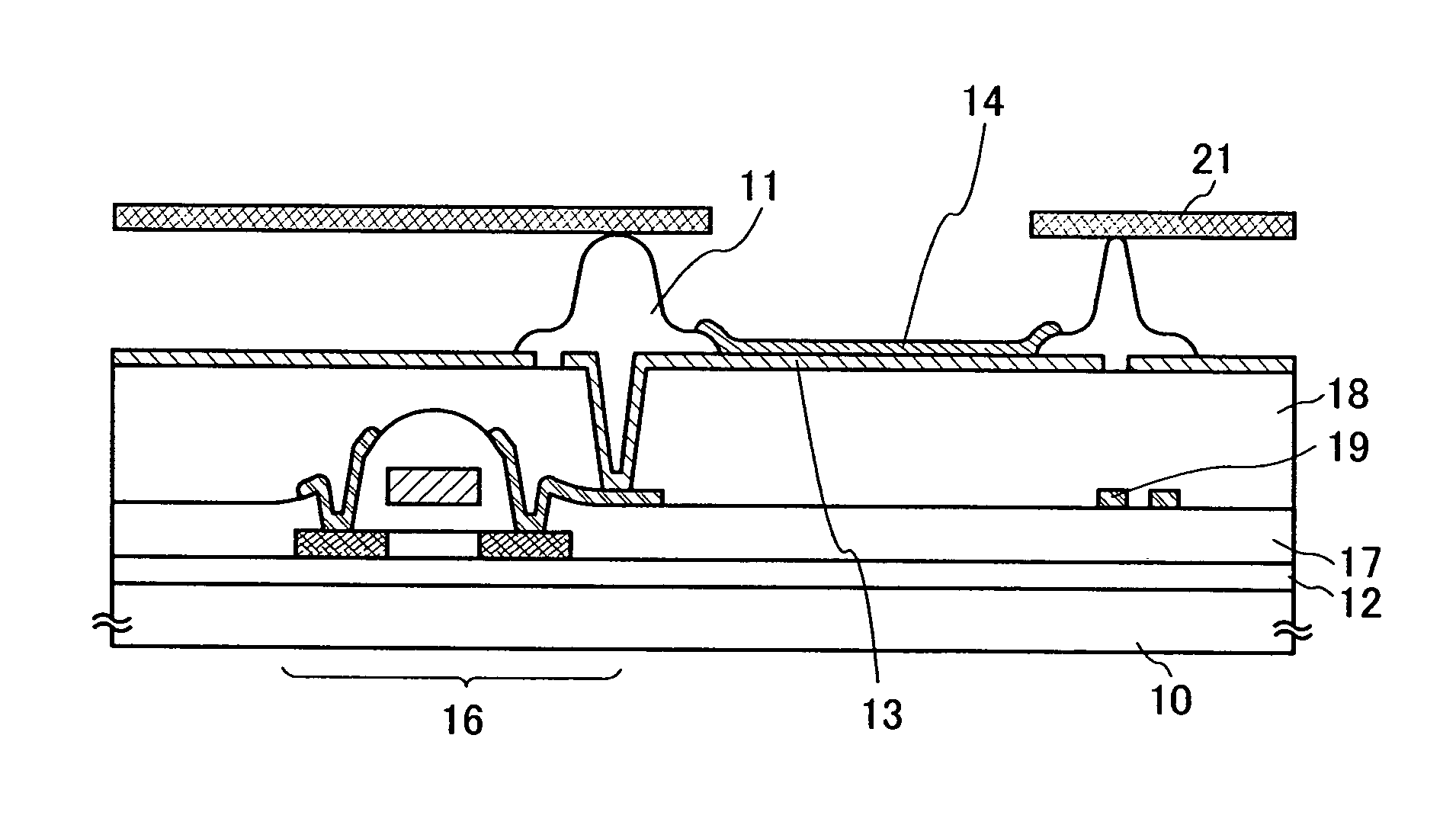

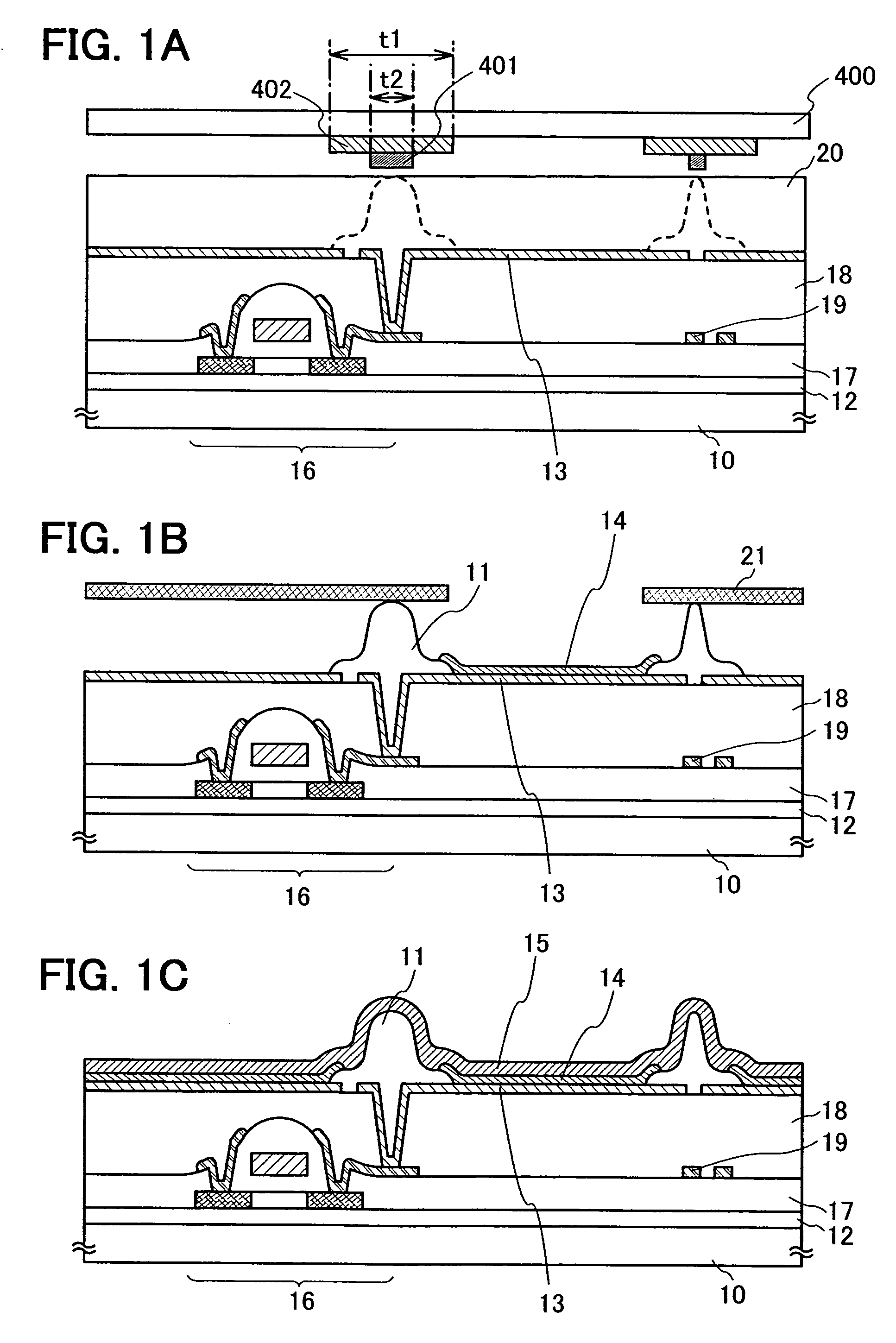

Semiconductor device and manufacturing method thereof

ActiveUS20070085475A1Reduce the number of stepsAvoid defectsDischarge tube luminescnet screensElectroluminescent light sourcesEvaporationMiniaturization

As a result of miniaturization of a pixel region associated with an improvement in definition and an increase in a substrate size associated with an increase in area, defects due to precision, bending, and the like of a mask used at the time of evaporation have become issues. A partition including portions with different thicknesses over a pixel electrode (also referred to as a first electrode) in a display region and in the vicinity of a pixel electrode layer is formed, without increasing the number of steps, by using a photomask or a reticle provided with an auxiliary pattern having a light intensity reduction function made of a diffraction grating pattern or a semi-transmissive film.

Owner:SEMICON ENERGY LAB CO LTD

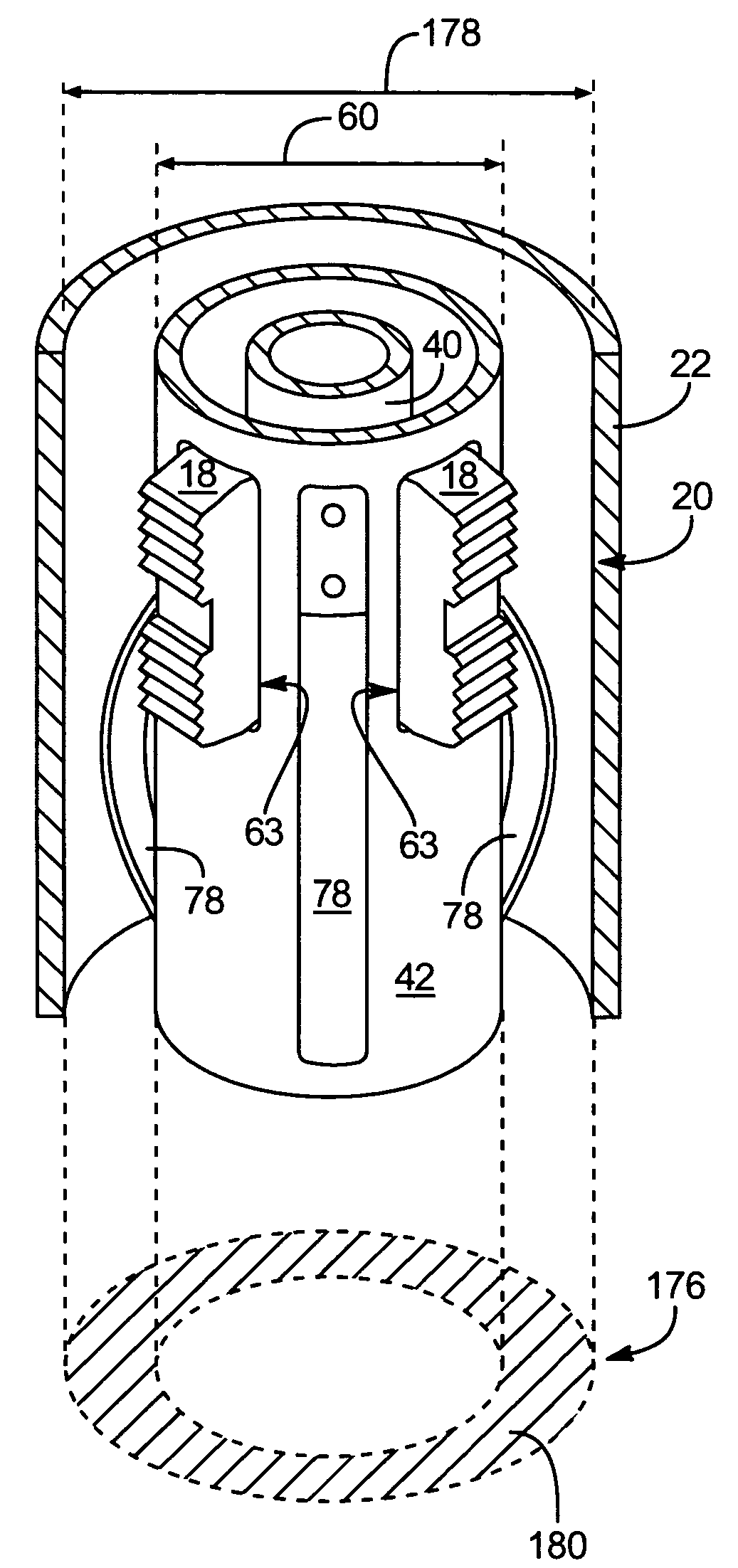

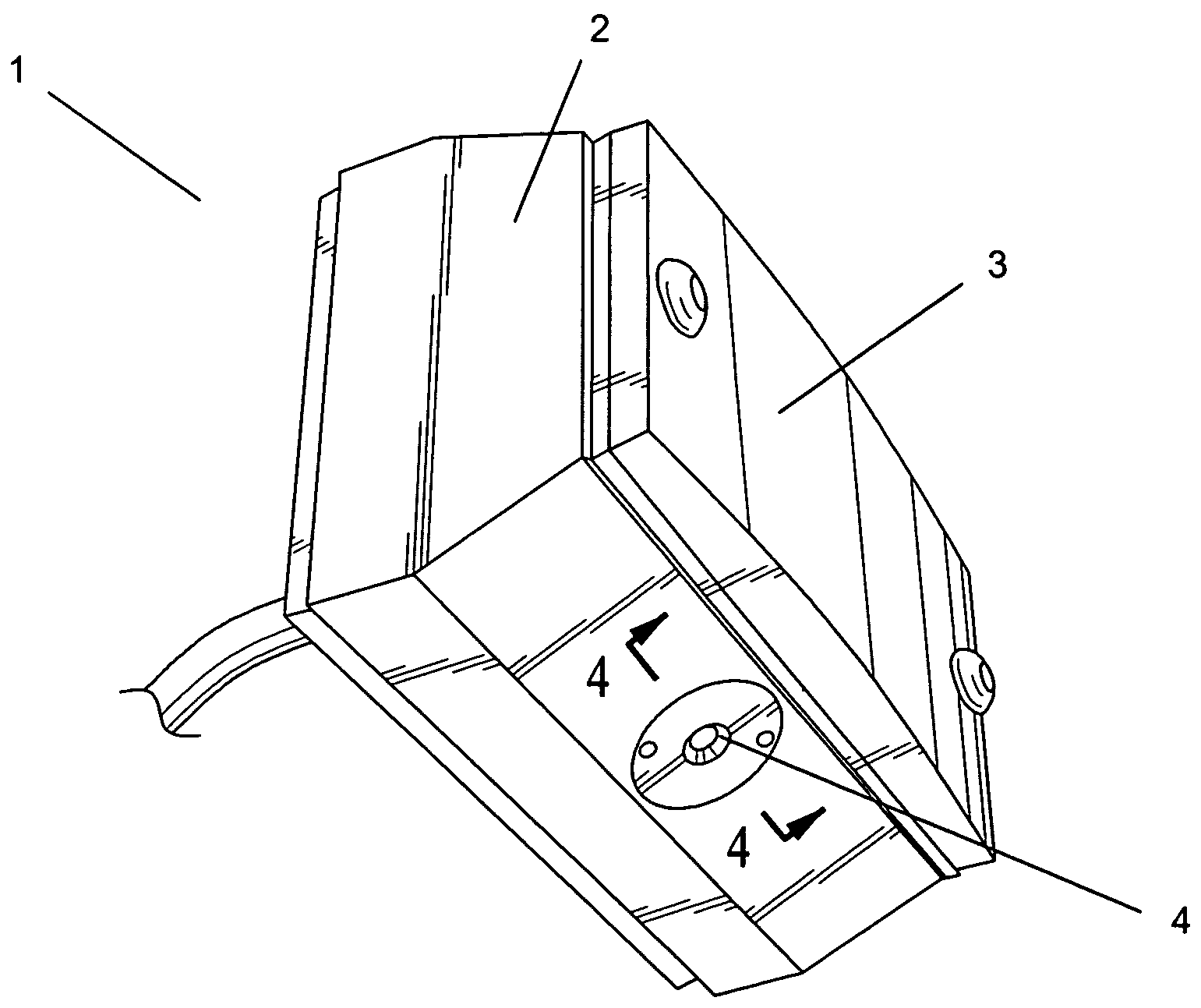

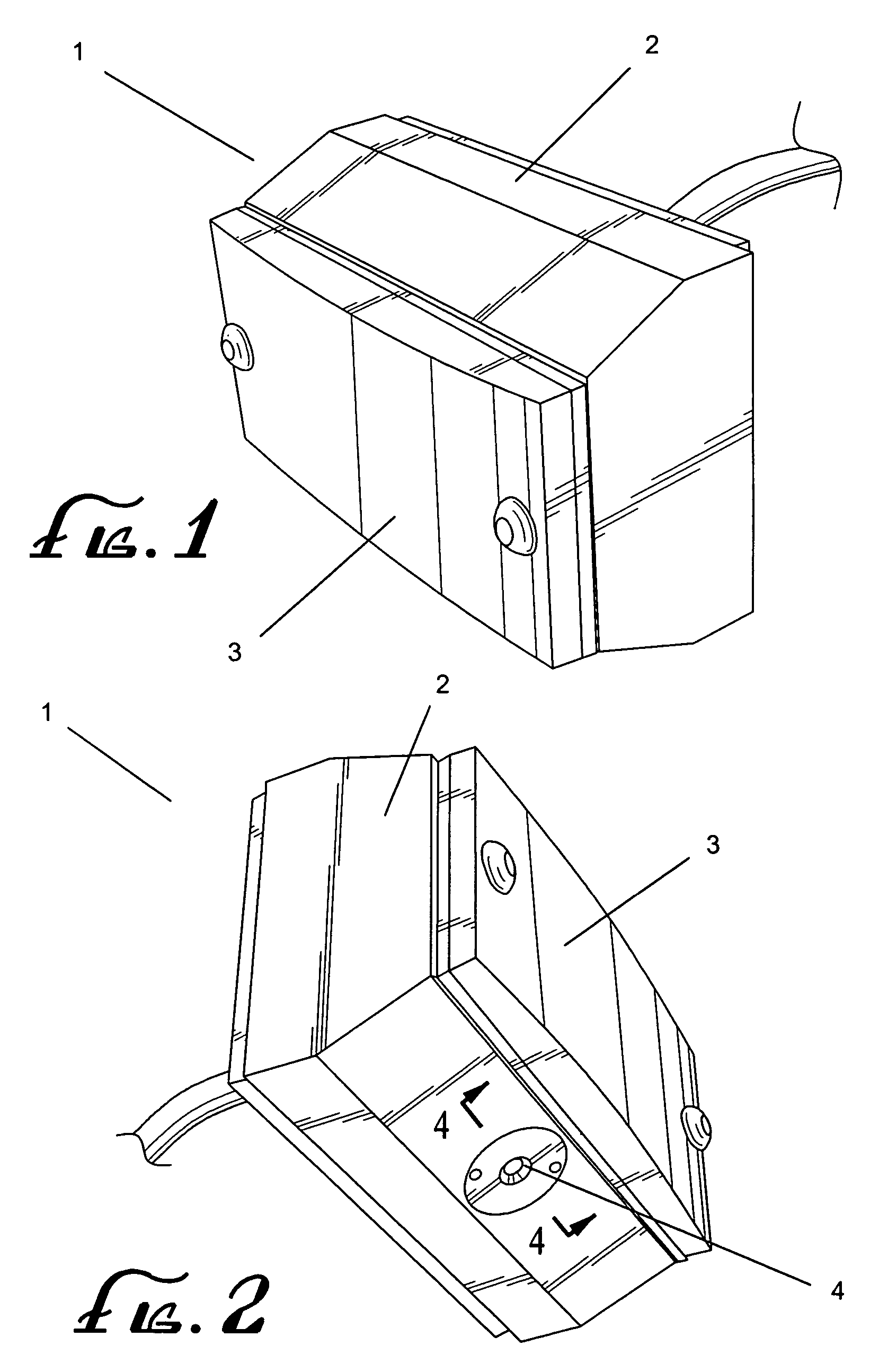

Hydrodynamic, down-hole anchor

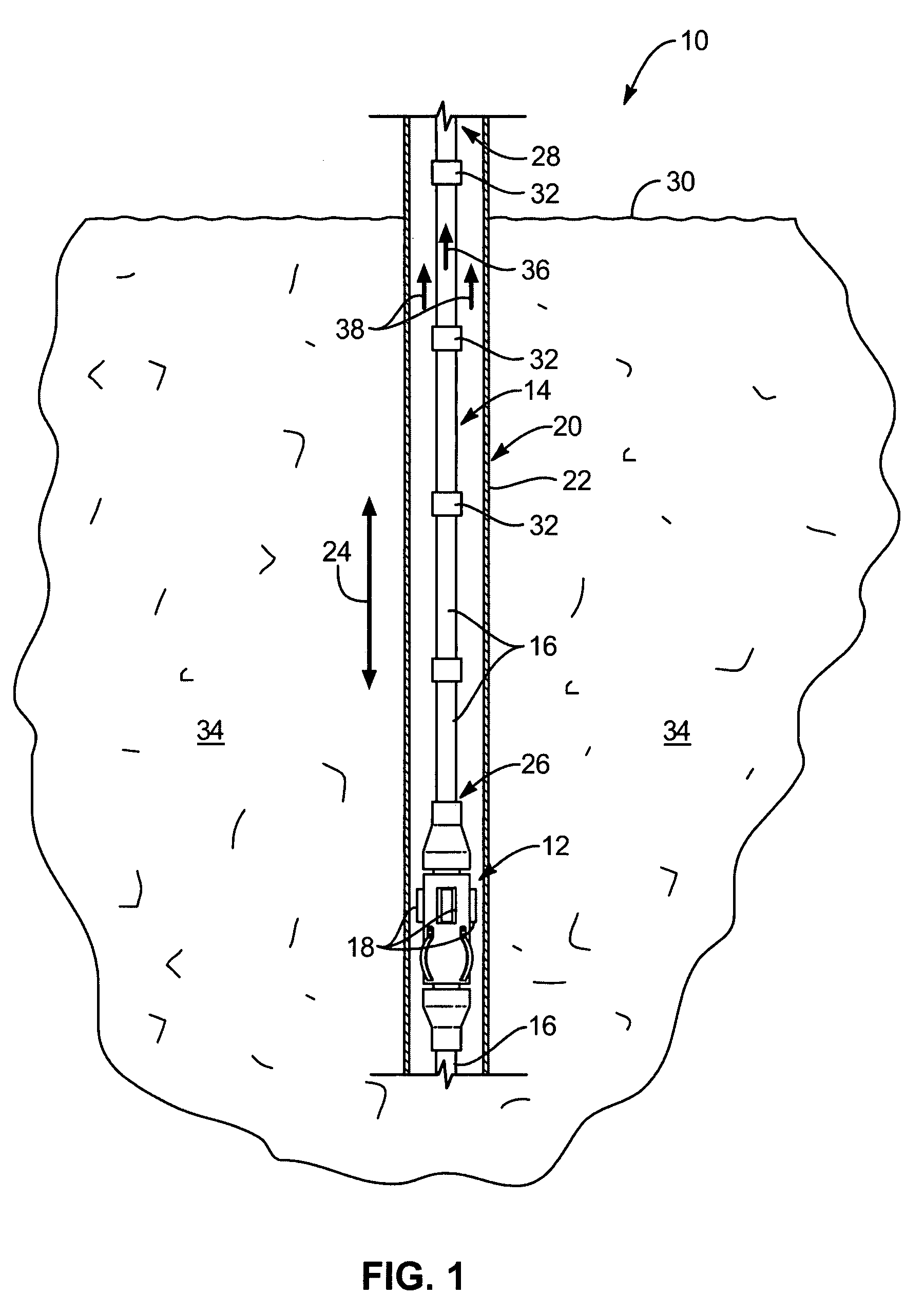

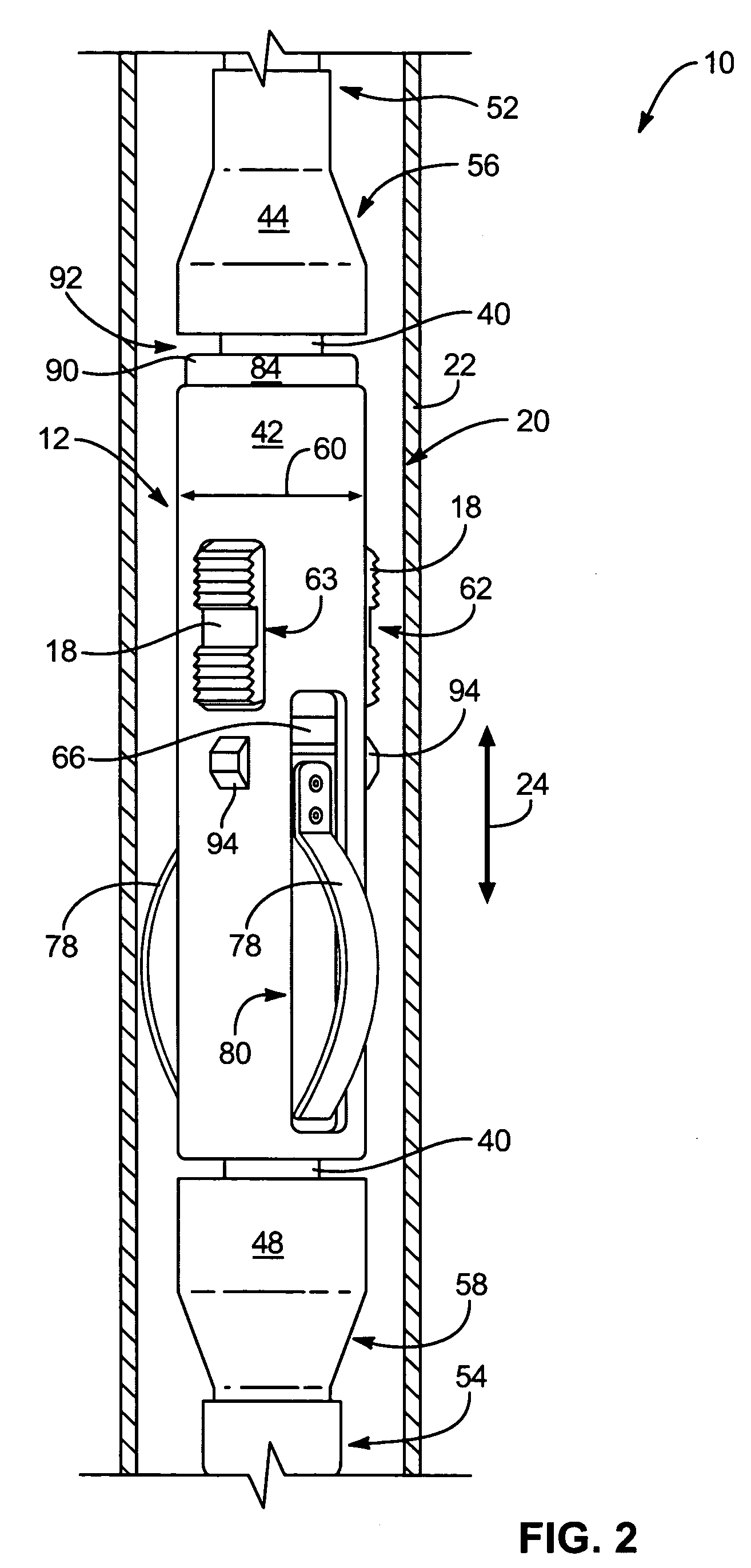

ActiveUS7255172B2Facilitate their admittanceIncrease gas productionDrilling rodsFluid removalMechanical engineeringWellbore

A method of removably anchoring well tubing in a well bore may include selecting a well having a bore diameter and an anchor positioned therein. The anchor may have a housing defining an anchor diameter and extension members extending therefrom toward the bore diameter. The bore diameter and anchor diameter may be spaced apart a distance defining an annulus therebetween and extending along the well. A tool sized to cut substantially exclusively within the annulus may be selected. The tool may be positioned within the annulus, rotated, and advanced to drive past the housing to remove the extension members between the housing and the bore diameter to free the anchor.

Owner:TECH TAC

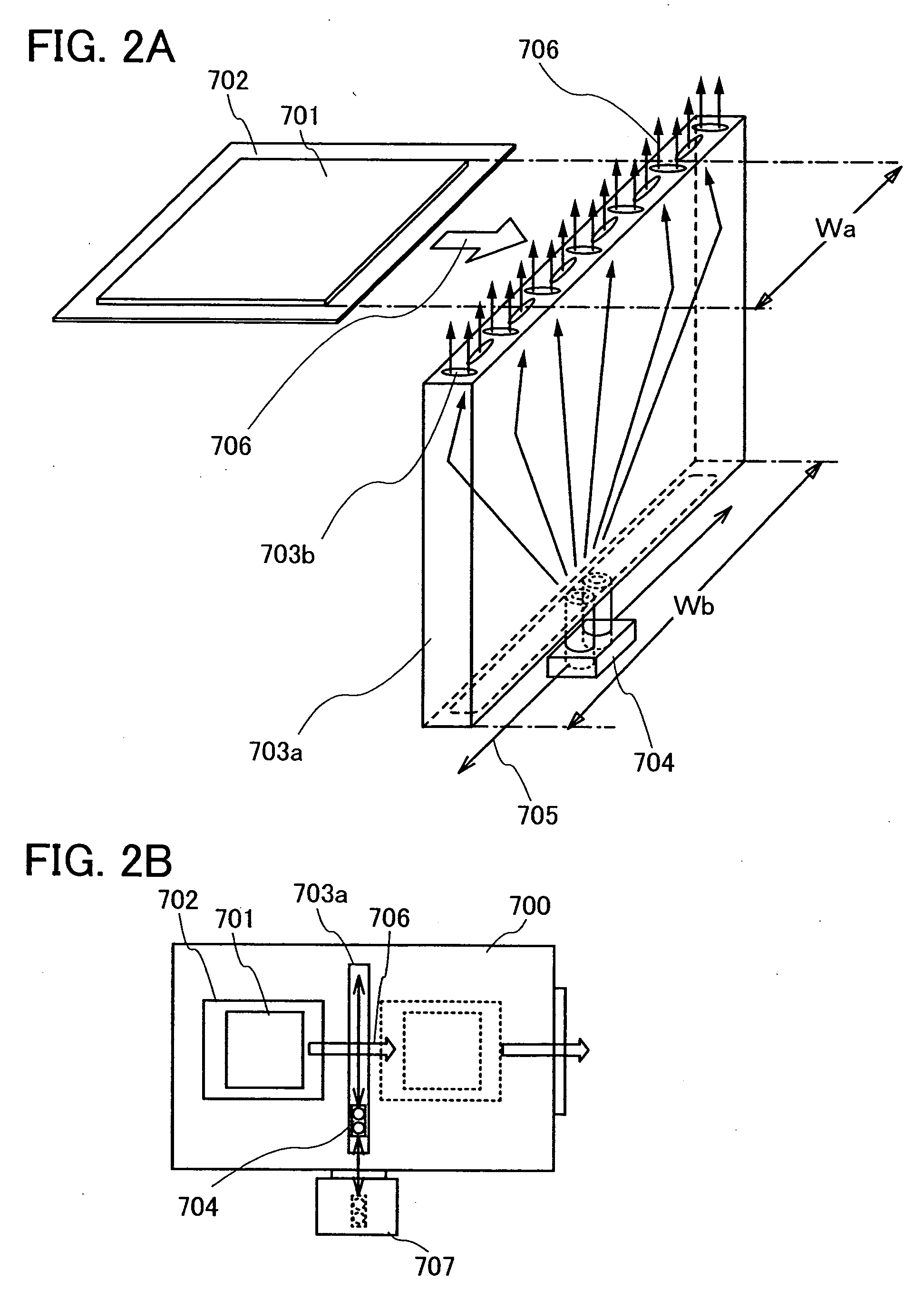

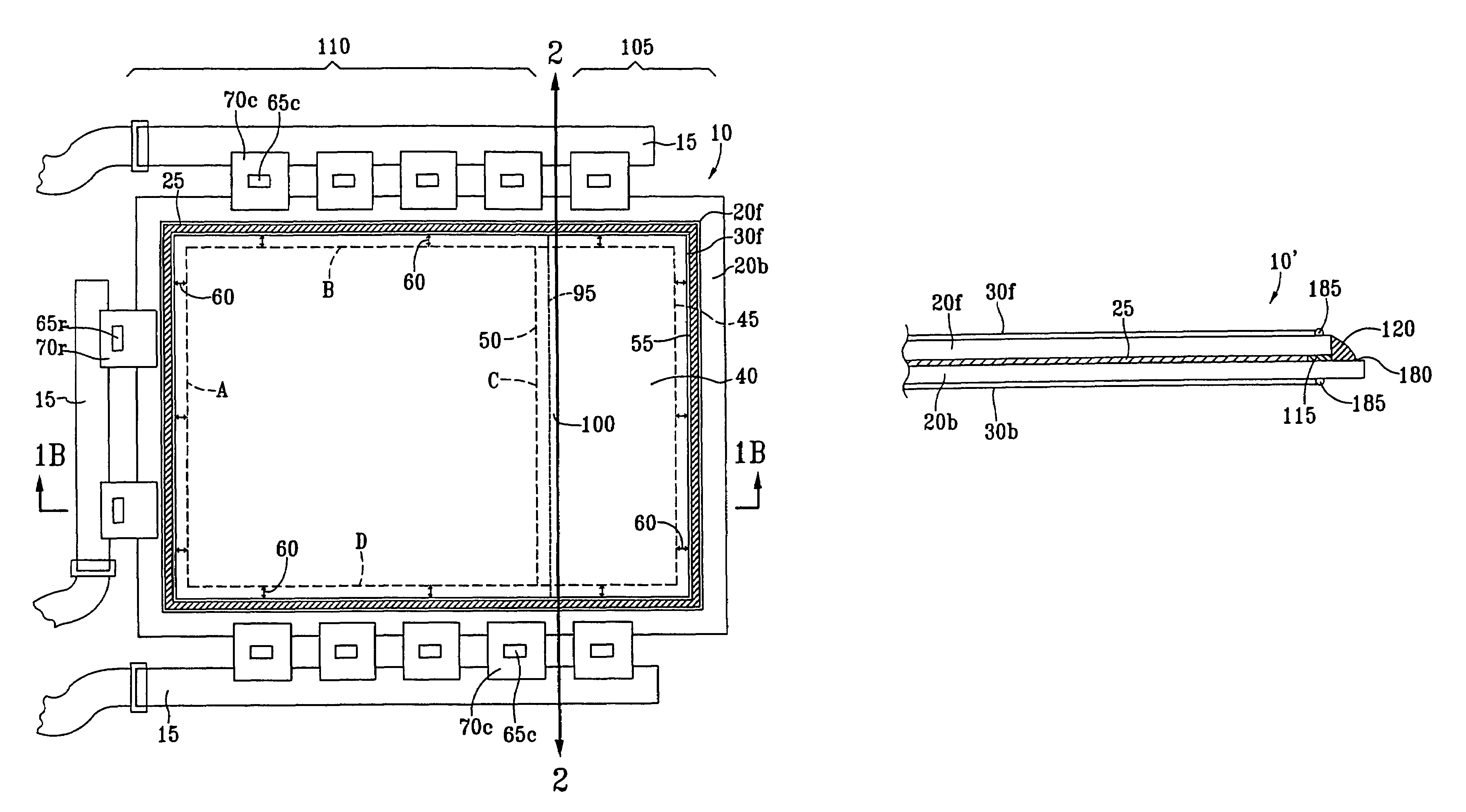

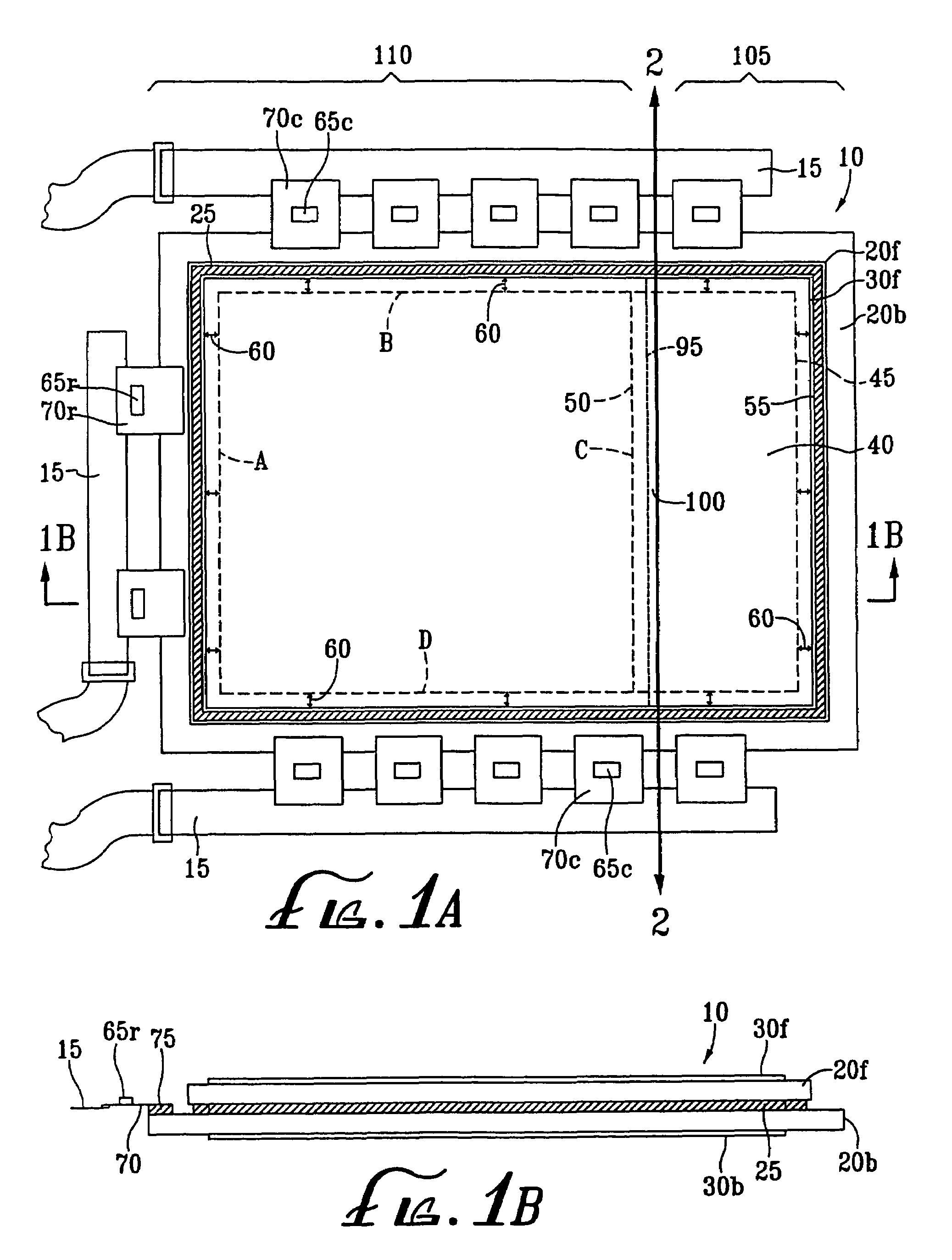

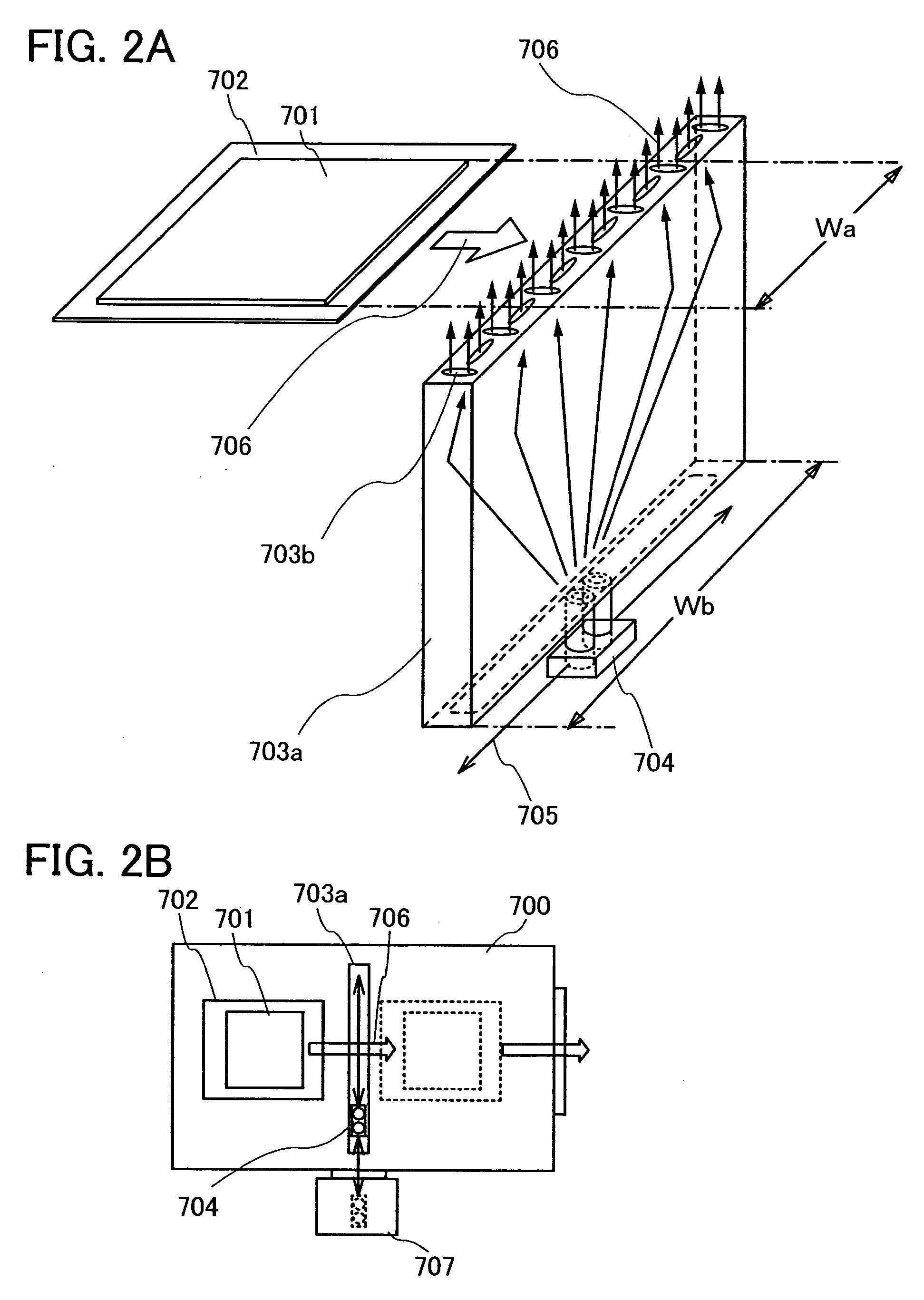

Method and apparatus for characterizing a glass ribbon

InactiveUS20070140311A1Quality improvementReduce shapingThermometer detailsGlass forming apparatusImage resolutionSpace resolution

A method and apparatus for measuring the temperature and / or displacement of a glass ribbon formed in a downdraw glass forming process, and measured across width of the ribbon. Temperature and displacement measurements may advantageously be performed simultaneously with a high degree of spatial resolution by a measurement assembly which does not contact the glass ribbon. Temperature measurements may be performed across substantially the entire width of the ribbon. Data developed by the measurement assembly may be used in an automated feedback loop to control the glass ribbon forming conditions.

Owner:CORNING INC

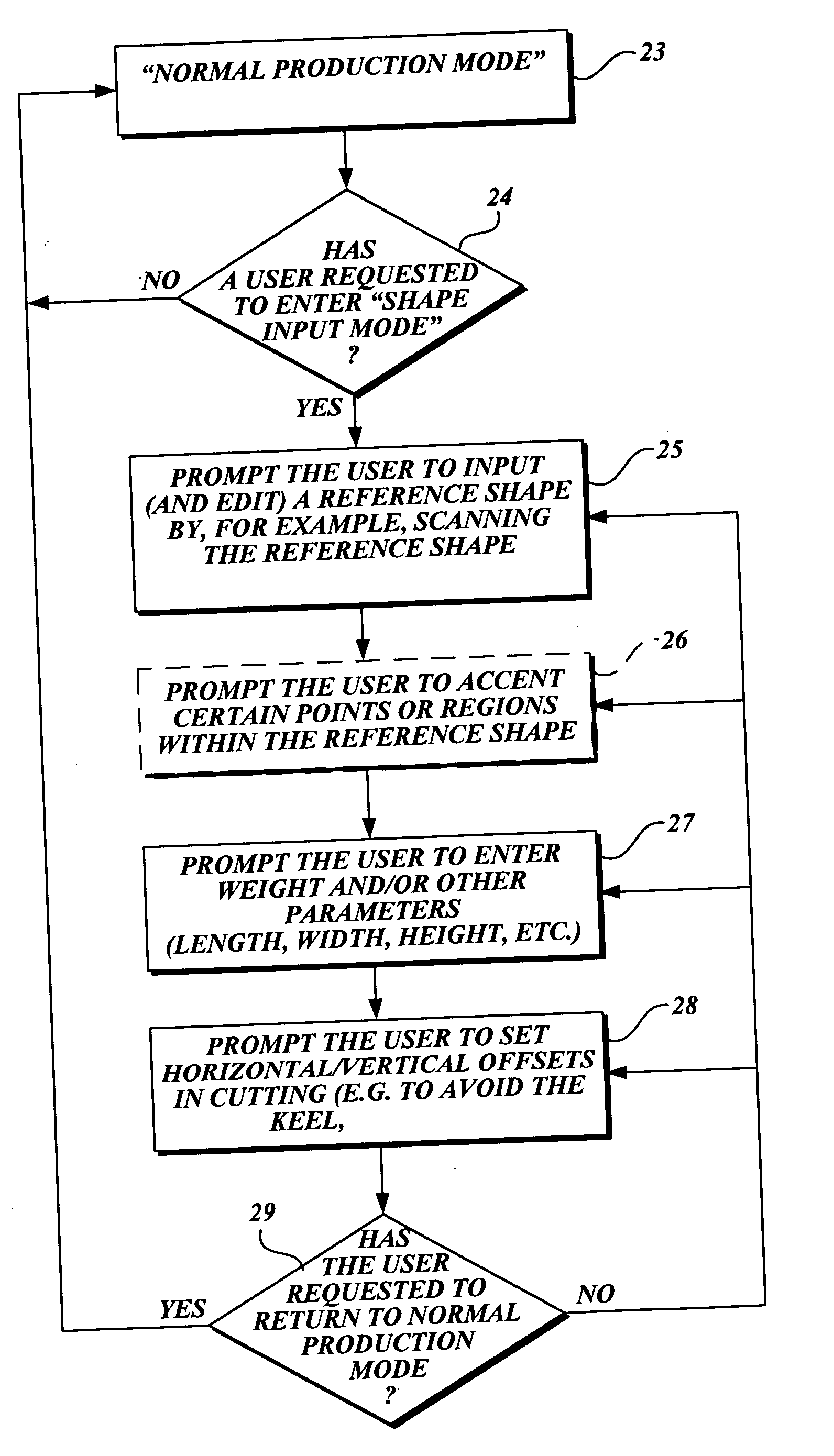

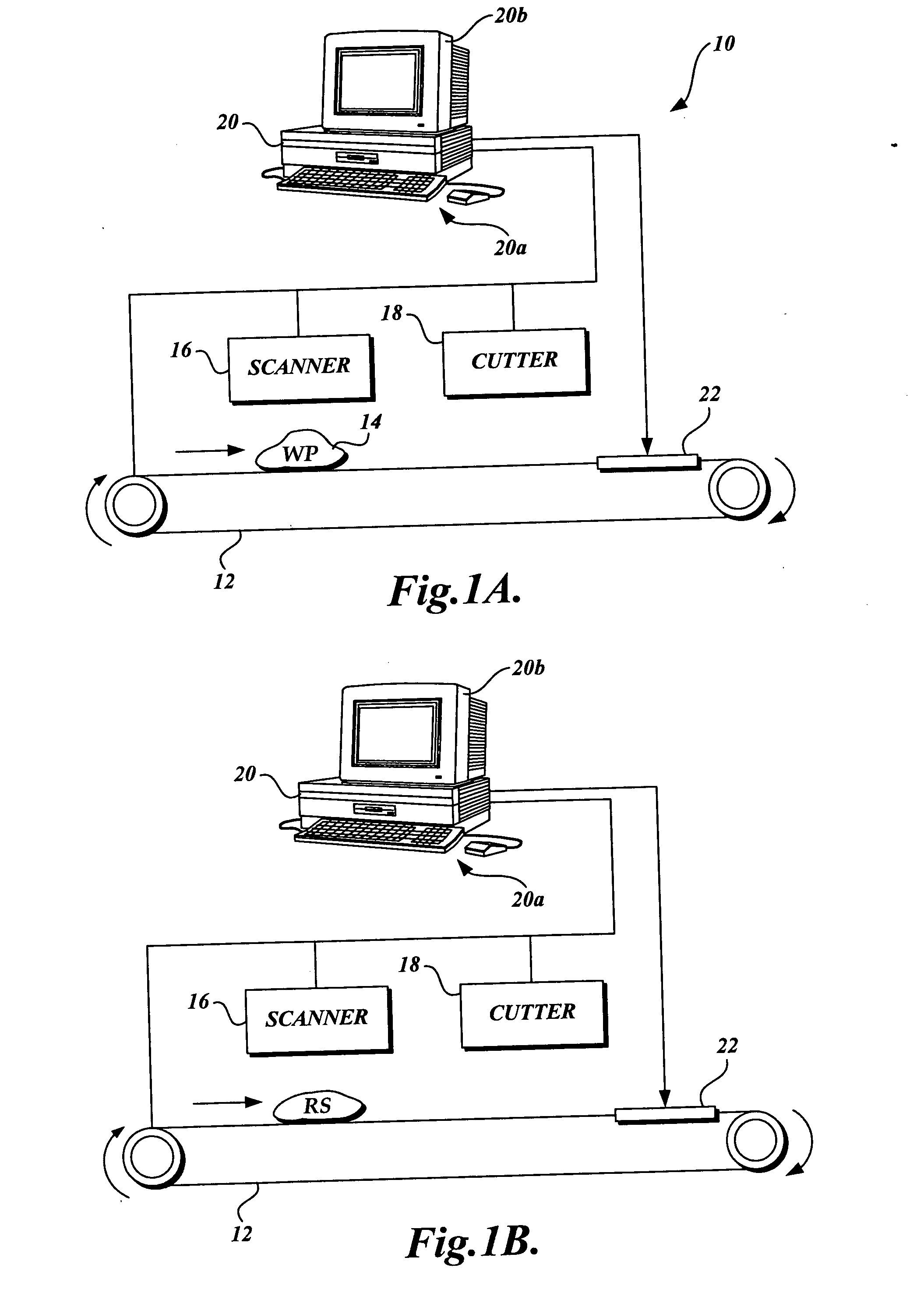

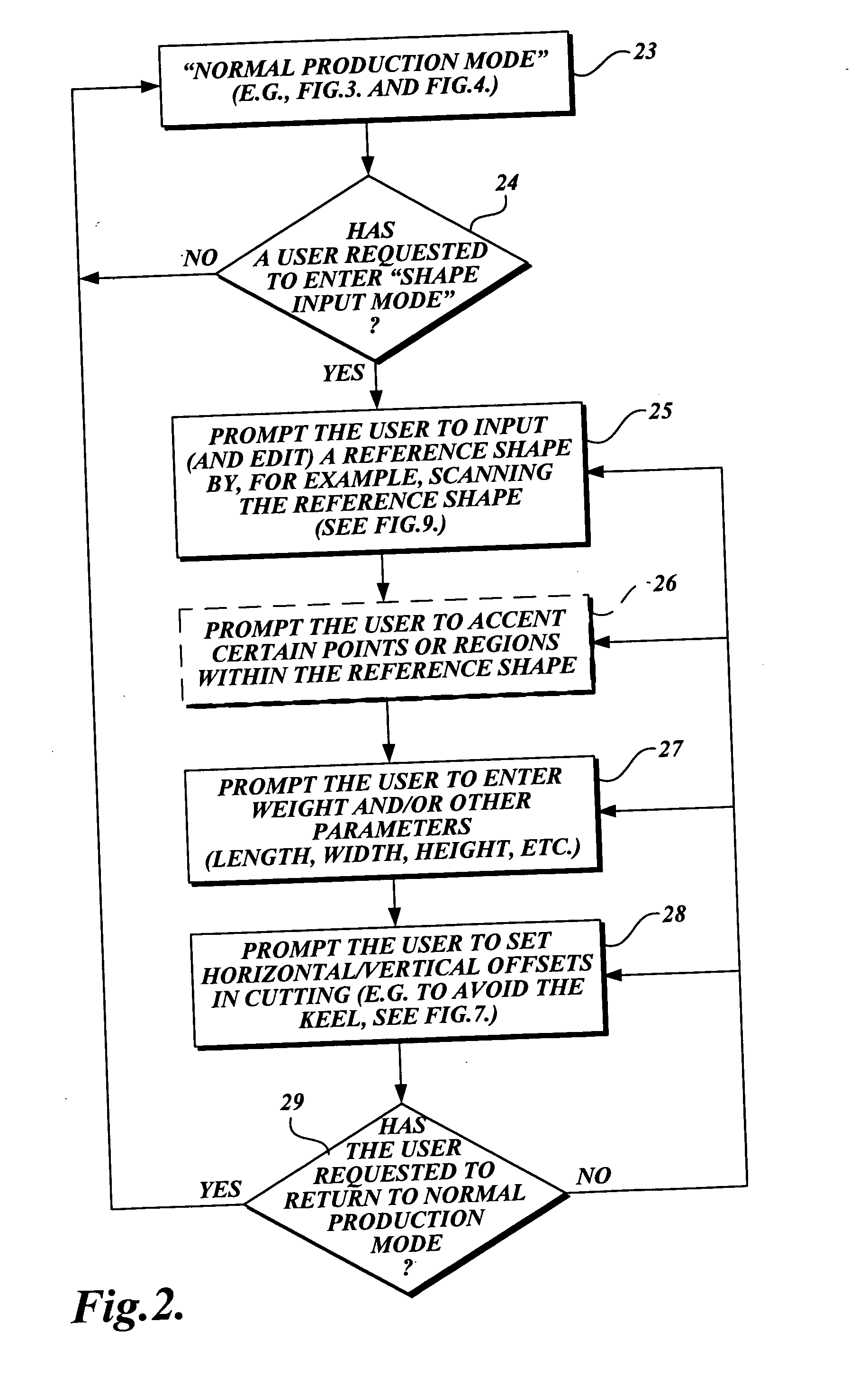

Method and system for portioning workpieces to user-scanned shape and other specifications

ActiveUS20050154490A1Satisfies specificationReduce shapingMetal working apparatusSpecial data processing applicationsMechanical engineeringFood products

A method and system are provided for automatically portioning workpieces, such as food products, into both shape and other user-defined specification(s). Workpieces are portioned both to shape and weight, such as to a weight-specific uniform shape, by adjusting (e.g., scaling up and down or slightly modifying) a desired template shape until the desired weight is achieved depending on the varying thickness of each workpiece. For example, from a thicker workpiece, a smaller-sized piece having a predefined shape and weight is portioned, while from a thinner workpiece, a larger-sized piece having the same predefined shape and weight is portioned. The system permits a user to scan in and edit a desired (reference) shape to be used as a template in the portioning process.

Owner:JOHN BEAN TECH CORP

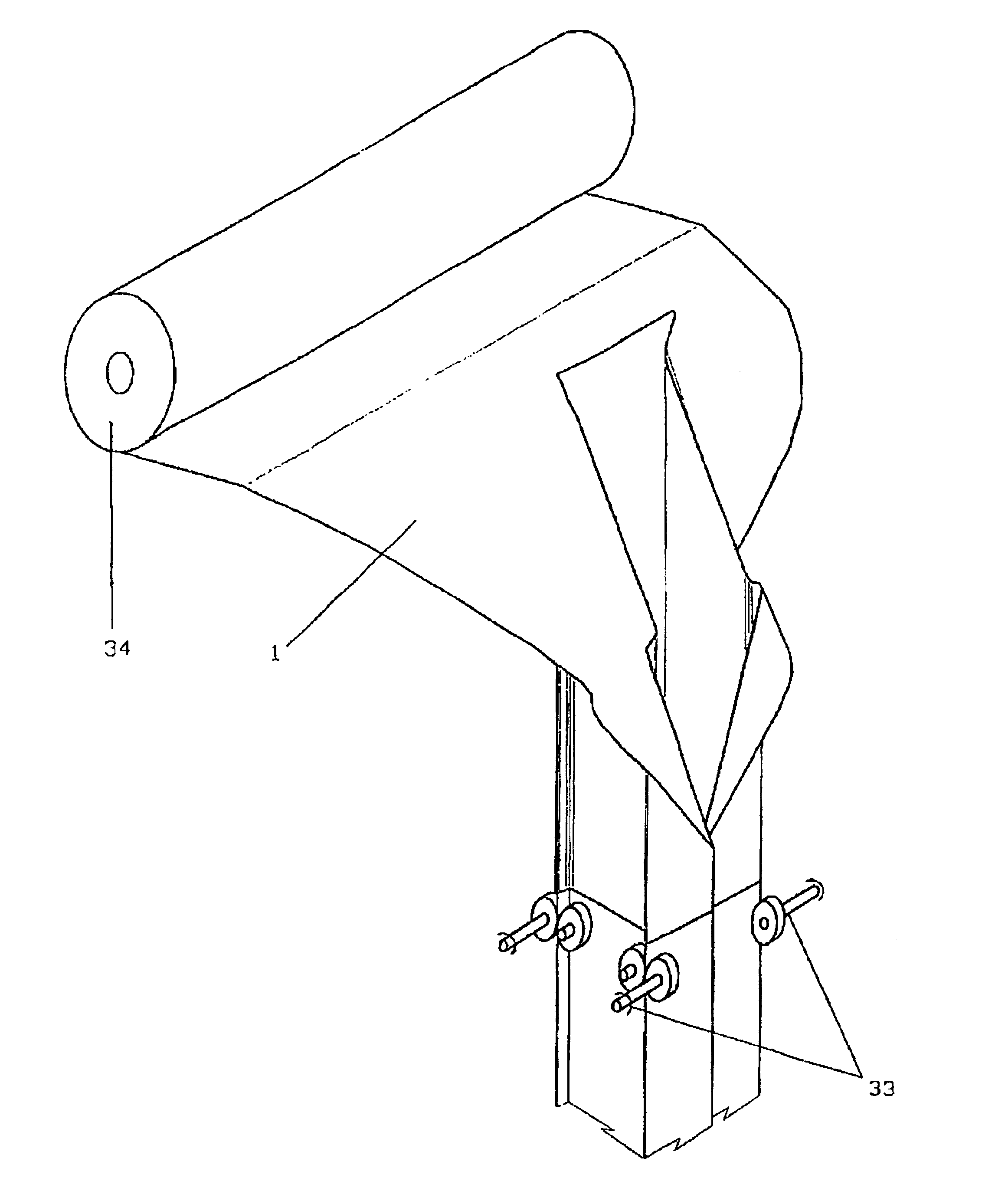

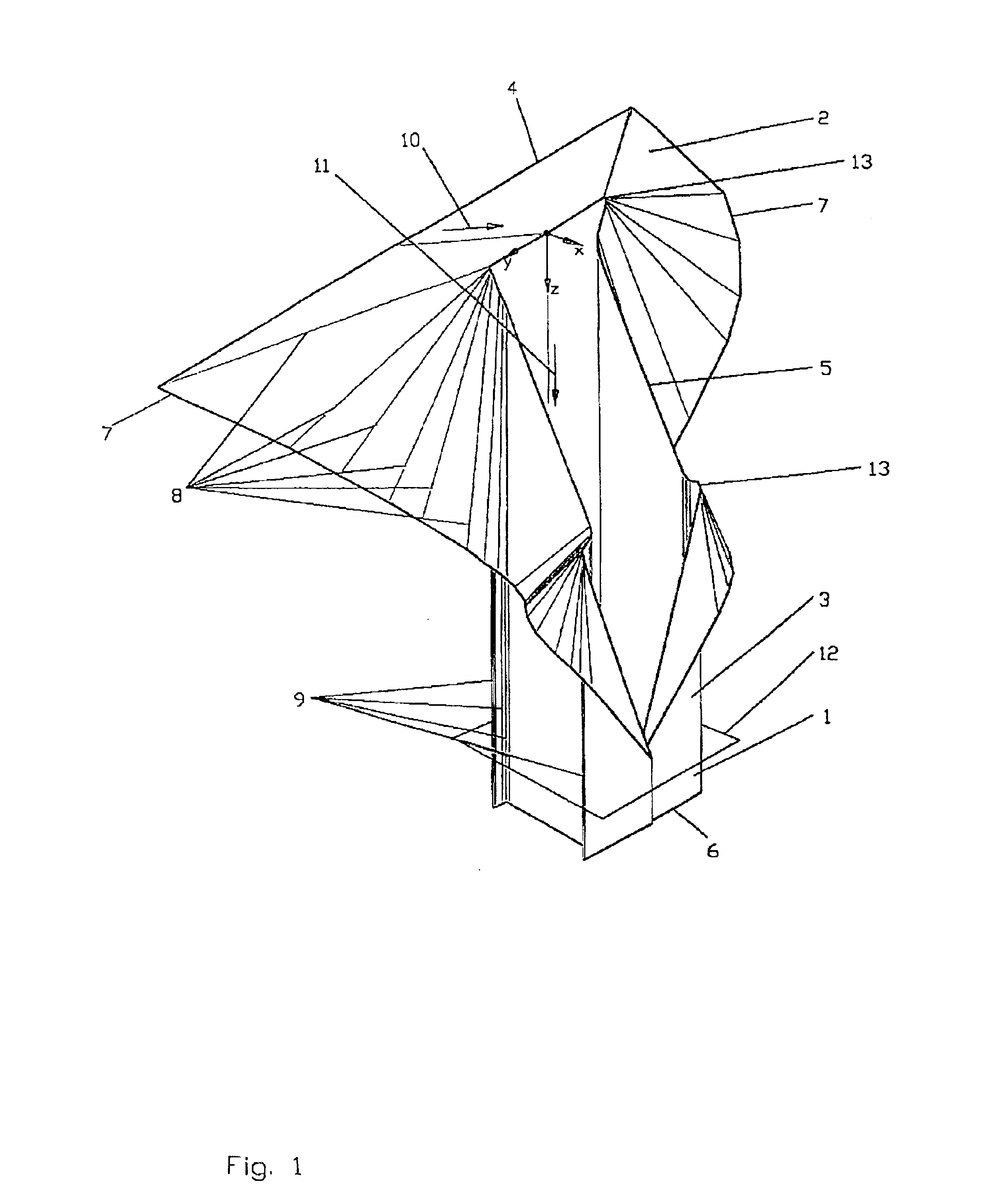

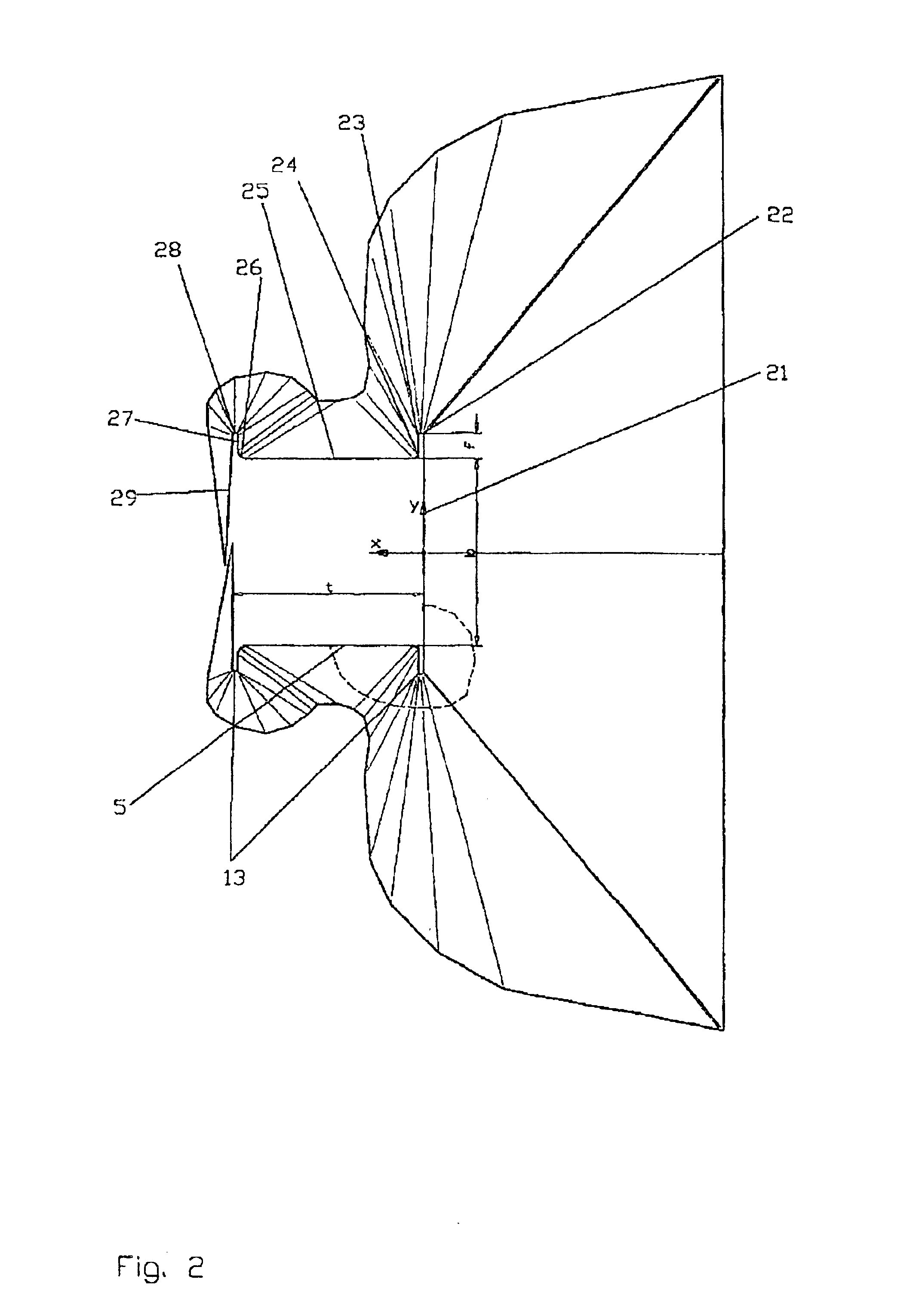

Shaping shoulder and a device for producing longitudinally shaped webs

InactiveUS6845602B2Reduction of total shaping heightReduce drop heightConfectioneryCeramic shaping apparatusEngineeringPrism

A shaping shoulder has a shoulder part and a prism part, joined at a shaping edge, for producing a web, shaped longitudinally in the web transport direction and having an open or closed cross-section and at least one area inside the web in which the cross-section is curved outwardly. The shoulder part has a web inlet and extends from the web inlet to the shaping edge. The prism part has an exit for the shaped web and extends from the shaping edge to the exit. The shaping edge is slanted relative to a cross-sectional prism plane. The prism cross-section is curved partially inwardly and outwardly not only in the vicinity of a web edge. The curvature of areas of the shaping edge belonging to outwardly curved areas of the prism part extend counter to the exit and the corresponding shoulder part areas are curved away from the exit.

Owner:GVL FUR VERPACKUNGSTECHN UND LOGISTIK MBH

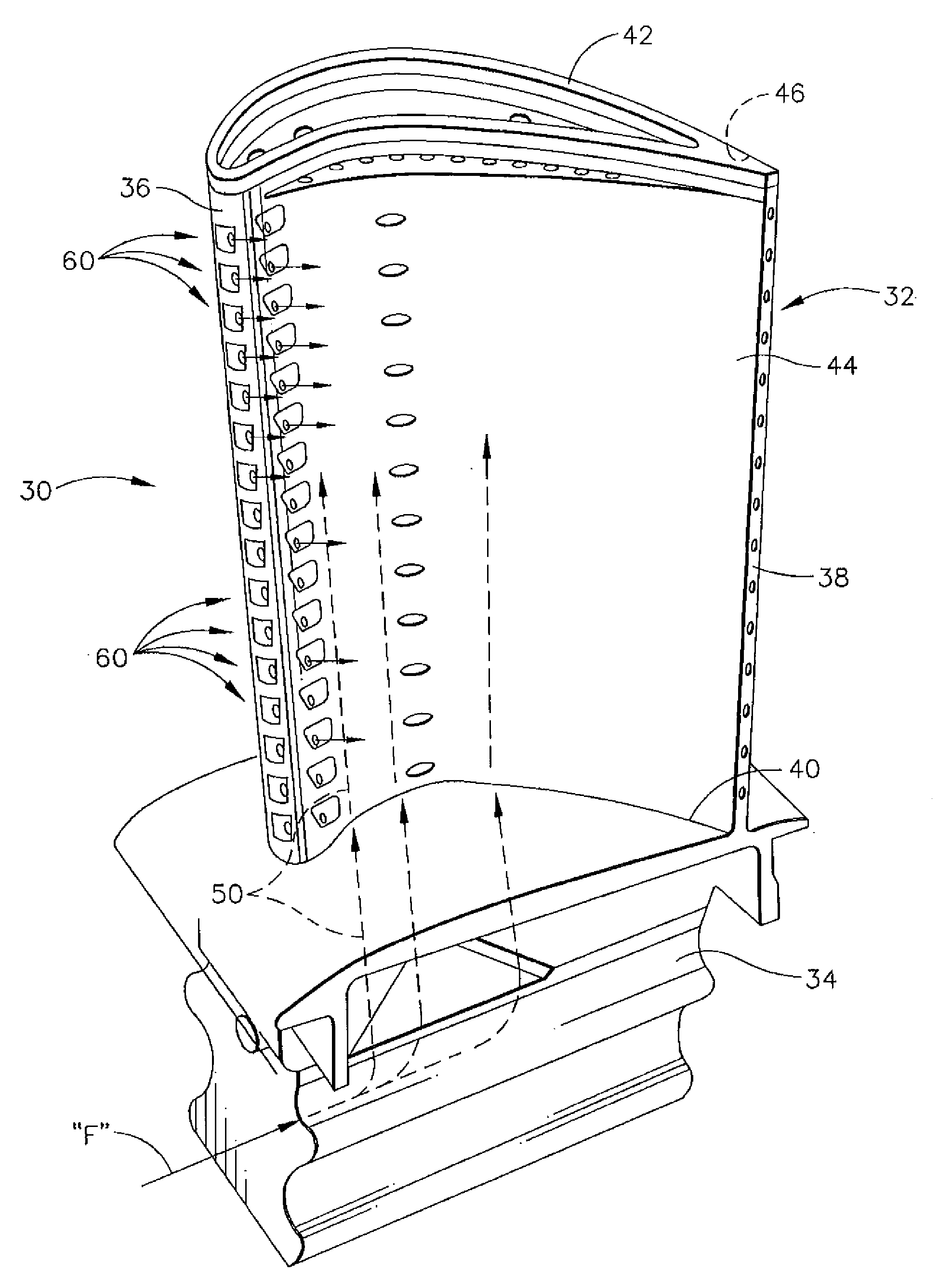

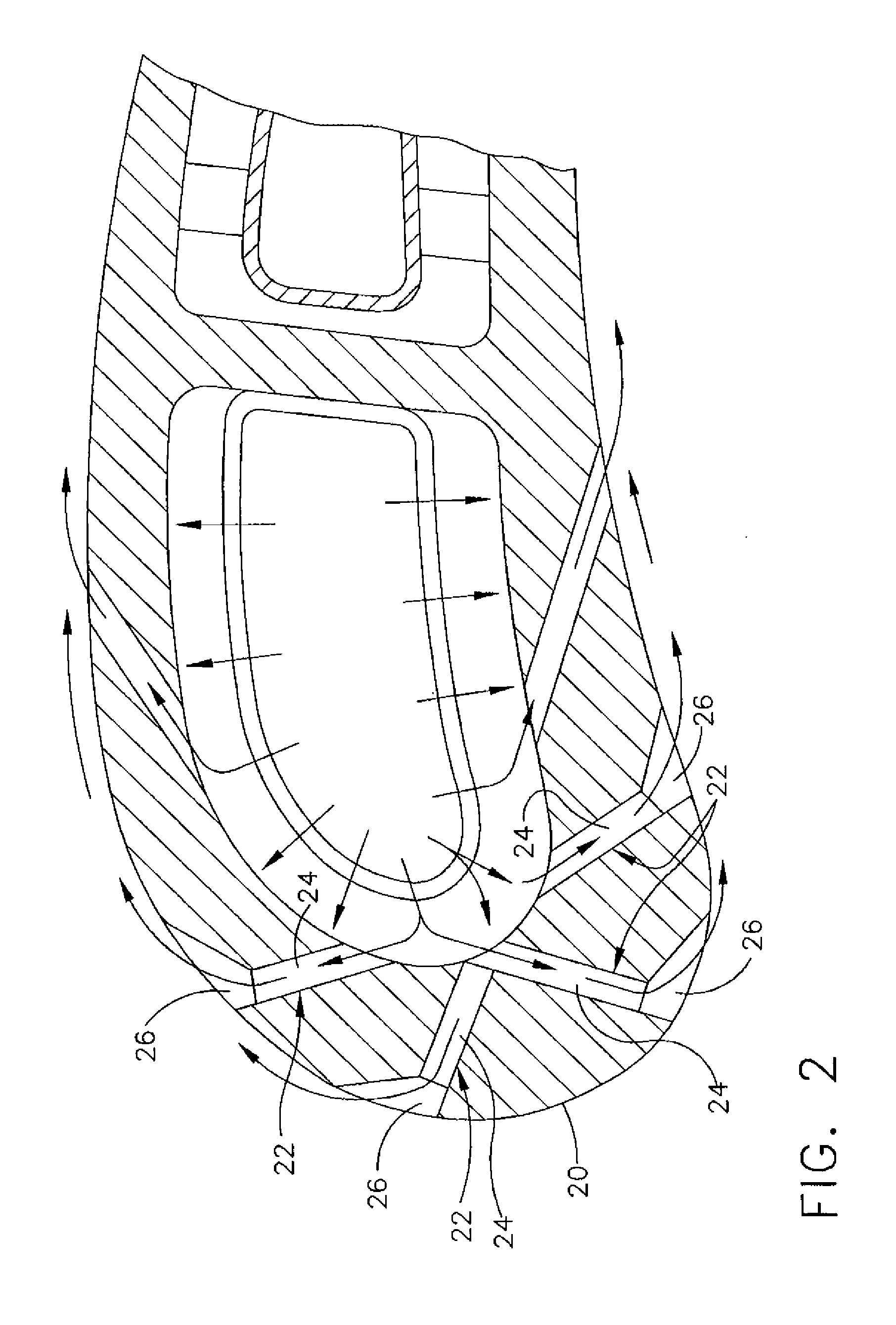

Method of forming cooling holes and turbine airfoil with hybrid-formed cooling holes

A method of forming a cooling hole in a workpiece that includes the steps of laser-forming a blind, inwardly-tapering transition opening into a first side of the workpiece, and EDM-forming a generally cylindrical through hole to a second, opposing side of the workpiece communicating with the inwardly-tapering transition opening to form a through cooling hole communicating with the first and second sides of the workpiece. An airfoil having cooling holes formed by use of both laser and EDM is also disclosed.

Owner:GENERAL ELECTRIC CO

Leather-Like Sheet And Method Of Manufacturing The Same

InactiveUS20090274862A1Dense feelingElegant surface appearanceFibre treatmentSynthetic resin layered productsFiberVitrification

A leather-like sheet composed of a microfine-fiber entangled body made of bundles of microfine fibers and an elastic polymer impregnated therein. The bundles of microfine fibers are composed of microfine monofibers having an average cross-sectional area of 0.1 to 30 μm2 and have an average cross-sectional area of 40 to 400 μm2. The bundles of microfine fibers exist in a density of 600 to 4000 / mm2 on a cross section taken along the thickness direction of the microfine-fiber entangled body. The elastic polymer contains 30 to 100% by mass of a polymer of ethylenically unsaturated monomer. The polymer of ethylenically unsaturated monomer is composed of a soft component having a glass transition temperature (Tg) of less than −5° C., a crosslinkable component, and optionally a hard component having a glass transition temperature (Tg) of higher than 50° C. and another component. The polymer of ethylenically unsaturated monomer is bonded to the microfine fibers in the bundles of microfine fibers. The leather-like sheet has a flexibility and hand such as dense feeling each resembling natural leathers and a high quality appearance. The leather-like sheet is highly stable in quality such as fastness and surface abrasion resistance and excellent in practical performance.

Owner:KURARAY CO LTD

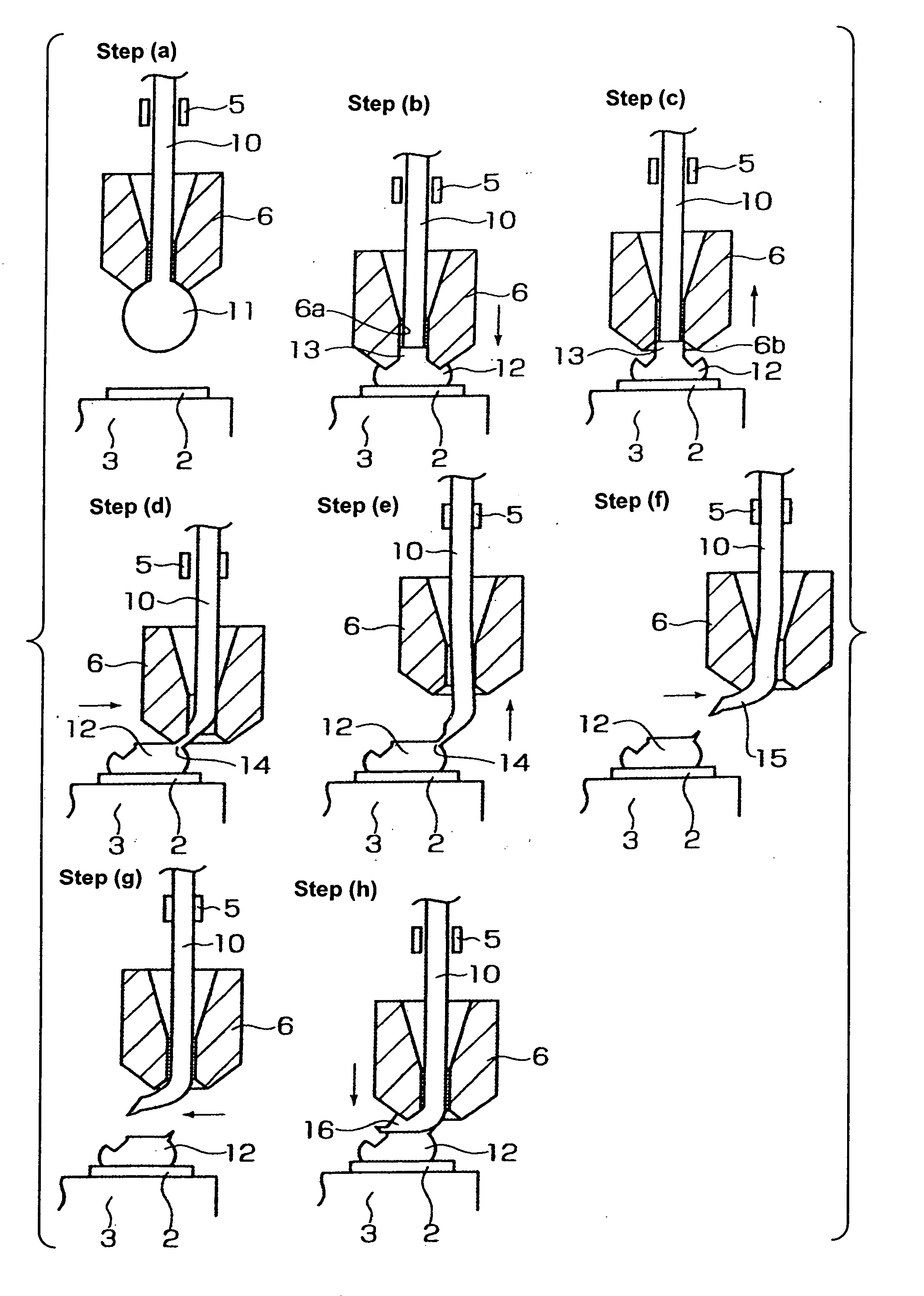

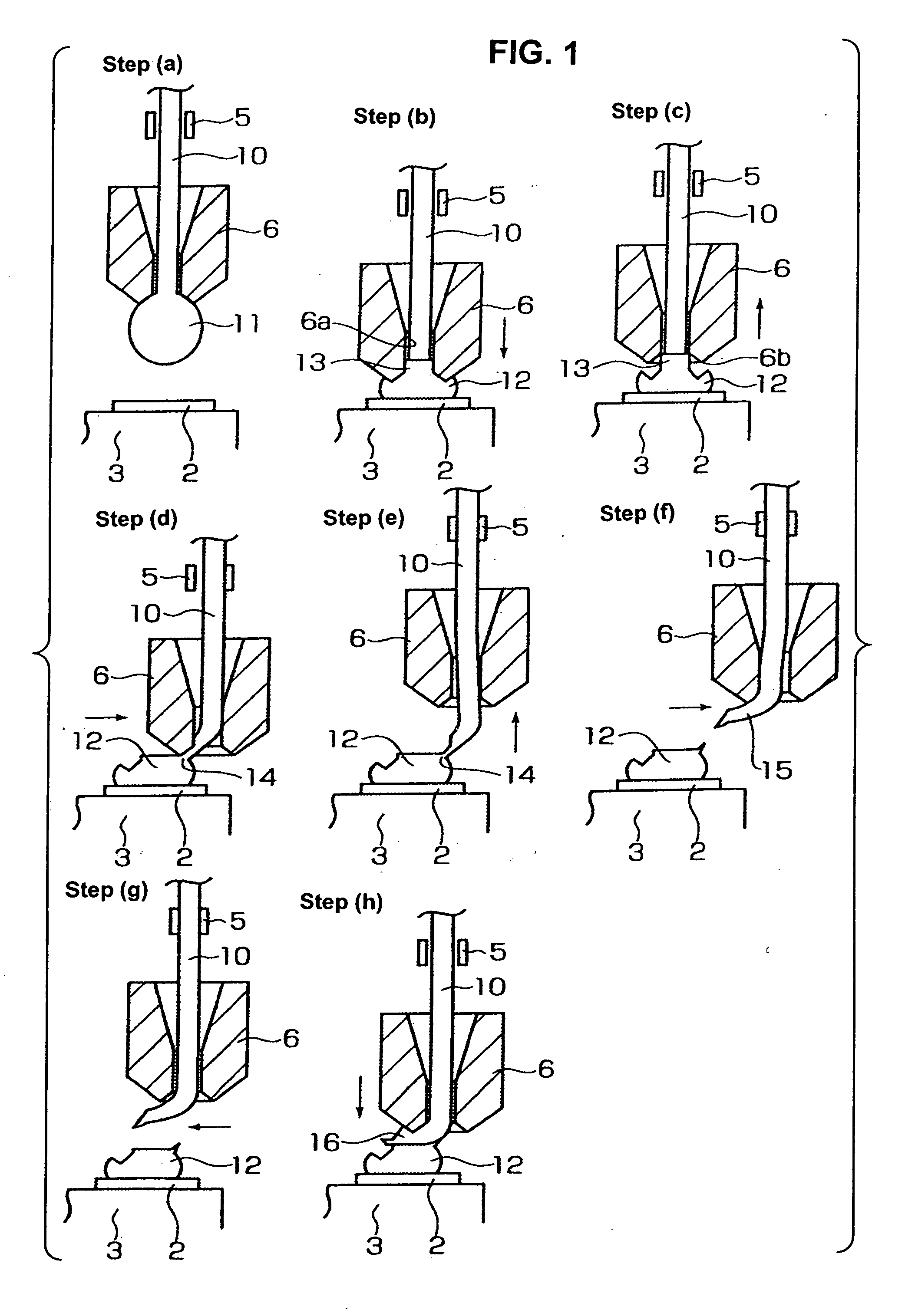

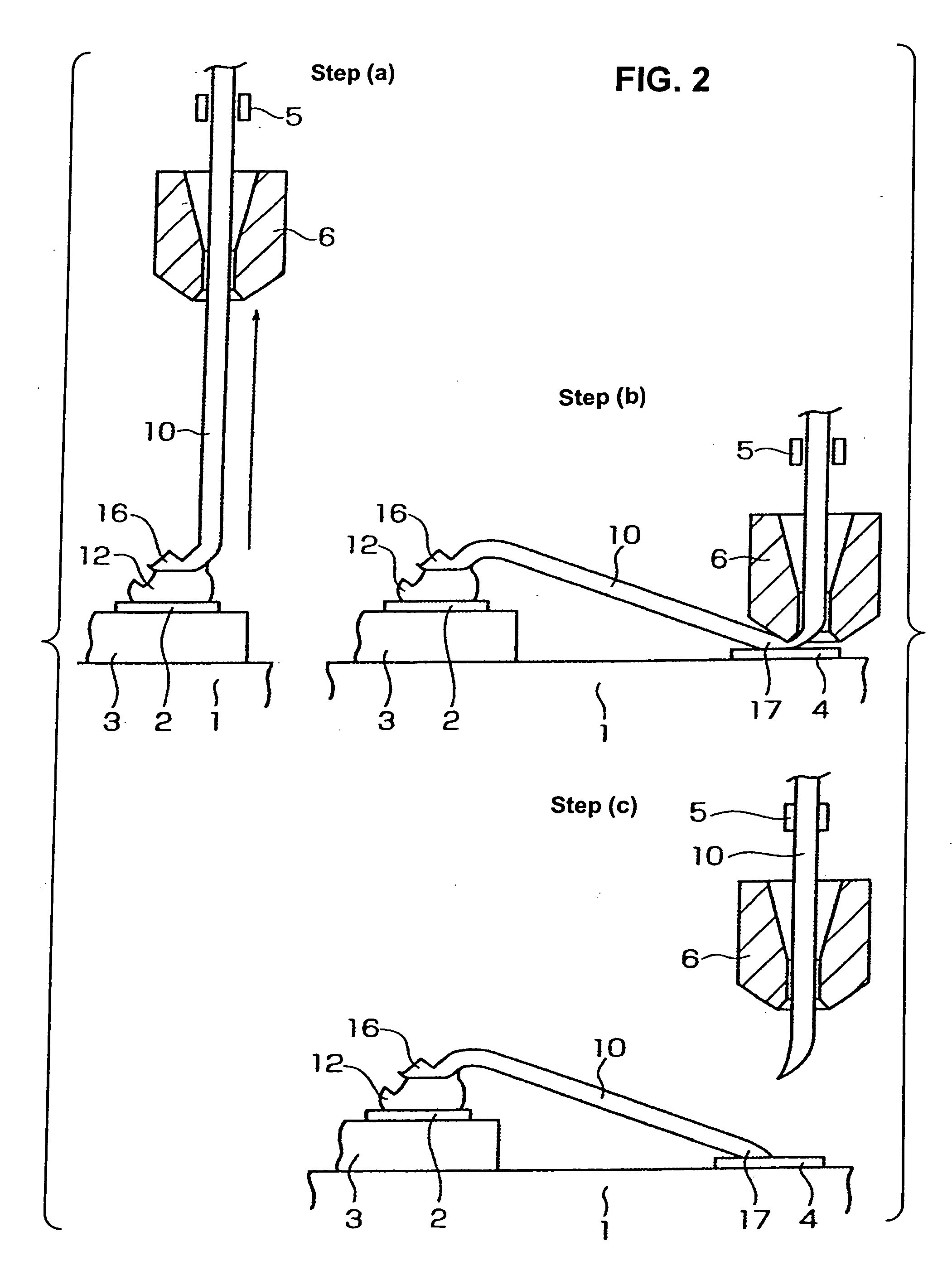

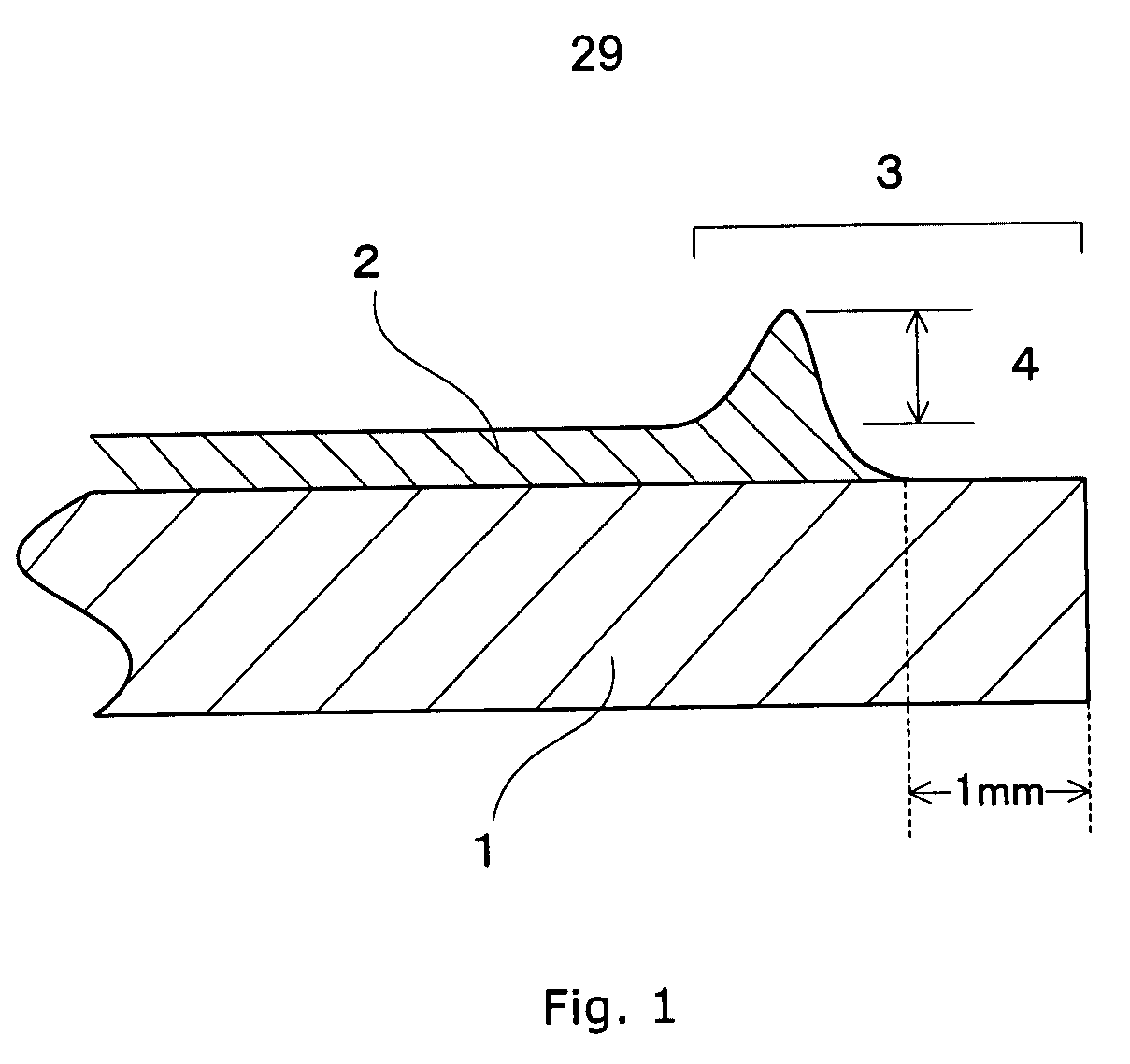

Wire bonding method

InactiveUS20060175383A1Improve implementationReduce decreaseSemiconductor/solid-state device detailsSolid-state devicesWire cuttingEngineering

A wire bonding method with the process of performing a first bonding to a pad of a die that is a first bond point, and the process of performing a second bonding to an interconnect wiring (or a lead) that is a second bond point, thus connecting the pad and the interconnect wiring with a wire. A bump is first formed on a pad, and, in a wire cutting step performed during the step of forming the bump, the wire protruding from the tip end of a capillary is bent in the lateral direction to form a bent part, and then the bent part is bonded to the bump, thus completing the first bonding process; after which the wire is bonded to the interconnect wiring, thus completing the second bonding process.

Owner:SHINKAWA CO LTD

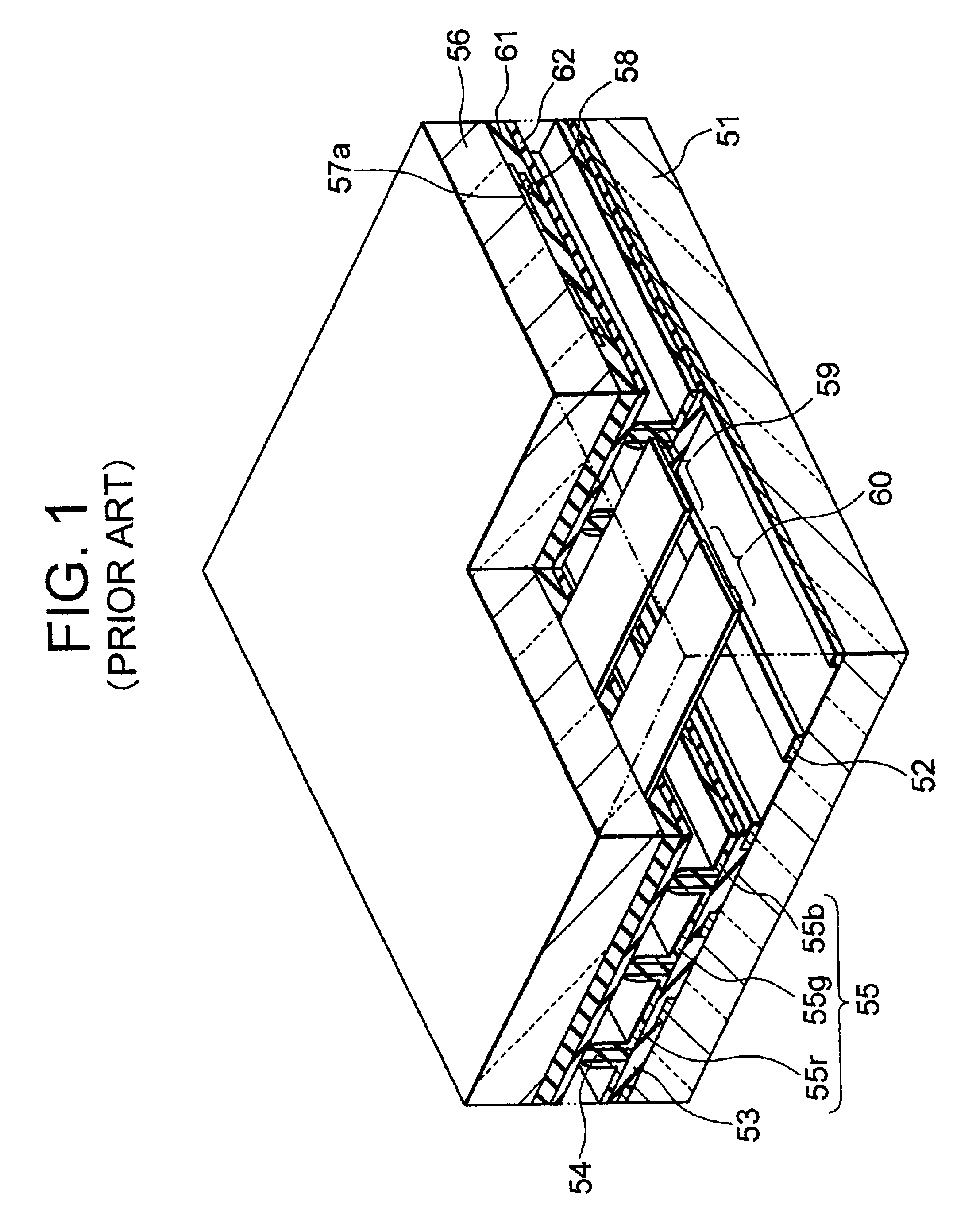

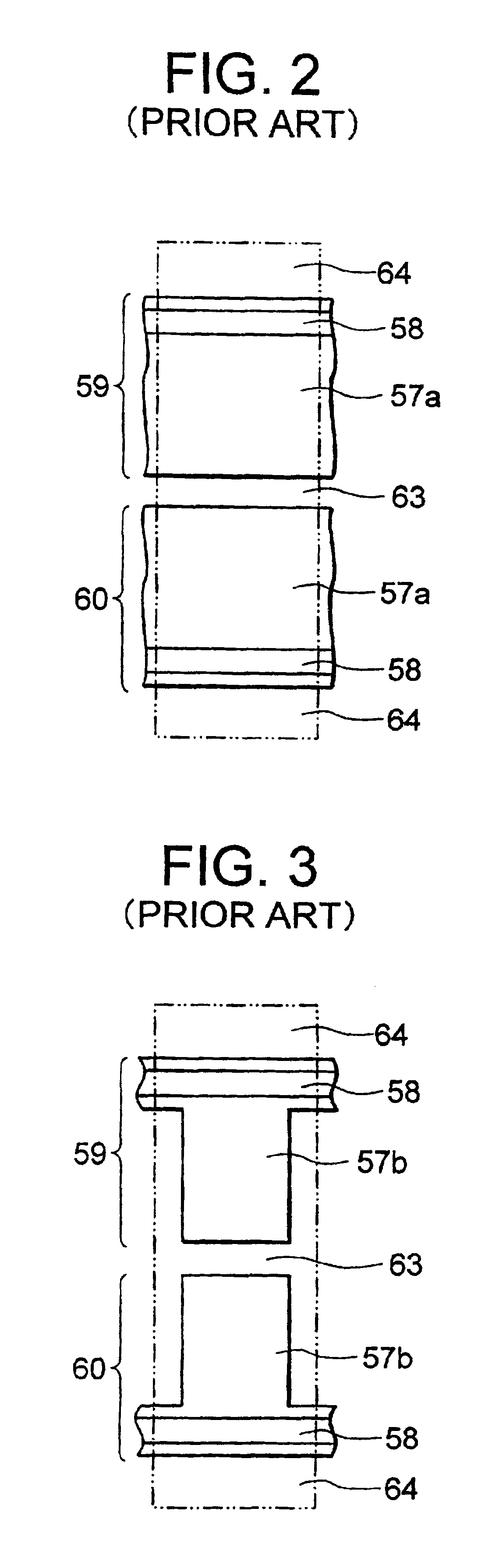

Plasma display panel having an improved plane electrode structure

InactiveUS6819046B2Wide operation marginReduce power consumption rateAddress electrodesSustain/scan electrodesPlanar electrodeFixed ratio

The PDP disclosed herein has a plurality of thin wire electrodes extending in the row direction, which are laid out in such a way as to widen the interval at a fixed ratio (2 times) from the discharge gap section toward the non-discharge gap section as well as to shorten the lengths of those row direction thin wire electrodes in steps with a fixed difference (approximately 20 mumxleft / right) from the cell's vertical center axis toward the partition walls. They are connected by thin wire electrodes that extend in the column direction to form antenna-shaped plane electrodes and the thin wire electrodes that extend in the column direction from the center of the antenna-shaped plane electrodes and the bus electrodes that extend in the row direction are connected to form a sustaining electrode pair (scan electrode and common electrode).

Owner:PIONEER CORP

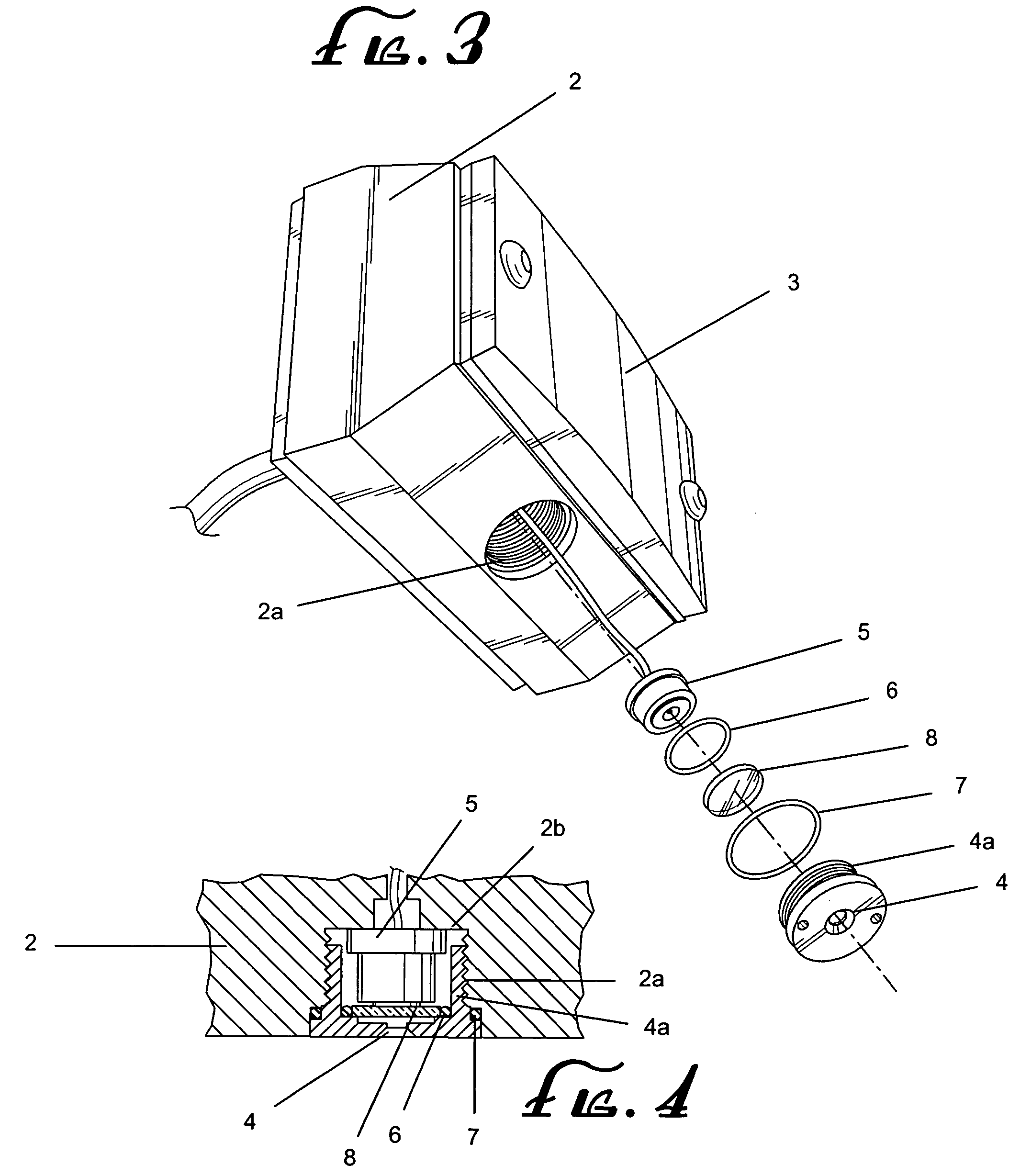

Concealed camera

InactiveUS7413357B2Broad visionReduce shapingPrintersConcealed burglar systemsMonitoring systemHigh resolution

A concealed camera comprising a housing, a subminiature camera and a peep hole of very small size through which the camera may perceive a large field of vision. With a high resolution camera and the tiny peep hole, the camera may be positioned or located in plain view as concealed within a myriad of functional objects, such as a clock, reflector, light or any other common looking device in the area of desired view or surveillance. Multiple concealed cameras may by employed and perhaps synchronized in a surveillance system such that the downstream viewed image may be automatically switched from one image to another as desired by the system user.

Owner:SILVERSTATE SAFETY IMAGE

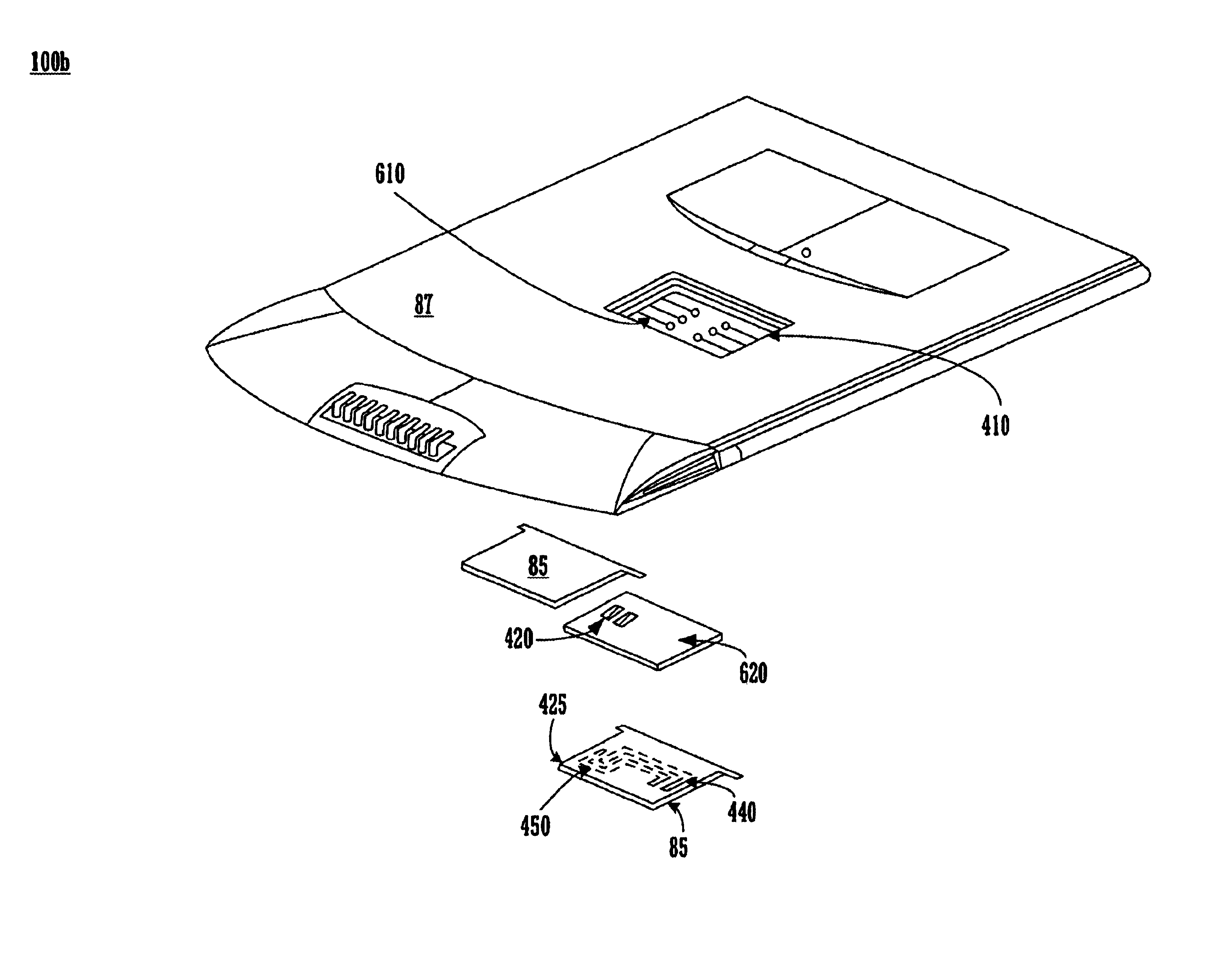

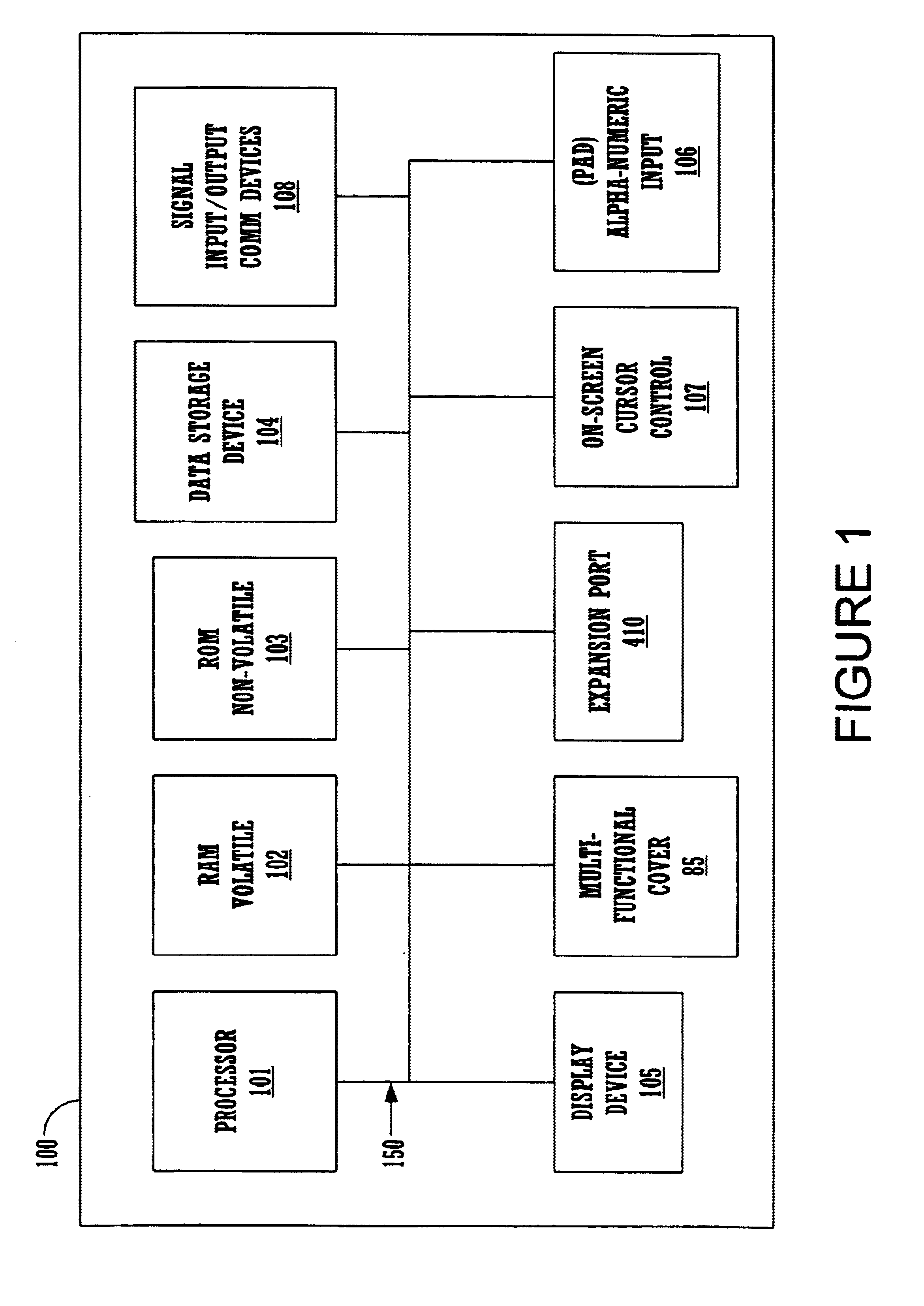

Multifunctional cover integrated into sub-panel of portable electronic device

InactiveUS6842335B1Function increaseSmall sizeDigital data processing detailsElectrical apparatus contructional detailsLoudspeakerEngineering

A cover for an opening in the housing of a portable electronic device that provides a function in addition to that of protecting the opening from dirt. The cover can be coupled to the housing so that it can move between a closed position within the housing's surface recess and an open position that allows access to the opening in the housing. In the closed position, the cover becomes part of the housing and the form factor of the device is generally unchanged. The cover can function as an antenna for wireless communication between the device and a network or access point, and it can contain circuitry for devices such as transmitter / receivers. The cover can also function as a display device, a speaker, or an alarm. Thus an existing cover that occupies space within the volume of a handheld device can be utilized for expanding the functionality of the device while generally retaining the current form factor of the device.

Owner:QUALCOMM INC

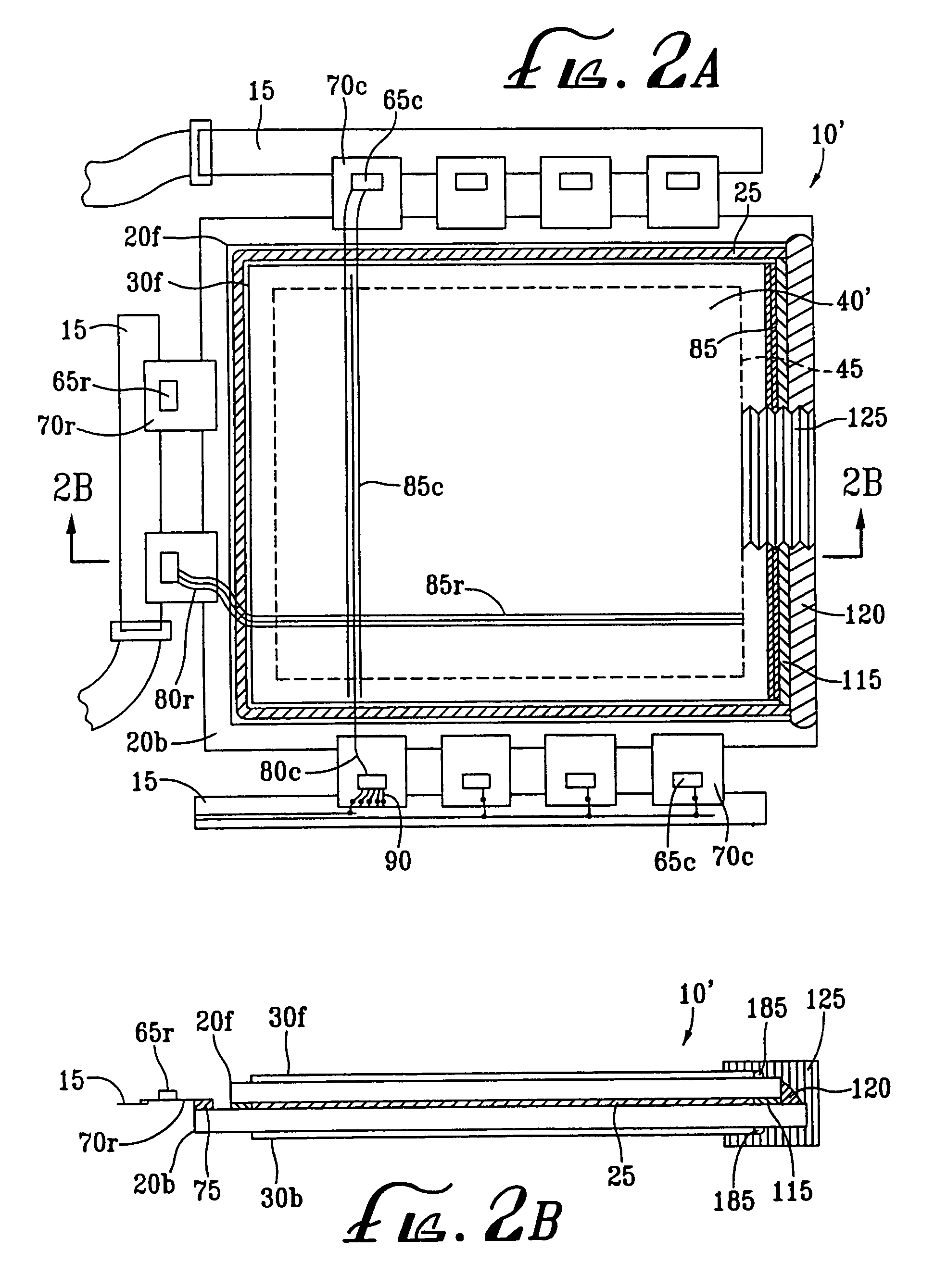

Customized electronic display and methods of customizing the physical size and/or shape thereof

Owner:PIXEL SCI

Stitching of near-nulled subaperture measurements

ActiveUS20090251702A1Reduce the differenceLimited rangeUsing optical meansOptical apparatus testingMetrologyWavefront

A metrology system for measuring aspheric test objects by subaperture stitching. A wavefront-measuring gauge having a limited capture range of wavefront shapes collects partially overlapping subaperture measurements over the test object. A variable optical aberrator reshapes the measurement wavefront with between a limited number of the measurements to maintain the measurement wavefront within the capture range of the wavefront-measuring gauge. Various error compensators are incorporated into a stitching operation to manage residual errors associated with the use of the variable optical aberrator.

Owner:QED TECH INT LLC

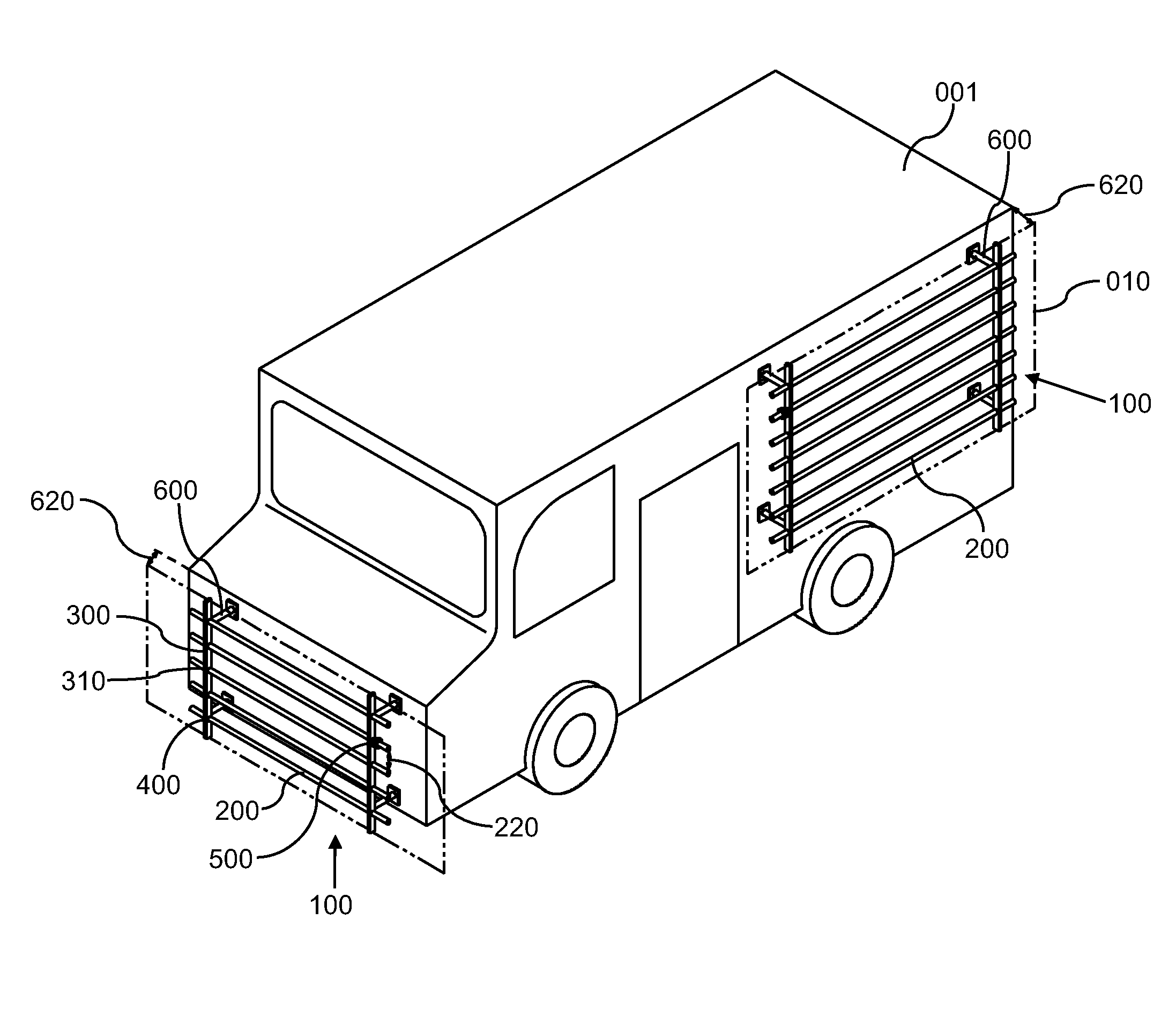

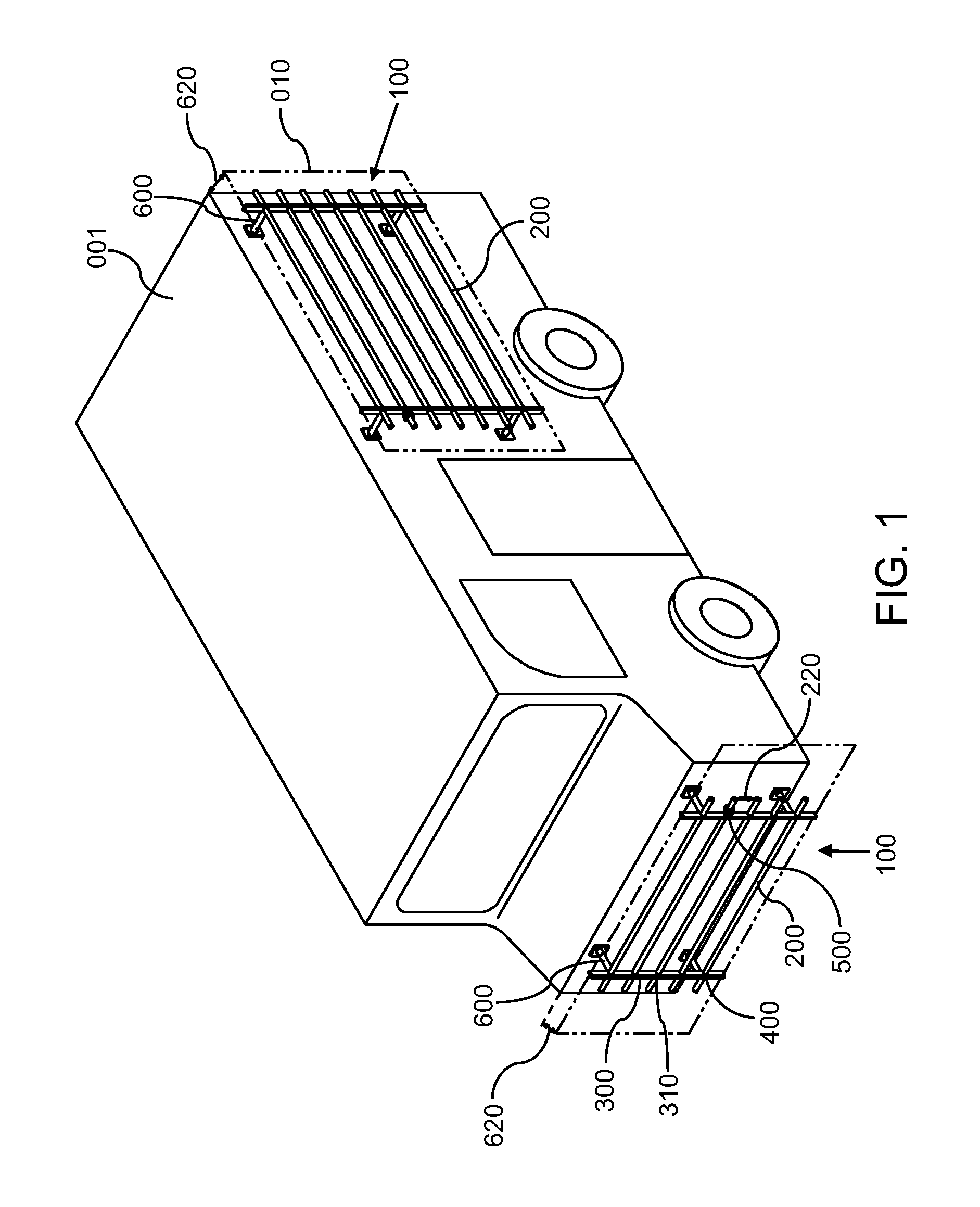

Bar armor system for protecting against rocket-propelled grenades

InactiveUS20110232472A1Optimize geometryInhibition of translationArmourArmoured vehiclesVertical barShaped charge

A bar armor system is provided for reducing damage caused by RPGs launched towards a vehicle. The bar armor system includes at least one bar array, comprised of lateral bars and vertical bars, wherein the lateral bars are set in predetermined positions so as to reduce the possibility of shaped charges being directed towards the target vehicle. Tubular shaft retainers are provided to be positioned in annular openings in the vertical bars. The lateral bars can be of a round or hexagonal cross-section, and when hexagonal lateral bars are employed, the flat surfaces of the cross-section are positioned horizontally by the tubular shaft retainers so as to minimize the area presented to an oncoming RPG, particularly when the RPG strikes at a non-normal incidence. Push washers can be employed at the outside surfaces of the vertical bars so as to hold them in position. A mounting system is provided that is capable of positioning the bar armor system at close distances to the vehicle so that the overall size and weight of the vehicle is not unduly increased by the bar armor system. The mounts can include rotary latches to provide easy installation and removal. The system can also be of an electrically-conductive unified composition so that efficient electrostatic coating techniques can be used to cover the system. The system can also be provided in the form of kits for ready installation and for more economical repair.

Owner:GENERAL ATOMICS

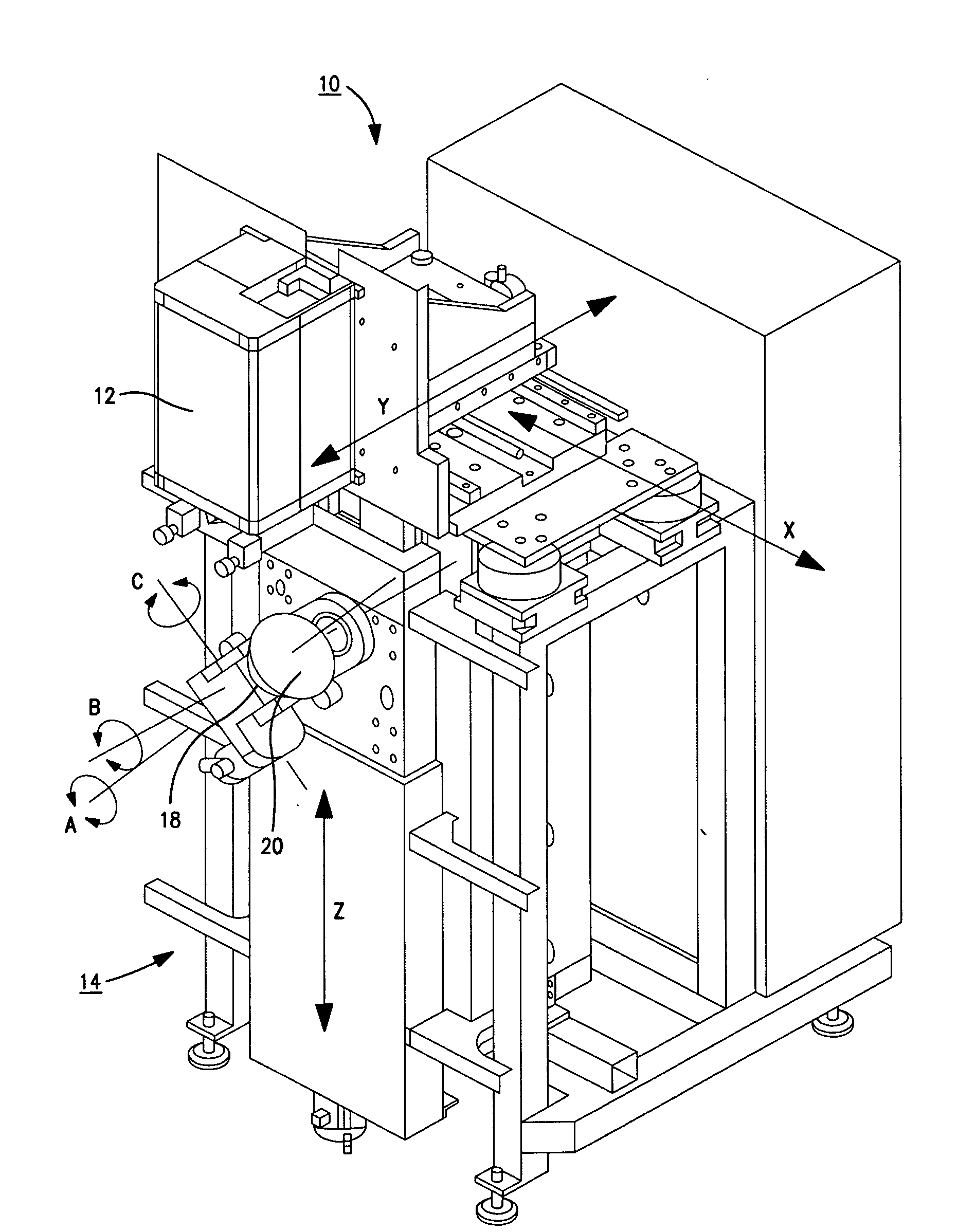

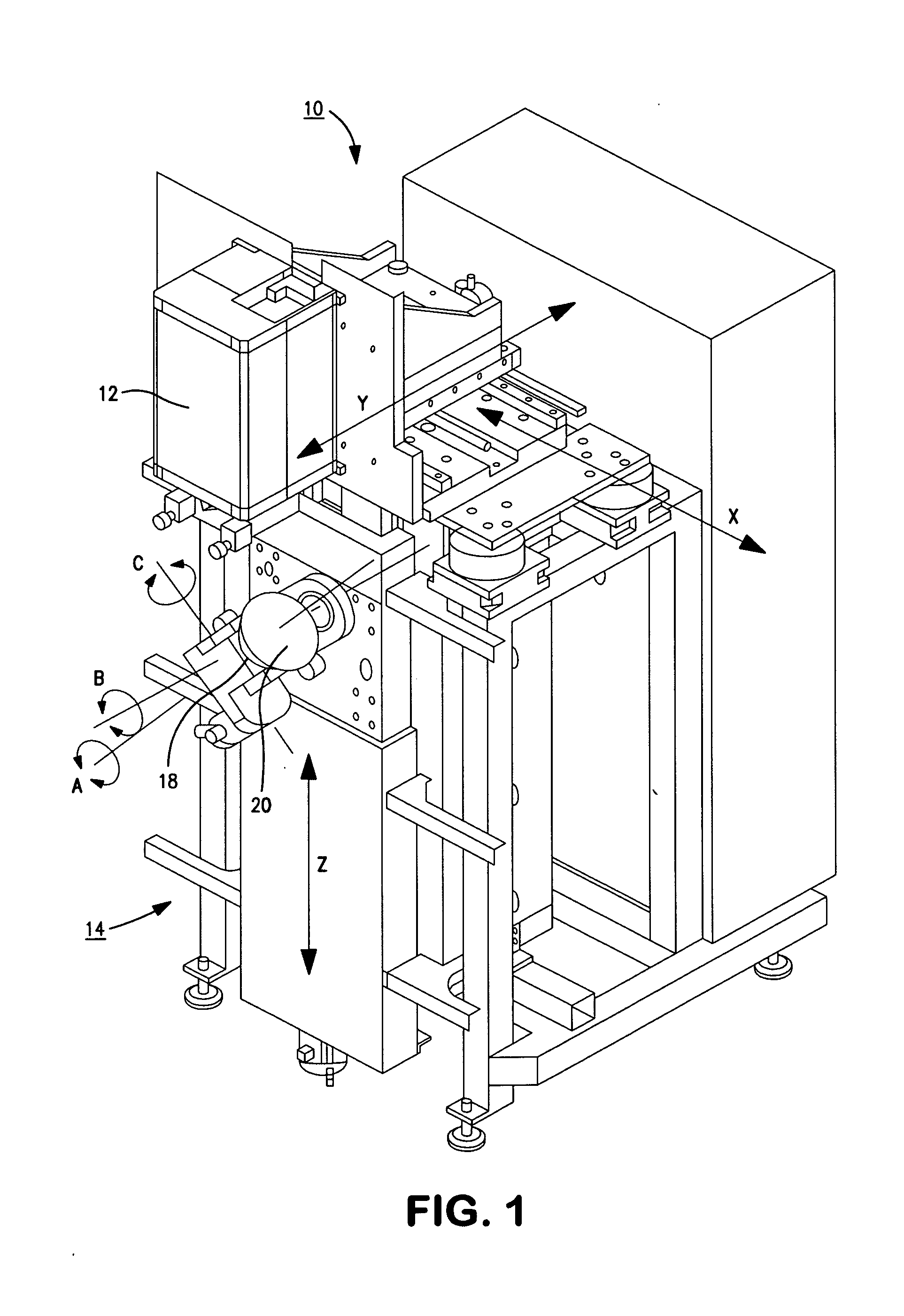

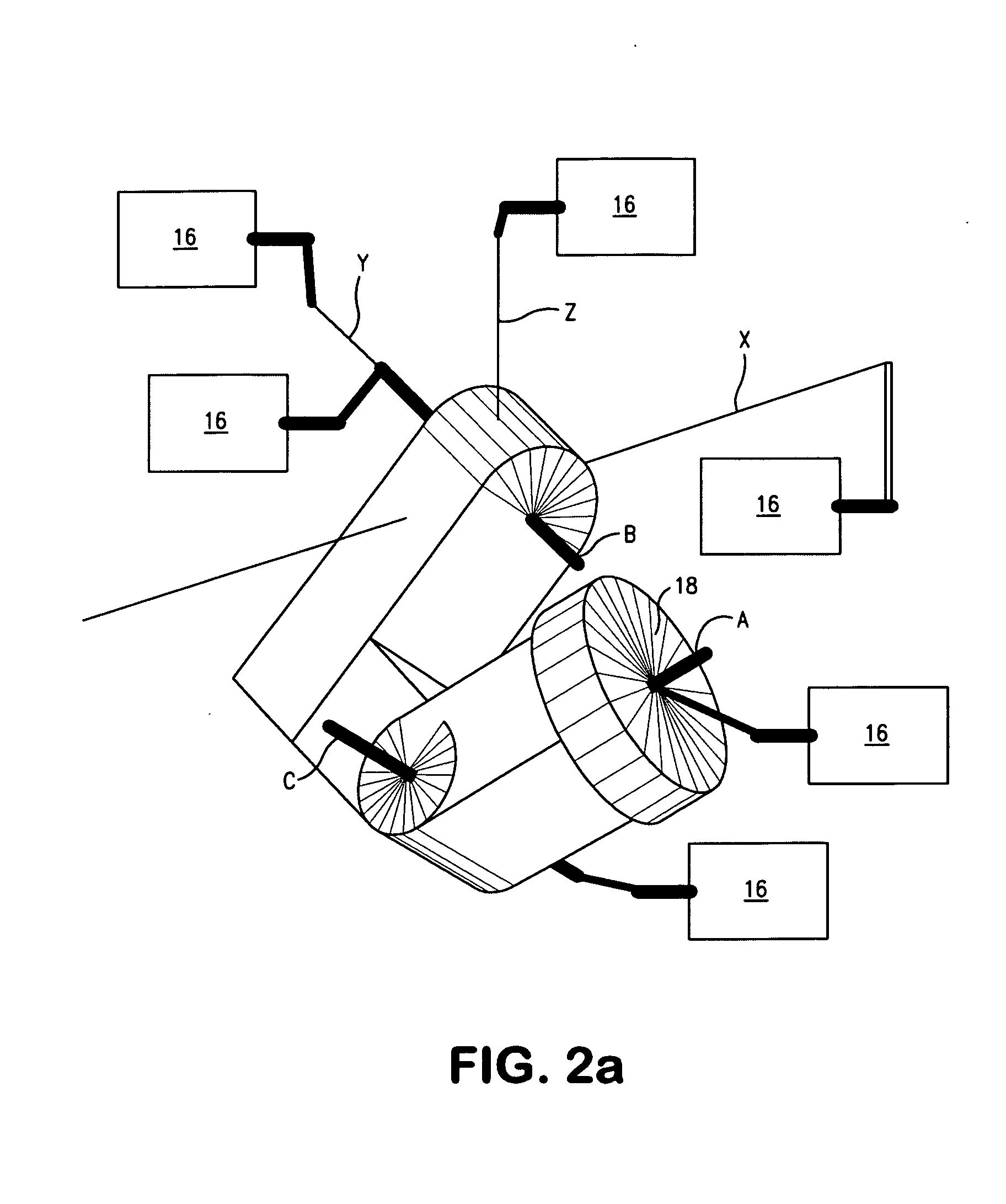

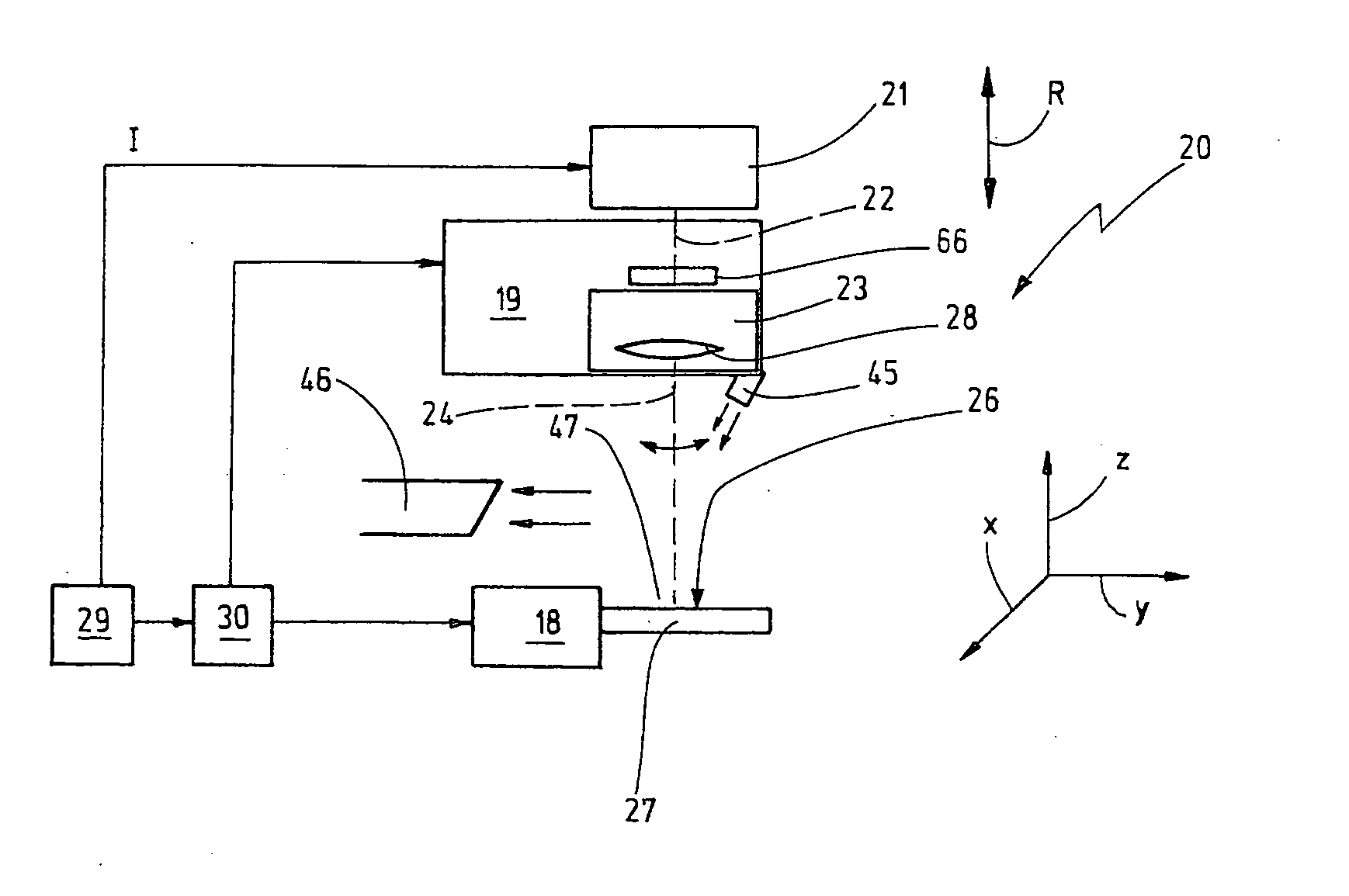

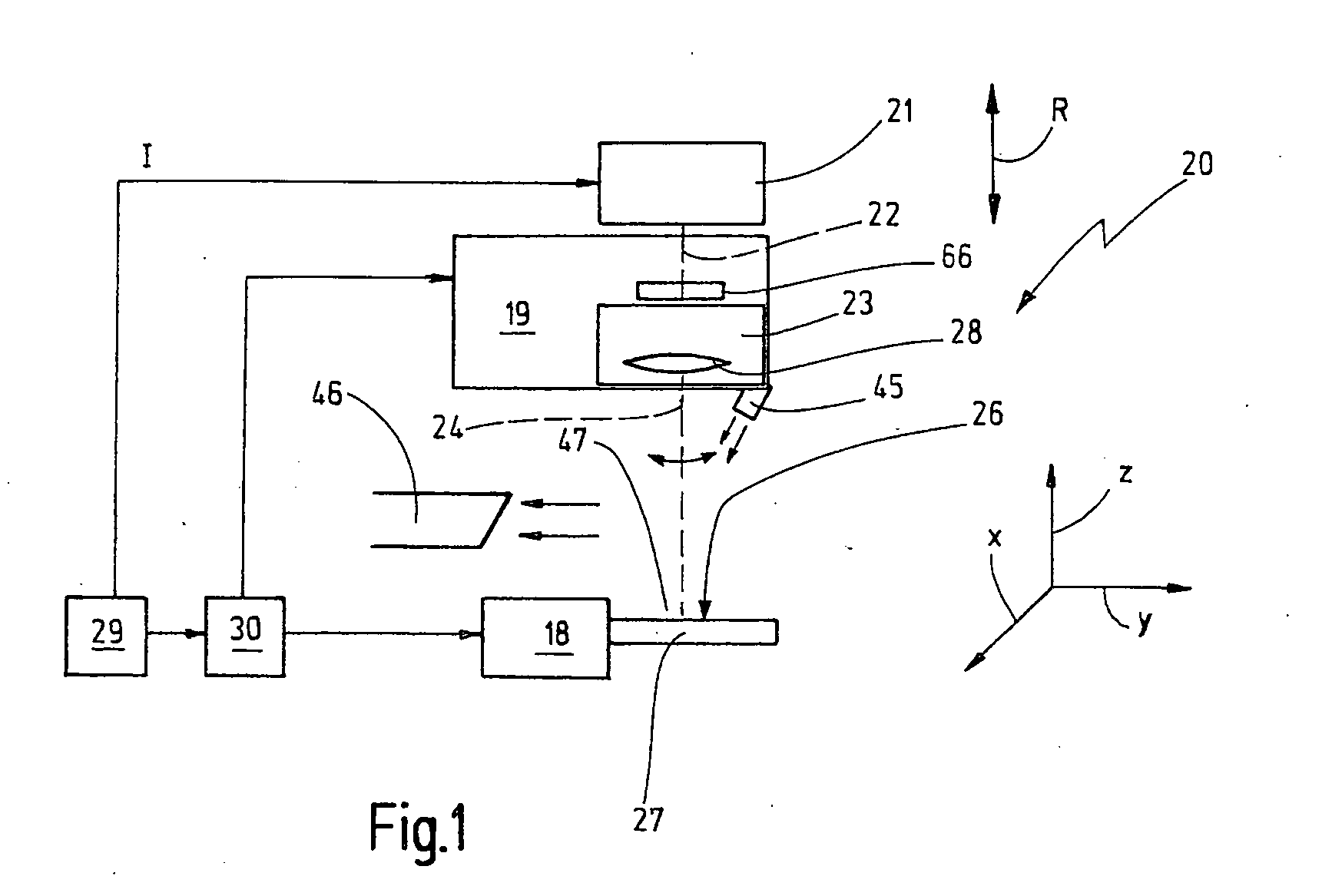

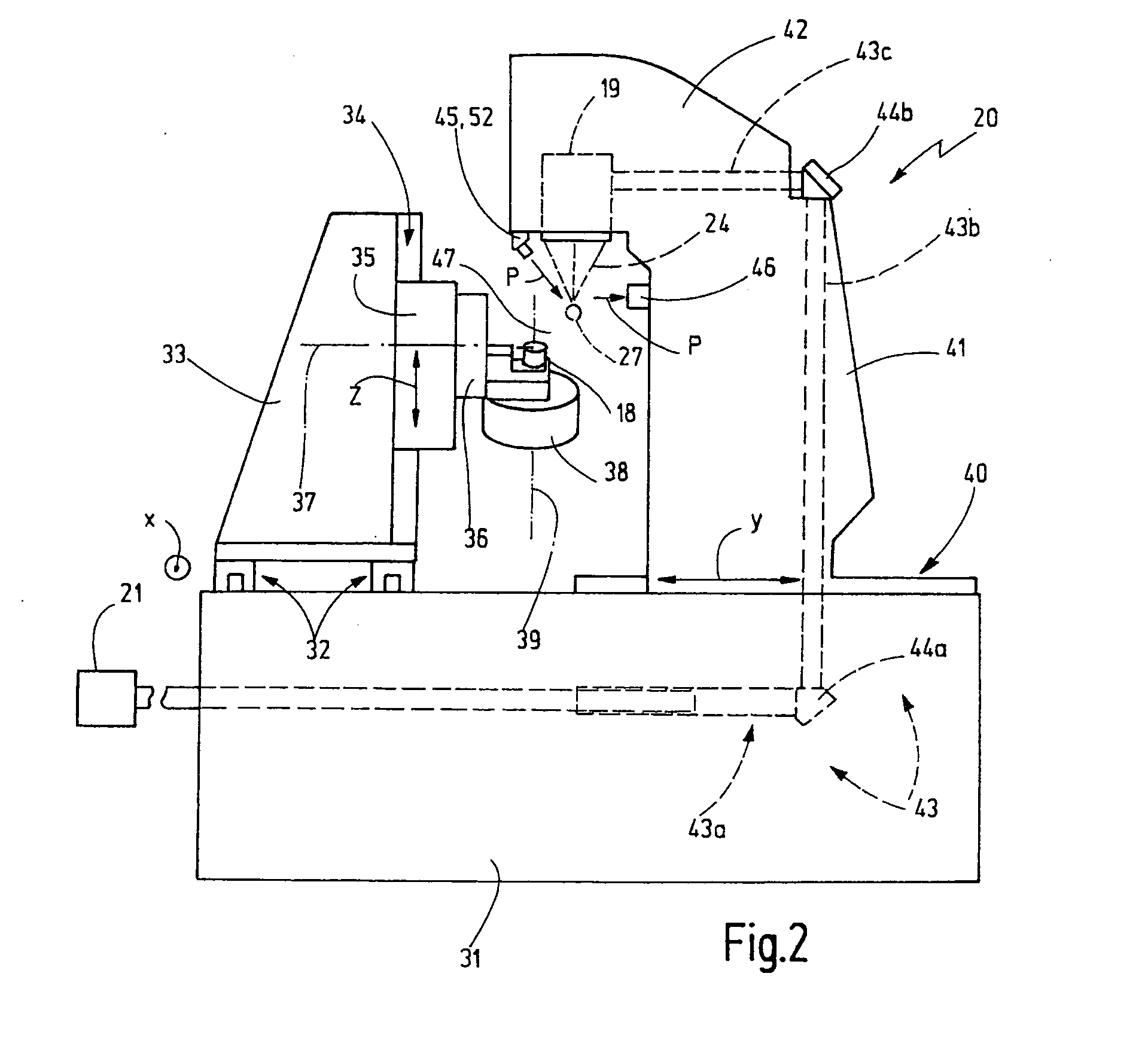

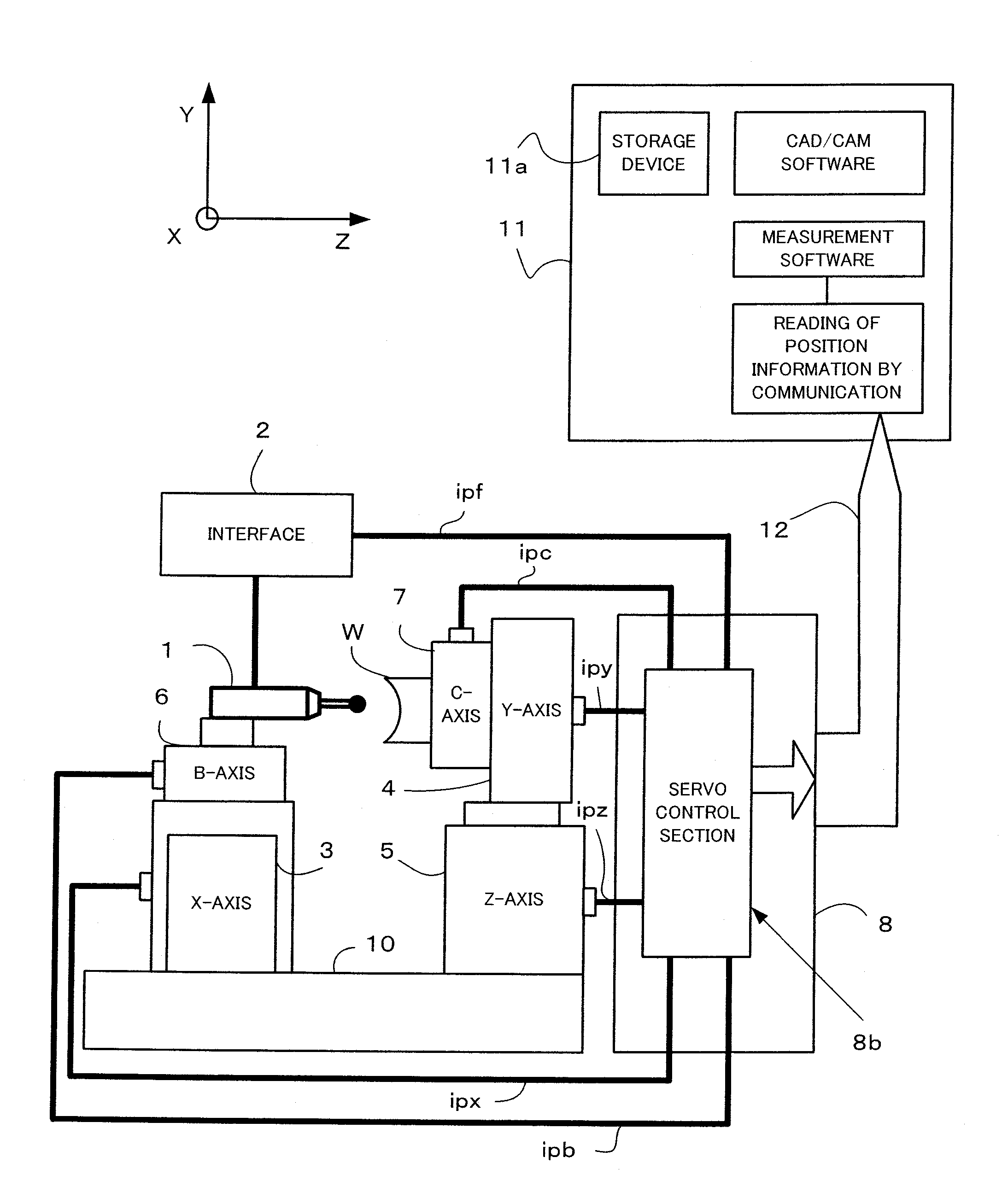

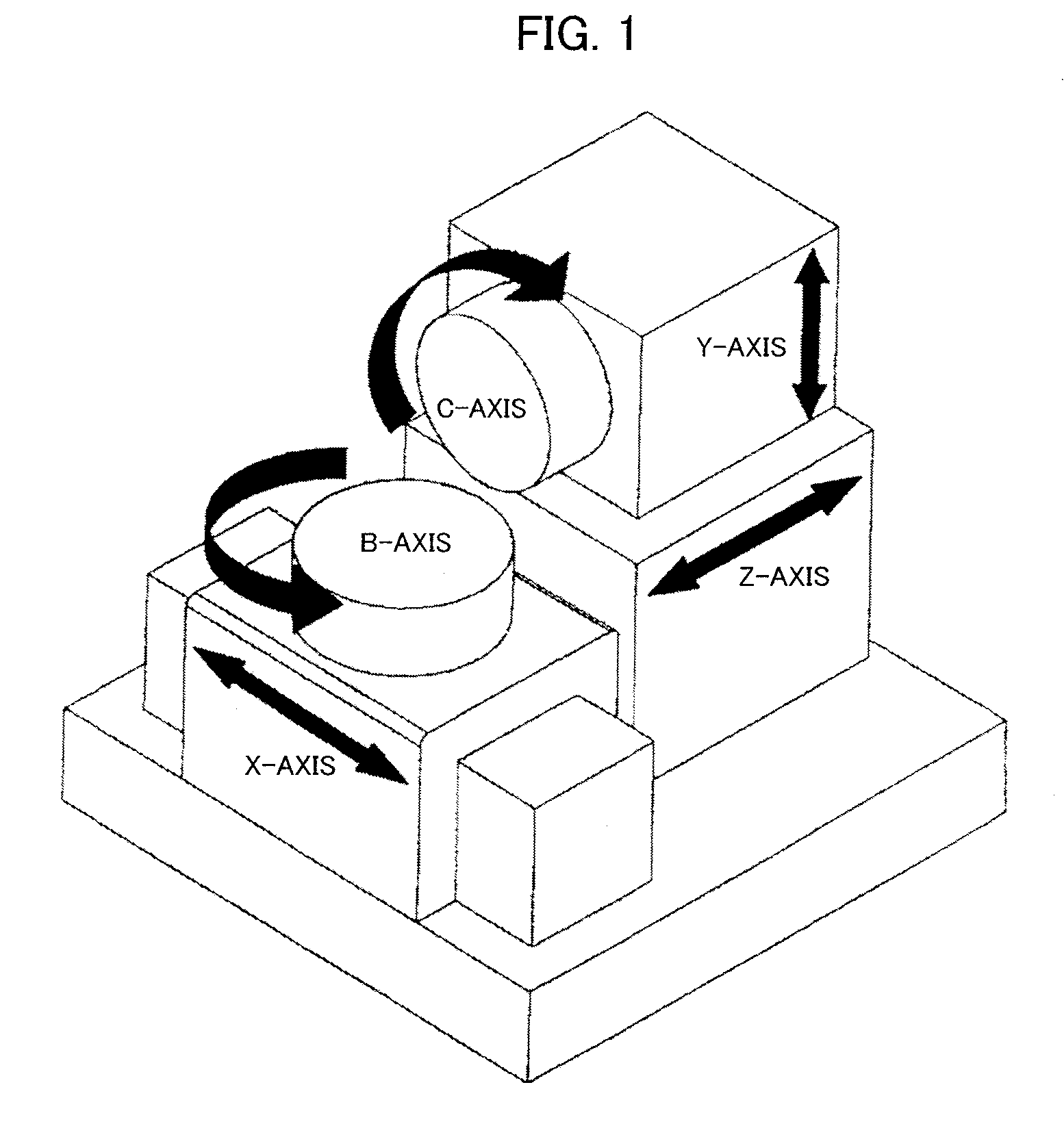

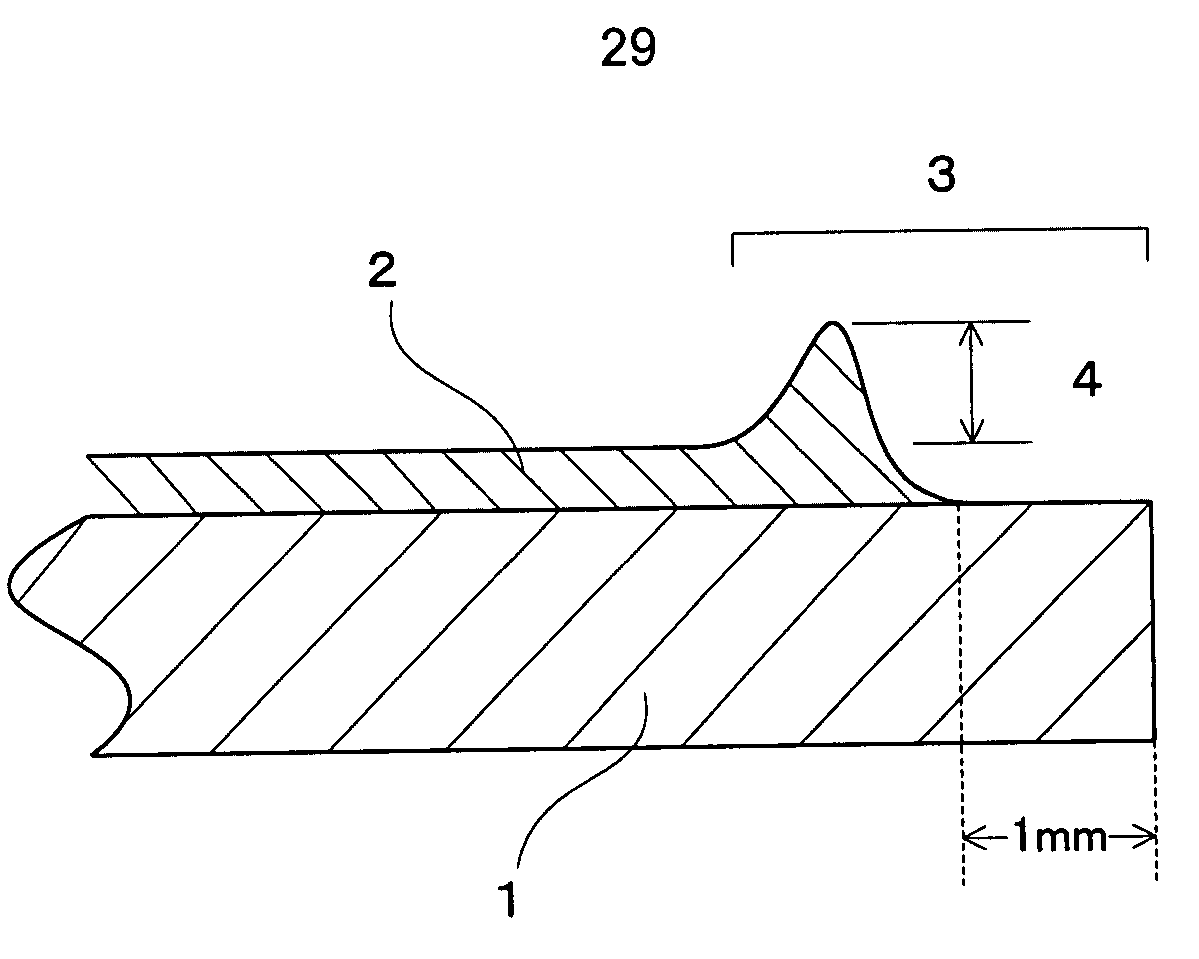

Laser machining apparatus and method for the manufacture of a rotationally symmetrical tool

The invention resides in a method and an apparatus for the manufacture of a tool from a blank (27) wherein the tool is, in particular, a rotational tool which rotates about a longitudinal axis (L). The rotational tool includes at least one cutting edge (60) and a chip groove (61). Preferably, the rotational tool is in its operating area (63) in a cross-section thereof radially symmetrical with respect to the longitudinal axis (L) thereof. It is manufactured from a cylindrical blank (27) exclusively by laser ablation using a laser machining apparatus (20) by means of a laser scanner with a pulse area (55) of, for example, rectangular contour. The laser beam impulses (24) are directed within the pulse area (55) onto a plurality of impact locations (25) disposed along a predetermined pulse path (B). This pulse area (55) is moved, like a tool, along the surface (26) of the blank (27). Hereby the chip groove (61) and subsequently the cutting edge (60) are formed from the blank (27) by sublimation of the material. The relative movement between a tool holder (18) supporting the blank (27) and the laser head (19) delivering the laser beam impulses (24) is achieved by a positioning arrangement (30) having several axes.

Owner:FRITZ STUDER AG

Semiconductor device with improved pixel arrangement

ActiveUS8441185B2Avoid defectsIncreasing number of stepDischarge tube luminescnet screensElectroluminescent light sourcesEvaporationMiniaturization

Owner:SEMICON ENERGY LAB CO LTD

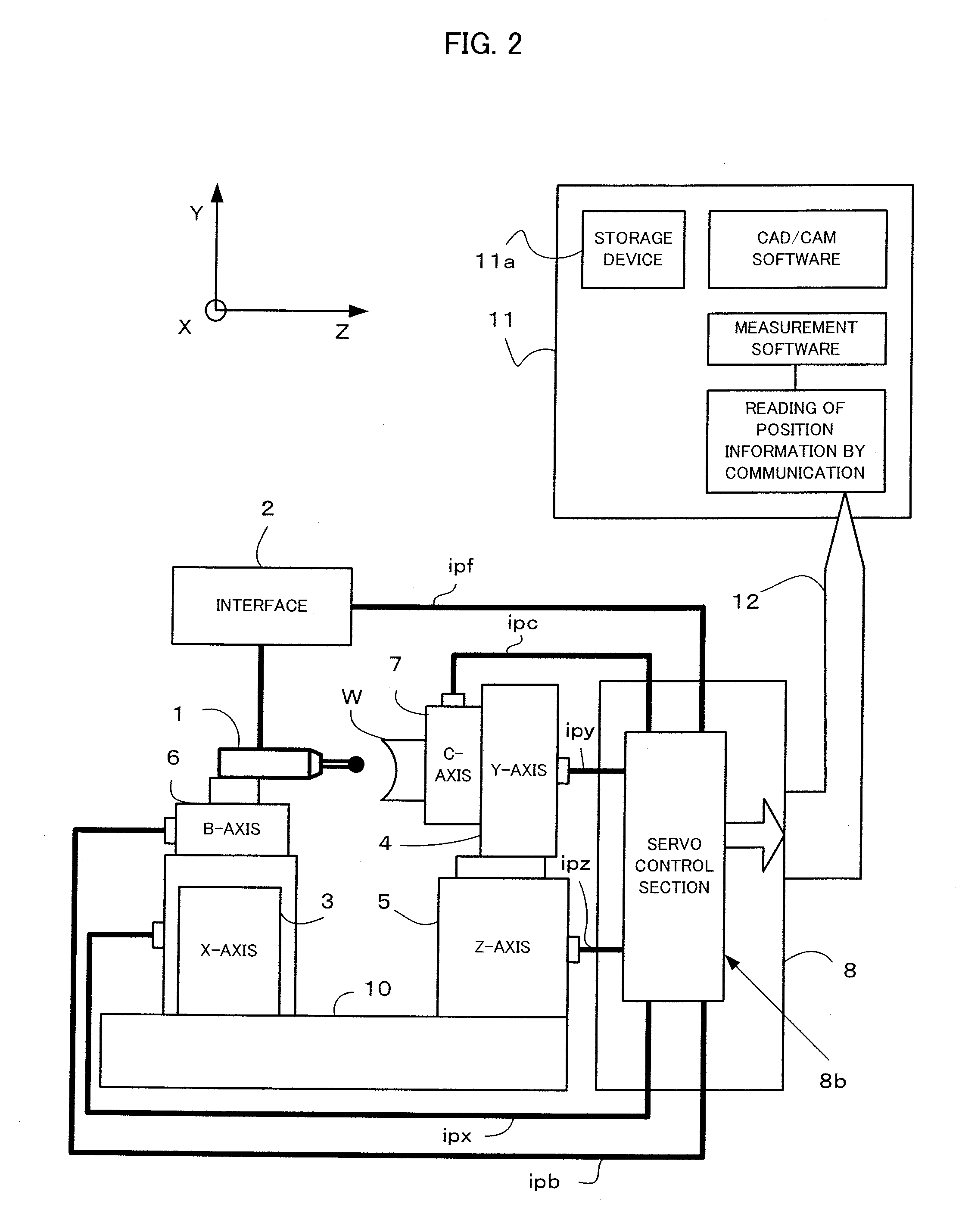

Machine tool with numerical controller and on-machine measuring device

ActiveUS20090292503A1Reduced shape errorReduce shapingFeeler-pin gaugesUsing subsonic/sonic/ultrasonic vibration meansMeasurement deviceEngineering

A machine tool is fitted with a position detector for detecting a position of a moving axis of the machine tool and an on-machine measuring device for measurement on the machine tool. An axial position detection signal output from the position detector and a measurement signal output from the on-machine measuring device are received through interfaces by a numerical controller that controls the machine tool. These interfaces are designed so that the numerical controller receives the axial position detection signal and the measurement signal with the same timing.

Owner:FANUC LTD

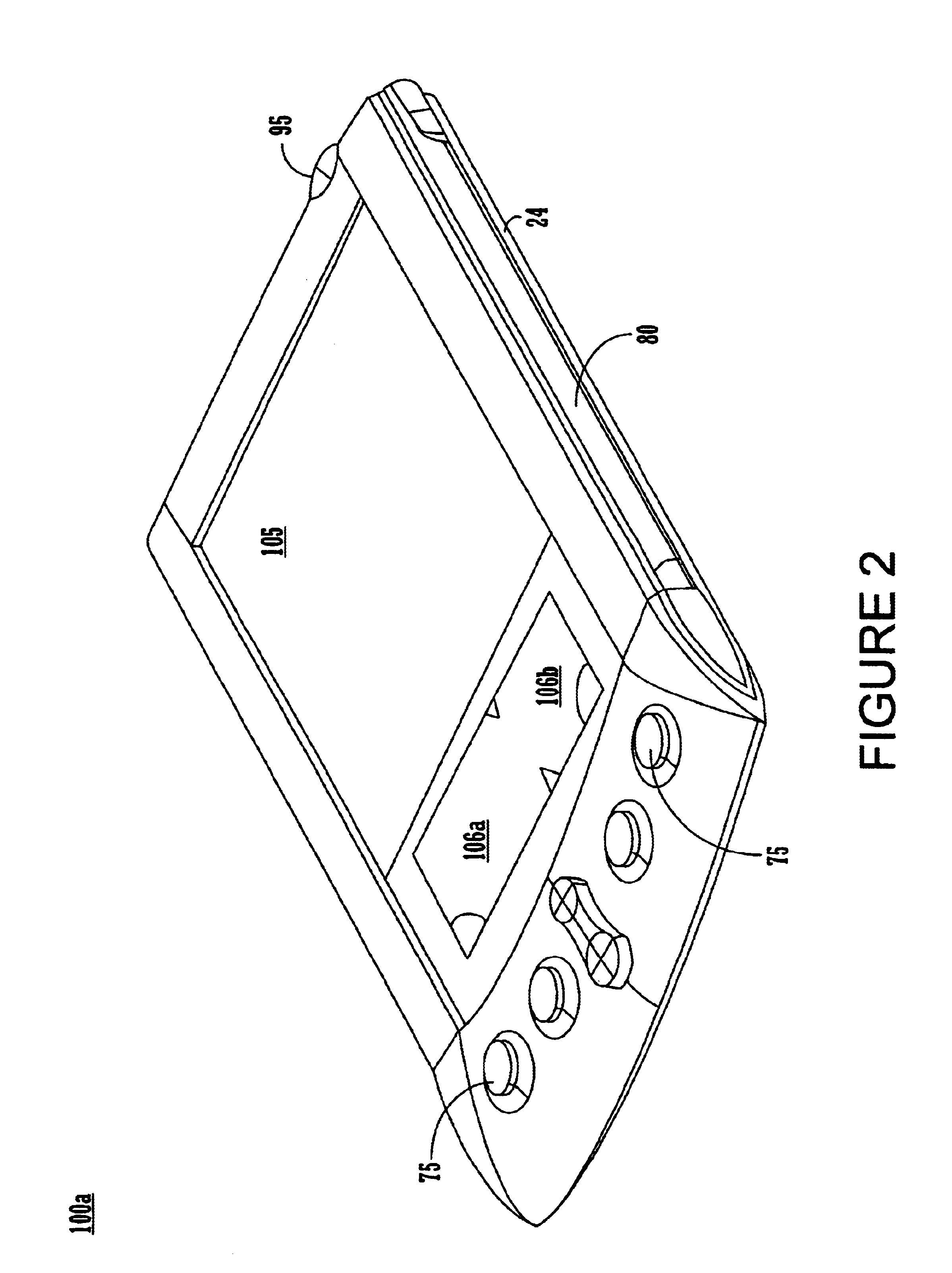

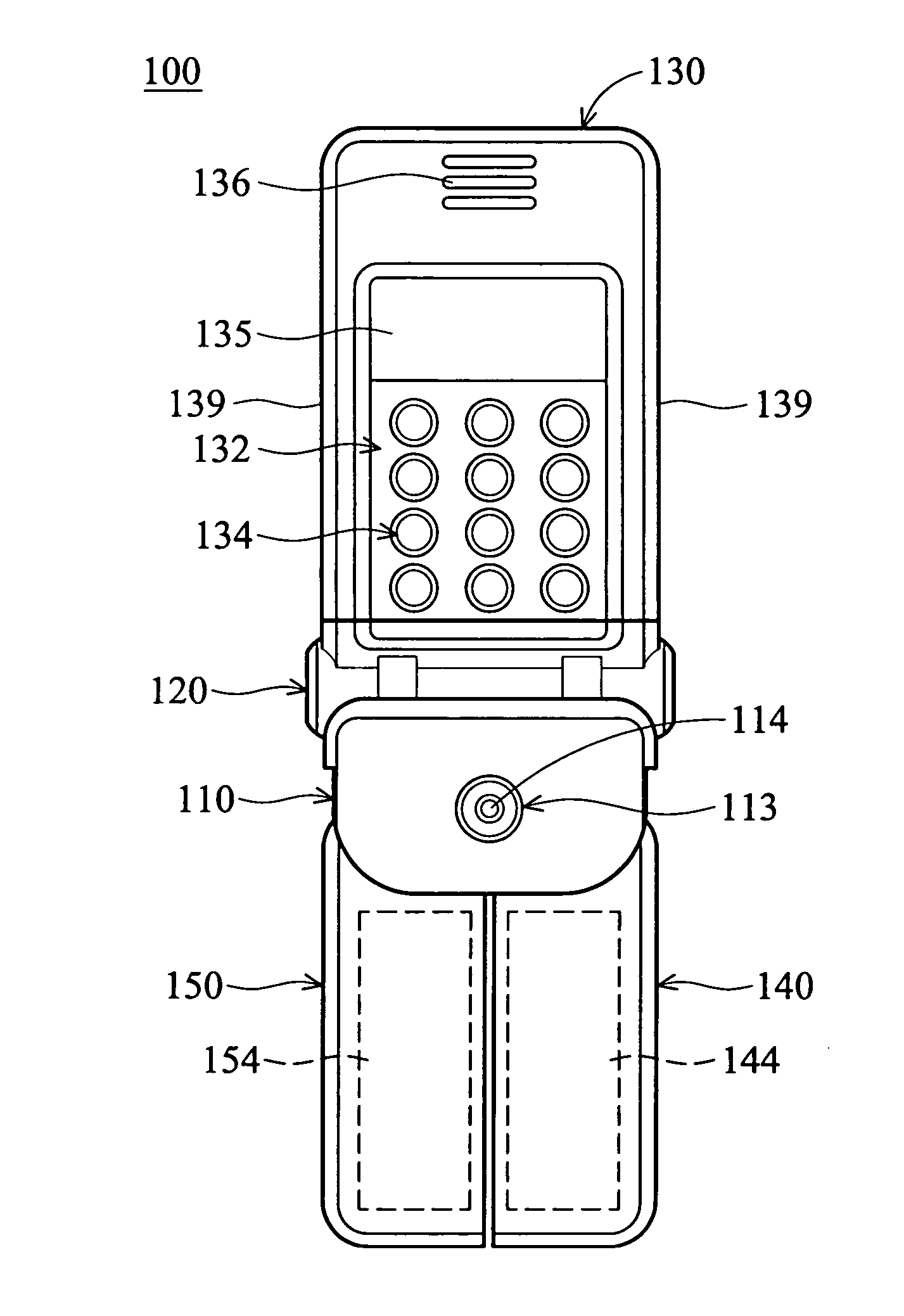

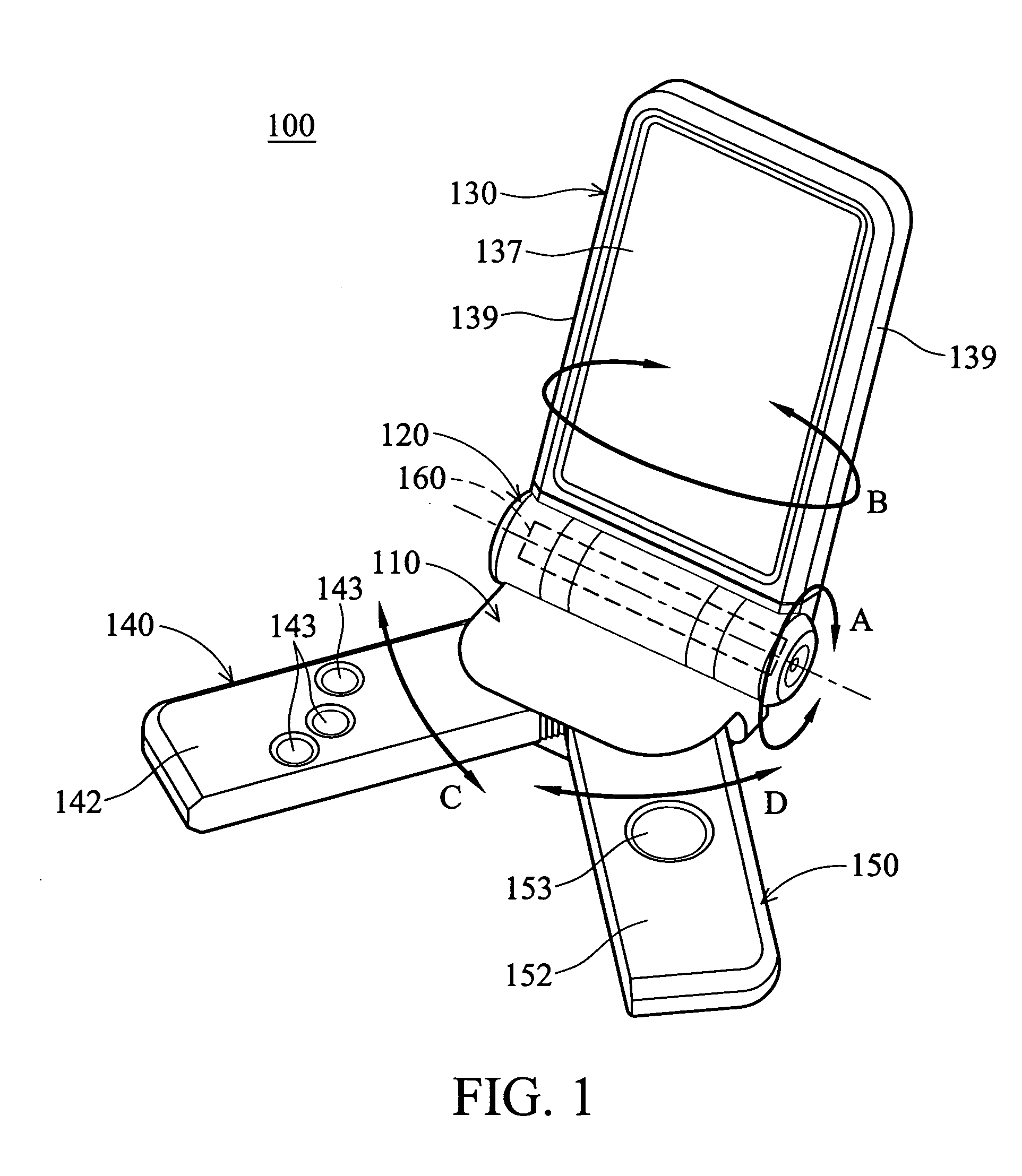

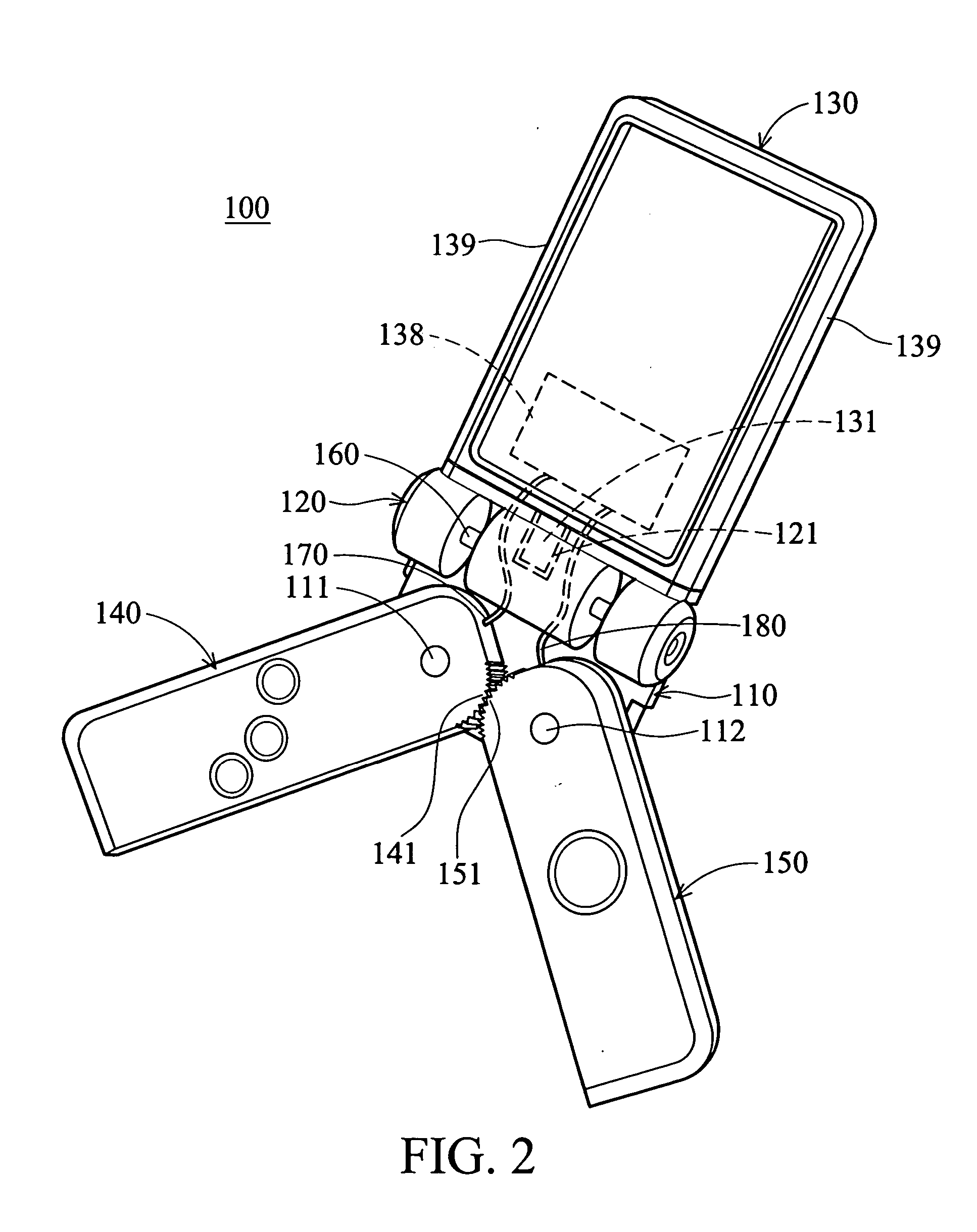

Handheld electronic apparatus

InactiveUS20050070328A1Reduce shapingReduce weightDetails for portable computersTelevision systemsEngineeringElectrical and Electronics engineering

A handheld electronic apparatus. The handheld electronic apparatus includes a first connecting member, a second connecting member, an operating member, a first holding member and a second holding member. The second connecting member is rotatably connected to the first connecting member. The operating member is rotatably connected to the second connecting member. The first holding member is rotatably connected to the first connecting member. The second holding member is rotatably connected to the first connecting member. The first and second holding members relatively rotate between a closed position and an open position. The invention thereby provides convenient use of communication, digital photography, PDA, and video game functions in a single device.

Owner:QUISDA CORP

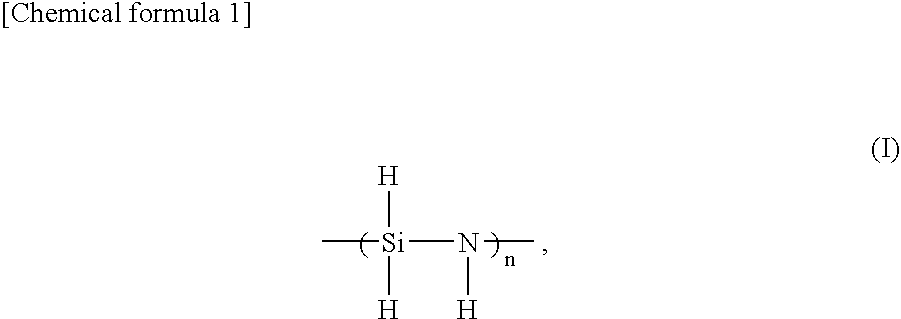

Polysilazane-Treating Solvent and Method for Treating Polysilazane by Using Such Solvent

InactiveUS20080102211A1Good edge cut part shapeImprove solubilityOrganic chemistryChemical paints/ink removersTetralinAlicyclic Hydrocarbons

Owner:MERCK PATENT GMBH

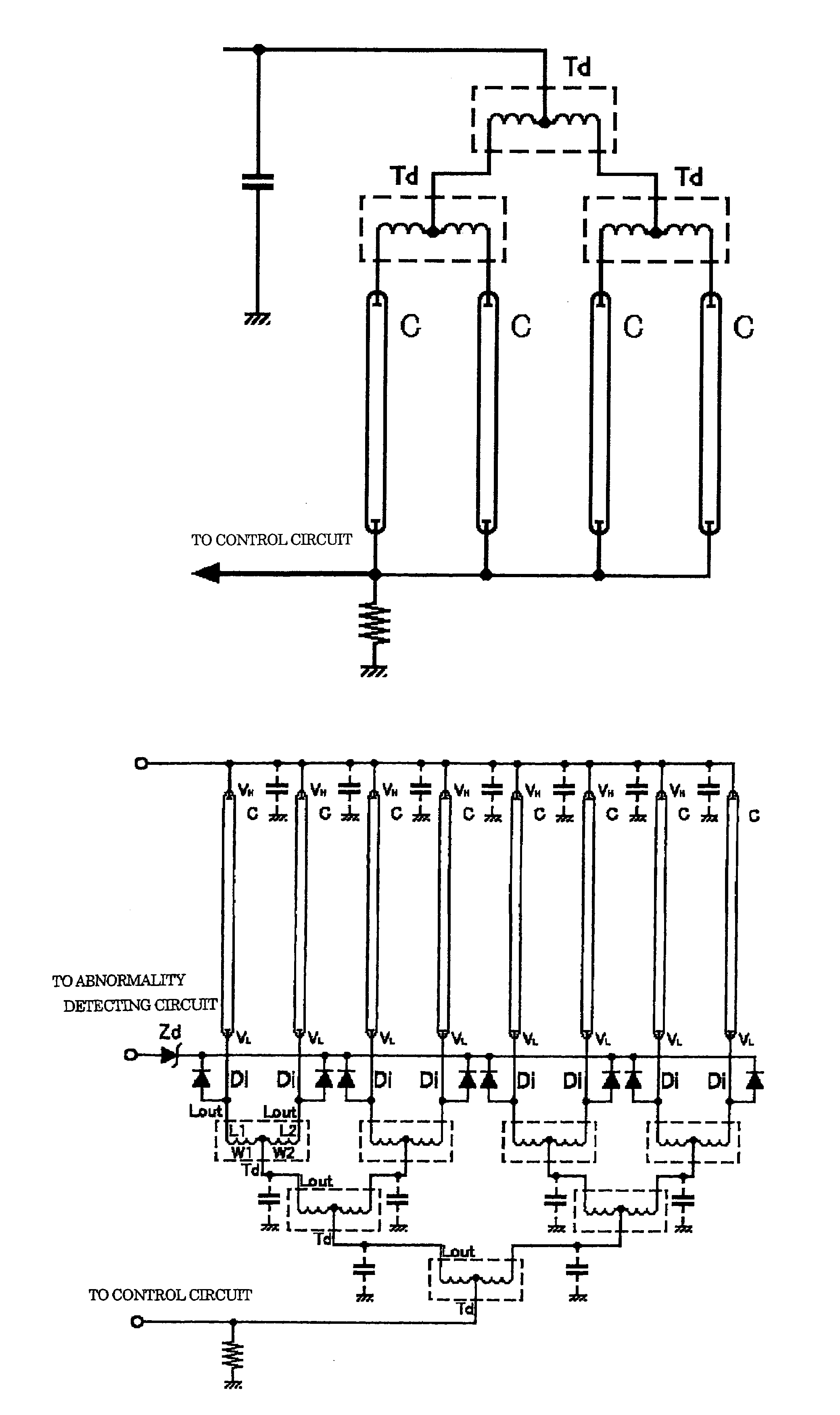

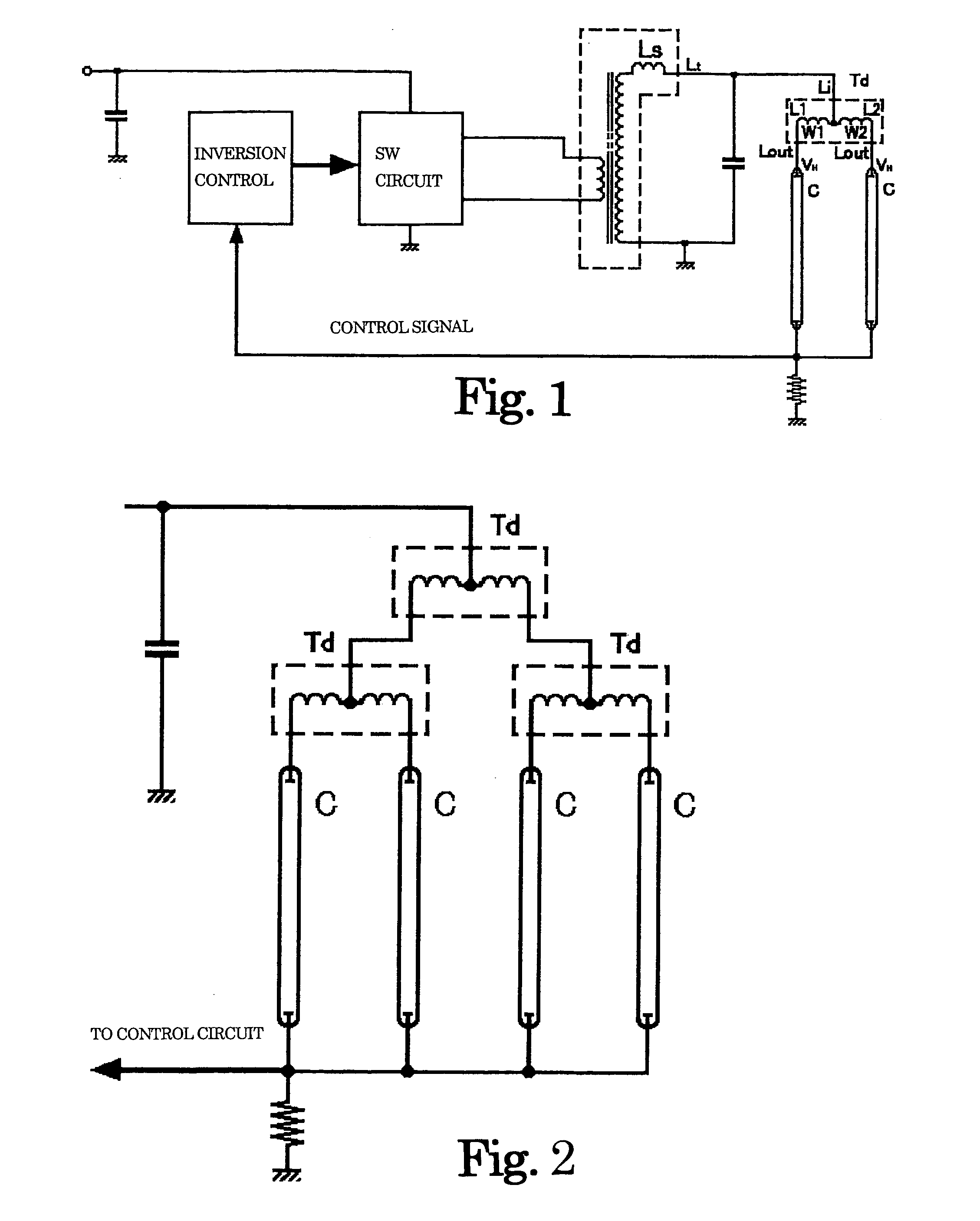

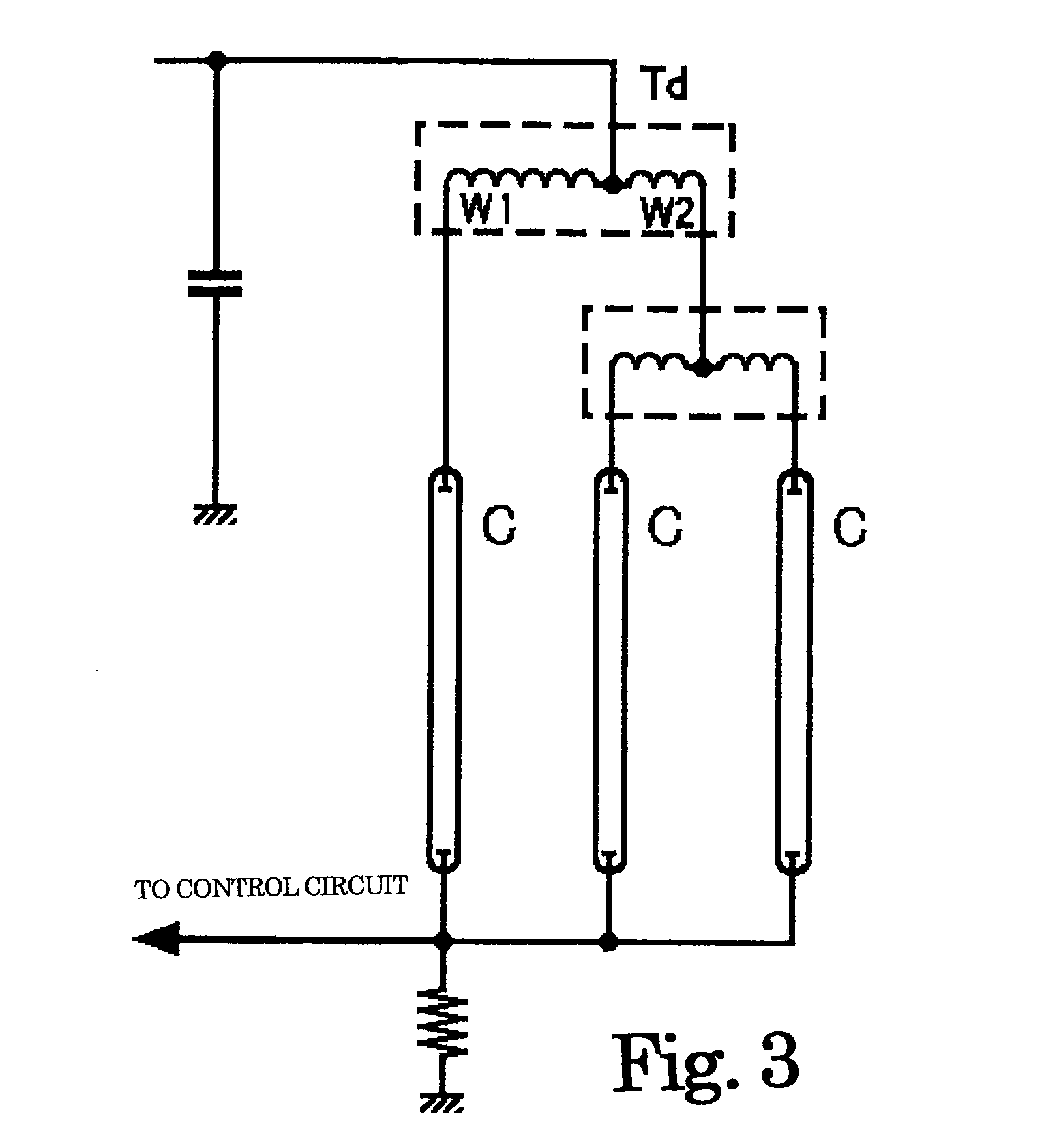

Inverter circuit for discharge lamps for multi-lamp lighting and surface light source system

InactiveUS7282868B2Uniform lightReduce shapingElongate light sourcesStatic indicating devicesGas-discharge lampElectrical resistance and conductance

An inverter circuit for discharge lamps for multi-lamp lighting in which the value of a negative resistance characteristic of a fluorescent lamp is controlled, and an excessively set reactance is eliminated by causing a shunt transformer to have a reactance exceeding the negative resistance characteristic. Two coils connected to a secondary winding of a step-up transformer of the inverter circuit are arranged and magnetically coupled to each other to form a shunt transformer for shunting current such that magnetic fluxes generated thereby cancel each other out. Discharge lamps are connected to the coils, respectively, with currents flowing therethrough being balanced. Each discharge lamp is lighted because a reactance of an inductance related to the balancing operation which is in an operating frequency of the inverter circuit, exceeds a negative resistance of discharge lamps.

Owner:MASAKAZU USHIJIMA +1

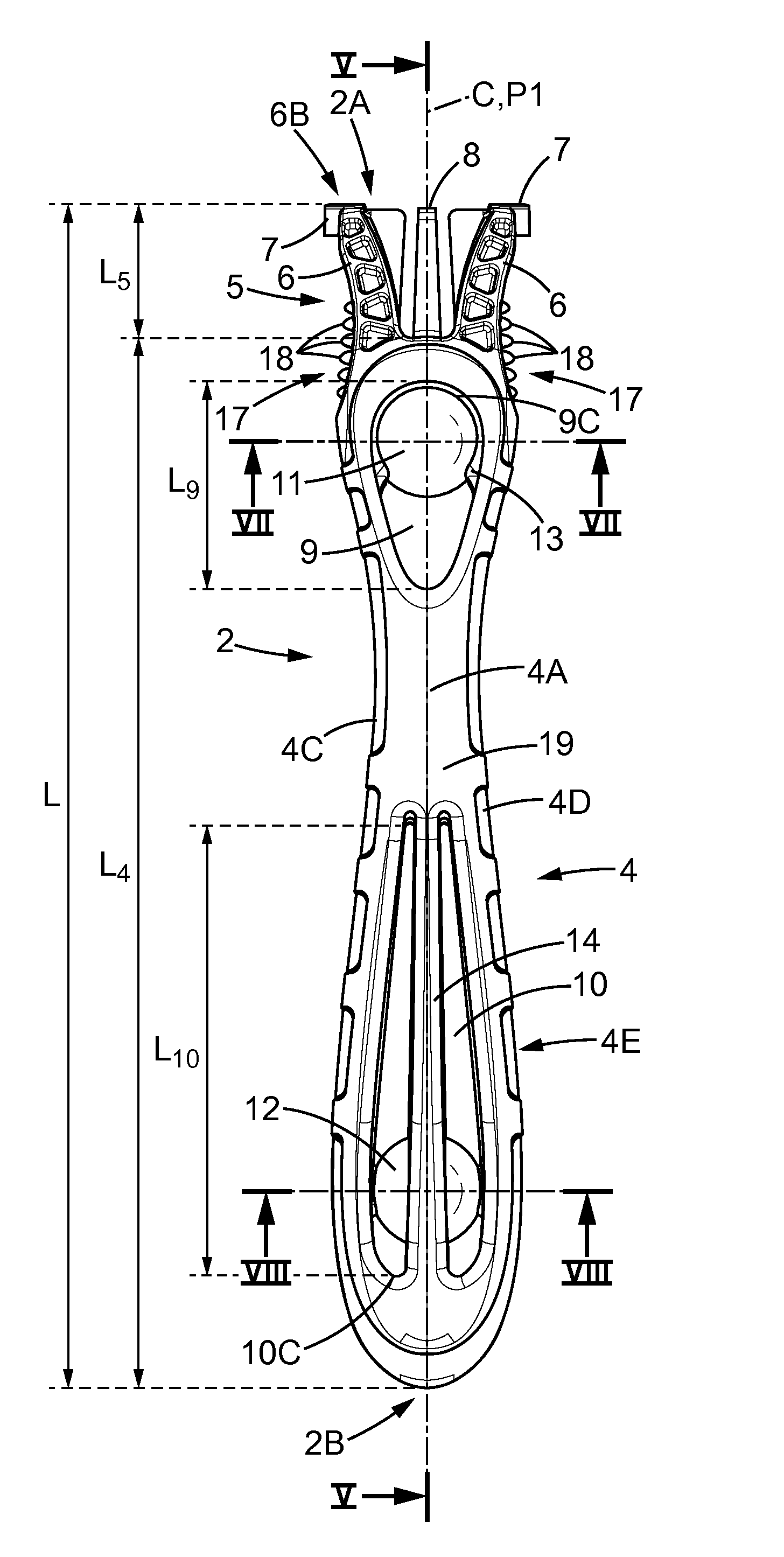

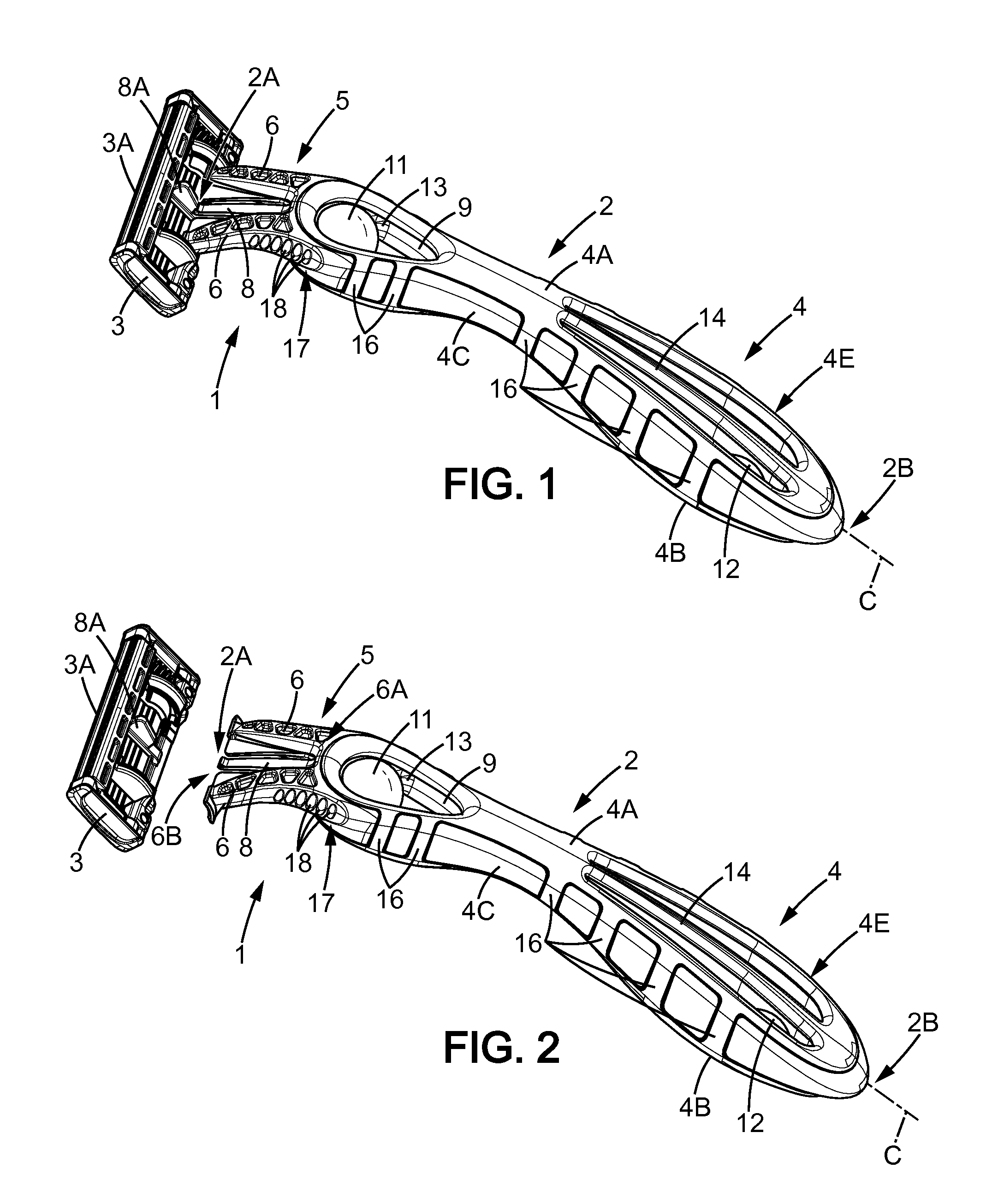

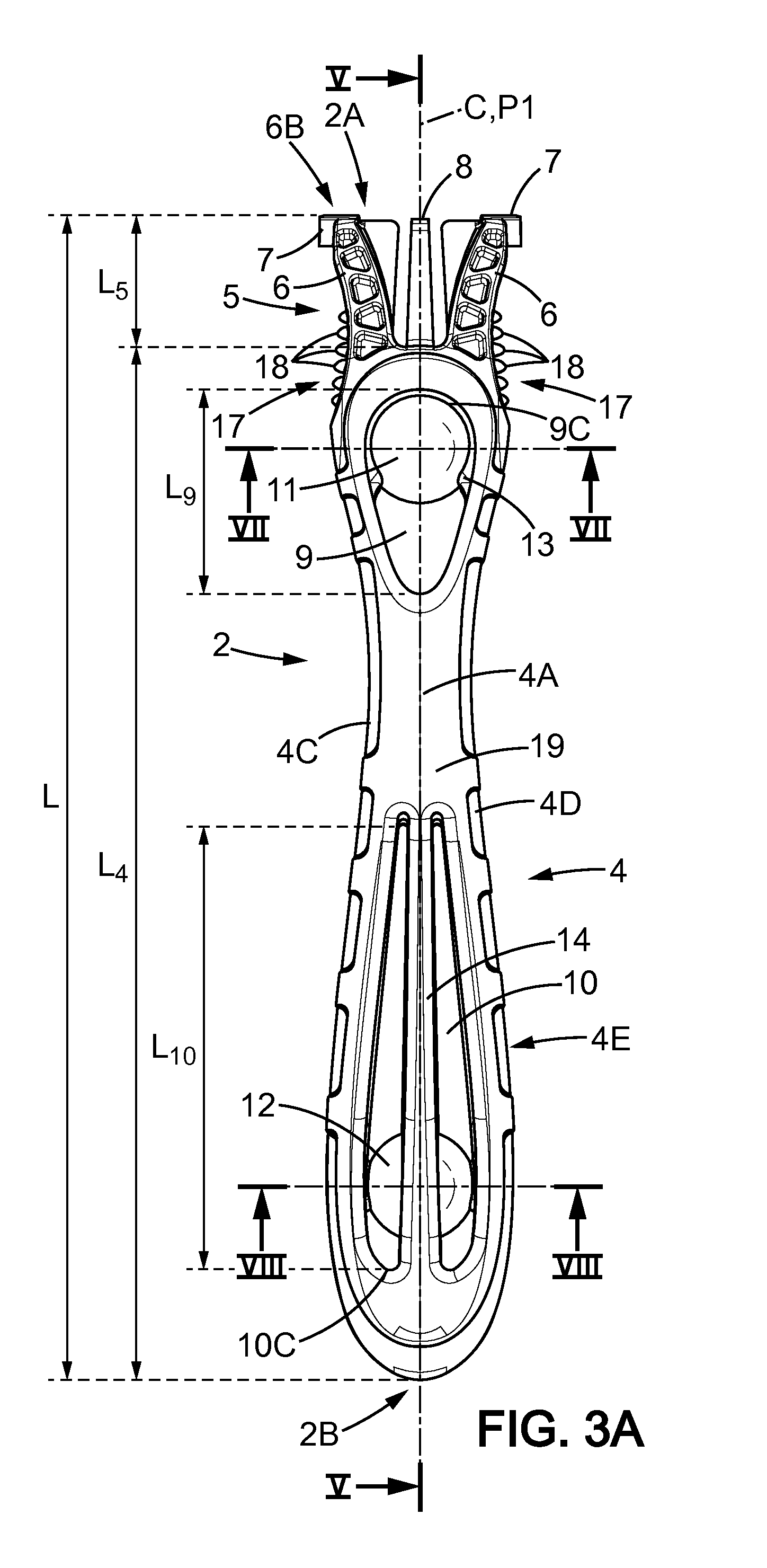

A Razor Handle Comprising Inserts Within Holes And Razor Comprising Such A Razor Handle

ActiveUS20160250765A1Precise and comfortable shavingAccurate weighingMetal working apparatusEngineeringKnife blades

A razor handle that includes an elongated body extending in a longitudinal direction (C), the elongated body having an outer surface and being provided with a first hole and a second hole, the first and second holes opening on the outer surface of the elongated body, the razor handle that includes a first insert and a second insert, the first and second inserts being respectively partially encapsulated within the first and second holes.

Owner:BIC VIOLEX SA

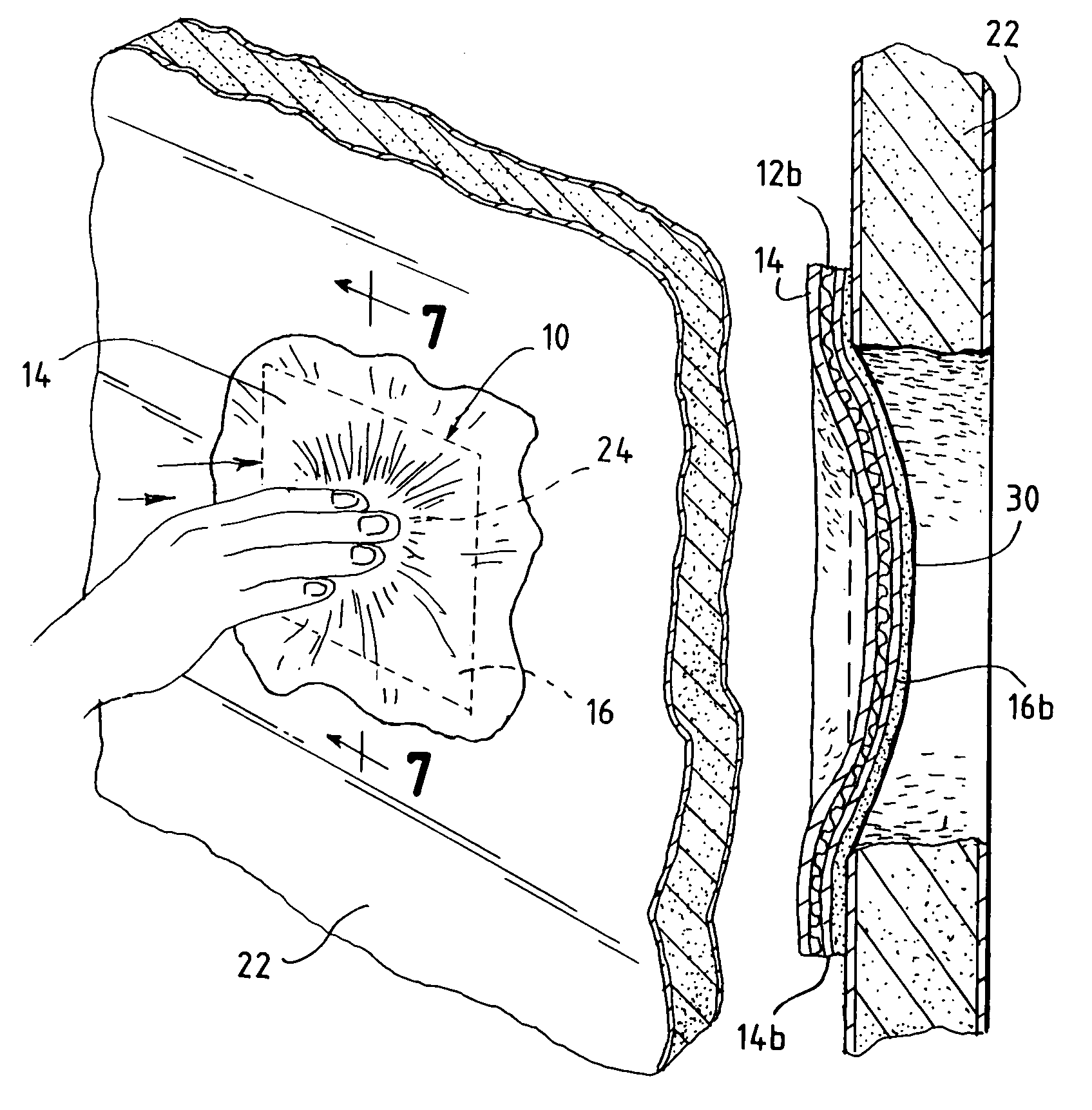

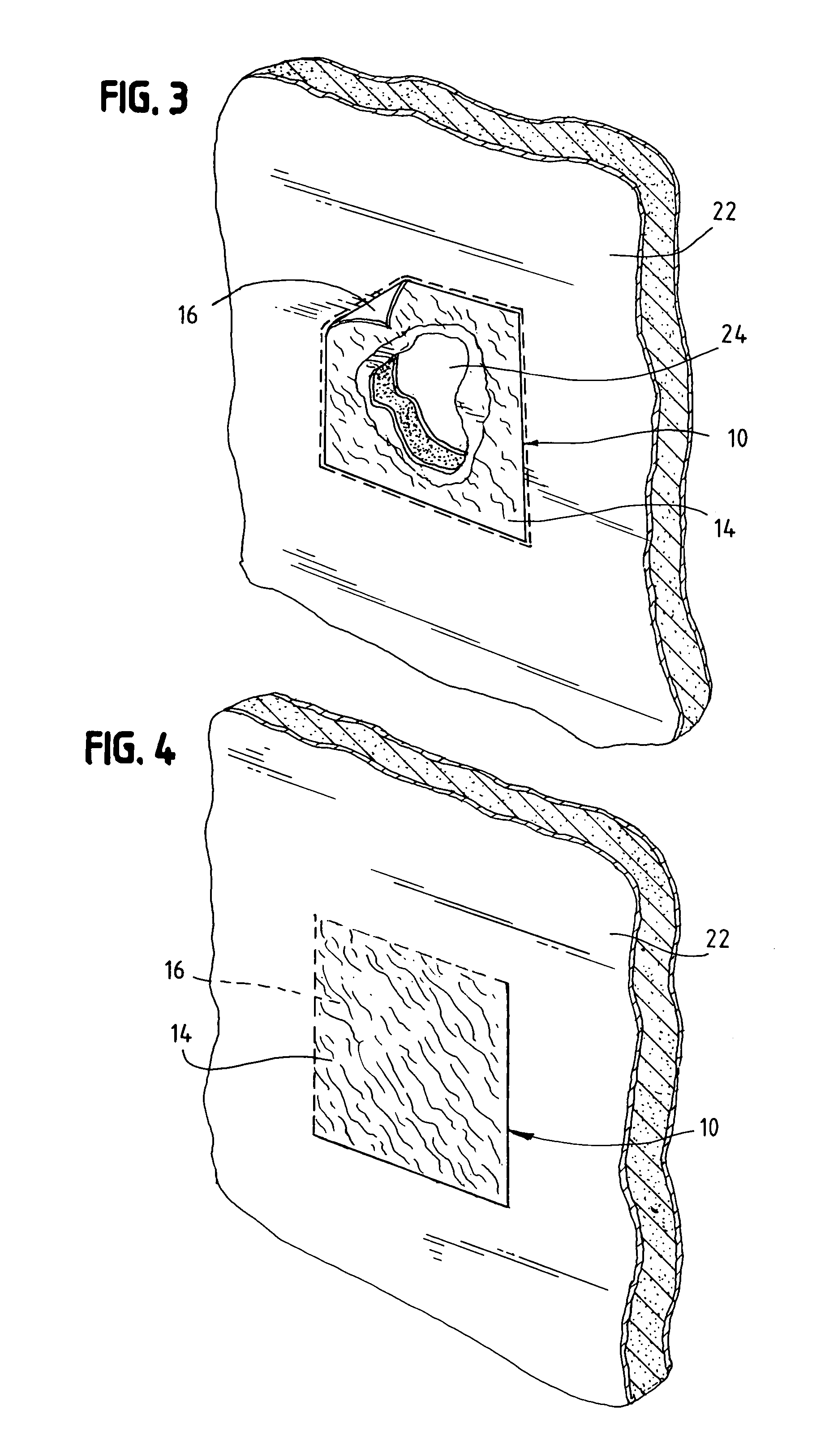

Drywall repair patch

InactiveUS7380382B2Prevent it from moving or breaking looseReduce shapingCovering/liningsLayered productsDrywallMaterials science

A drywall repair patch comprises: a mesh sheet which carries a dry, pressure sensitive adhesive layer on at least one side thereof, and at least one layer of a dry, water hardenable cement product carried on a side of the mesh sheet. The mesh sheet is free of any rigid supporting plate. Further by this invention, water is applied to the water hardenable cement, typically after placement on the wall, followed by pushing a portion of the cement layer and mesh sheet into the hole being covered, without substantially breaking the adherence to the wall, to form a concave portion of the patch in the hole. After hardening, a second portion of water hardenable cement material is applied to form a smooth wall surface over the hole and drywall patch.

Owner:GREAT WALL PATCH CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com