Wire bonding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

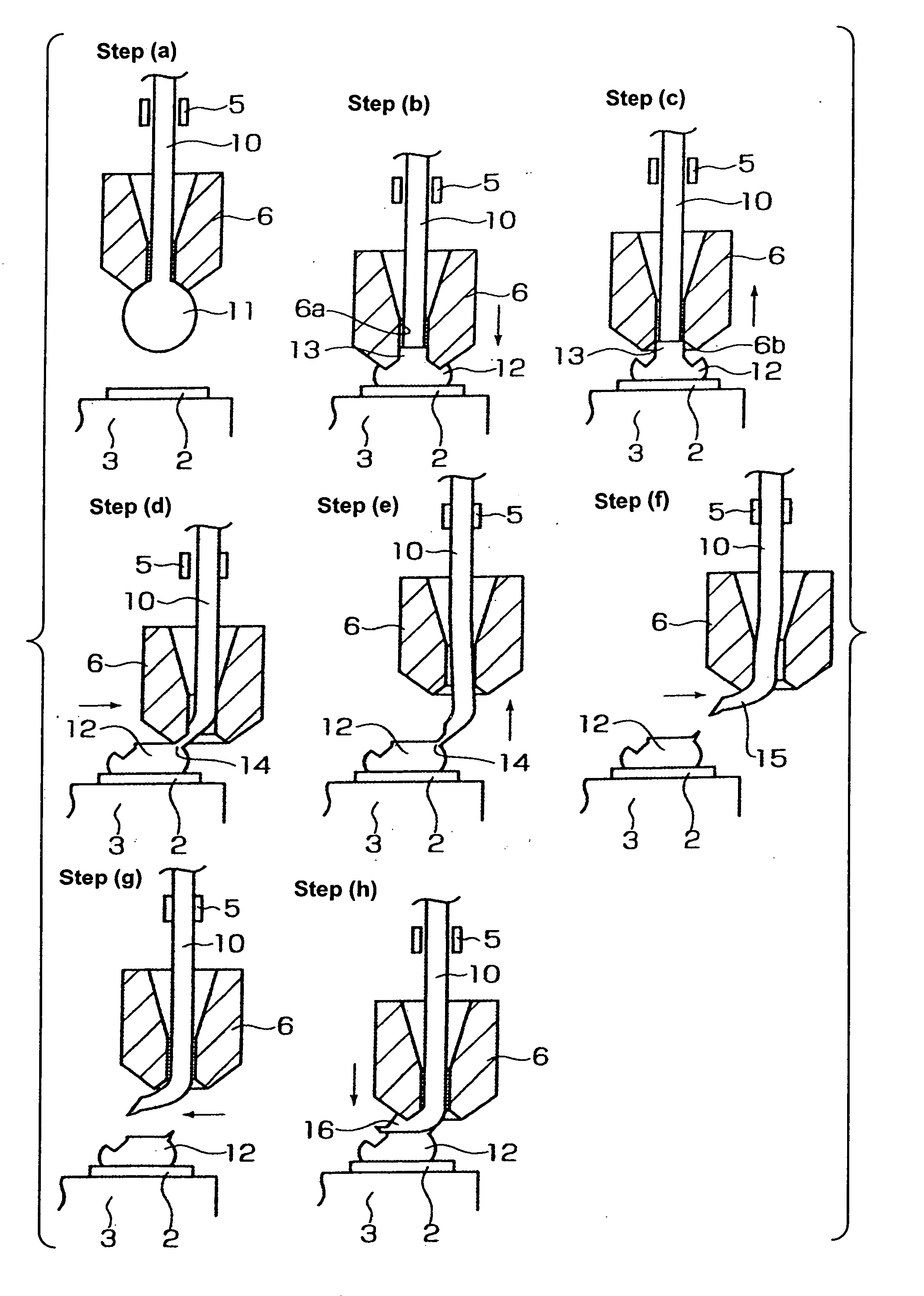

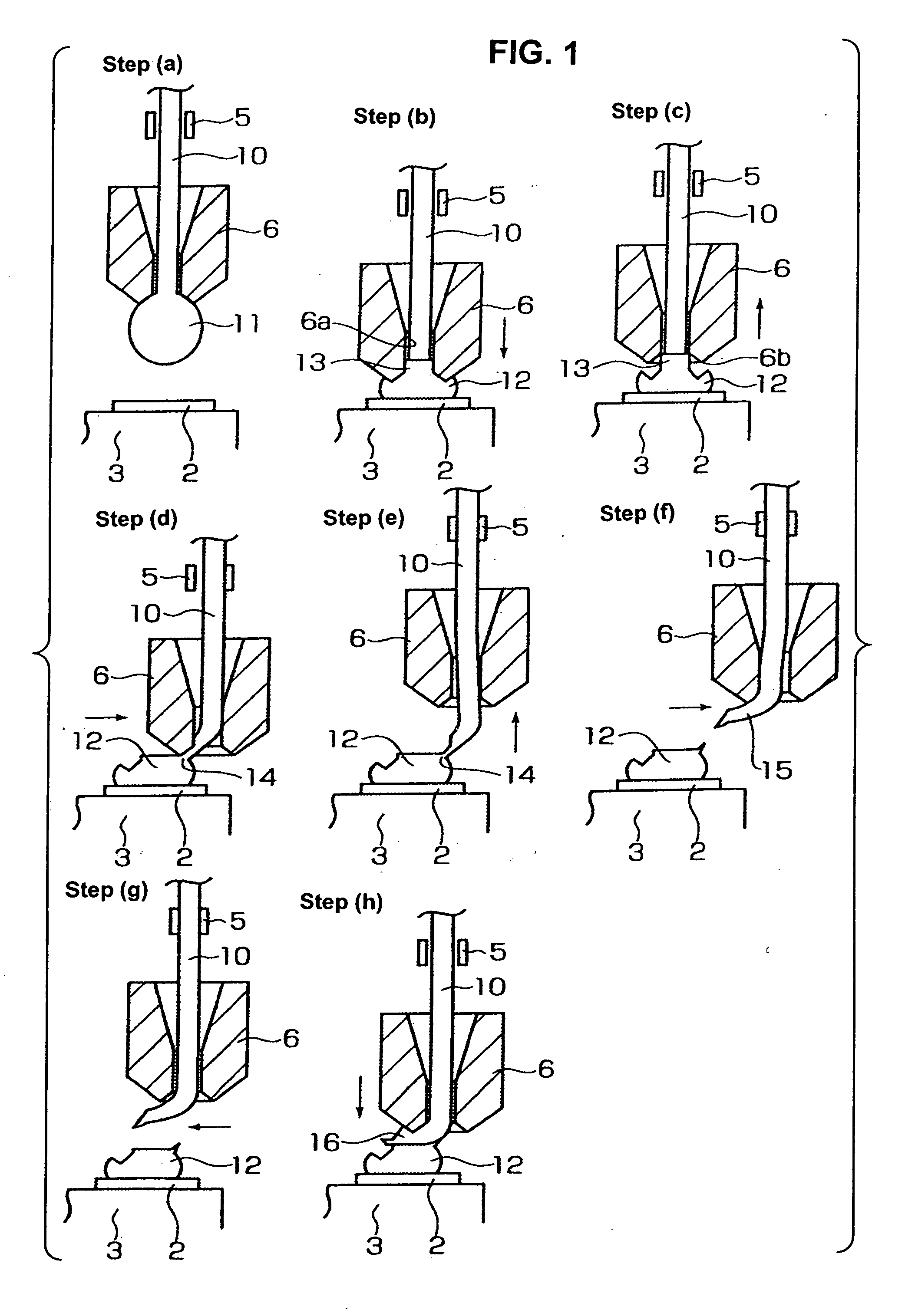

[0040] the wire bonding method of the present invention is described with reference to FIG. 1 and FIG. 2. As shown in FIG. 2, a die 3 on which a pad 2 of a die (or “die pad”) is formed is mounted on a circuit board 1 comprising a ceramic substrate or print board or lead frame or the like. An interconnect wiring (or an outer lead or conductive pathways) 4 is formed on the circuit board 1.

[0041] First, in step (a), a ball 11 is formed by an electric torch (not shown in the drawing) at the tip end of a wire 10 passed through a damper 5 and inserted through a capillary 6, after which the damper 5 is in an open condition.

[0042] Next, in step (b), the capillary 6 descends (or lowered) and bonds the ball 11 to the pad 2 that is the first bond point. Thereby, a portion of the ball 11 bulges up into the through-hole 6a in the capillary 6, and a pillar portion 13 is formed on a bump 12.

[0043] Following the step (b), in step (c), the capillary 6 is raised so that the edge 6b at the lower end...

second embodiment

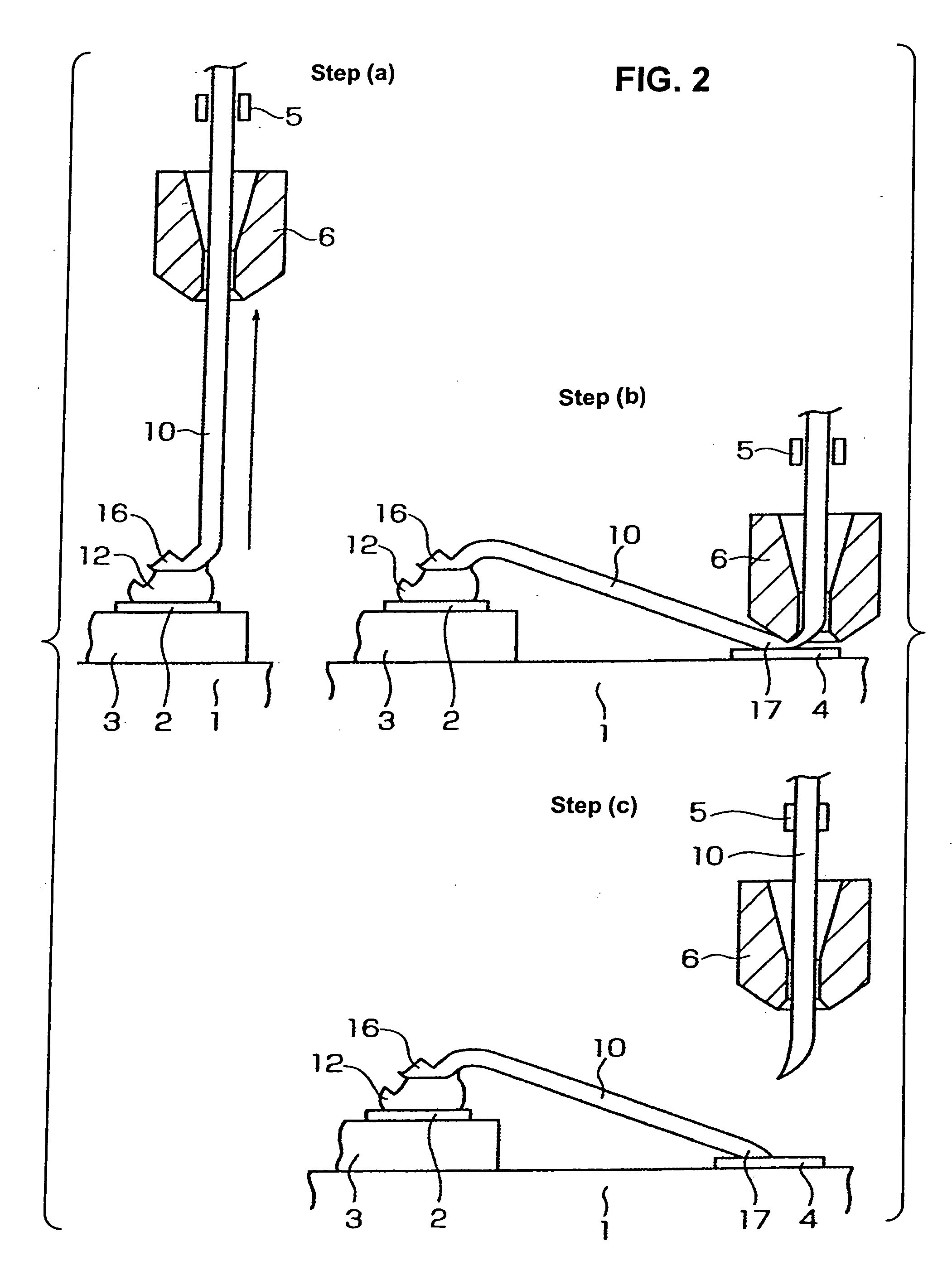

[0054] In the second embodiment, after the step (f) shown in FIG. 1 where the bump forming process is completed, the capillary 6 is moved upward from the interconnect wiring 4 in step (a) of FIG. 3.

[0055] Next, in step (b), the damper 5 closes, the capillary 6 descends, bonds the bent part 15 to the interconnect wiring 4 that is the first bond point, and forms a lower first bonding part 20. Also, the damper 5 is brought in an open condition.

[0056] Next, in step (c), the capillary 6 is raised, and then is moved above the lower first bonding part 20 in step (d).

[0057] In the next step (e), the damper closes, the capillary 6 is lowered, the wire portion 21 shown in the illustration for step (d) is bent, and the wire portion 21 is bonded onto the lower part first bond point, forming an upper first bonding part 22, thus making it a first bonding part 3 and completing the first bonding process.

[0058] After the step (e), the wire 10 is connected onto the bump 12 formed on the pad 2 that...

fourth embodiment

[0070] More specifically, in the fourth embodiment, after the step (d) of FIG. 5, the damper 5 opens, and the capillary 6 is moved in step (a) shown in FIG. 7 to above the interconnect wiring 4.

[0071] Then, in step (b), the capillary 6 descends, bonds the bent part 15 to the interconnect wiring 4 that is the first bond point, and forms the lower first bonding part 20.

[0072] Next, in step (c), the capillary 6 is raised, and in step (d), the capillary 6 is moved above the lower first bonding part 20.

[0073] In the next step (e), the capillary 6 is lowered, the wire portion 21 show in the illustration for step (d) is bent, the wire portion 21 is bonded onto the lower first bonding part 20, whereupon the upper first bonding part 22 is formed, and that is made the first bonding part 23.

[0074] After the step (d), the wire 10 is connected onto the bump 12 formed on the pad 2 that is the second bond point. More specifically, in step (f) shown in FIG. 7, the capillary 6 ascends and moves i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com