Non-inductive electric power generation all-in-one machine and electric vehicle

A technology for electric power generation and electric vehicles, applied in electric vehicles, motors, electric components, etc., can solve problems such as efficiency reduction, conversion efficiency limitation, adverse effects, etc. adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

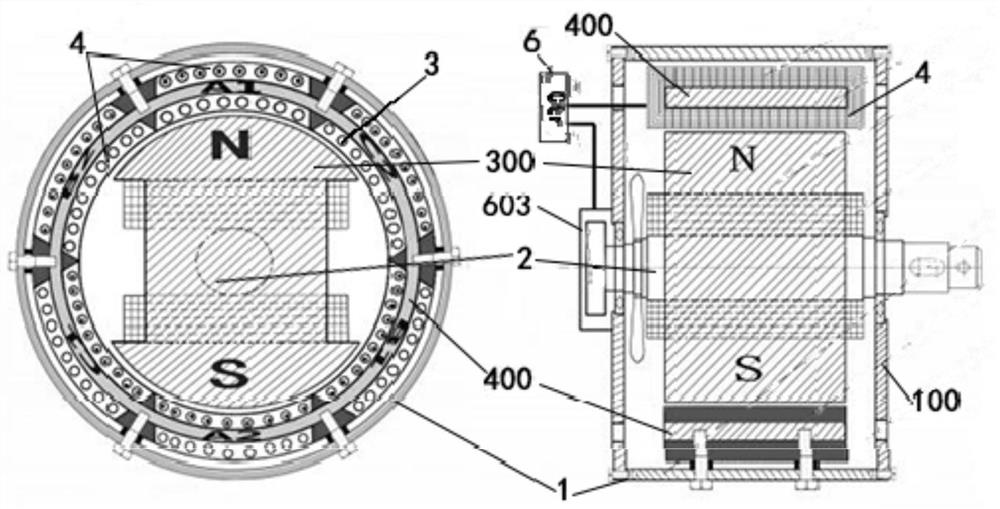

[0058] This embodiment relates to an ineffective electric generator to provide a new motor based on the law of ridiculum, which helps to minimize the alternating magnetic field and magnetization curve characteristics of motor coils on the energy conversion efficiency of motor energy.

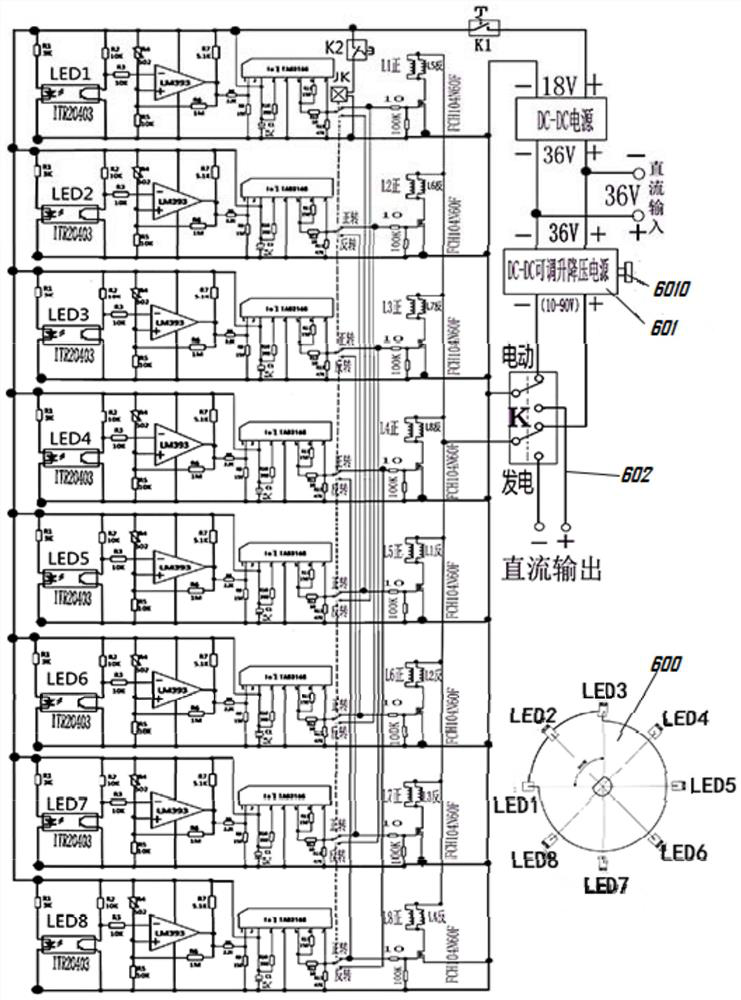

[0059] The inductive electric power generation unit includes a housing, and a spindle that is rotatable relative to the housing, the unusual electric power generator further comprising a ring magnetic field formed within the housing, several forming a coil and a control unit set. Among them, the ring magnetic field is formed in the housing in the housing by the spindle, and the magnetic field direction of the annular magnetic field is located in the radial direction of the spindle, and the annular magnetic field is configured to be distributed and the magnetic field direction is opposite. Each of the coils is partially in a ring magnetic field; the two coils in the same group are arranged in paralle...

Embodiment 2

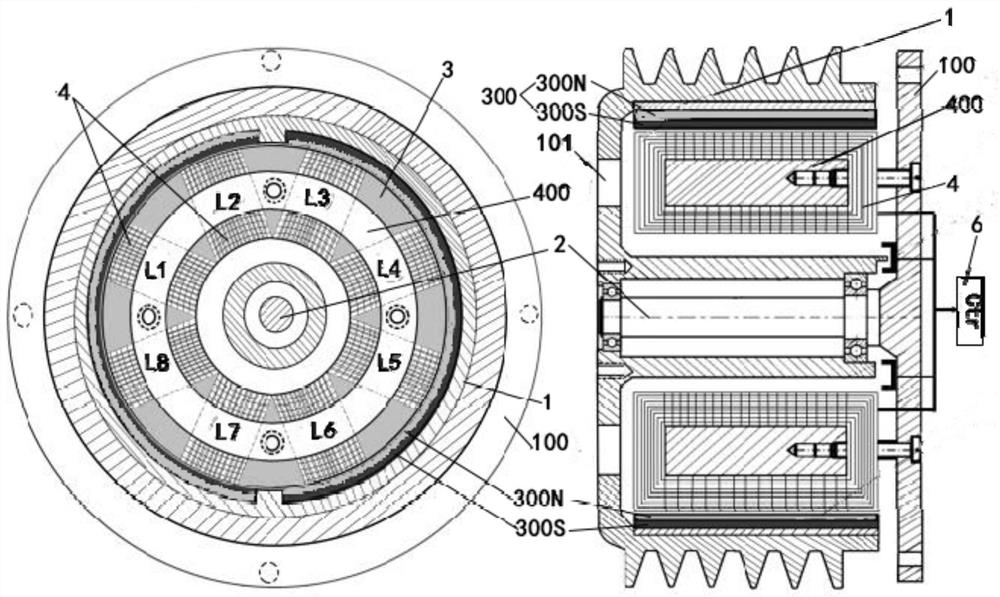

[0081] In this embodiment, an exemplary structure, such as an unusual electric power generation unit, such as an inductive electric power generator in the form of another configuration. Figure 5 As shown in the present embodiment, the inductive electric generator is used with a DC power source or provides a DC power generation, and is fixed by the housing 1, the internal spindle 2 is in the form of inner rotor in the housing 1.

[0082] In this inner rotor structure, the magnet 300 is a permanent magnet or electromagnet, and the two parts of the magnet 300 are formed between the two poles and the annular core 400 of the magnet 300 respectively form two parts of the annular magnetic field 3. One magnet 300 is disposed inside the annular core 400, and two magnetic poles of the magnet 300 can form the magnetic field direction of the magnetic field 3 between the magnet 300 and the annular core 400 in terms of two portions.

[0083] Of course, the magnet 300 can use a permanent magnet ...

Embodiment 3

[0086] This embodiment relates to an ineffected electric power generator suitable for three-phase AC electric fields, and an exemplary structure is Figure 6 with Figure 7 As shown, in the present embodiment, the unusual motor generator is driven by a three-phase AC power source, or provides a three-phase AC power supply; in the same, it can employ the inner rotor or the outer rotor.

[0087] Such as Figure 6 As shown, the spindle 2 is fixed, and the housing 1 is rotated to the spindle 2, and the outer rotor form is formed. Two semi-circular magnets 300 are fixed to the housing 1, and the annular magnetic field 3 is formed around the annular core 400. Among them, the magnet 300 uses a permanent magnet. The entire structure form and examples of embodiments.

[0088] Such as Figure 7 As shown, the housing 1 is fixed, and the internal spindle 2 is rotated relative to the housing 1, and the inner rotor form is formed. The magnet 300 is disposed inside the annular core 400, which can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com