Method for excavating micro benches of large-section loess tunnel, and bench structure of large-section loess tunnel

A technology of loess tunnels and micro-steps, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of difficulty in large-scale machinery and equipment, which has not been reported in reports, and slow construction of loess tunnels. Effects of Instability, Duration and Project Cost Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

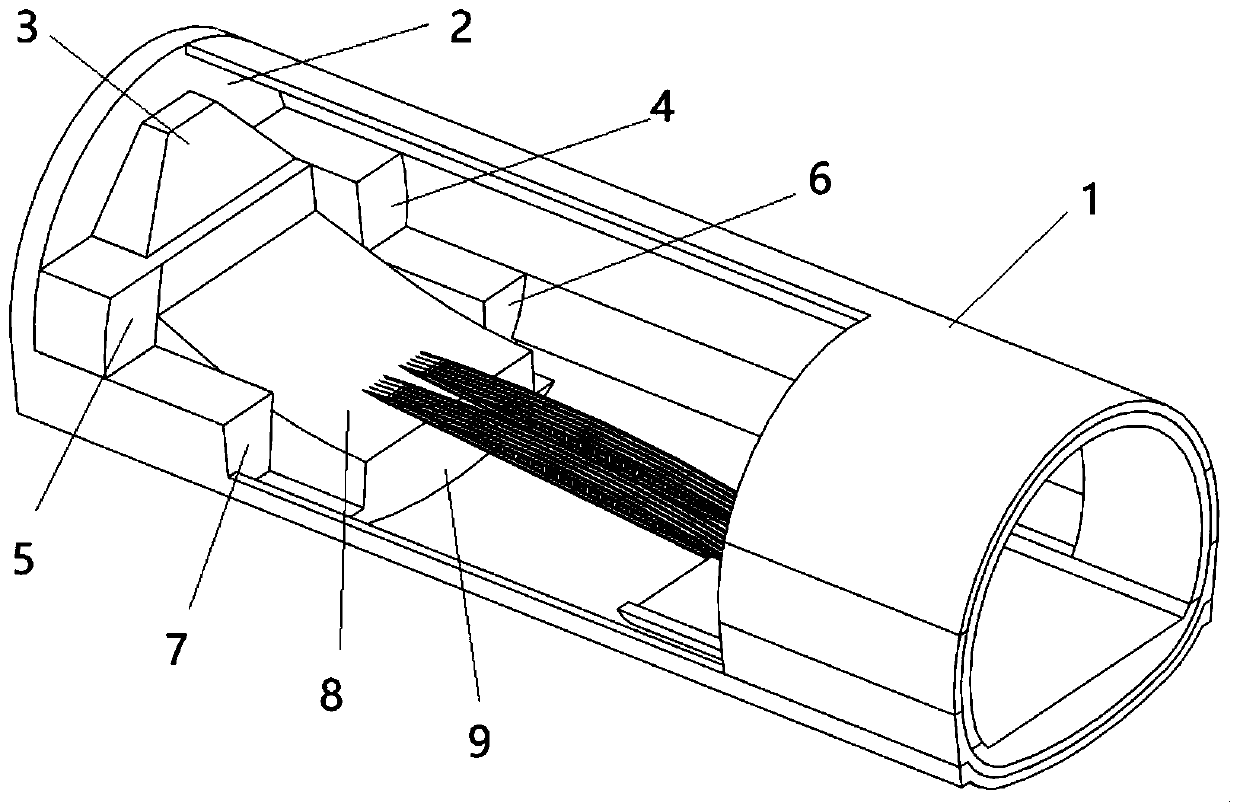

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] Such as figure 1 The shown step structure has an excavation method, and this excavation method excavates steps with two construction levels in the excavation construction direction located at the ramp 8, which are respectively formed by the first construction level at the middle level of the ramp 8. The middle steps of the construction and the lower steps of the construction of the second construction layer located at the bottom of the ramp 8, the middle steps include the left middle steps 5 and the right middle steps 4 respectively located on both sides of the ramp 8, and the lower steps Including the lower left step 7 and the lower right step 6 located on both sides of the ramp 8, during the excavation process, the specific excavation steps of the above-mentioned upper step, middle step and lower step include the following:

[0024] Step 1: excavate the ramp 8, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com