Patents

Literature

142results about How to "Increase cycle rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-zone atomic layer deposition apparatus and method

InactiveUS20060073276A1Quality improvementIncrease deposition rateChemical vapor deposition coatingSurface reactionReactive gas

Method and apparatus for producing a thin film on a substrate set in a moving substrate holder is disclosed. Within a deposition chamber, a substrate is moved across a series of dedicated deposition zones and is subjected to repeated surface reactions with at least two different reactants. The reactants are fed into the dedicated deposition zones from a gas supply system that may include high speed valves that are timed to coordinate with the passage of the substrate so as to inject reactive gases repeatedly into the deposition zones. The dedicated deposition zones are separated by dedicated exhaust zones that direct each reactive gas along separate paths so as to minimize or eliminate mixing of different reactive species in the exhaust thus decreasing deposition within the exhaust system.

Owner:ATOMICITY SYST

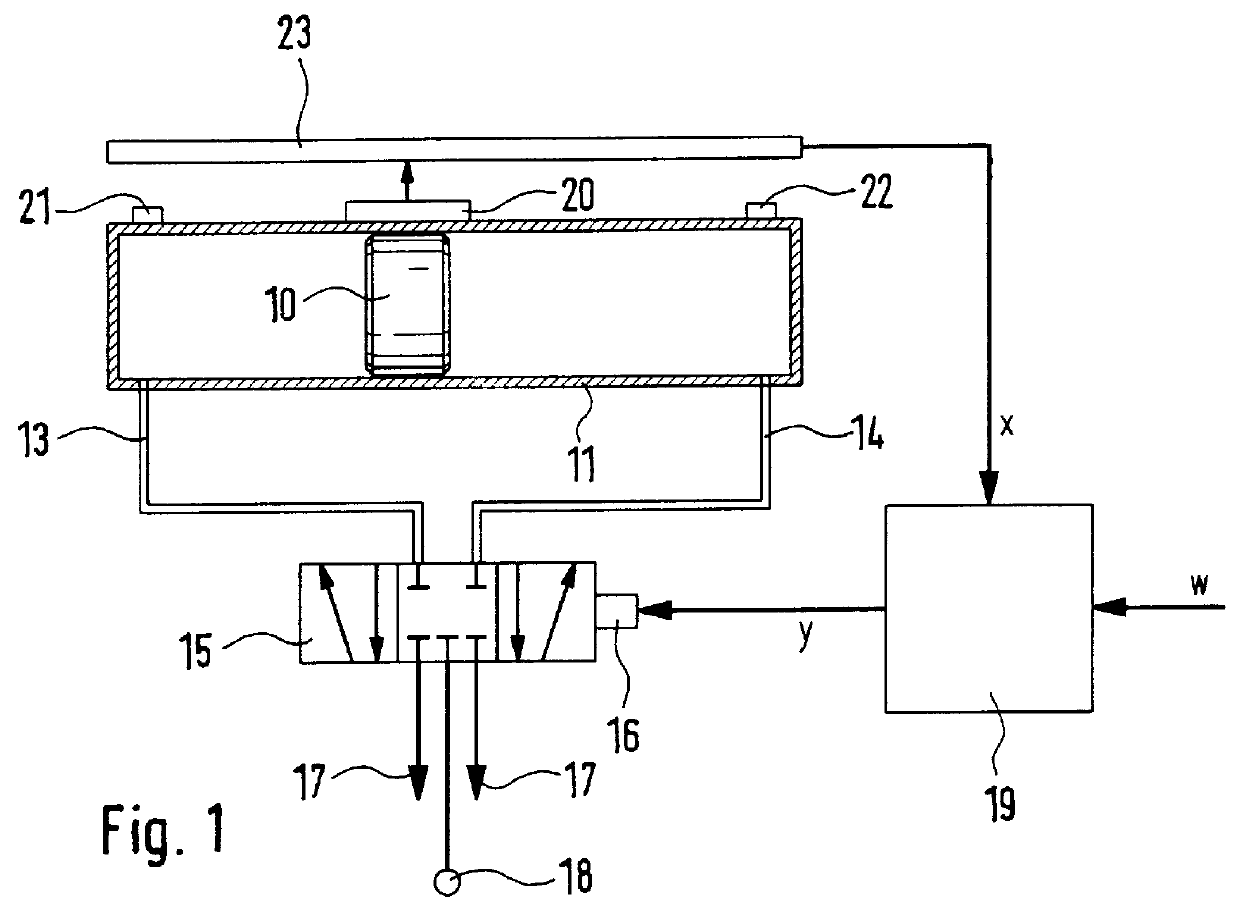

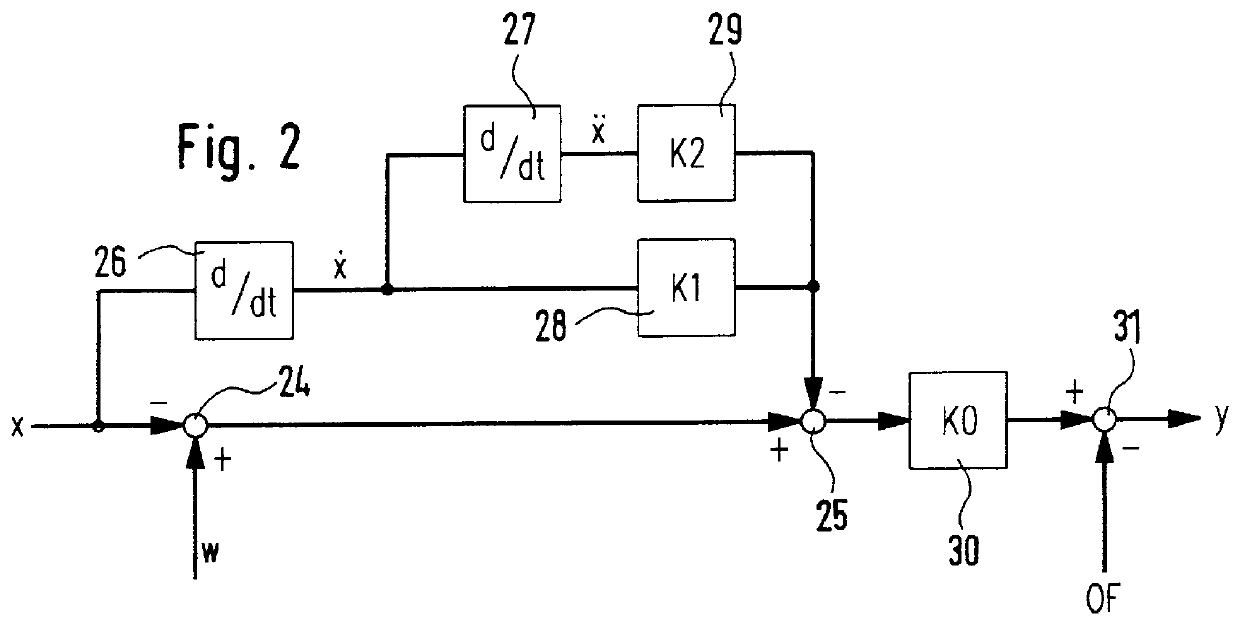

Apparatus for the damped positioning of a piston

InactiveUS6085632AImproved regulation of brakingHigh precisionServomotor componentsServomotorsAbutmentControl theory

An apparatus for the damped positioning of a piston running in a cylinder at one fixed abutment at least and more particularly for setting in a terminal position. The apparatus includes sensor means connected with an electronic regulating means for detecting the piston position as an actual value signal. A valve means adapted to be regulated by the regulating means serves for regulated braking of the piston prior to reaching the respective desired position by influencing opposing pressure in the cylinder outlet side. For forming the setting quantity for the proportional valve a position regulating means is provided which is modified by a value dependent on the respective speed and / or acceleration of the piston. This apparatus ensures an extremely accurate regulation of position simply by detecting of the position of the piston as an actual value signal. It is more particularly possible to brake the piston in the terminal positions with a damping action that an additional damping system is no longer necessary.

Owner:FESTO AG & CO KG

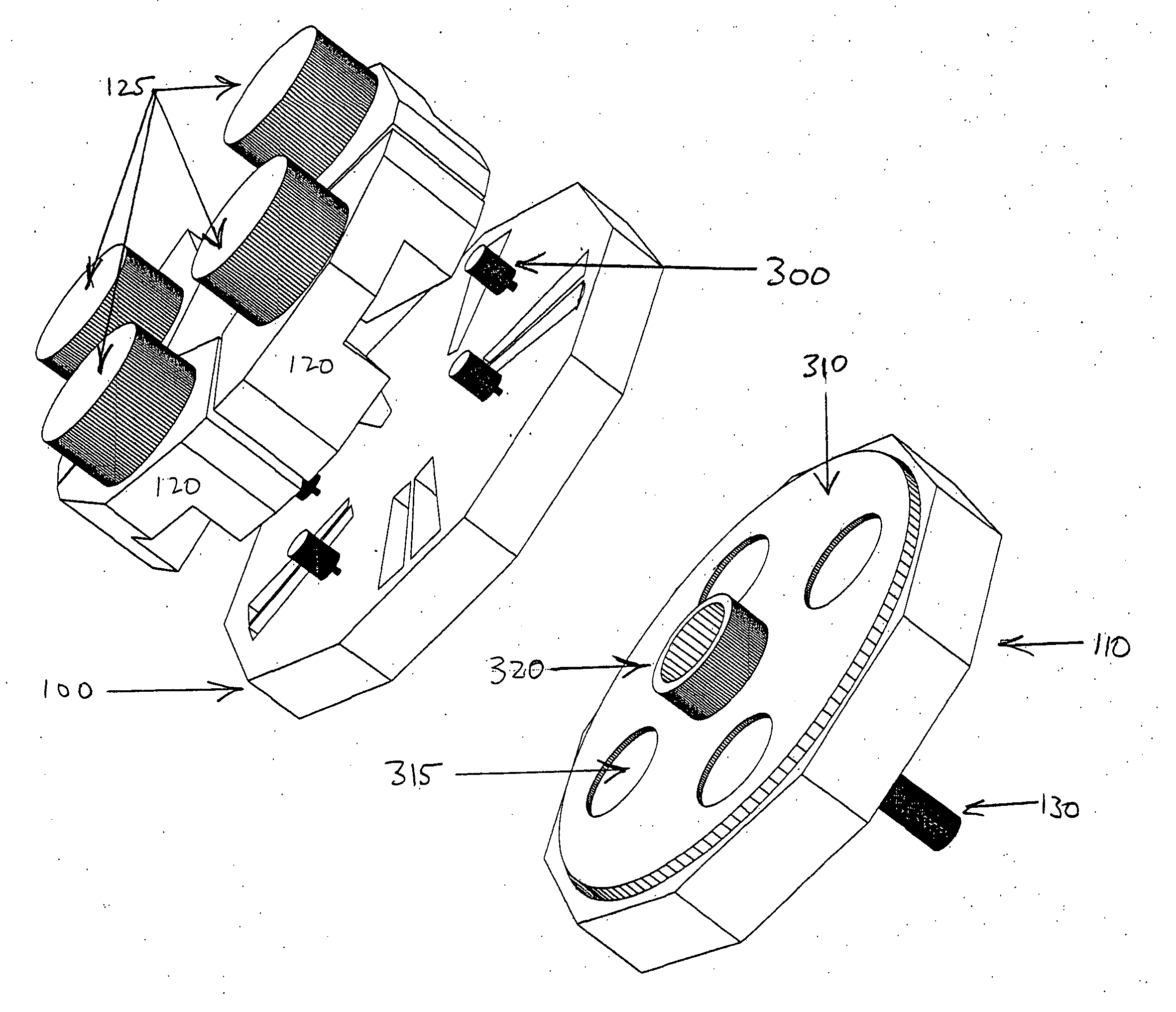

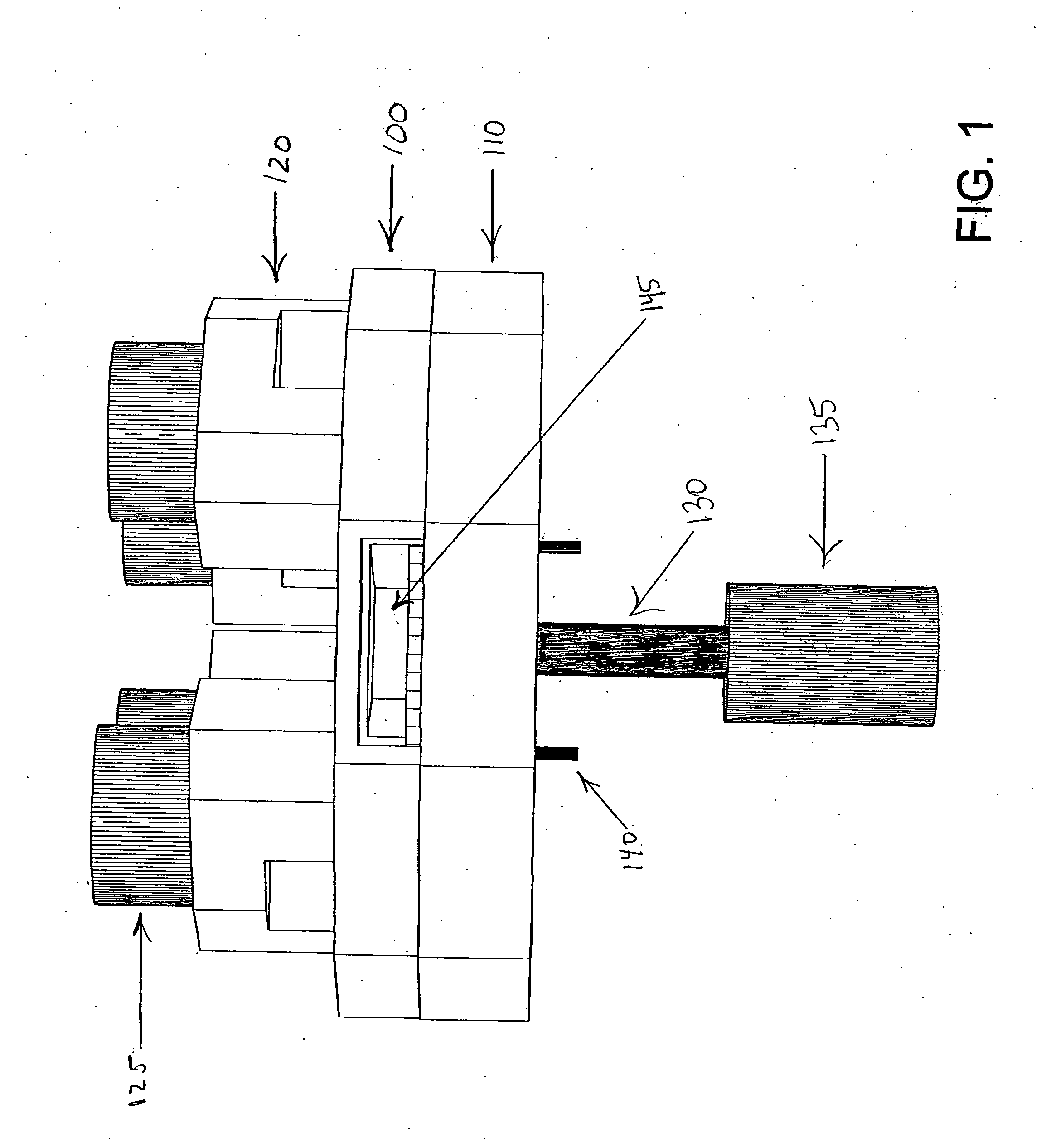

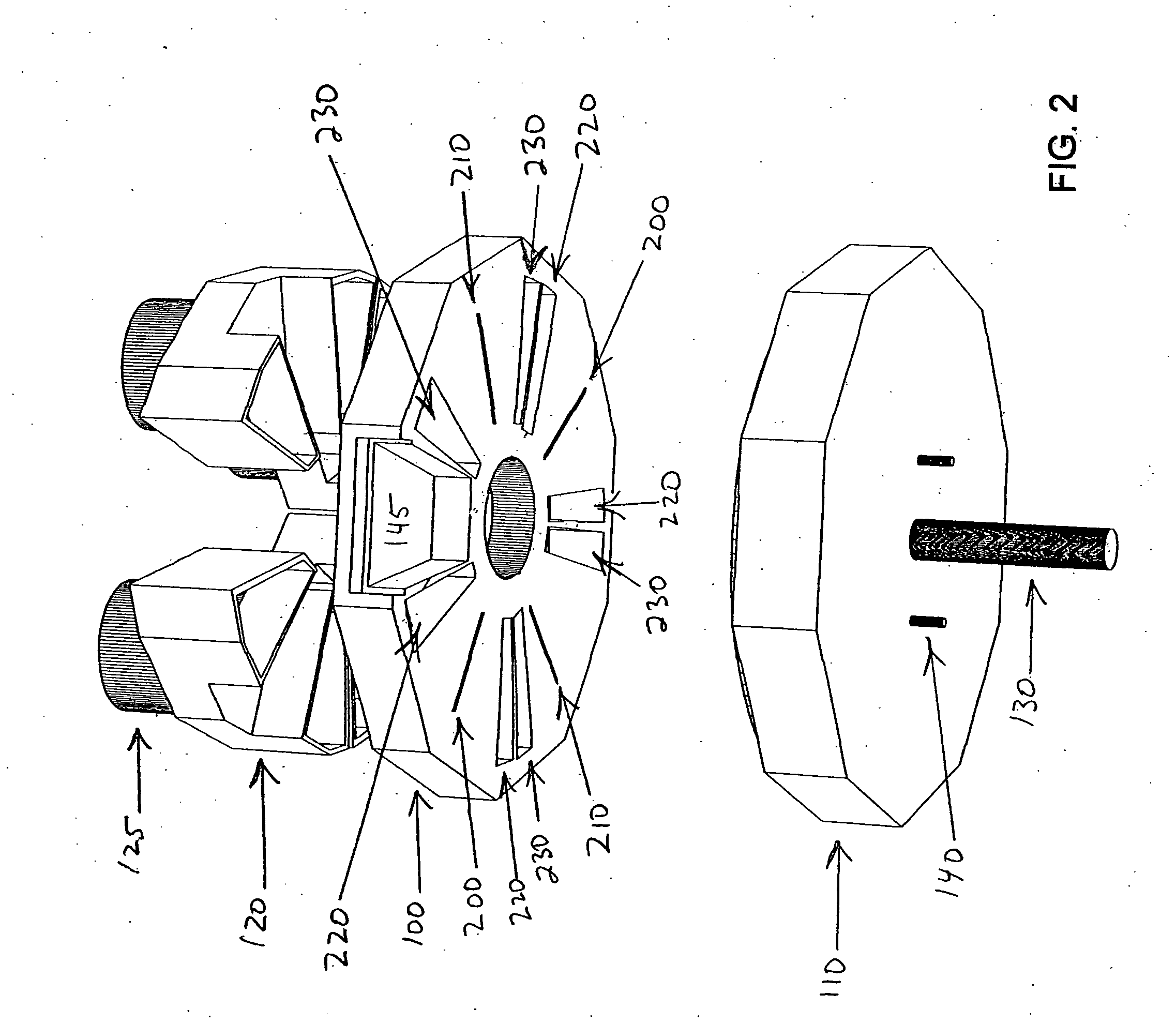

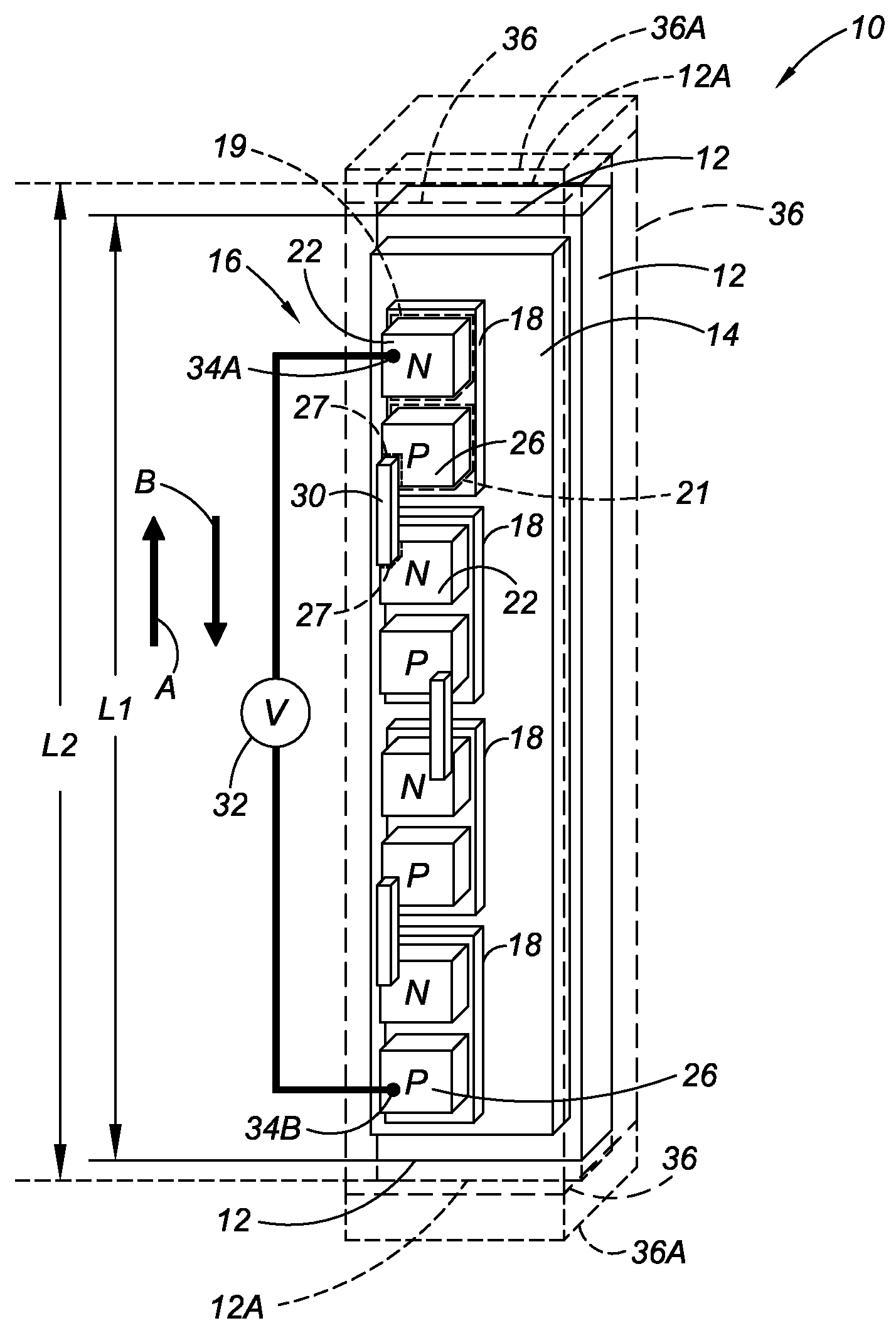

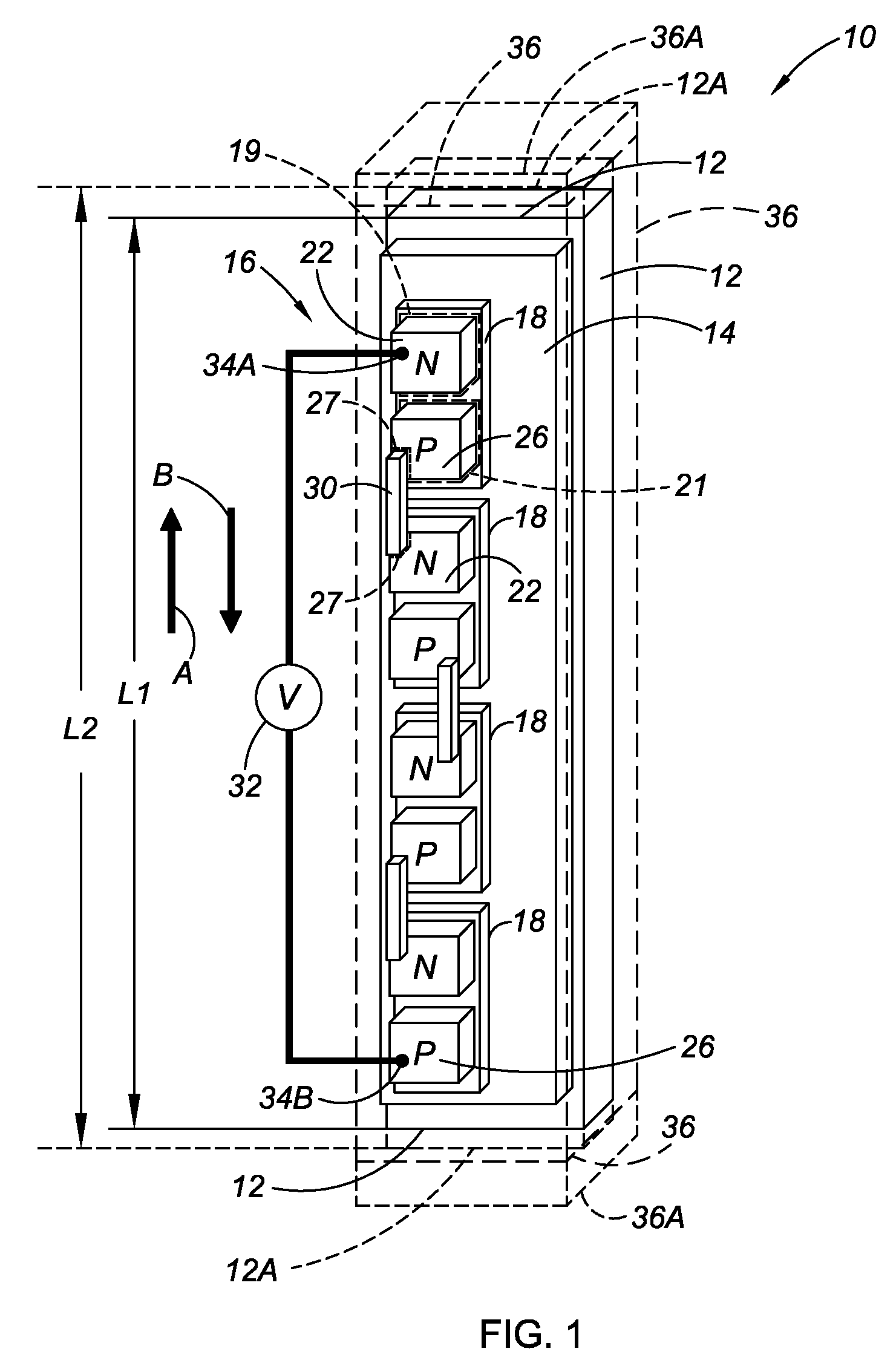

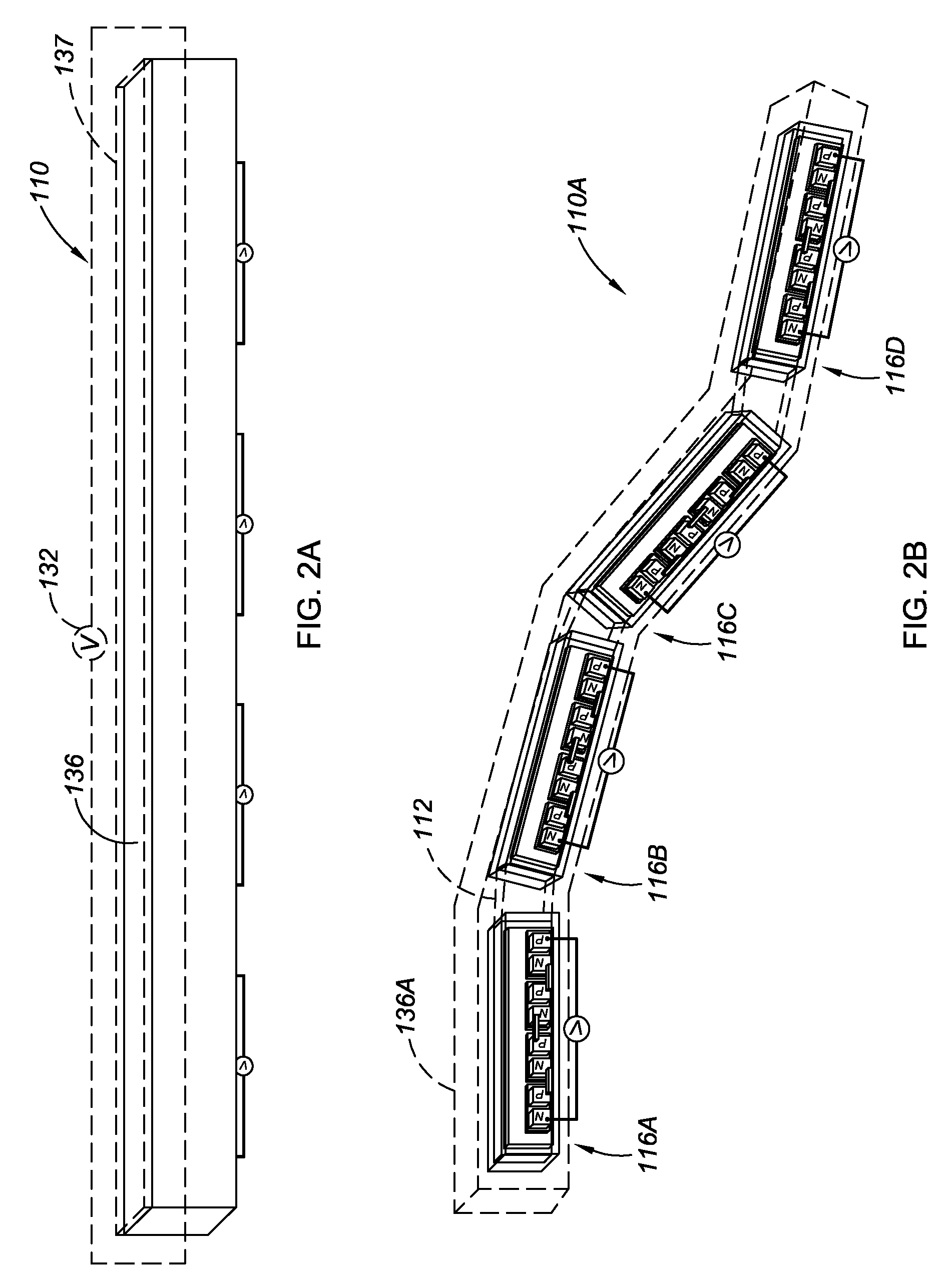

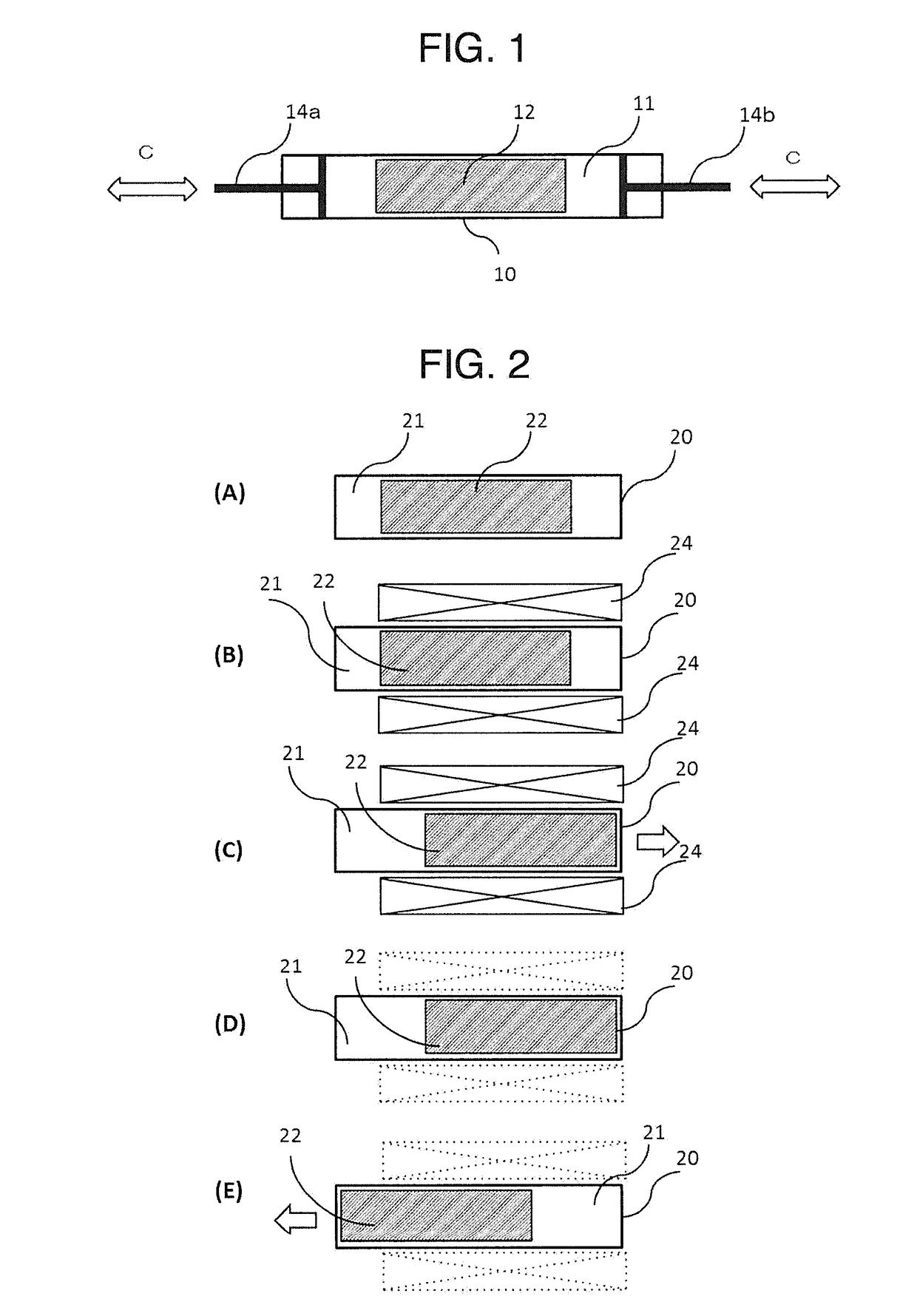

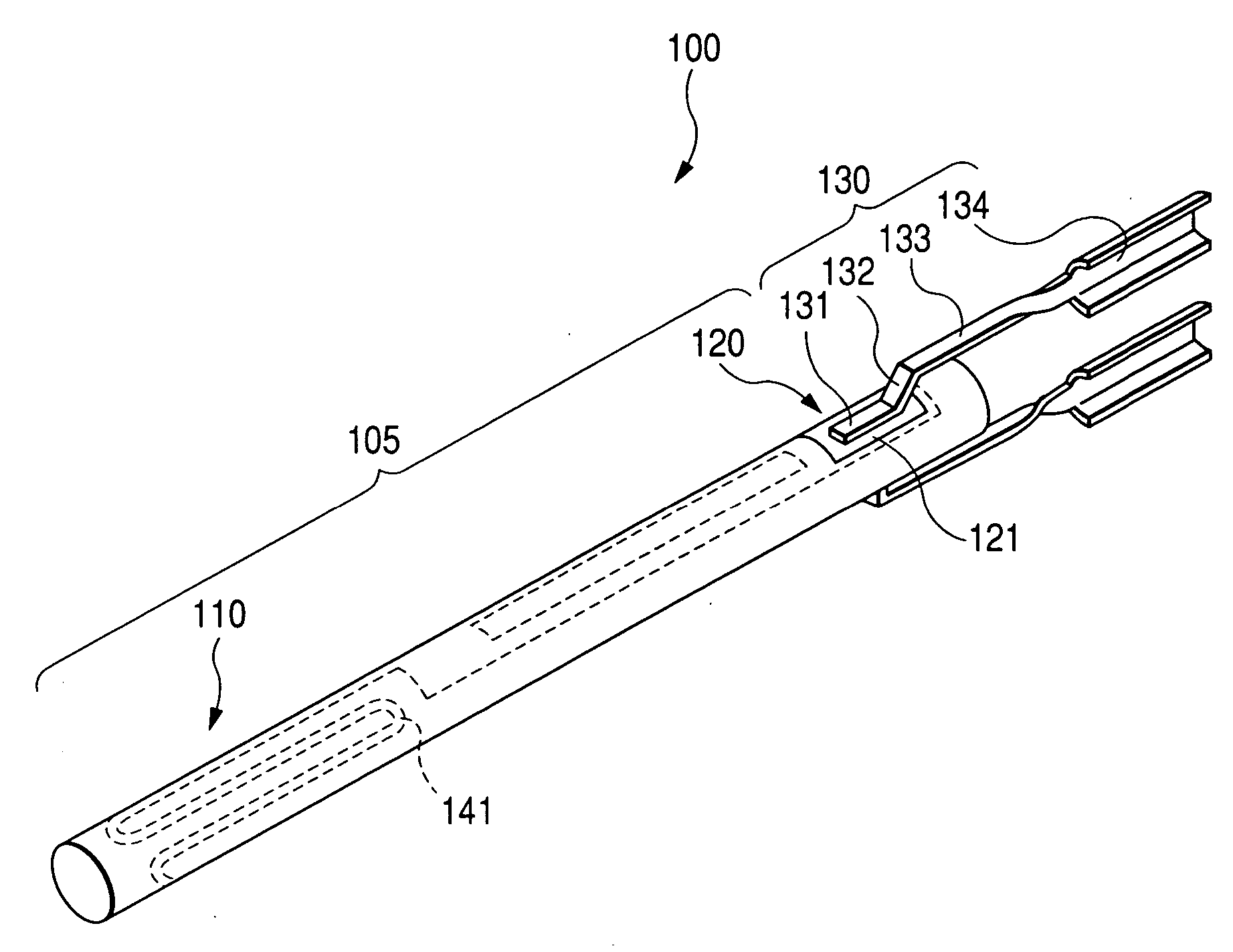

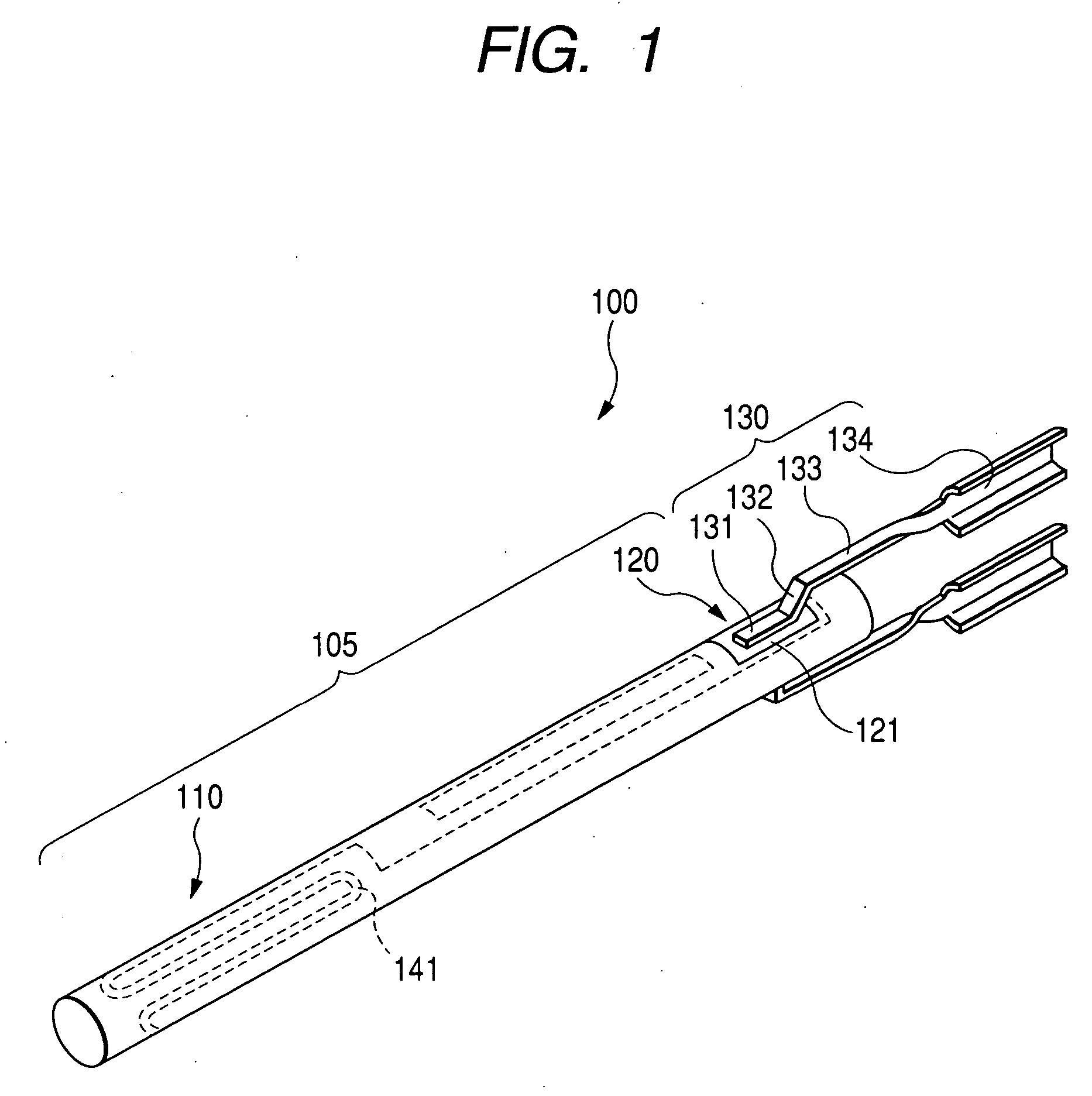

Active material apparatus with activating thermoelectric device thereon and method of fabrication

InactiveUS20090020188A1Reduce restrictionsIncrease ratingsMachines using electric/magnetic effectsThermal electric motorPower flowFlexible electronics

An active material assembly is provided having a thermally-activated active material apparatus with an elongated, non-planar shape and a thermoelectric device in thermal contact therewith. The thermoelectric device is characterized by a thermal differential when current flows through the device to activate the thermally-activated active material apparatus, thereby altering at least one dimension thereof. Multiple discrete thermoelectric devices may be in thermal contact with the active material apparatus and electrically in parallel with one another. The active material apparatus, which may be multiple active material components, each with one of the thermoelectric devices thereon, may be encased within a flexible electronic-insulating material to form an articulated active material assembly that can achieve different geometric shapes by separately activating one or more of the different thermoelectric devices. A method of fabricating an articulated active material assembly is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

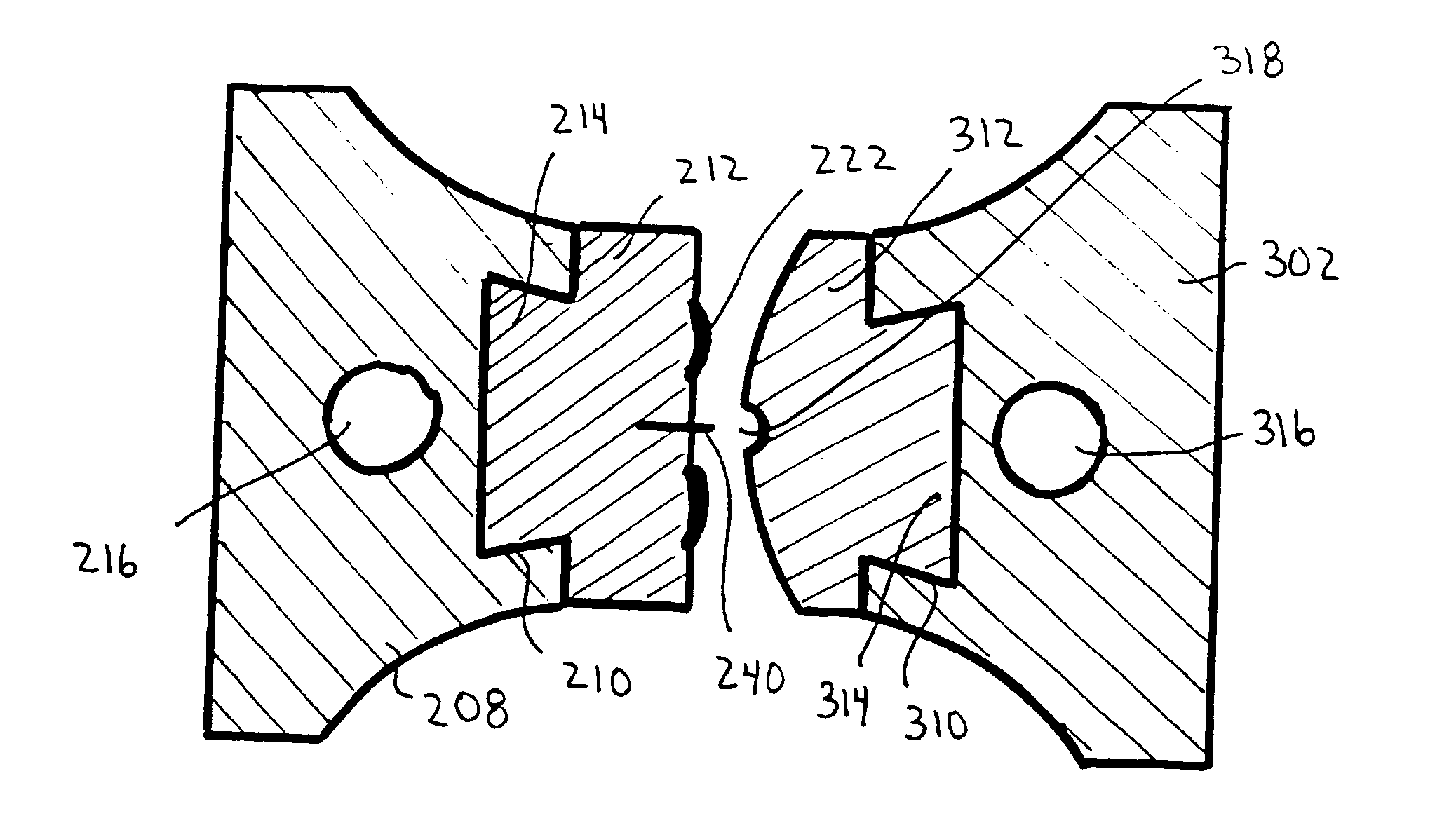

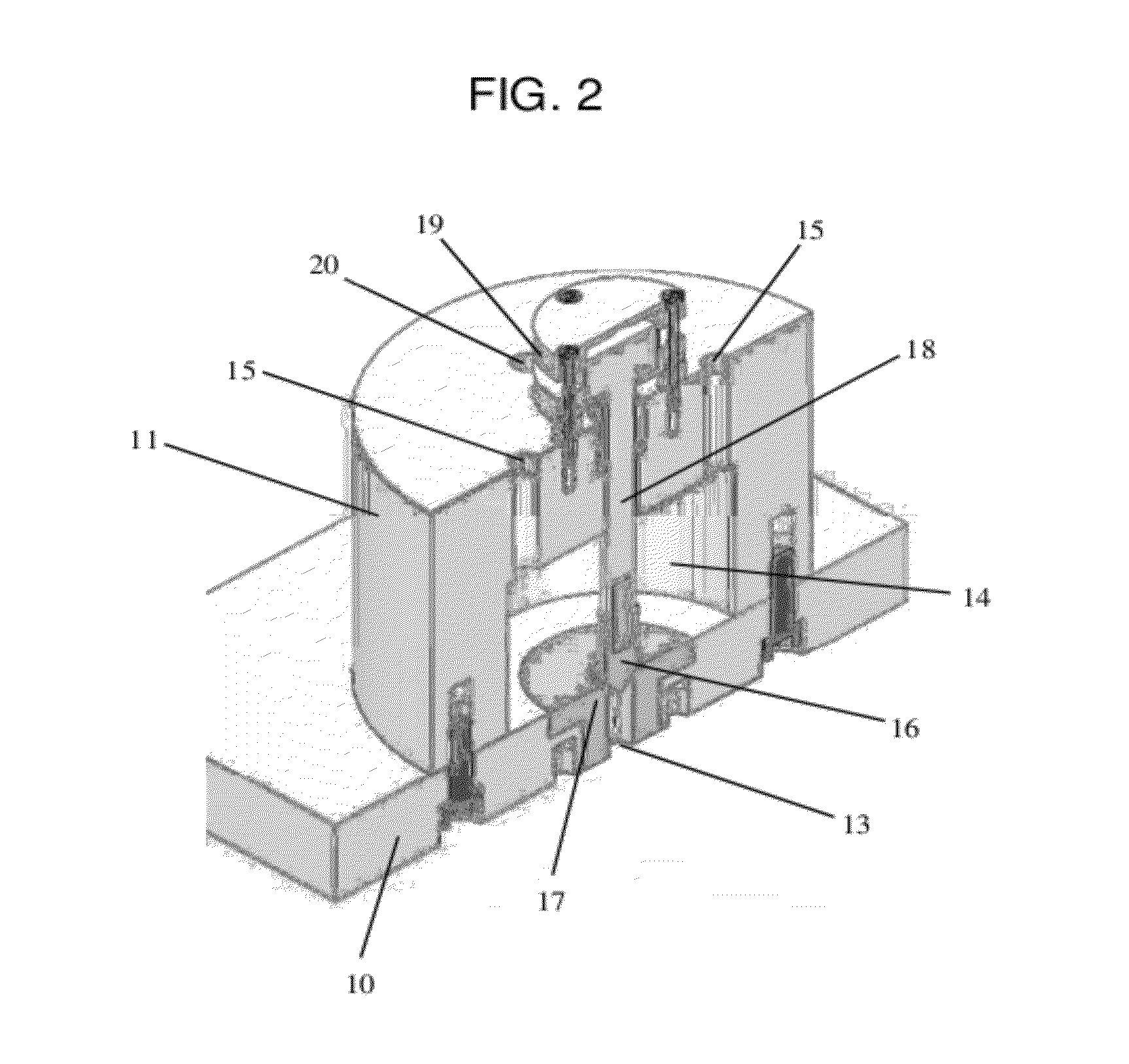

Constant volume combustion chamber

InactiveUS9279503B2Mitigate, alleviate or eliminate one or more disadvantagesImprove business performanceCosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberCombustor

A constant volume combustion chamber, combustor, and method for constant volume combustion involve combusting a fuel in a chamber sealed by a pintle having a conical portion fitted into a conical nozzle throat and pulling the pintle away from the nozzle throat to allow combustion products to exhaust through a nozzle outlet. The shapes and surfaces of the pintle and nozzle throat provide for sealing the chamber at high pressures while resisting surface wear. Operational parameters for the combustor may be computer controlled in response to measured pressures and temperatures in the combustor.

Owner:STREAMLINE AUTOMATION LLC

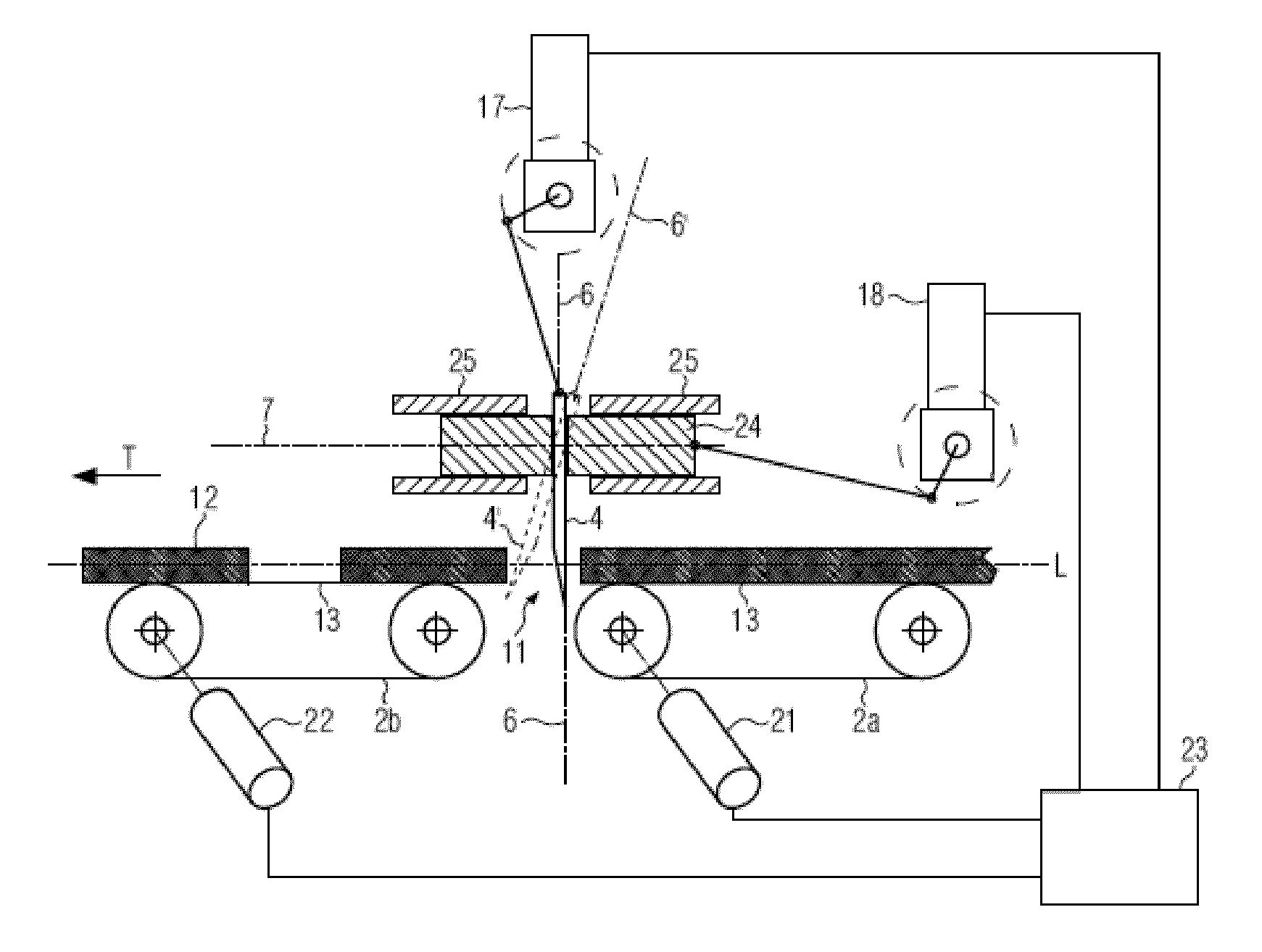

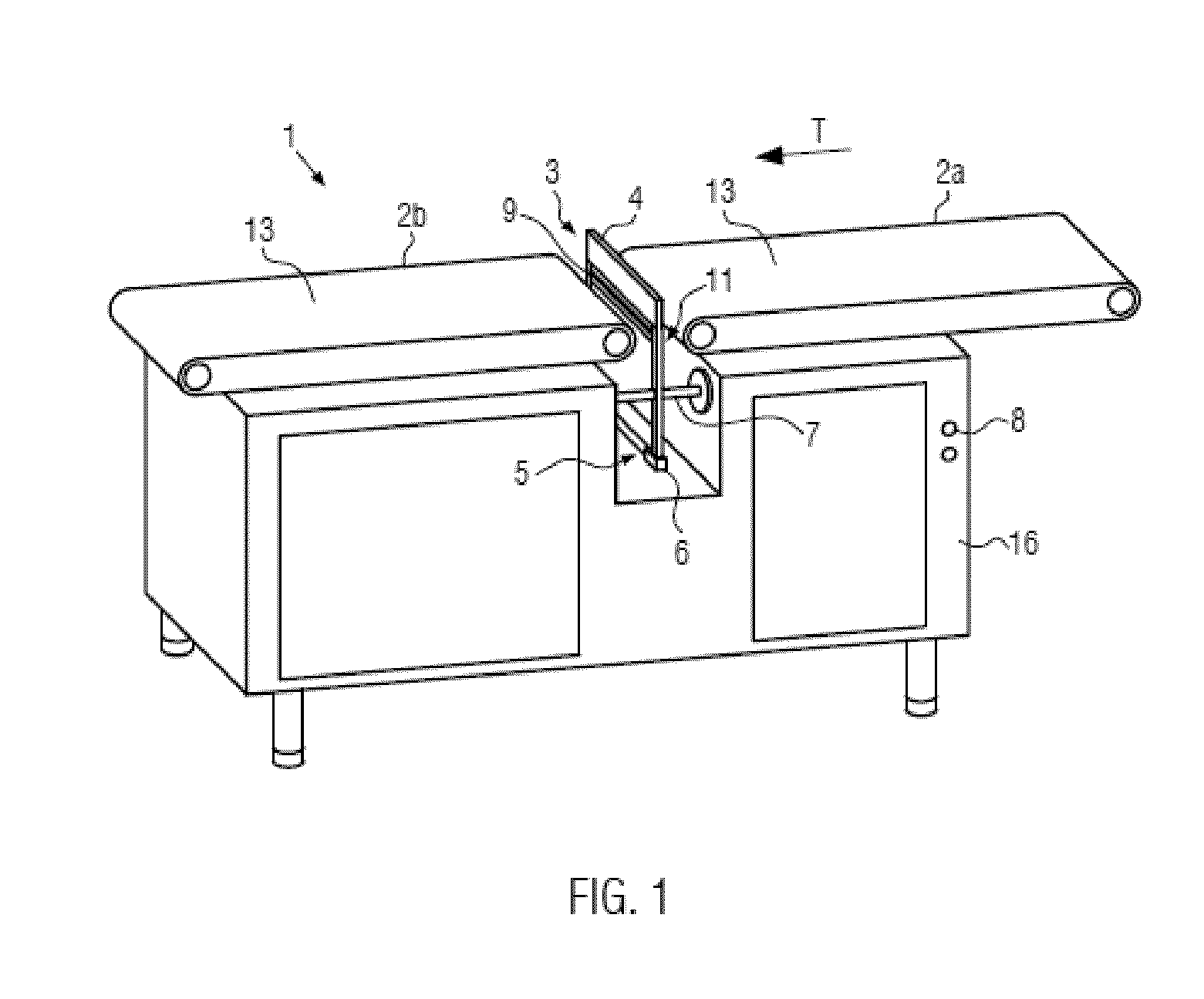

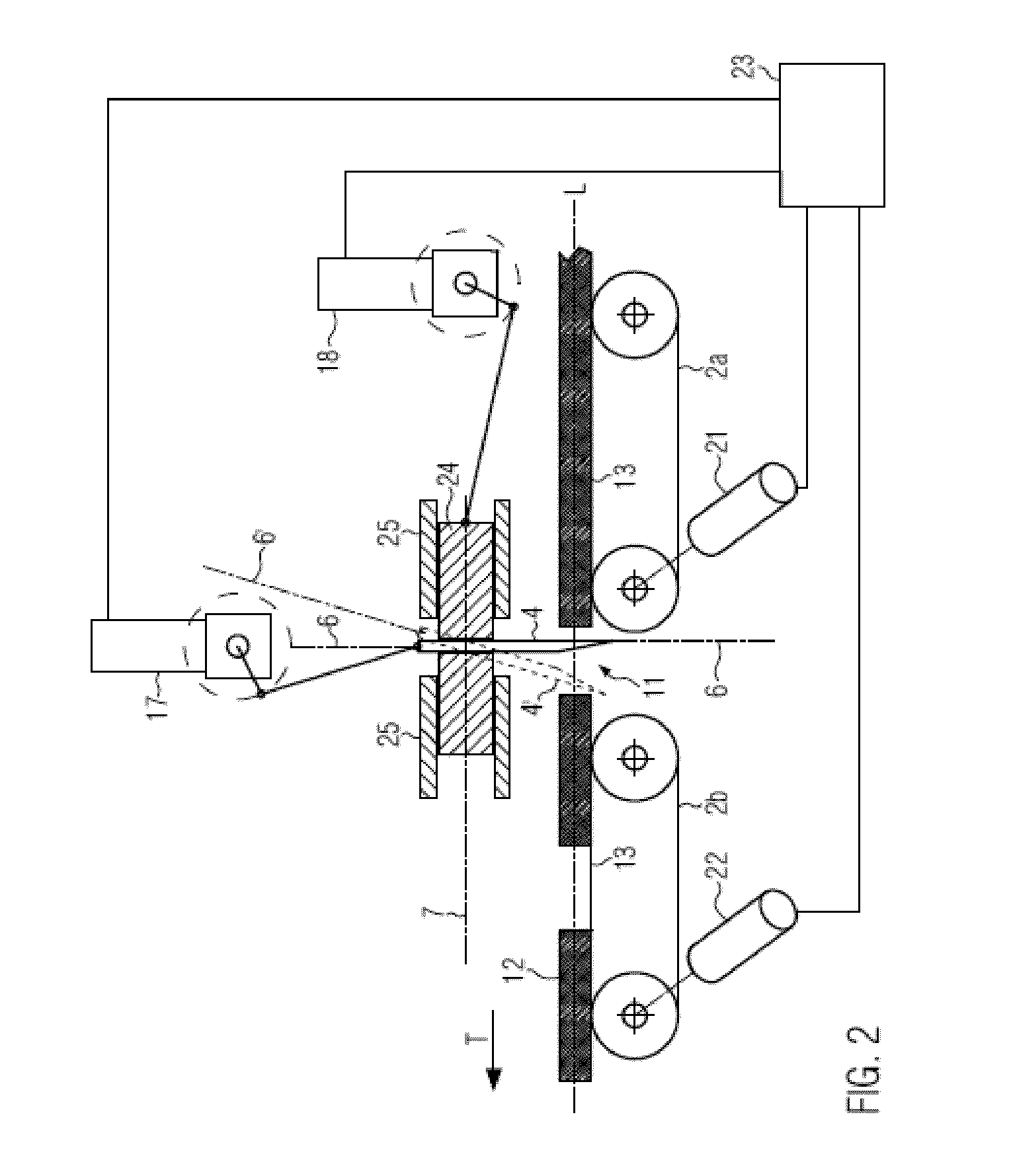

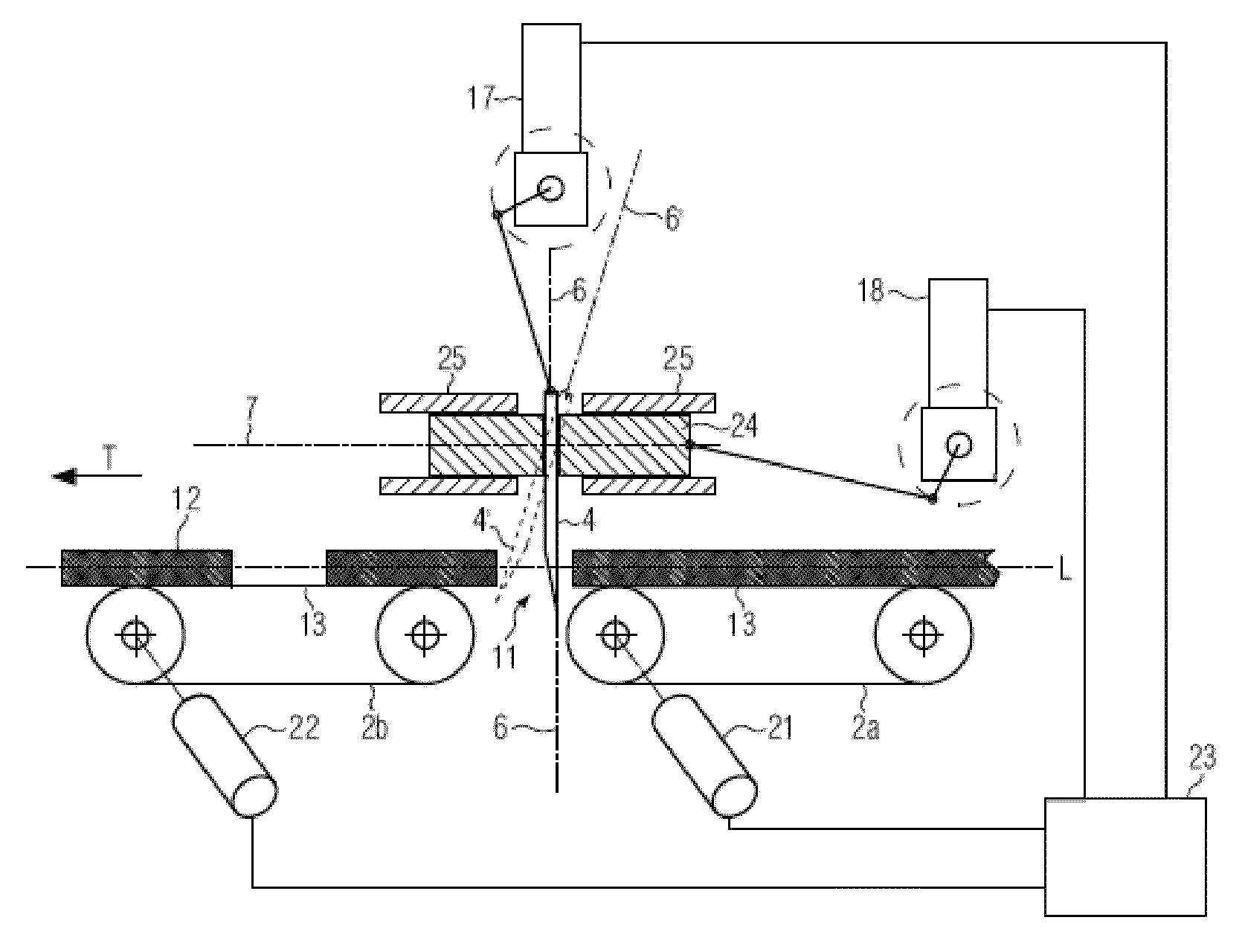

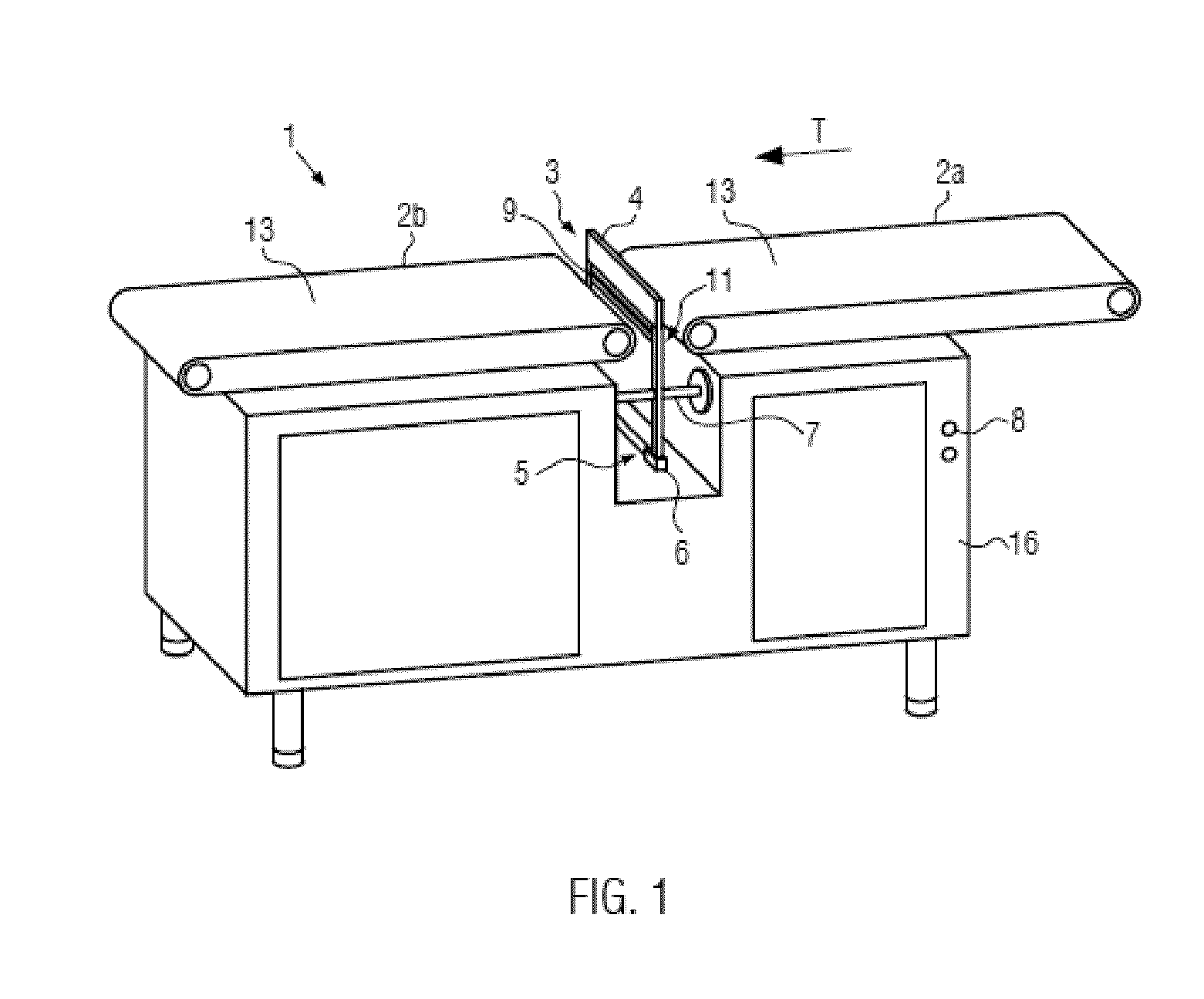

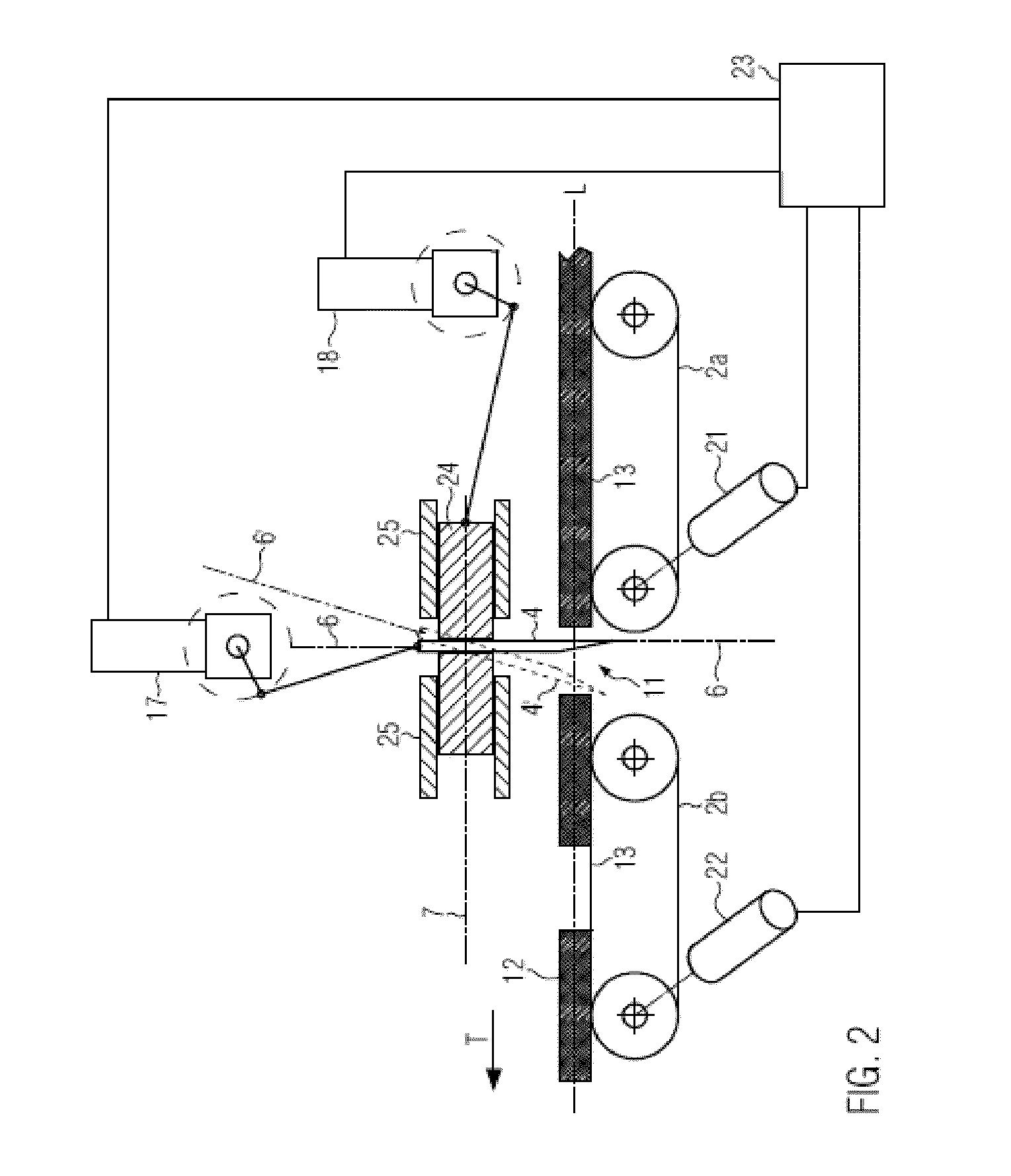

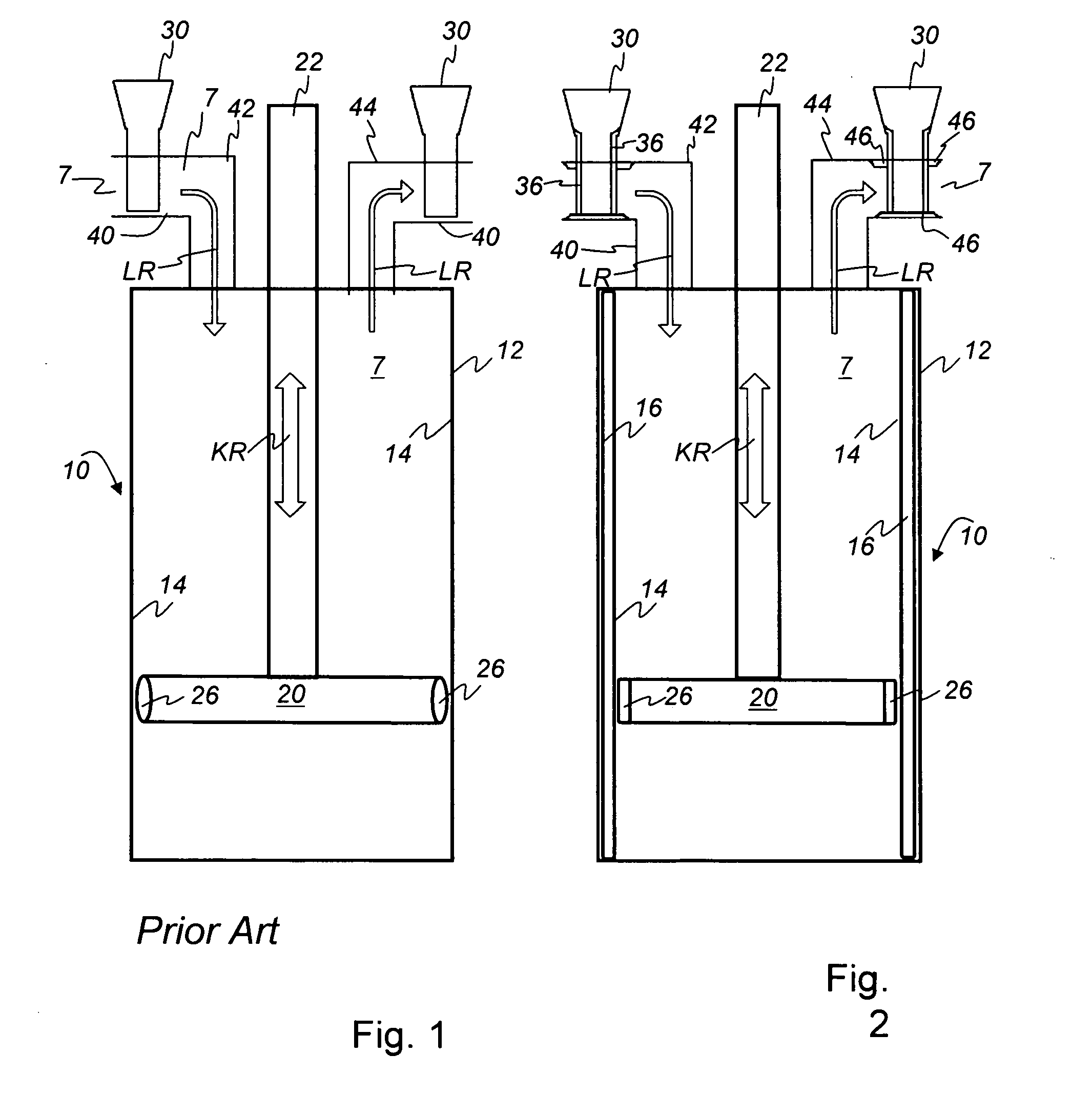

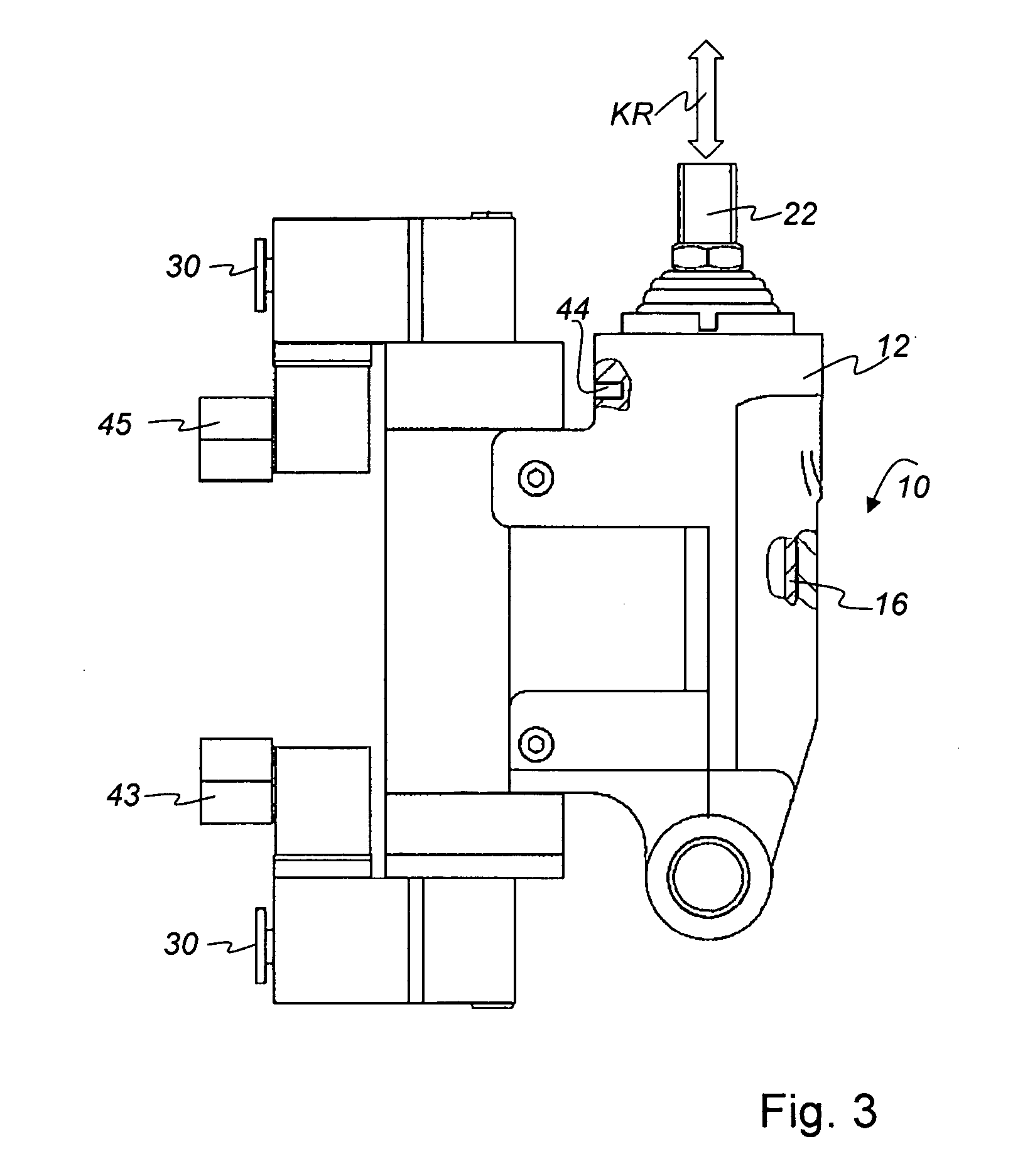

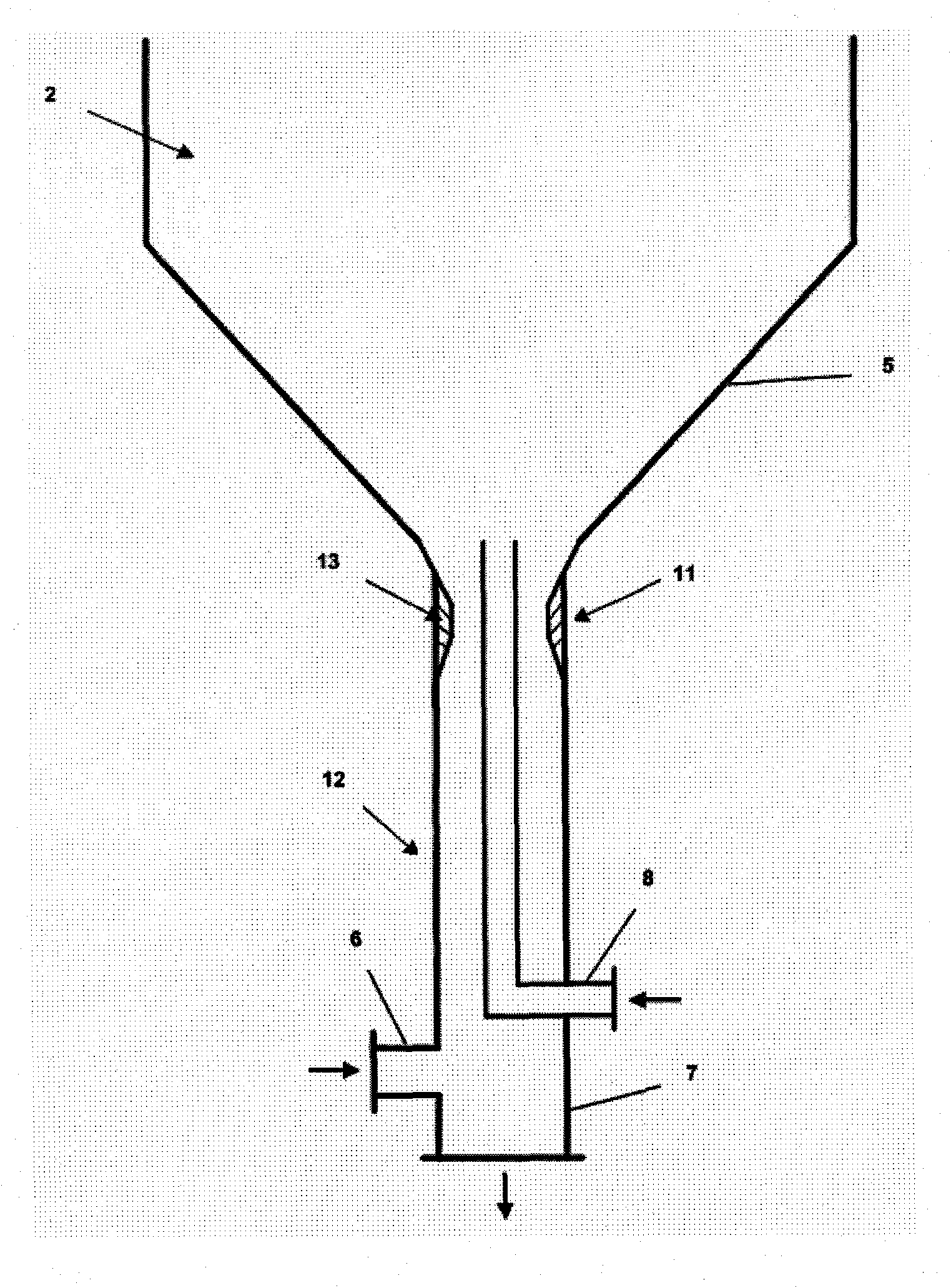

Method and device for separating products

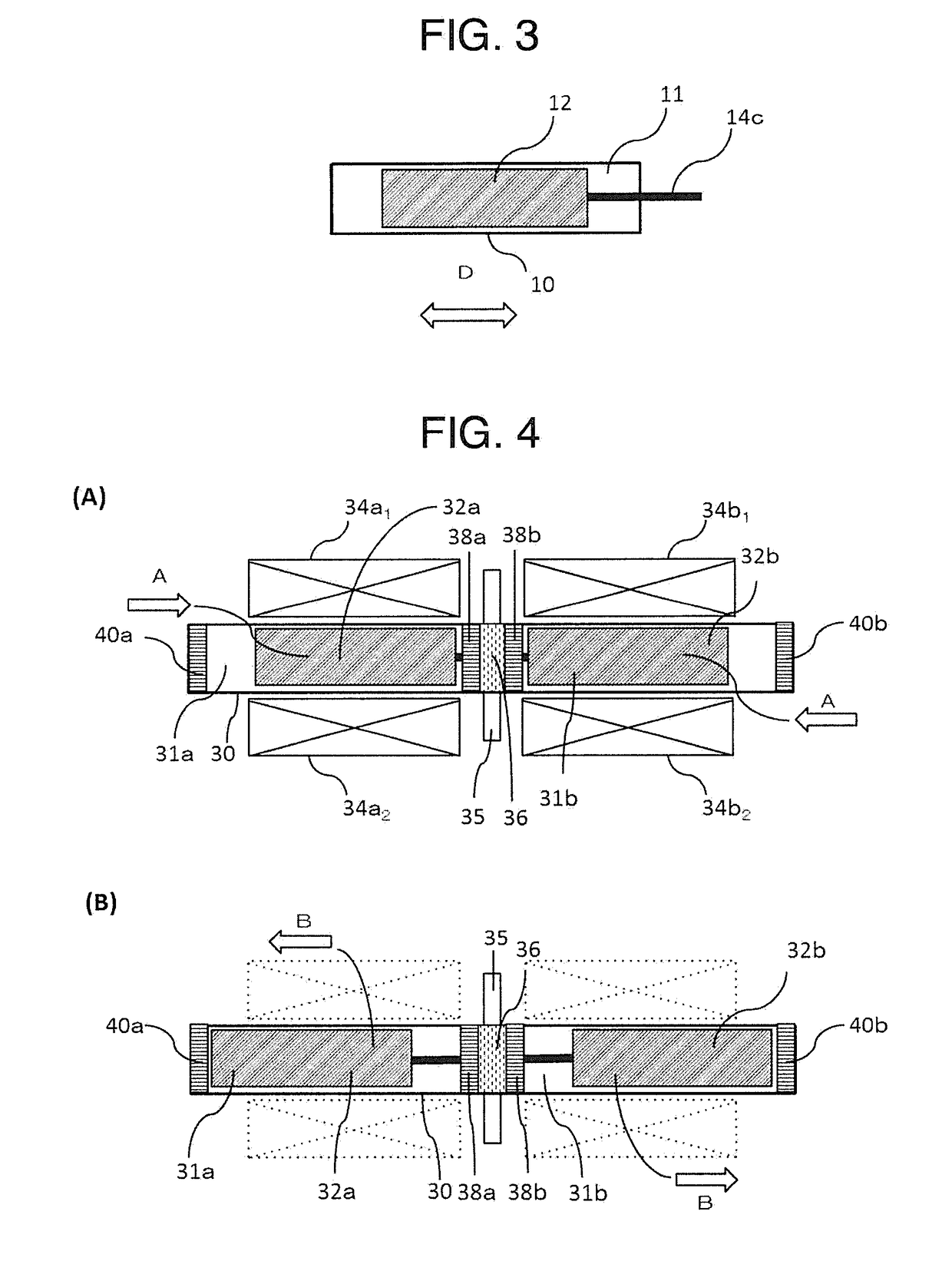

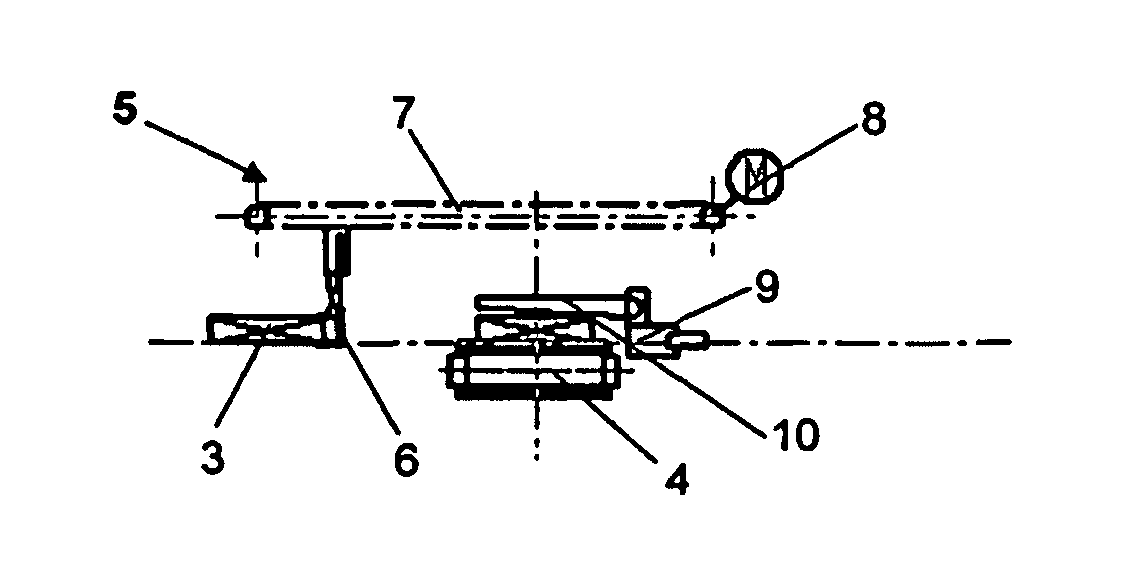

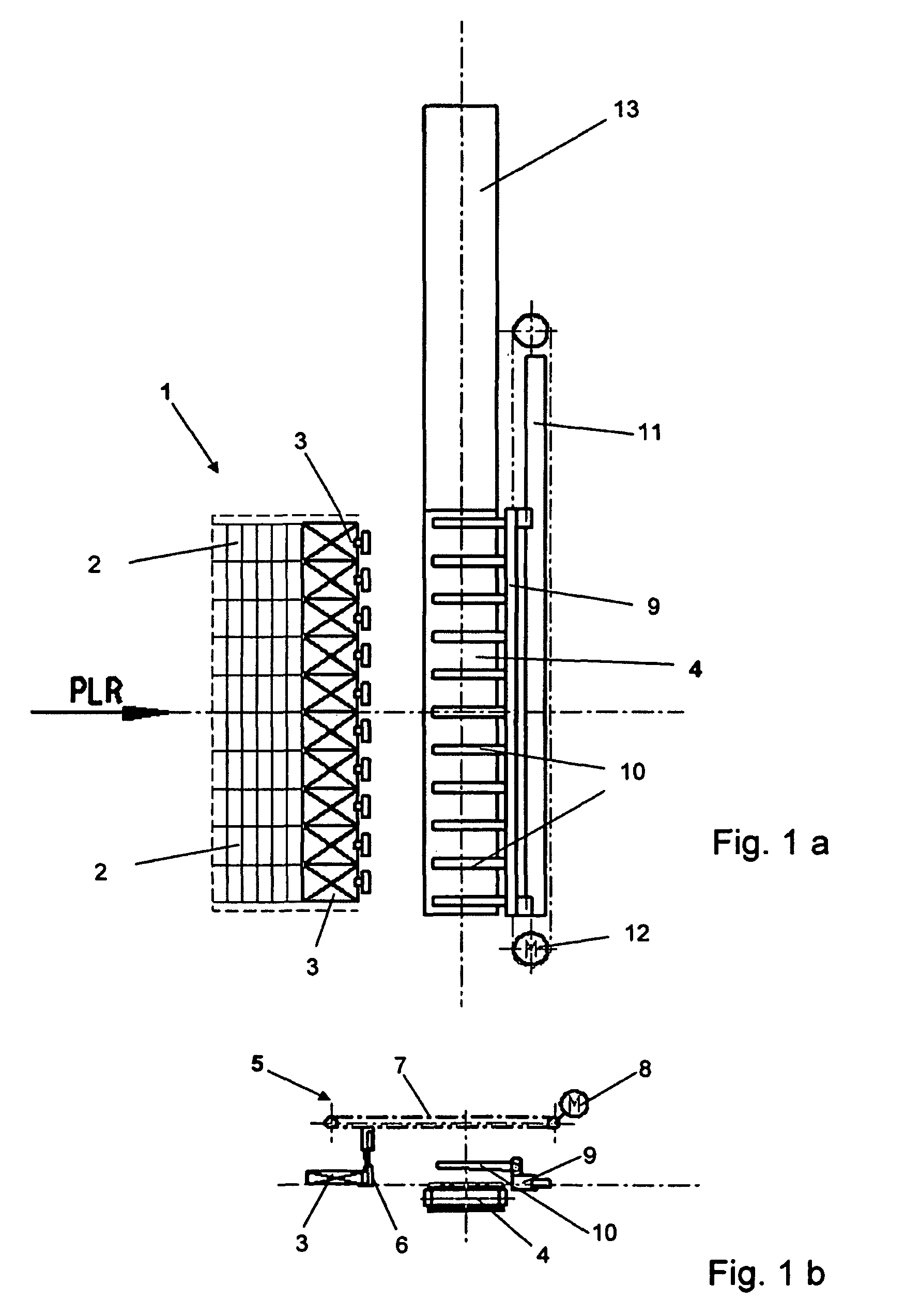

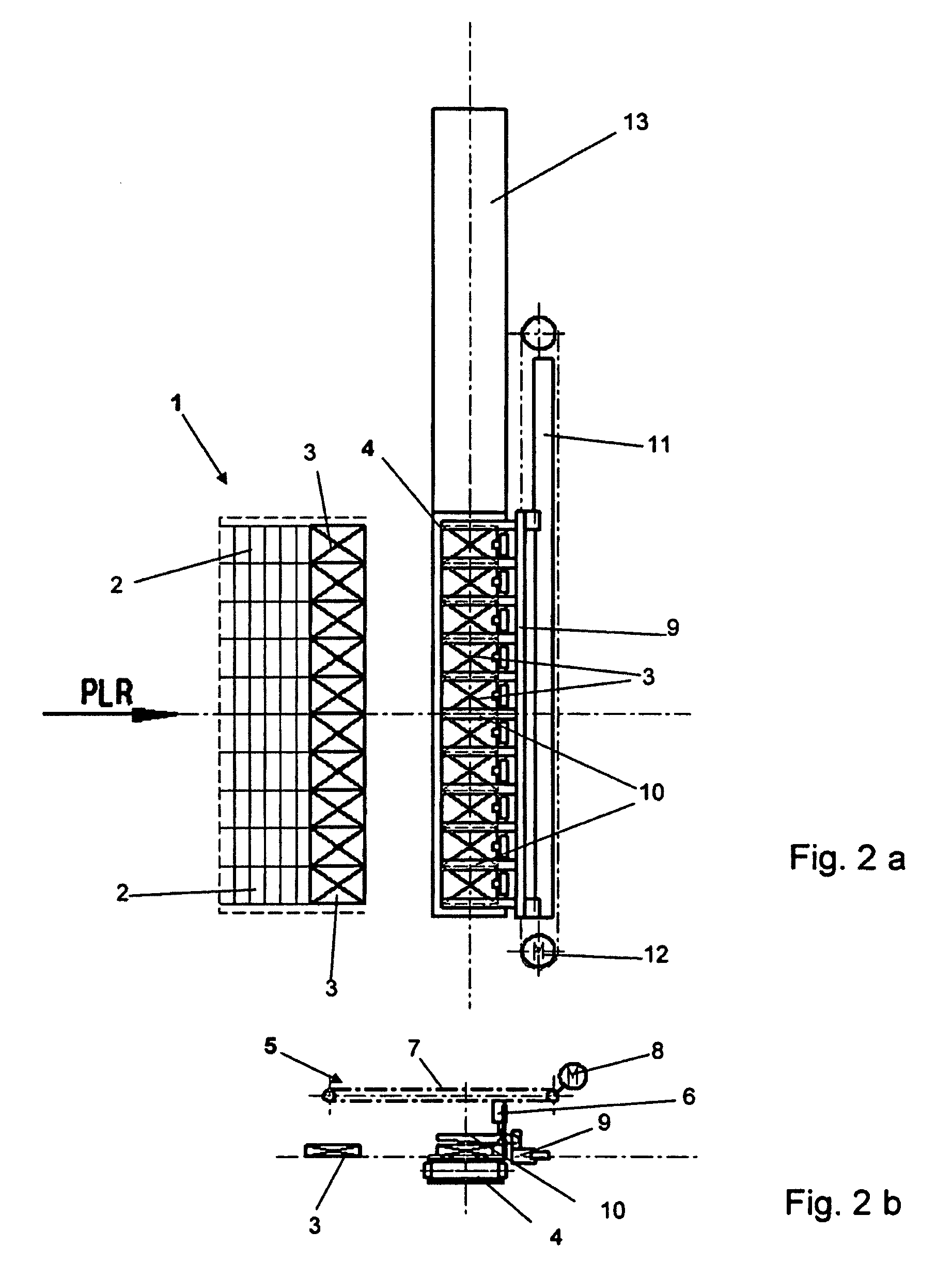

ActiveUS20130205961A1Exact weight precisionIncrease cycle rateStock shearing machinesMetal working apparatusCycle rateEngineering

A method and a device for separating food products, including to permit a straight cut at high cycle rates, the food product is conveyed by a conveying device in the direction of transport. The food product is cut through, where a cutting element is moved in the direction of transport and transverse to the direction of transport, wherein the motion of the cutting element transverse to the direction of transport is controlled independently of its motion in the direction of transport and the food product does not rest on the cutting area on the conveying means.

Owner:ALBERT HANDTMANN MASCHFABRICK

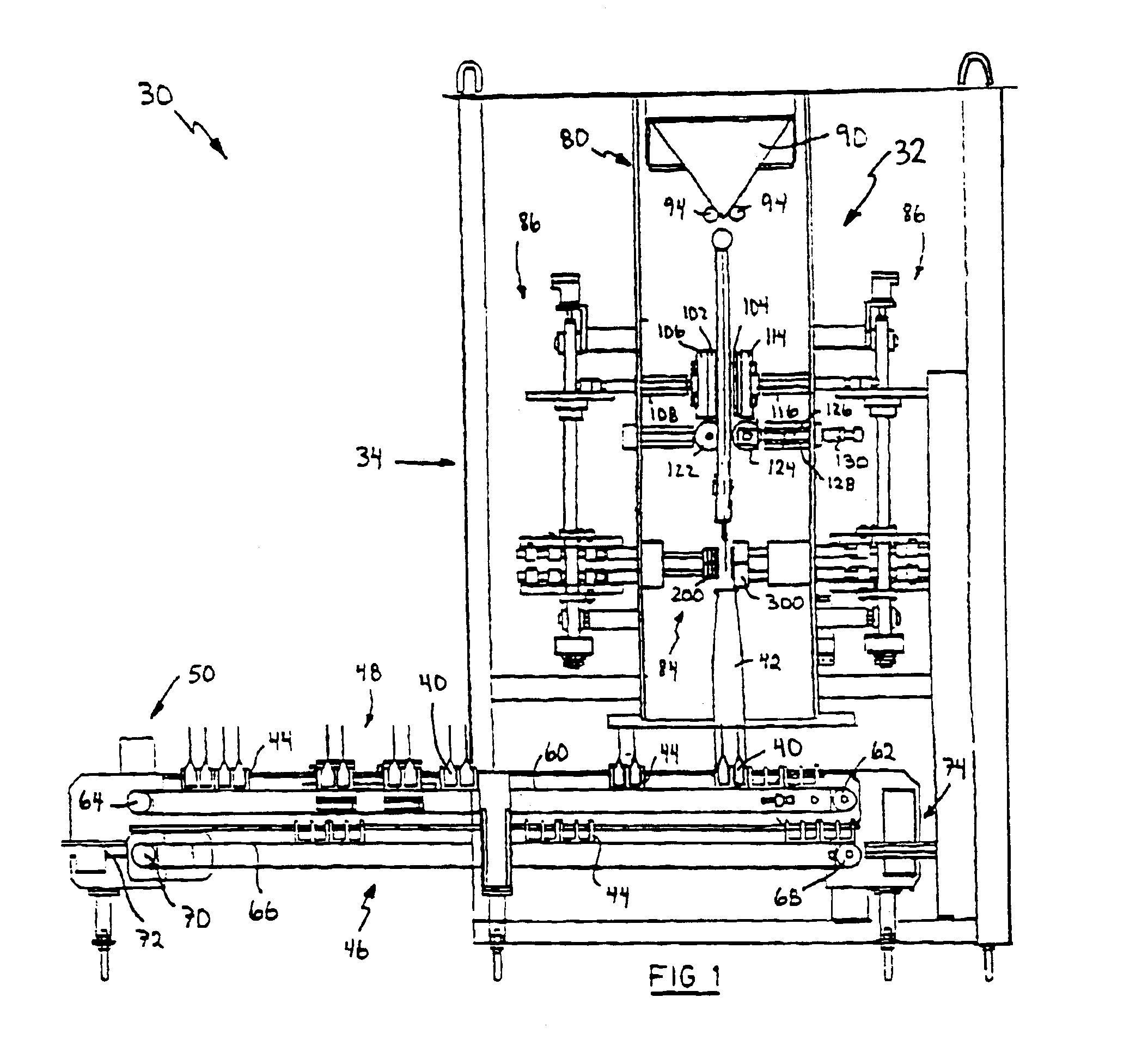

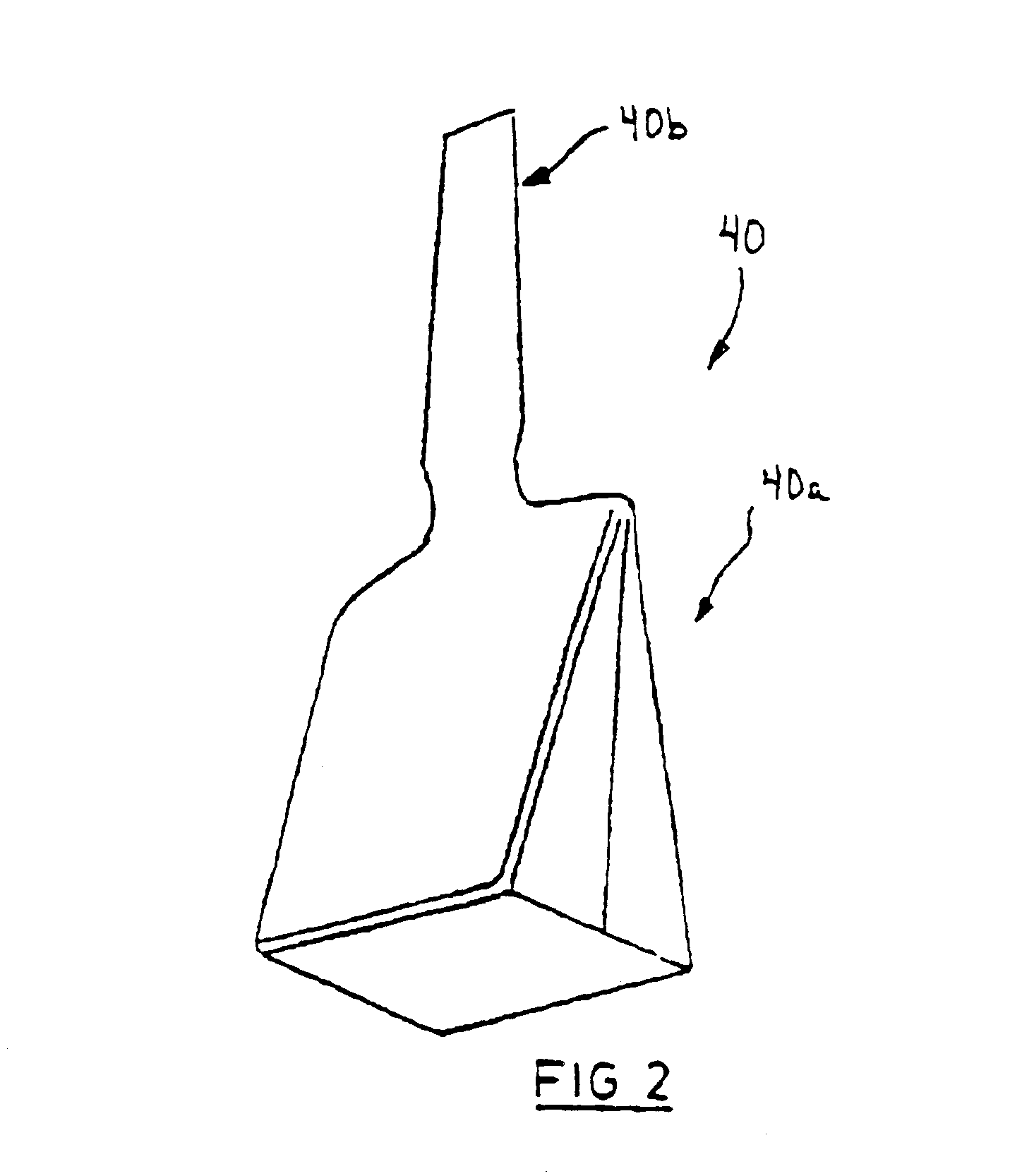

Heat sealing and cutting mechanism and container forming apparatus incorporating the same

InactiveUS6871476B2Improve sealingEasy to fillPaper-makingWrapper twisting/gatheringTemperature gradientElectrical and Electronics engineering

A heat sealing and cutting mechanism to form a heat seal and a cut across a tube of flexible packaging material includes a carrier to contact the tube. A pair of closely spaced heat sealing bands are disposed on the carrier and are energizable to form closely spaced heat seals across the tube when the carrier is in contact with the tube. The heat sealing bands are configured to define temperature gradients along the heat sealing bands. A cutting wire is also disposed on the carrier and is positioned between the heat sealing bands. The cutting wire is energizable to cut the tube when the carrier is in contact with the tube.

Owner:TOBOLKA STEFAN

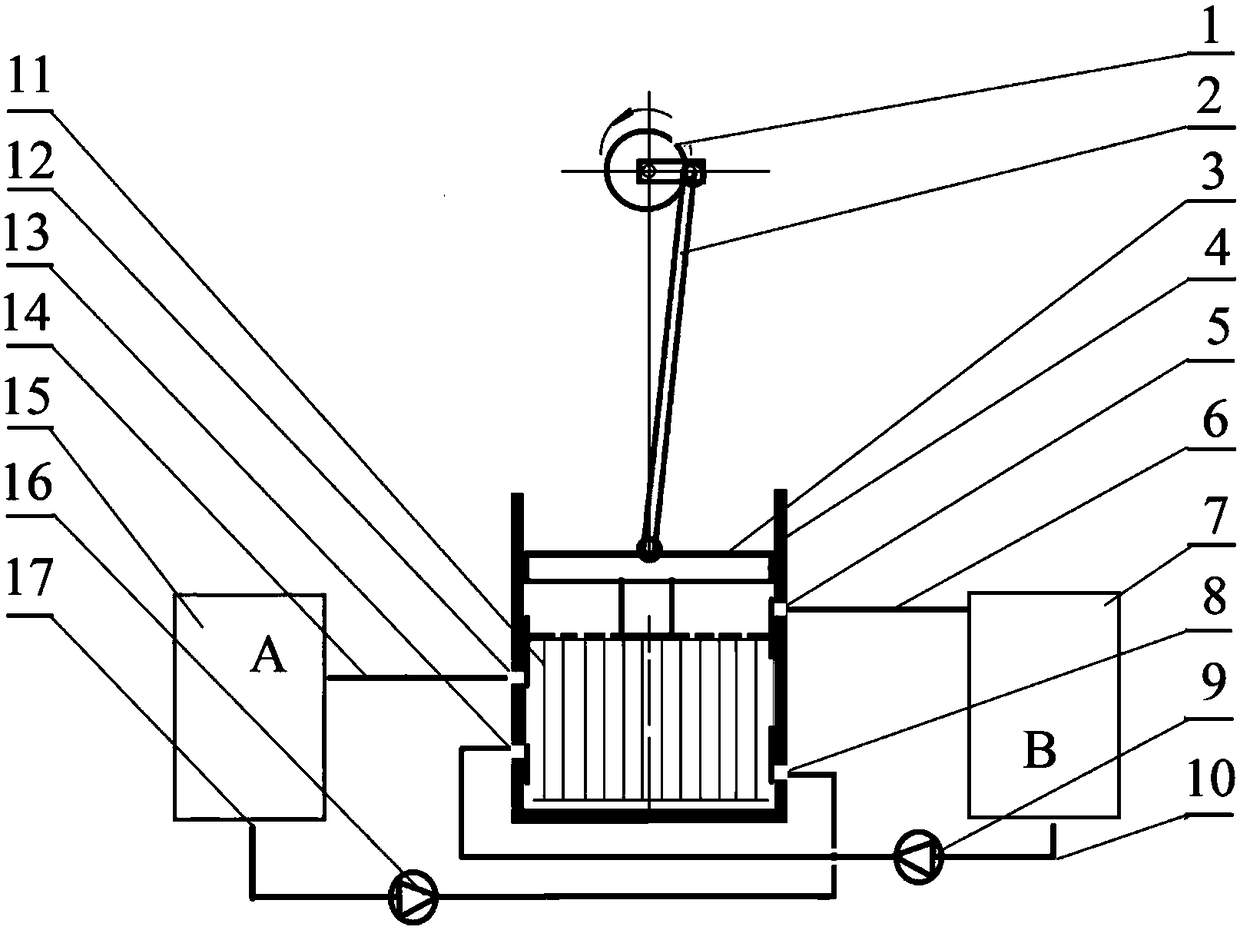

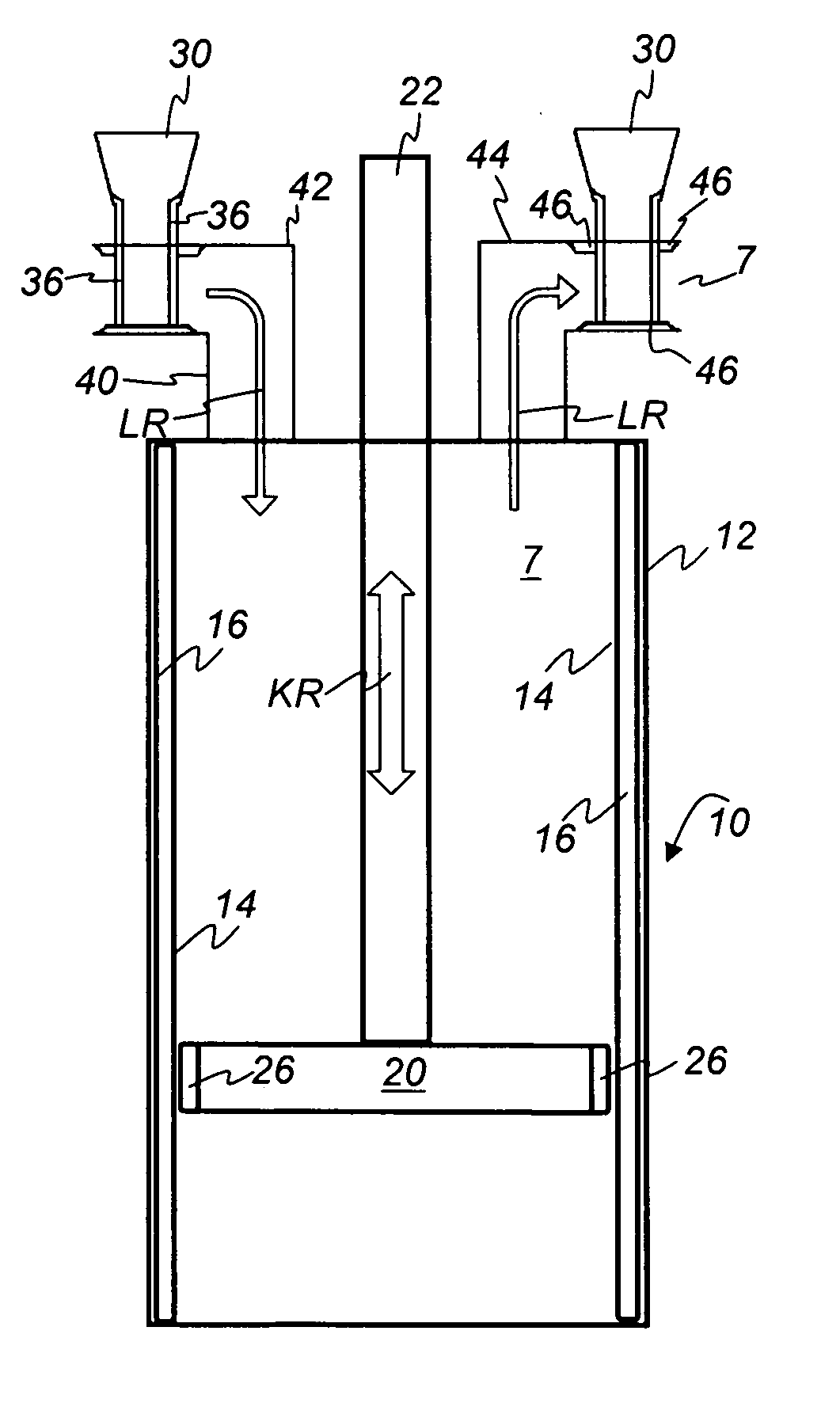

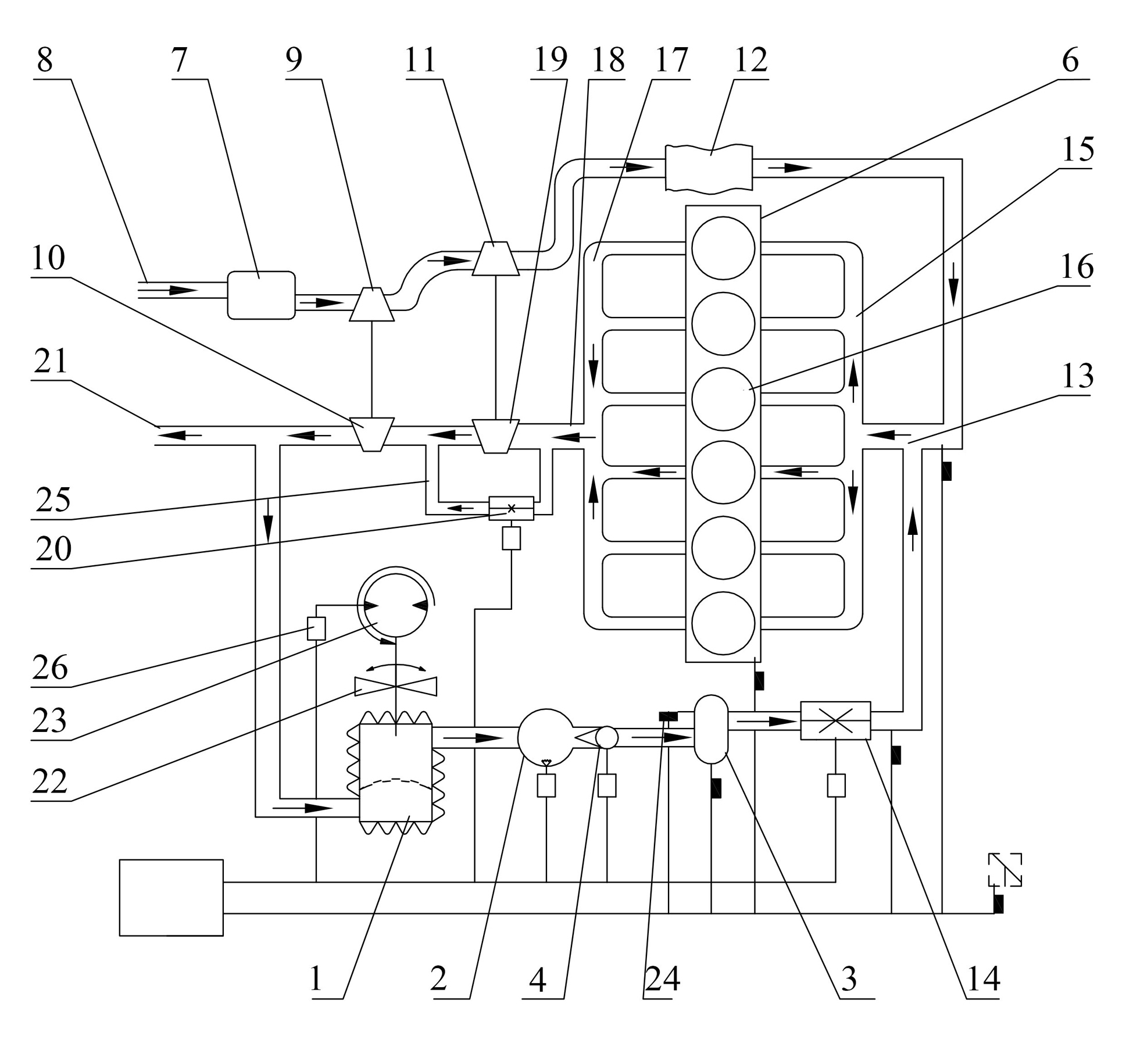

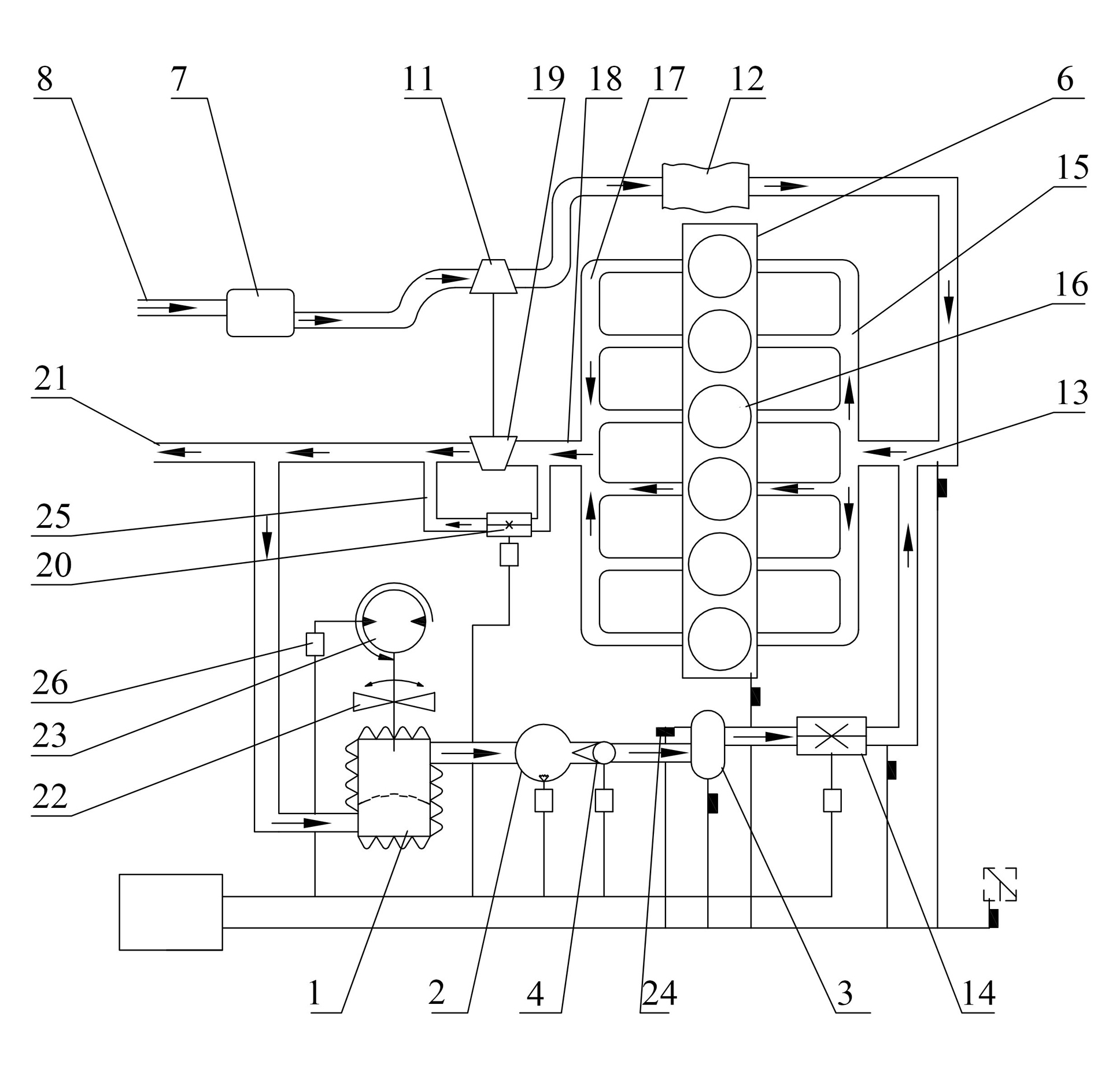

Piston-cylinder refrigerating device based on memory alloy thermoelastic effect

PendingCN108562061AEnhanced Controllable Transfer EfficiencyImprove insulation performancePositive displacement pump componentsFluid circulation arrangementMartensite transformationHydraulic cylinder

A piston-cylinder refrigerating device based on memory alloy thermoelastic effect belongs to the technical field of refrigeration and comprises a motor power system, a memory alloy thermoelastic effect refrigerator, and a dual-circuit controllable liquid-flow heat exchange system. A motor drives a piston to linearly reciprocate in a hydraulic cylinder. Memory alloy is arranged in space between thepiston and the bottom of the hydraulic cylinder; reciprocating of the piston enables the memory alloy to periodically deform by loading and restore by unloading, and alternate martensite phase-changeheat release and inverse-change heat absorption are generated correspondingly. A piston spool and holes in the sidewall of the hydraulic cylinder form two pairs of spool inlets and two pairs of spooloutlets; when the piston moves during upper and lower half cycles, one pair of spool inlets and one pair of spool outlets are opened, one heat exchange flow is controlled to enter the hydraulic cylinder and exchange with heat with the memory alloy; after the piston reciprocates once, heat is transmitted from the flow to another flow through the memory alloy; a single refrigerating cycle is completed. The piston-cylinder refrigerating device based on memory alloy thermoelastic effect is compact in structure, high in refrigerating capacity and applicable to the refrigerating systems, such as anair conditioner and a refrigerator.

Owner:UNIV OF SCI & TECH BEIJING

Constant Volume Combustion Chamber

InactiveUS20120317956A1Simplified ignition systemAbsence of extremely high pressureCosmonautic vehiclesCosmonautic propulsion system apparatusCombustorCombustion chamber

A constant volume combustion chamber, combustor, and method for constant volume combustion involve combusting a fuel in a chamber sealed by a pintle having a conical portion fitted into a conical nozzle throat and pulling the pintle away from the nozzle throat to allow combustion products to exhaust through a nozzle outlet. The shapes and surfaces of the pintle and nozzle throat provide for sealing the chamber at high pressures while resisting surface wear. Operational parameters for the combustor may be computer controlled in response to measured pressures and temperatures in the combustor.

Owner:STREAMLINE AUTOMATION LLC

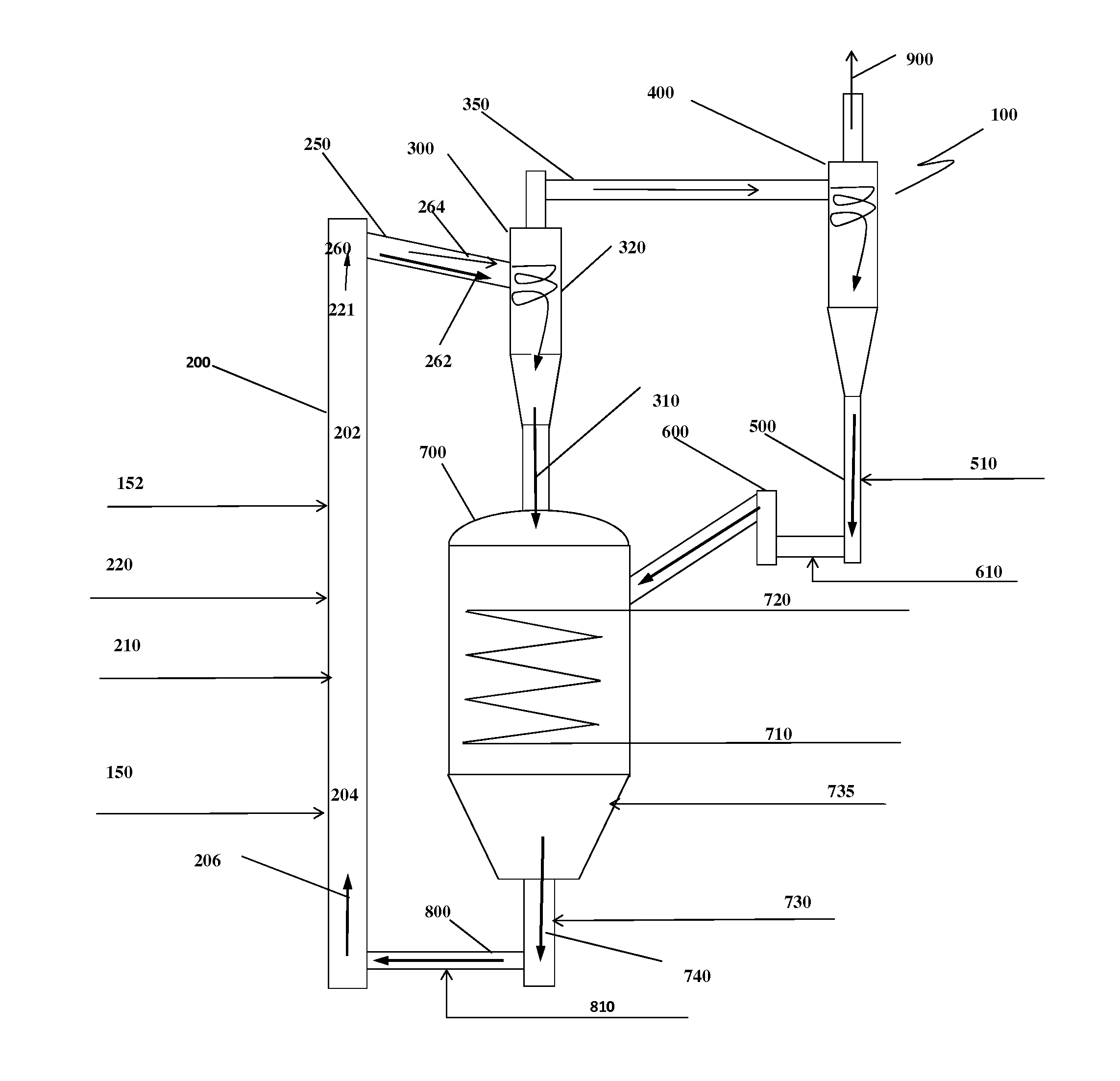

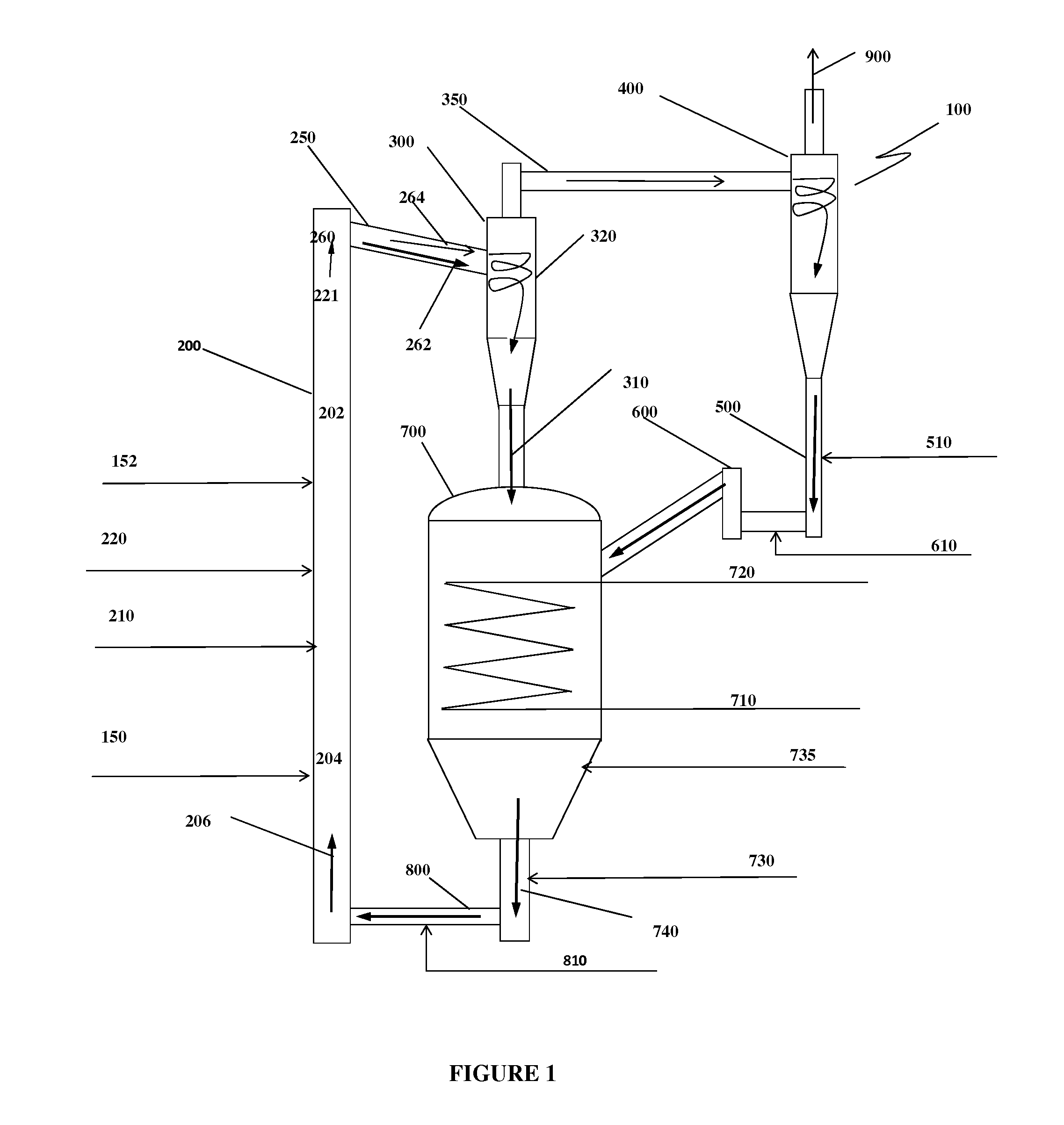

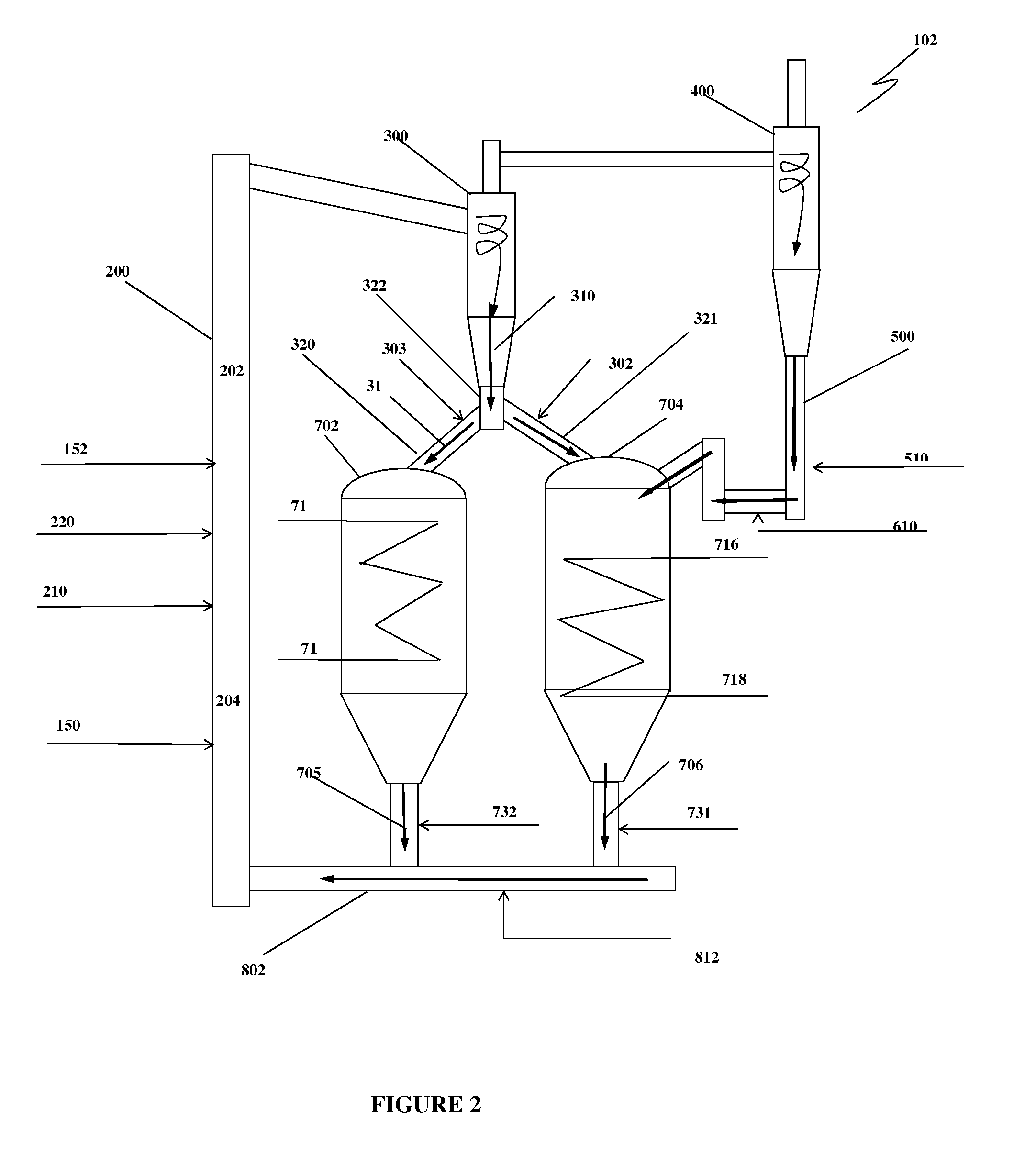

Oxycombustion In Transport Oxy-Combustor

ActiveUS20130055936A1Efficient removalReduce operating costsFluidized bed combustionSteam generation using pressureFlue gasMoisture condensation

A pressurized transport oxy-combustor with different configurations is disclosed. Substantially pure oxygen is fed to the transport oxy-combustor under pressure to combust fossil fuels, generating steam for power generation. The end product is the flue gas containing substantially pure CO2 after moisture condensation. The low excess oxygen necessary to achieve complete combustion in the combustor is scavenged by adding another fuel so that substantially all oxygen fed to the combustor is completely consumed. The capability to operate the transport oxy-combustor as a circulating fluidized bed combustor at very high solids circulation rates makes it unnecessary to use recycled CO2 or flue gas as a means to moderate and control the combustion temperature. The temperature in the combustor is effectively controlled by relatively cooler circulating solids that enter the combustion zone. A small amount of CO2 is recycled for aeration and to convey solids fuel to the combustor.

Owner:THE SOUTHERN CO

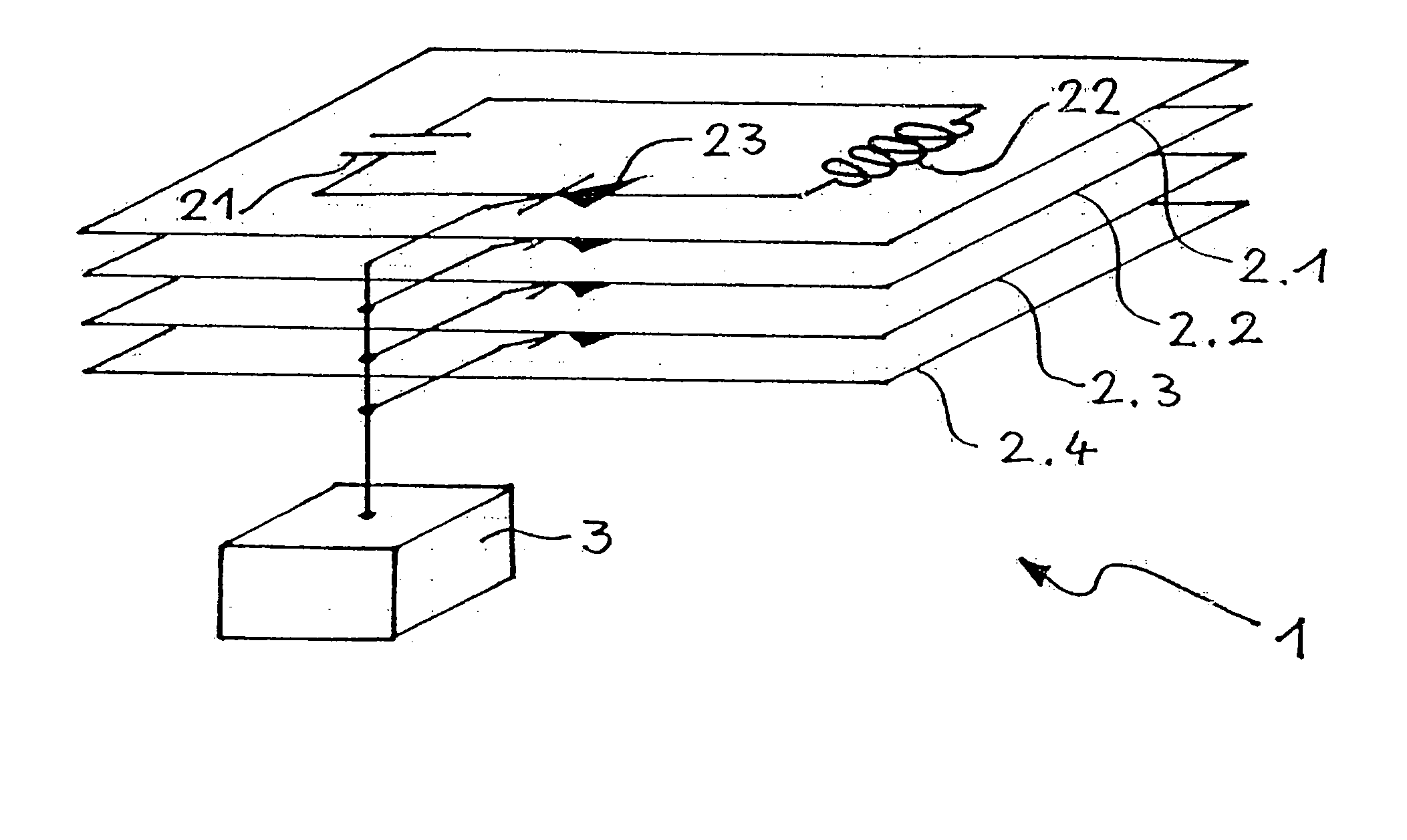

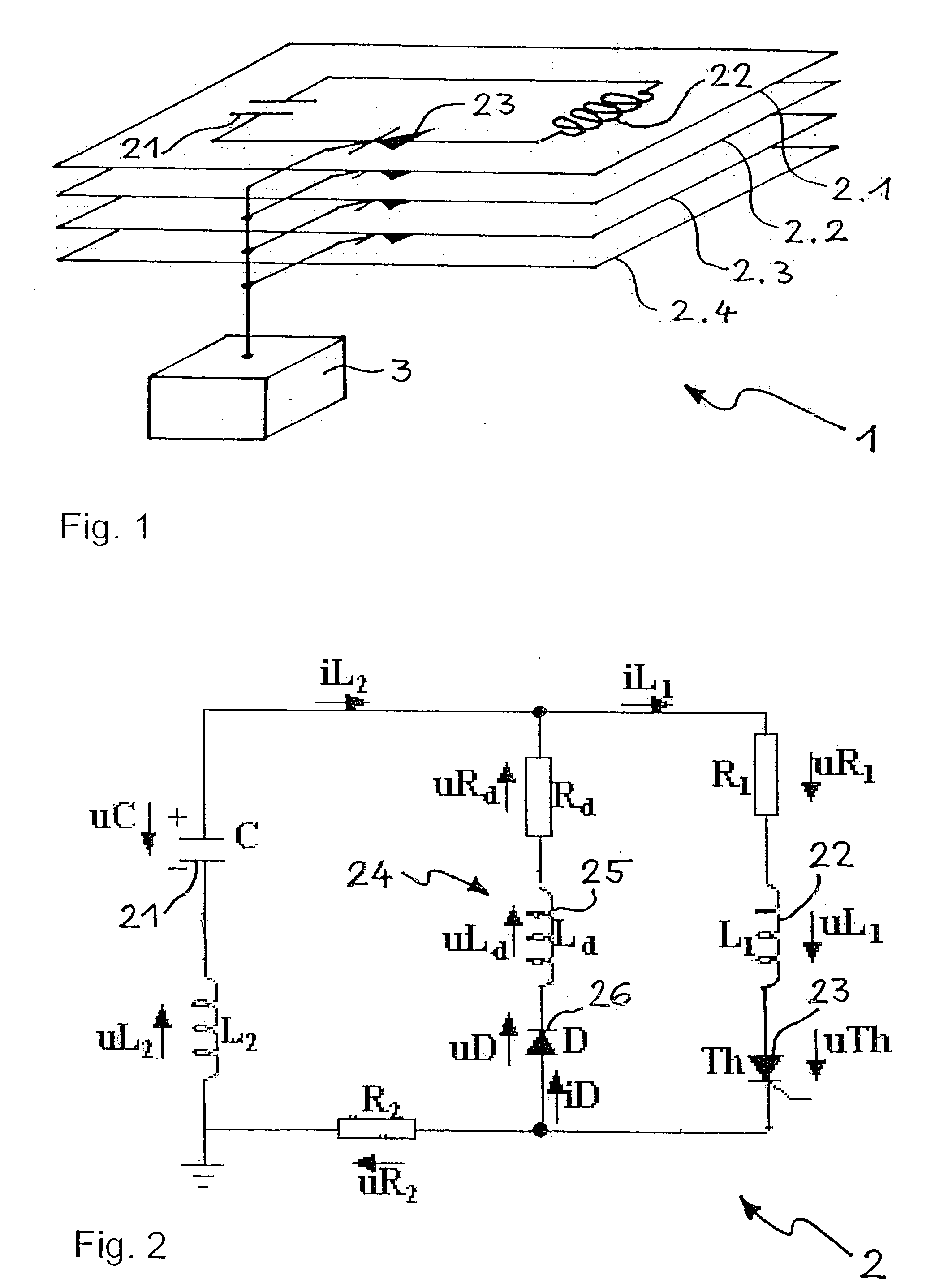

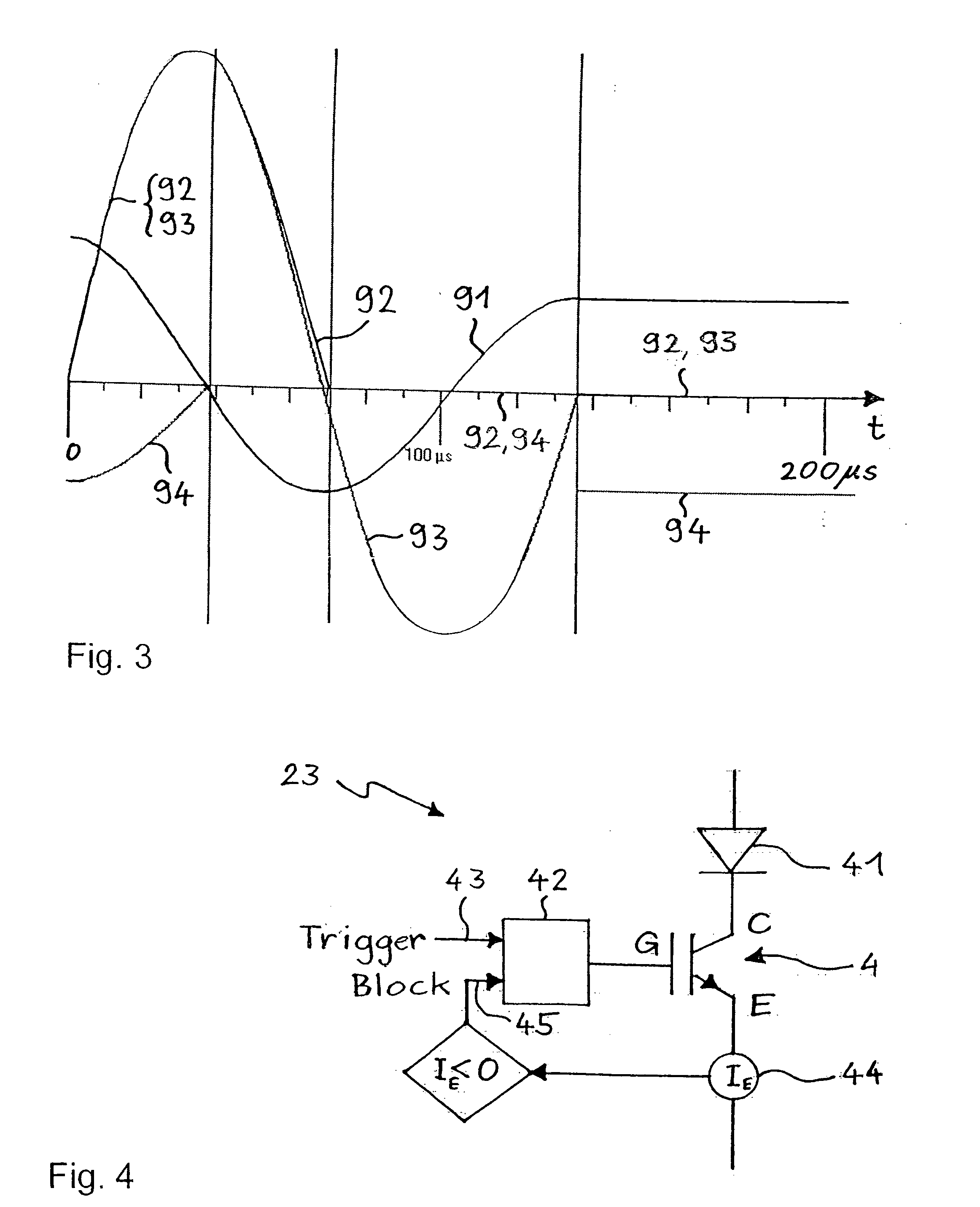

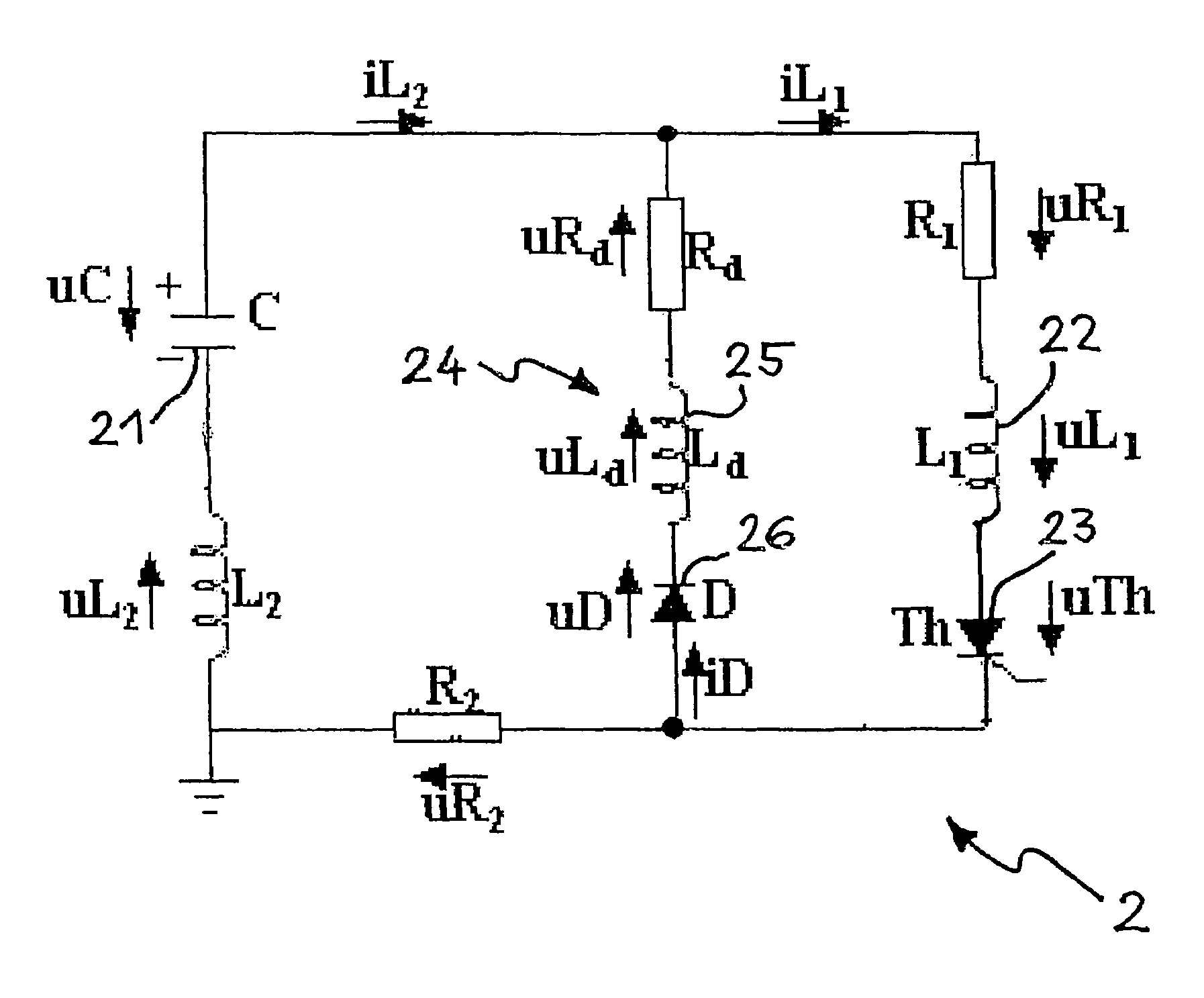

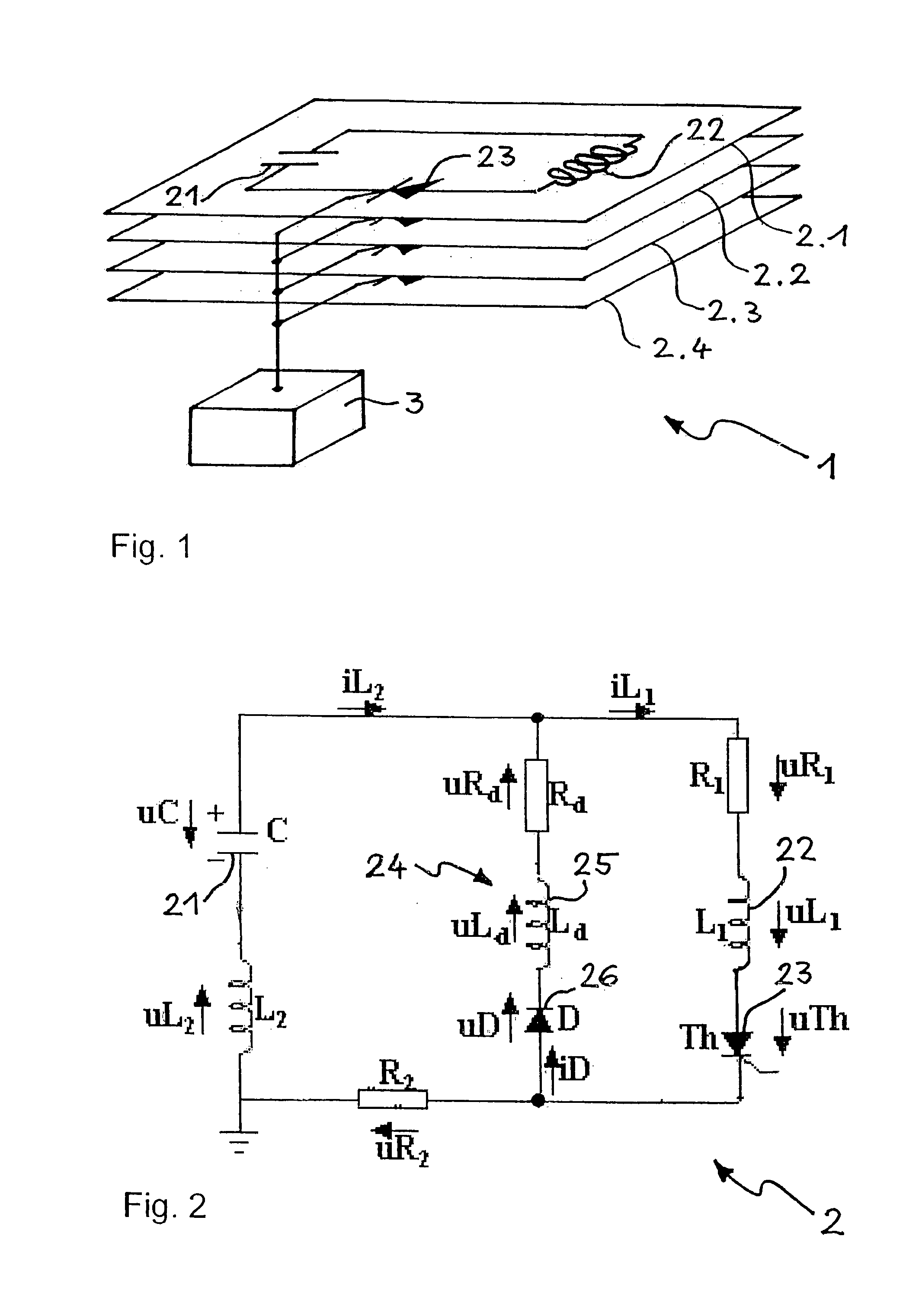

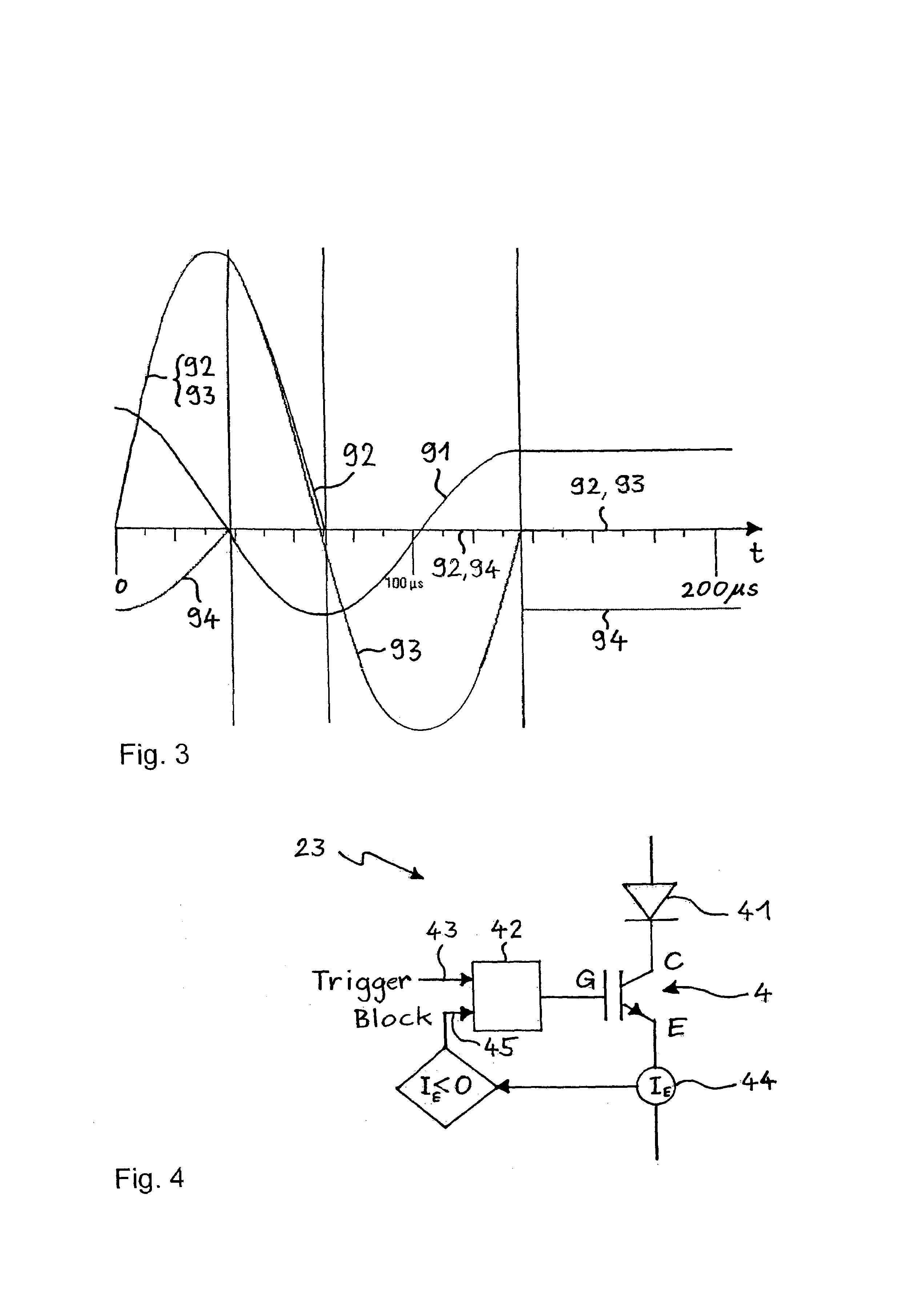

Device and a method for magnetizing a magnet system

ActiveUS20050195058A1Increase cycle rateImprove productivityElectromagnets without armaturesRelaysElectricityHeating time

A device for magnetizing a magnet system preferably having several pulse-generator circuits which are mutually arranged so that their magnetic fields superimpose in a cumulative manner. Each pulse-generator circuit includes a capacitor element, a magnetization coil electrically connected to the capacitor element and a switch element by way of which actuation the magnetization coil can be impinged with a current pulse of a limited pulse duration arising by the discharge of the capacitor element, and thus the build-up of a magnetic field may be triggered. The pulse-generator circuit is built up so that the pulse duration of the current pulse is limited to a value between 10 μs and 500 μs. With such short pulse durations, undesirable heating of the magnetization coil is short so that the device may be applied in automatic production installations with cycle times of below 1 s.

Owner:MAURER MAGNETIC

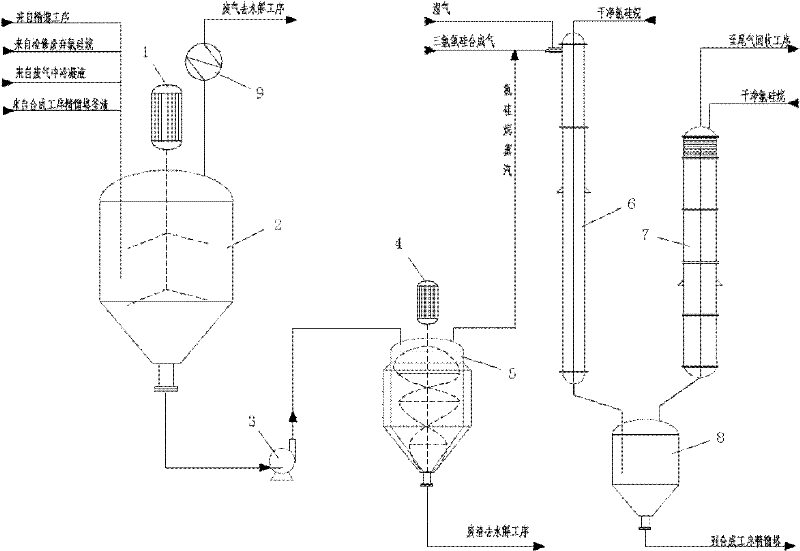

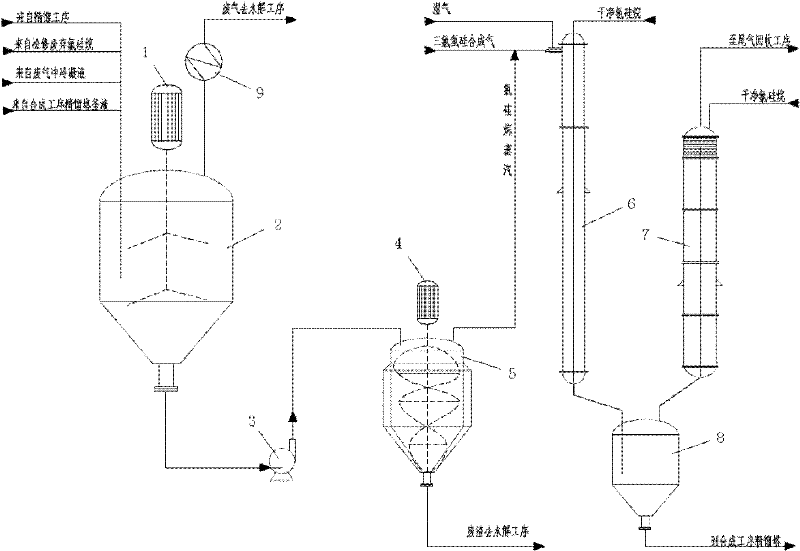

Recovery method of waste chlorsilane in polysilicon produced through modified Simens Method

InactiveCN102372271AIncrease cycle rateLow investment costHalogenated silanesForeign matterRecovery method

The invention relates to a recovery method of waste chlorsilane in polysilicon production through an improved Simens Method, which belongs to the production field of the polysilicon, and comprises the following steps that: 1) collecting waste chlorsilane to be transported to a liquid storage tank; 2) conveying the waste chlorsilane in the liquid storage tank to an evaporator; 3) heating the evaporator: the evaporator is heated to 30 DEG C to 180 DEG C, so the chlorsilane inside the evaporator is vaporized to produce the chlorsilane steam, and residual liquid in the evaporator is hydrolyzed; 4) enabling the vaporized chlorsilane to be reacted with damp air, and foreign matters are reacted to generate high-boiling residues; and 5) recycling gas: micro solid foreign matters in the gas are eliminated through the gas-solid separation, and the chlorsilane is condensed to recycle. By adopting the method, the foreign matters in the polluted chlorsilane with high content of foreign matters in the production process can be eliminated, so the requirement on the foreign matter content in the chlorsilane raw material in the process that the improved Simens Method is used for producing the polysilicon can be satisfied; and the cost is low, environmental protection can be realized and no additional equipment is required.

Owner:LESHAN LEDIAN TIANWEI SILICON TECH CO LTD

Method and device for separating products

ActiveUS8997614B2Exact weight precisionIncrease cycle rateStock shearing machinesMetal working apparatusCycle rateEngineering

A method and a device for separating food products, including to permit a straight cut at high cycle rates, the food product is conveyed by a conveying device in the direction of transport. The food product is cut through, where a cutting element is moved in the direction of transport and transverse to the direction of transport, wherein the motion of the cutting element transverse to the direction of transport is controlled independently of its motion in the direction of transport and the food product does not rest on the cutting area on the conveying means.

Owner:ALBERT HANDTMANN MASCHFABRICK

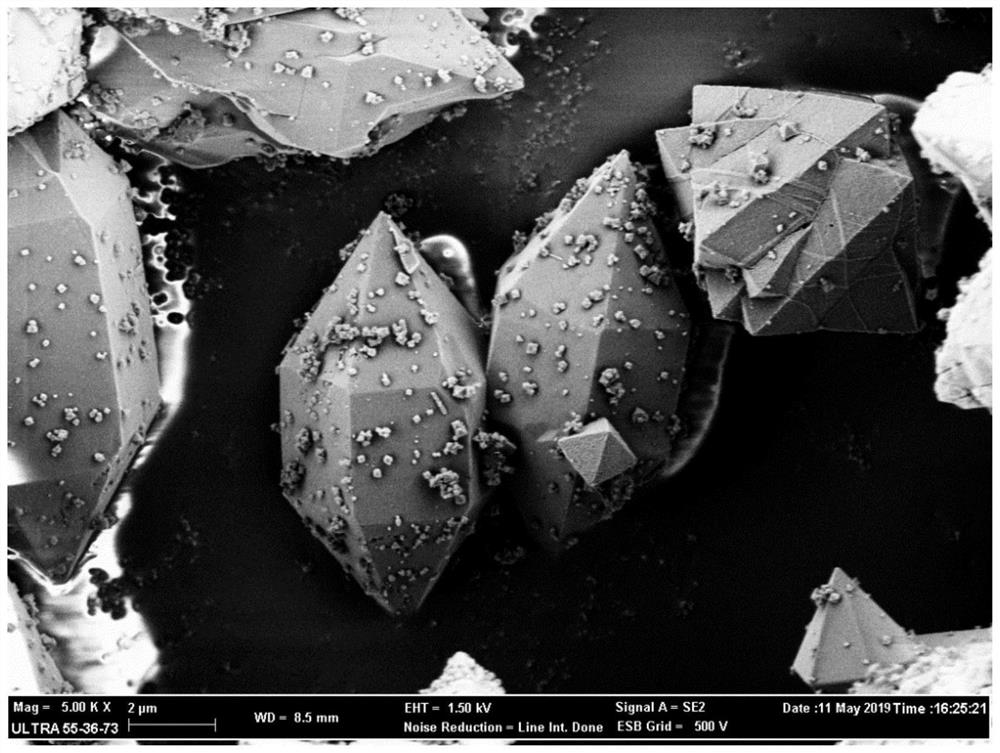

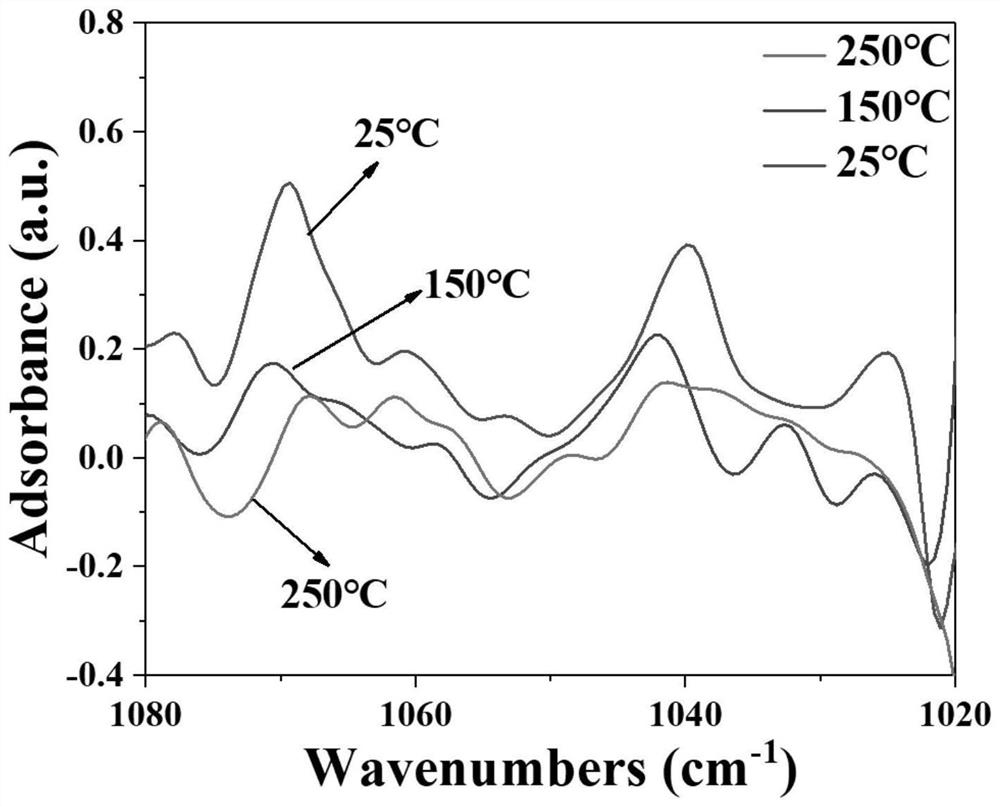

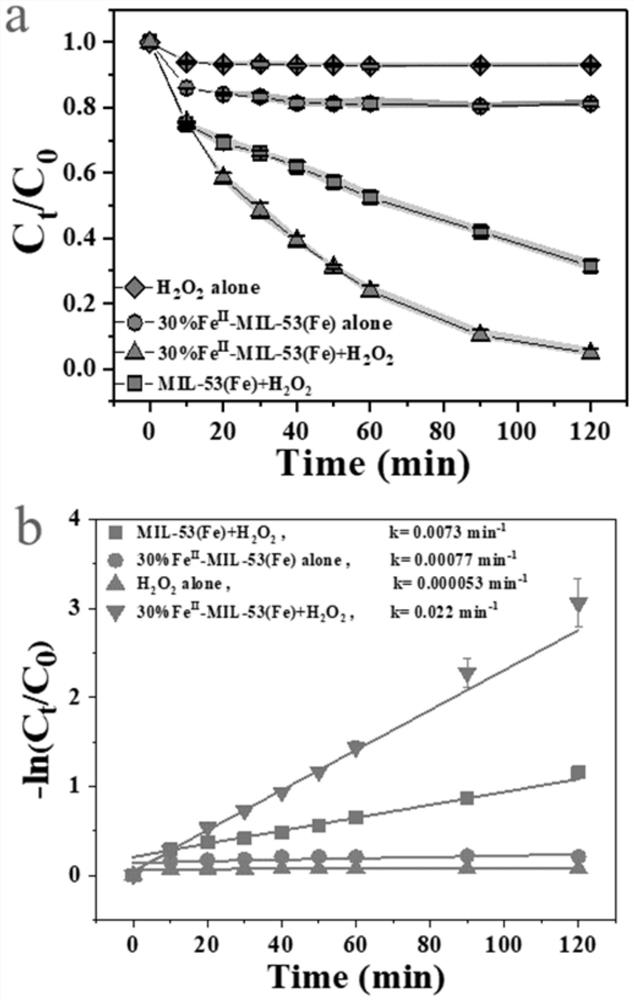

Preparation method, product and application of ferrous doped Fe-MOFs Fenton-like catalyst

PendingCN112206828AHigh heterogeneous Fenton performanceQuick activationWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystFerrous salts

The invention provides a preparation method, a product and application of a ferrous doped Fe-MOFs Fenton-like catalyst. The preparation method comprises the following steps: dissolving an organic ligand in a solvent to obtain an organic ligand solution; adding a mixed metal salt of a ferric salt and a ferrous salt into the organic ligand solution, and conducting uniform stirring to obtain a ferrous doped Fe-MOFs Fenton-like catalyst precursor mixed solution; and carrying out a solvothermal reaction on the mixed solution, and then carrying out solid-liquid separation and solid-phase drying to obtain the ferrous doped Fe-MOFs Fenton-like catalyst. The ferrous doped Fe-MOFs Fenton-like catalyst can improve Fenton-like mass transfer adsorption and catalytic decomposition rate and the efficiency of catalyzing Fenton-like oxidative degradation and mineralizing organic pollutants in water. The catalyst is applied to the field of organic wastewater pollution treatment, the catalytic Fenton-like activity of Fe-MOFs can be improved, the decomposition rate of Fenton-like reactions is promoted, and removal of organic pollutants in water is enhanced.

Owner:ZHEJIANG SCI-TECH UNIV

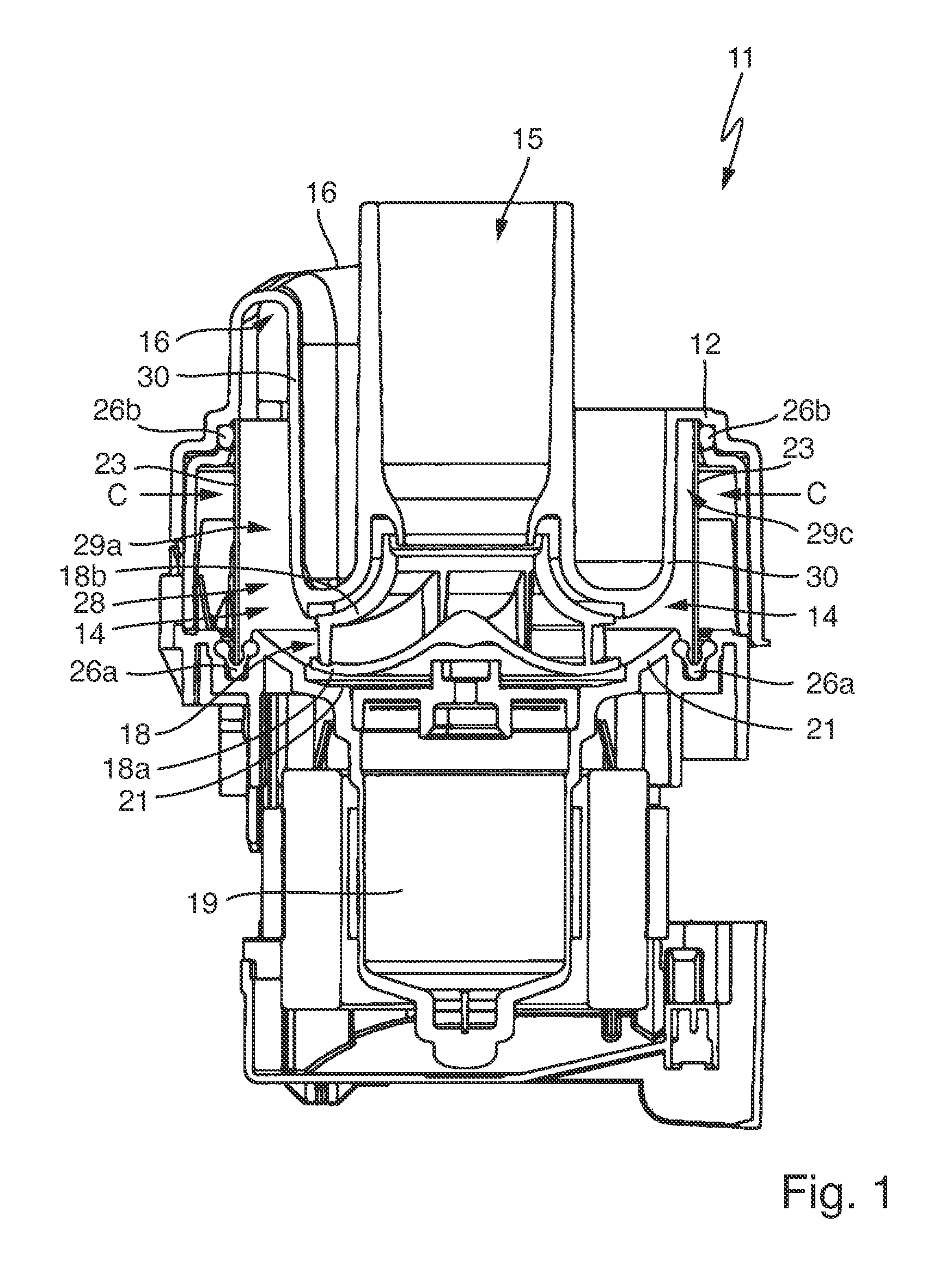

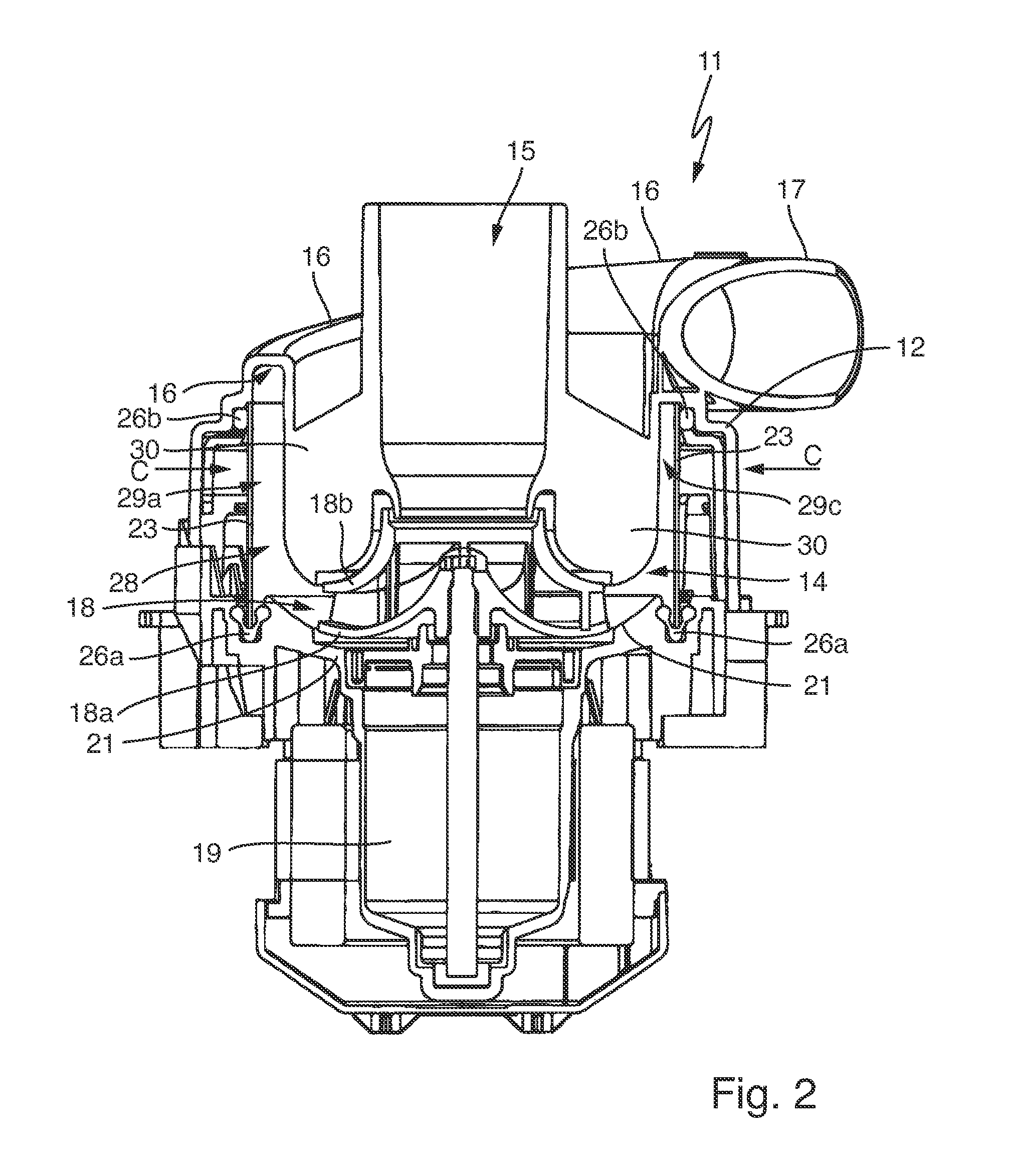

Device and piston for segregating articles

InactiveUS20100070096A1Avoid easy sealingReduce coefficient of frictionEngine sealsPiston ringsEngineeringMechanical engineering

A device and a piston for segregating articles is being disclosed. The device encompasses a segregating element comprising at least one cylinder with a cylinder housing and a piston installed in the cylinder that has at least one valve. A medium can be fed into and discharged from the cylinder via at least one line. The at least one valve interacts with the at least one line so as to create a hard sealing, and a housing sealing element interacts with a piston sealing element so as to create a hard sealing. The piston can used in a device for segregating liquid containers.

Owner:KRONES AG

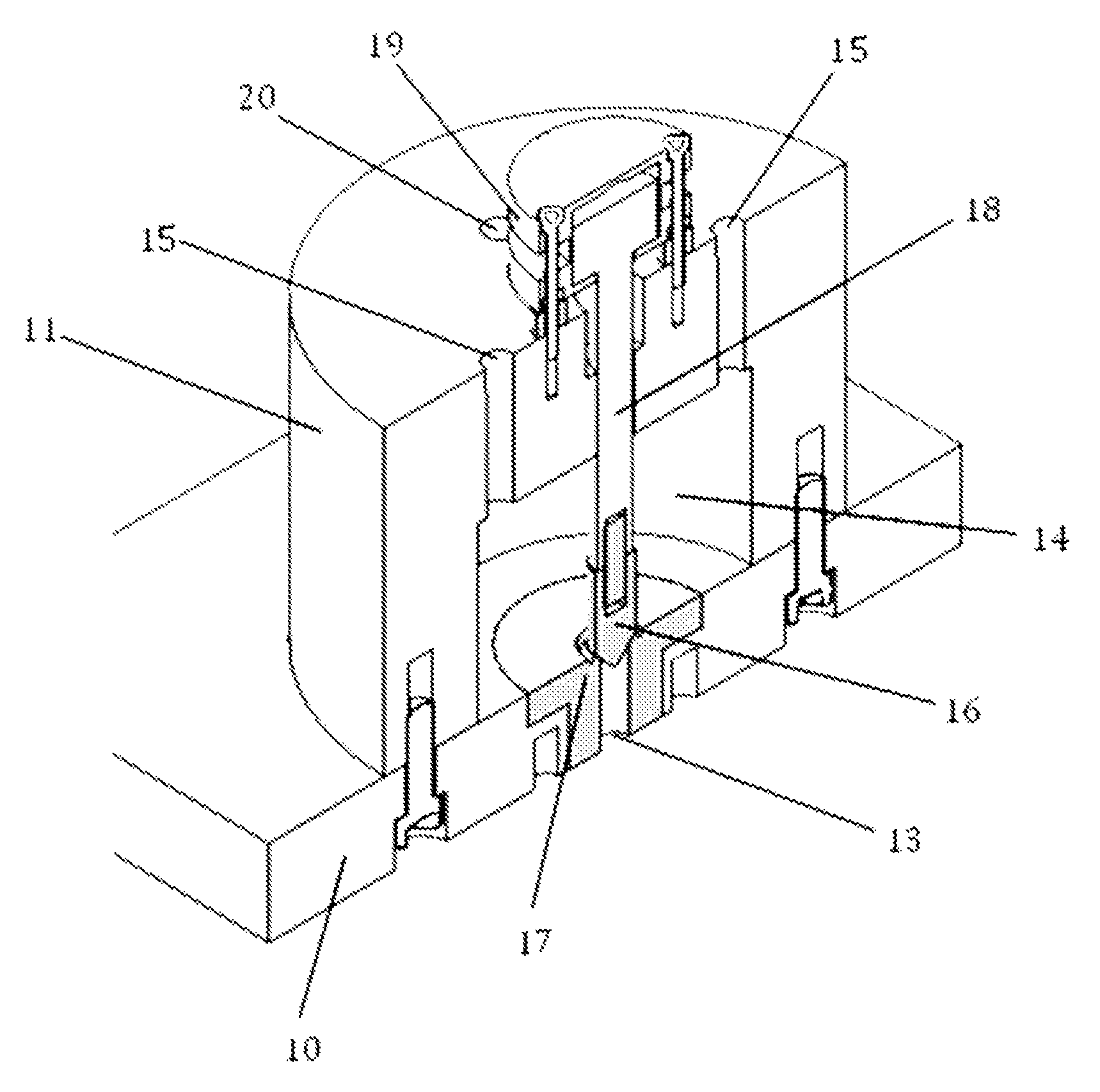

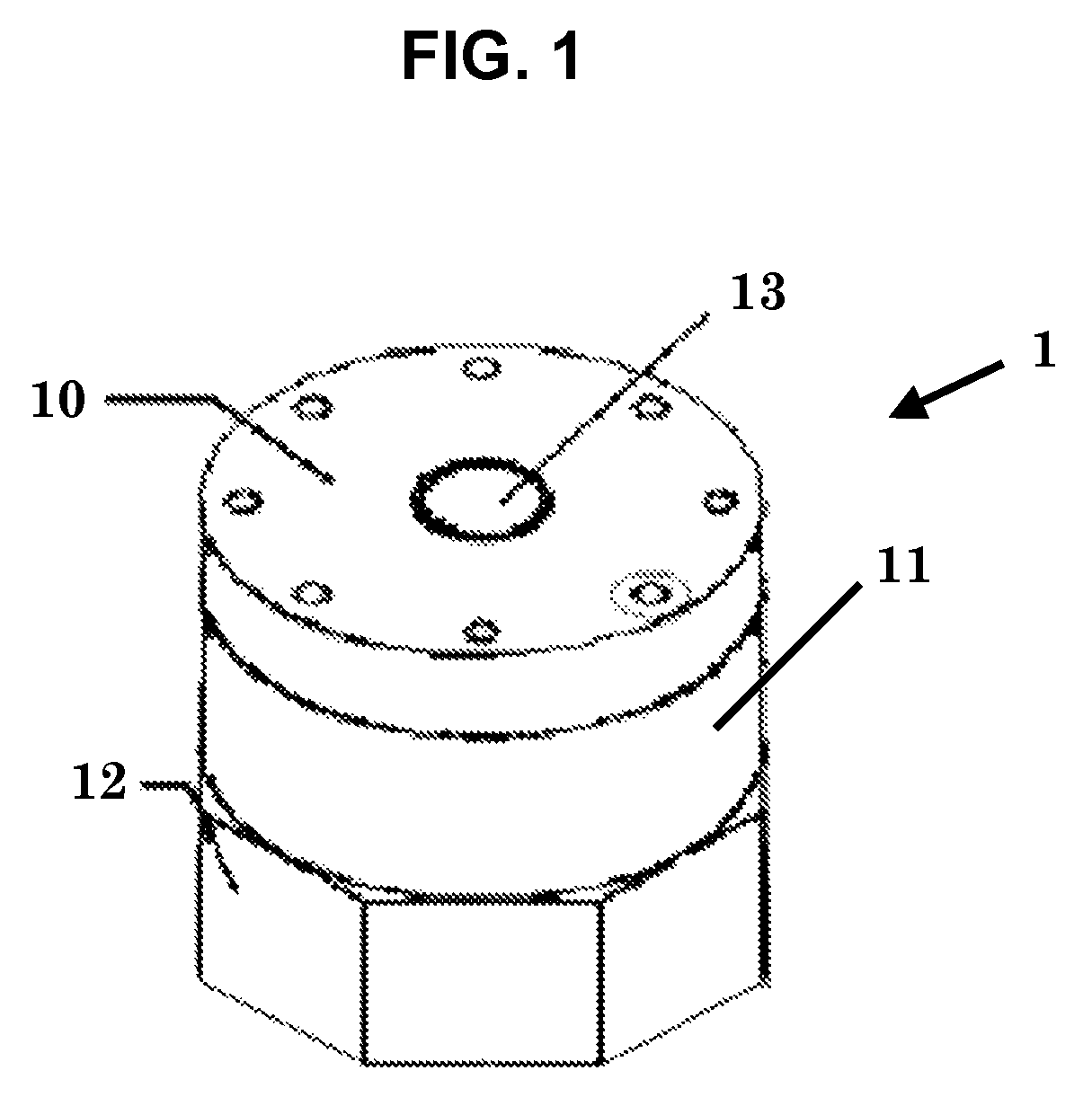

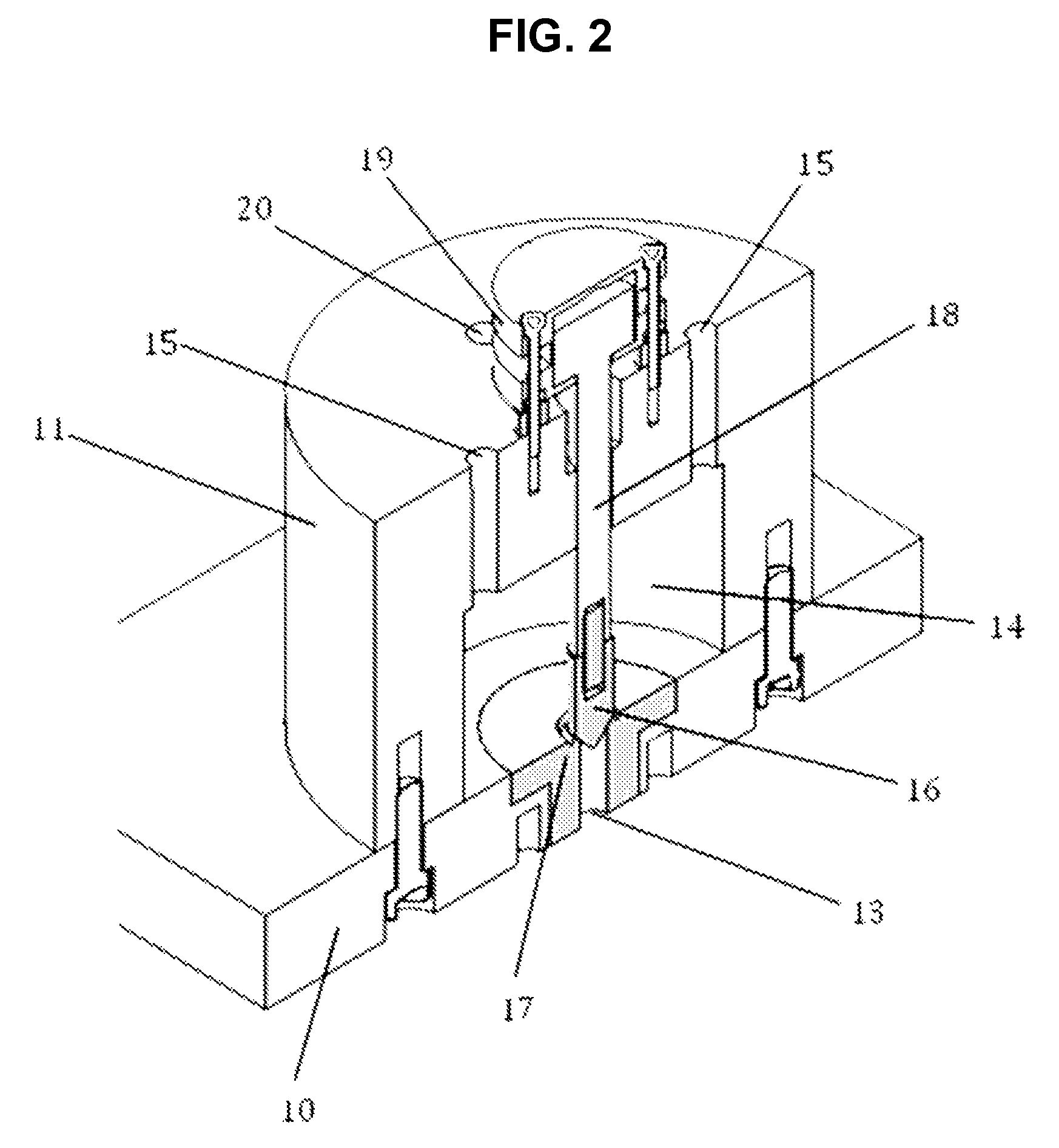

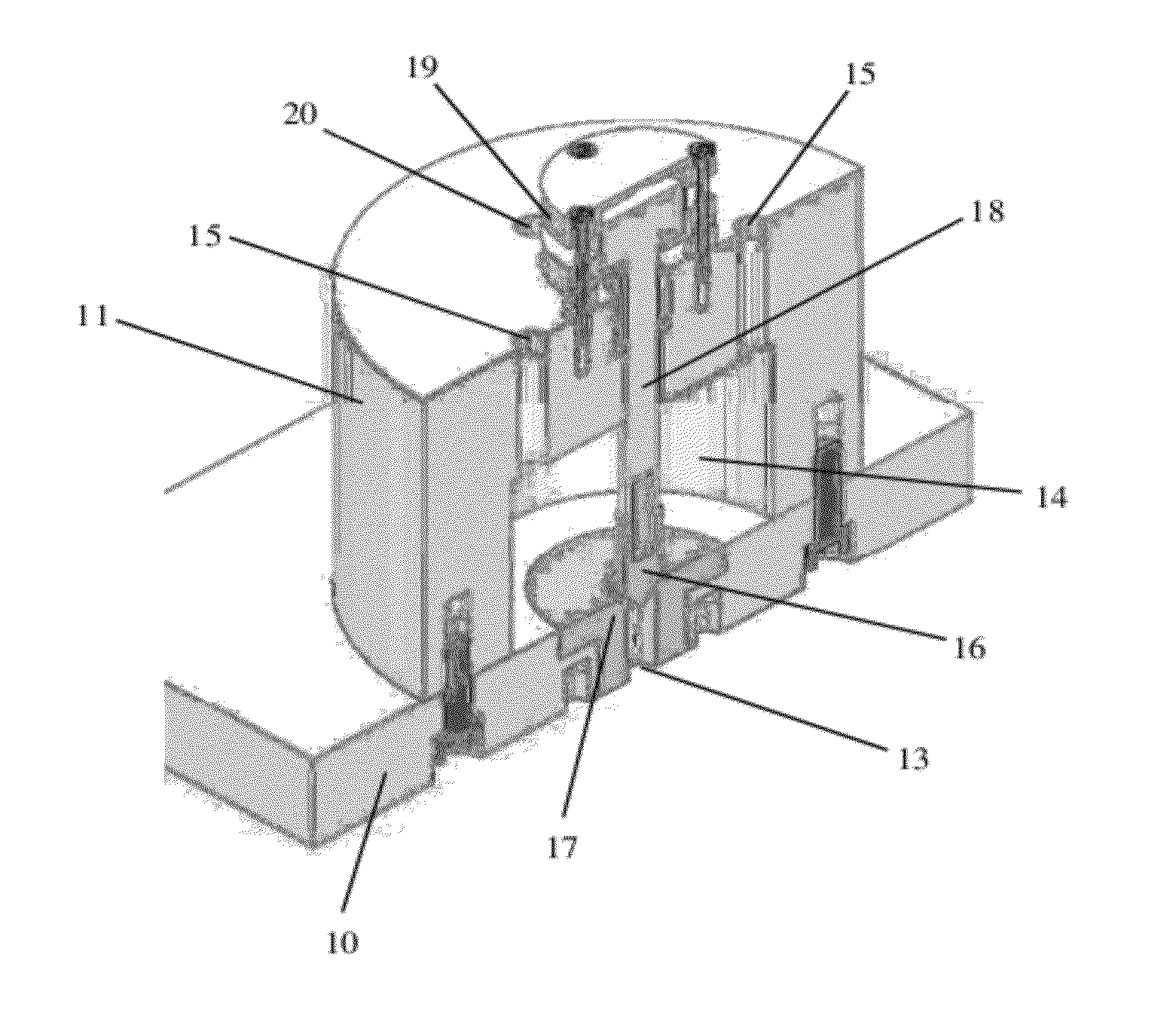

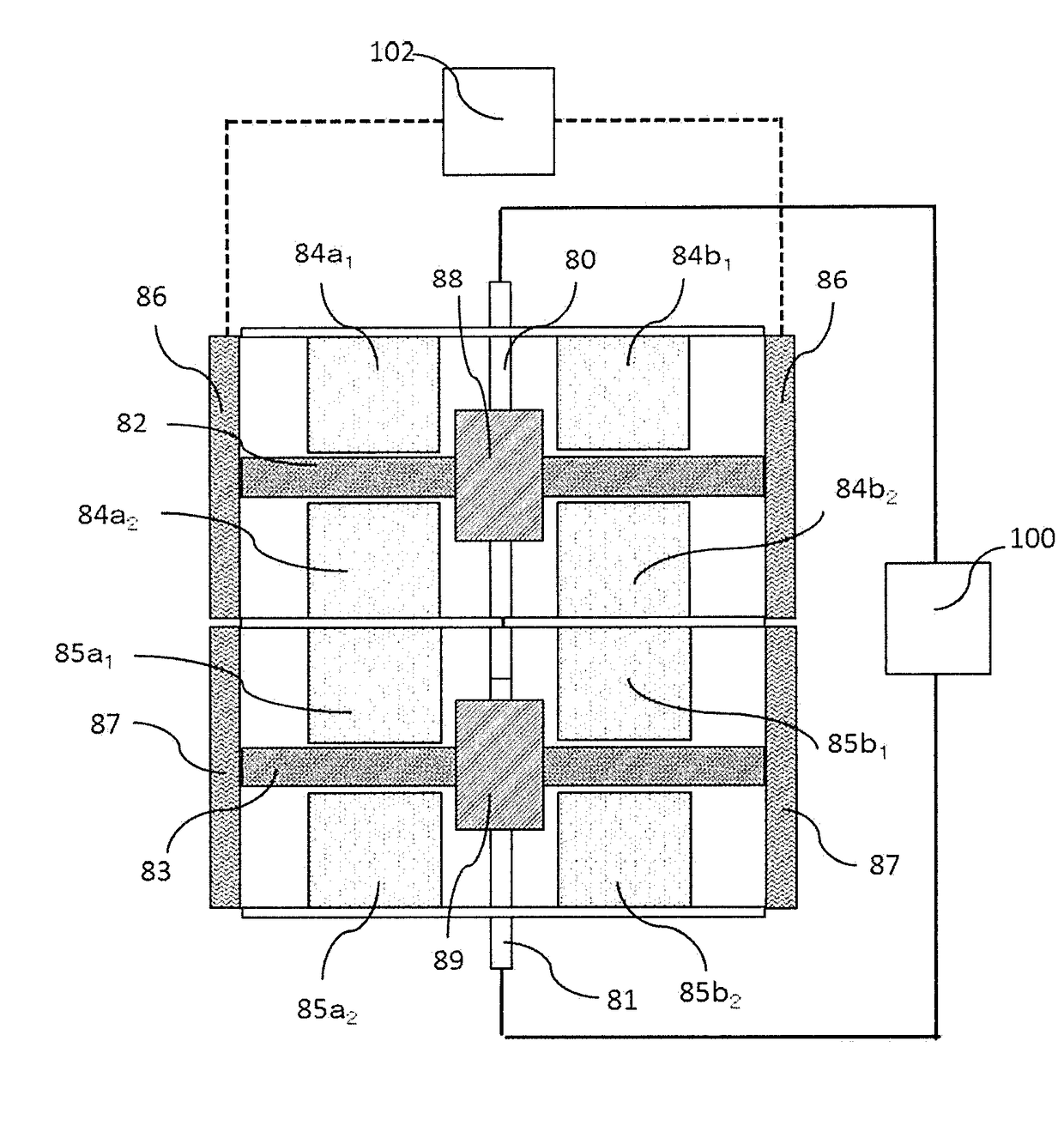

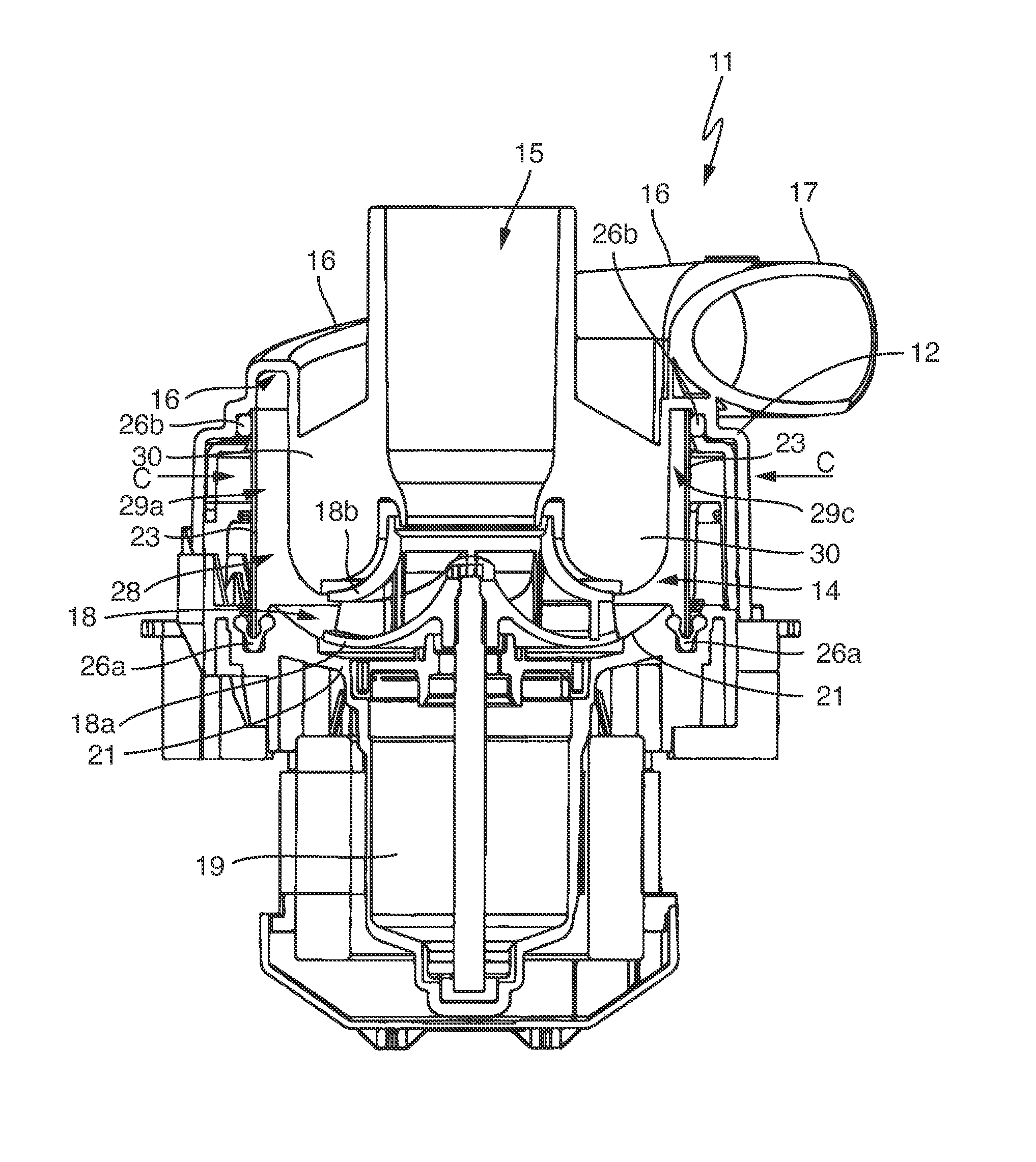

Magnetic refrigerating device

ActiveUS20170130999A1Increase cycle rateEliminate needMachines using electric/magnetic effectsSustainable buildingsRefrigerantMagnet

Magnetic refrigerating device improves refrigerating capacity and efficiency by improving the heat exchanging method between a magnetic material and a heat exchanging fluid and devising a magnetic field applying method. The magnetic refrigerating device comprises: a cylindrical active magnetic regenerator (AMR) bed accommodating refrigerant therein; two magnetic materials disposed in the AMR bed in the axial direction, configured to be movable in the axial direction of the AMR bed, and made of material having a magnetocaloric effect; at least two permanent magnets positioned to face the two magnetic materials; a rotary shaft positioned between the two magnetic materials in the AMR bed and positioned between the at least two permanent magnets; and a magnetic rotary movement unit that rotationally moves the permanent magnets about the rotary shaft and that repeatedly moves the permanent magnets and the two magnetic materials closer together and farther apart in association with the rotational movement.

Owner:NAT INST FOR MATERIALS SCI

Chinese herbal medicinal composition capable of increasing chicken immunity

InactiveCN104258063AStimulate immune activityEnhance phagocytosisPowder deliveryAnimal feeding stuffRadix bupleuriDisease resistant

The invention relates to a Chinese herbal medicinal composition capable of increasing chicken immunity. The Chinese herbal medicinal composition is a powder prepared from the following raw materials in parts by weight: 4-8 parts of Echinacea, 4-6 parts of radix astragali, 2-4 parts of radix bupleuri, 2-4 parts of white atractylodes rhizome, 2-4 parts of sealwort, 2-4 parts of mushroom, 1-3 parts of cherokee rose fruit, 1-3 parts of angelica sinensis, 1-3 parts of the bark of eucommia, and 1-3 parts of licorice, and prepared by the steps of crushing the raw materials, packaging the crushed materials so as to prepare the composition capable of increasing chicken immunity. The Chinese herbal medicinal composition capable of increasing chicken immunity can increase chicken disease-resistant and disease-preventing capability, and increase the immunity well.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Device and a method for magnetizing a magnet system

ActiveUS7324320B2Increase cycle rateImprove productivityElectromagnets without armaturesRelaysElectricityMagnetization

A device for magnetizing a magnet system preferably having several pulse-generator circuits which are mutually arranged so that their magnetic fields superimpose in a cumulative manner. Each pulse-generator circuit includes a capacitor element, a magnetization coil electrically connected to the capacitor element and a switch element by way of which actuation the magnetization coil can be impinged with a current pulse of a limited pulse duration arising by the discharge of the capacitor element, and thus the build-up of a magnetic field may be triggered. The pulse-generator circuit is built up so that the pulse duration of the current pulse is limited to a value between 10 μs and 500 μs. With such short pulse durations, undesirable heating of the magnetization coil is short so that the device may be applied in automatic production installations with cycle times of below 1 s.

Owner:MAURER MAGNETIC

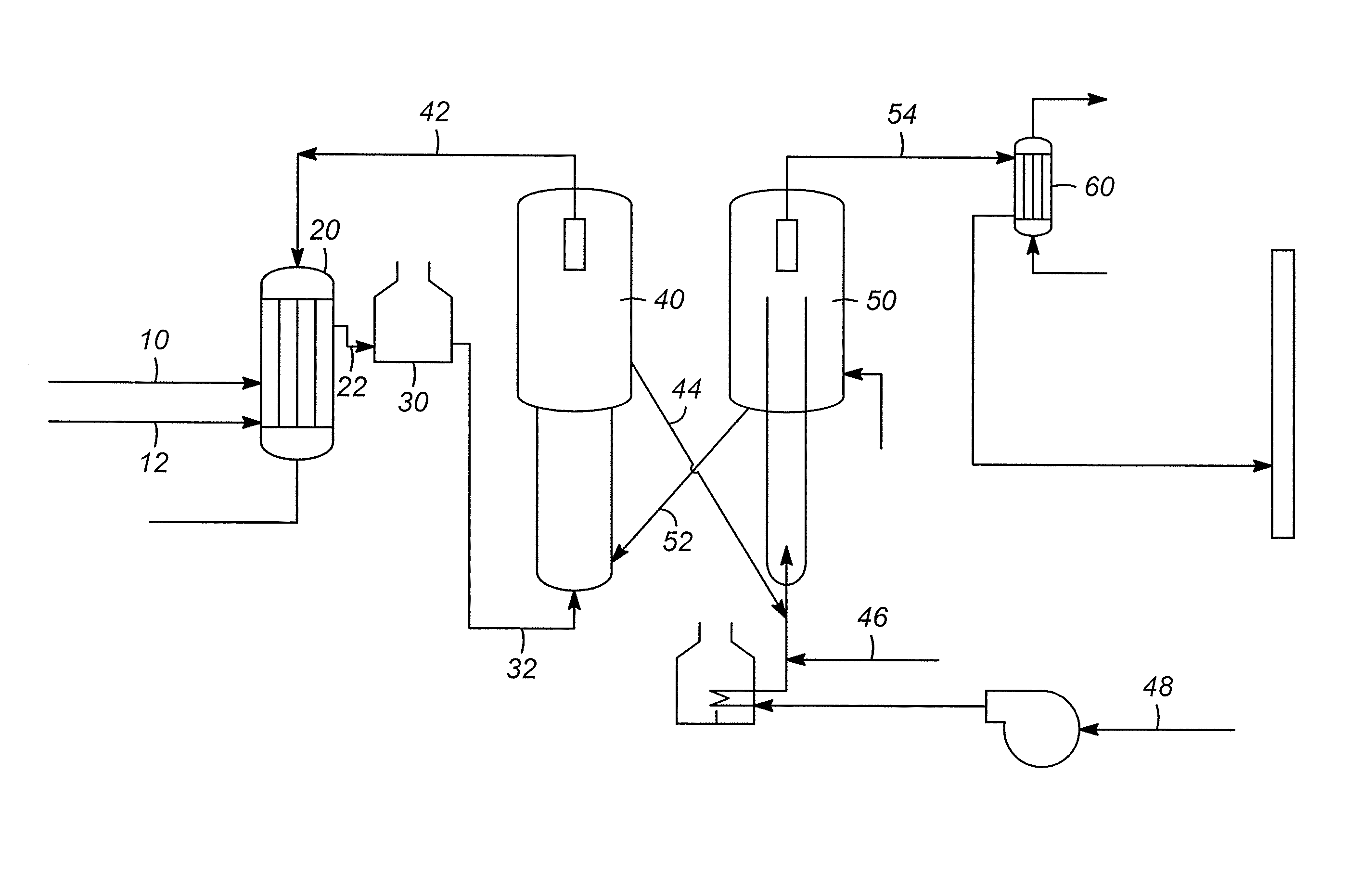

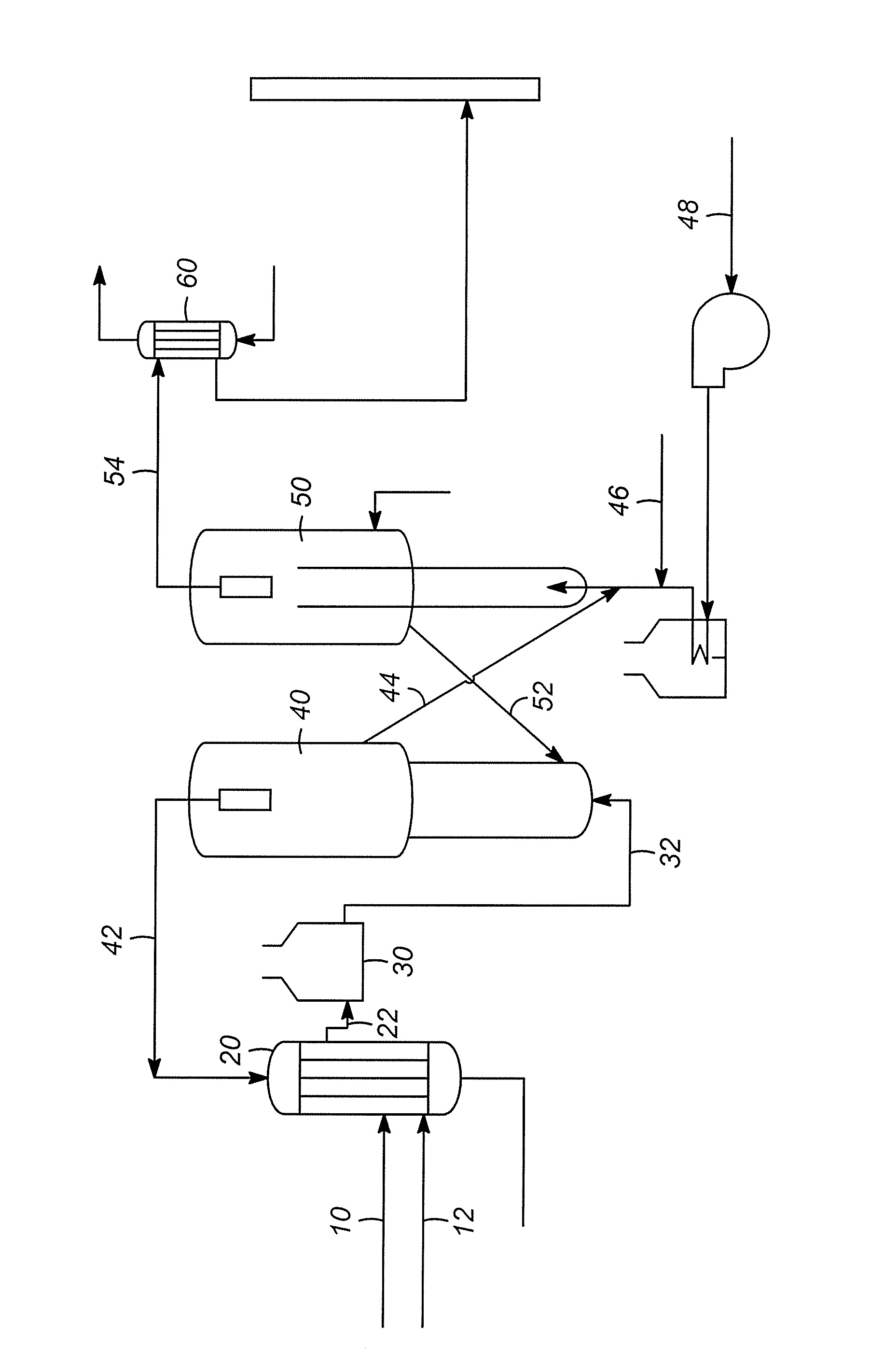

Reactor Flowscheme for Dehydrogenation of Propane to Propylene

ActiveUS20110230698A1Increase productivityHigh cycle rateHydrocarbonsChemical recyclingPARAFFIN HYDROCARBONSChemistry

A process for the dehydrogenation of paraffins is presented. The process utilizes a rapid recycling of dehydrogenation catalyst between the dehydrogenation reactor and the catalyst regeneration unit. The process comprises preheating a combined hydrogen and paraffin hydrocarbon feedstream and passing the combined stream to a dehydrogenation reactor. The hydrocarbon feedstream and the catalyst pass through the reactor at a rate to limit the average residence time of the catalyst in the reactor. The catalyst is cycled to a regeneration unit, and passed through the regeneration unit to limit the average residence time of the catalyst in the regeneration unit.

Owner:UOP LLC

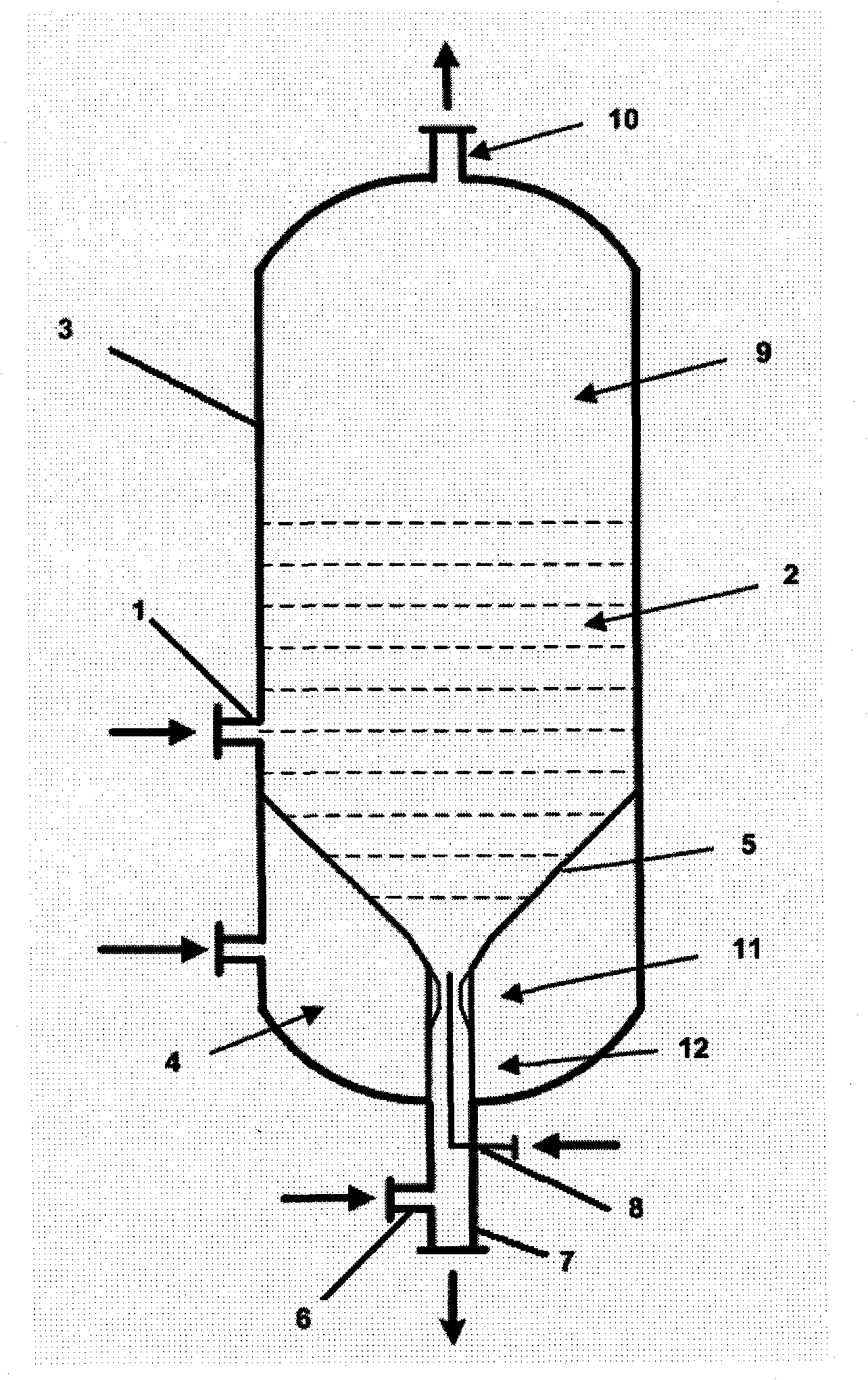

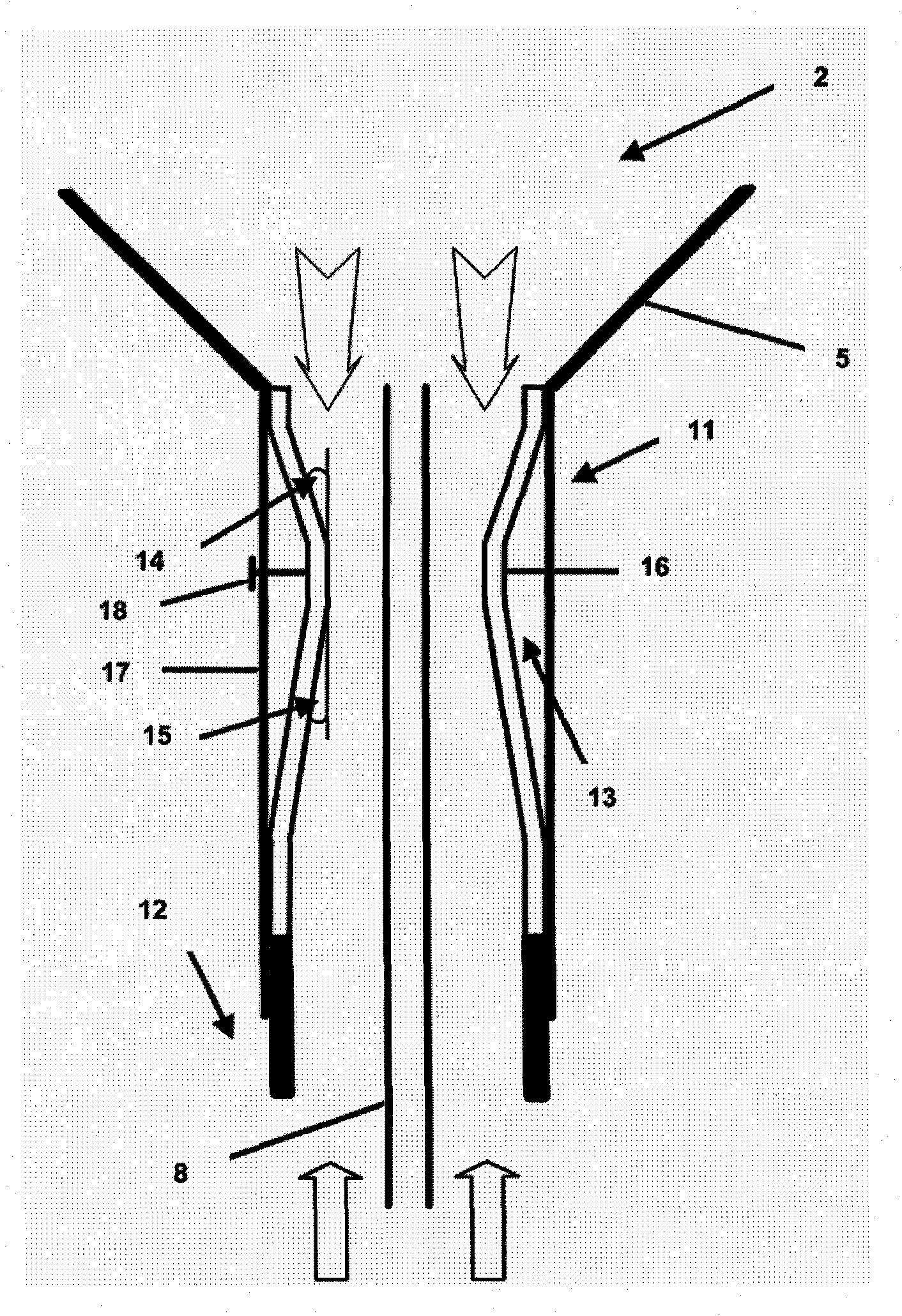

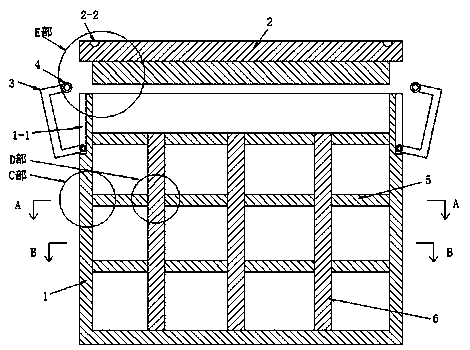

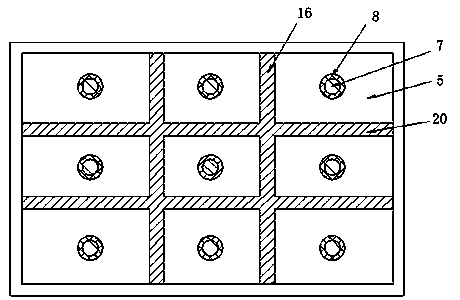

Fluidized bed gasifier with solids discharge and classification device

InactiveCN102083521ASpread evenlyIncrease cycle rateGasifier feeding meansGasifier mechanical detailsFluidized bed gasifierFluidized bed

The present invention provides an apparatus for withdrawing solids from a fluidized bed reactor, comprising a venturi tube connected to the stem end of a funnel-shaped distribution plate, and a center jet pipe enclosed within the venturi, wherein a jet stream of feed gas is delivered above the venturi throat. Preferably, the distribution plate is equipped with multiple horizontally- or downwardly- oriented grid holes through which the feed gases flow and enter the fluidized bed, which holes may be covered by metal plates to prevent solids from weeping through grid holes and falling into the plenum below the distribution plate. The venturi is preferably engineered to be readily removable from the rest of the gasifier reactor for repair or replacement. Also provided is a fluidized bed reactor comprising the above apparatus.

Owner:SYNTHESIS ENERGY SYST

Cold-chain logistics conveying and transferring equipment

InactiveCN109229753AAvoid non-circulationAvoid the possibility of qualitative changeLiving organism packagingDomestic cooling apparatusCold chainLogistics management

The invention discloses cold-chain logistics conveying and transferring equipment, and relates to the technical field of cold-chain logistics. Multiple partition plates are arranged in a cold-chain box in sequence from top to bottom, the left side and the right side of each partition plate are erected on an L-shaped support frame, the L-shaped support frame is fixed to sliding blocks which are slidably arranged on sliding rails, the sliding rails are fixed to the left inner side wall and the right inner side wall of the cold-chain box respectively, and the side walls of the sliding blocks arescrewed and fixed to the sliding rails through positioning bolts, cool air delivery columns penetrate through the multiple partition plates in sequence from top to bottom, and the bottoms of the coolair delivery columns are erected at the inner bottom of the cold-chain box; the cool air delivery columns are composed of heat conducting silica gel columns and metal support columns, the metal support columns penetrate through the partition plates, and the heat conducting silica gel columns are inserted into the metal support columns. Goods needing to be subjected to cold-chain transportation canbe separated, mutual stacking between the goods is effectively avoided, the ventilation performance is poor, the cold storage effect is affected, the quality safety of the goods during transportationis effectively guaranteed, and the practicability is higher.

Owner:YIBIN UNIV

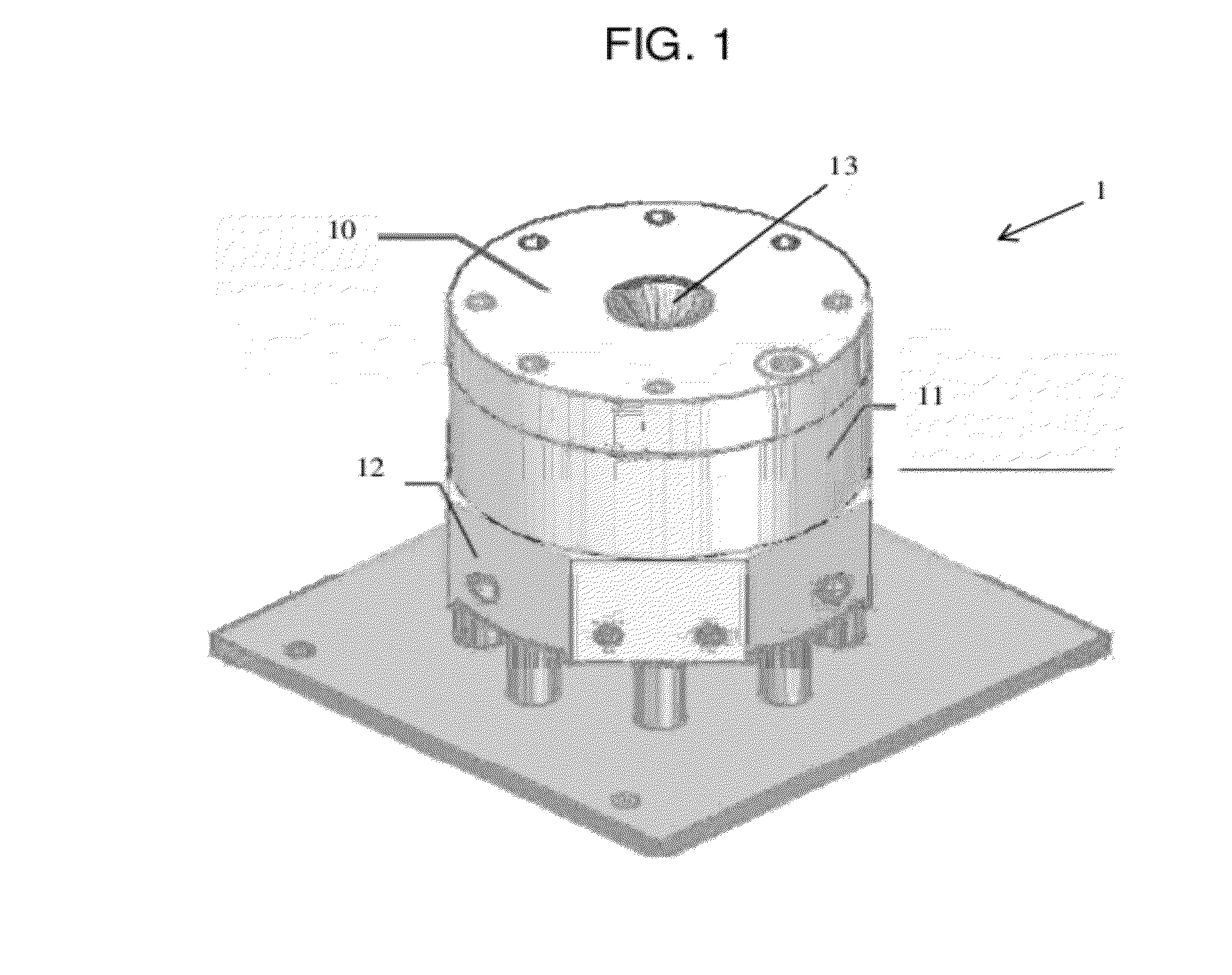

Ceramic-metal assembly and ceramic heater

InactiveUS20060283849A1Improve adhesionIncrease cycle rateHeater elementsHot plates heating arrangementsSecondary layerCeramic metal

A ceramic-metal assembly including: a ceramic base; an electrode pad provided on a surface of the ceramic base; a connection terminal for external electrical connection; and a joining portion which joins the connection terminal to the electrode pad. The electrode pad has a first layer which is in contact with the ceramic base and a second layer which is in contact with the joining portion. The first layer contains 20 to 50 vol % of a ceramic component, and the second layer contains a component of the joining portion.

Owner:NGK SPARK PLUG CO LTD

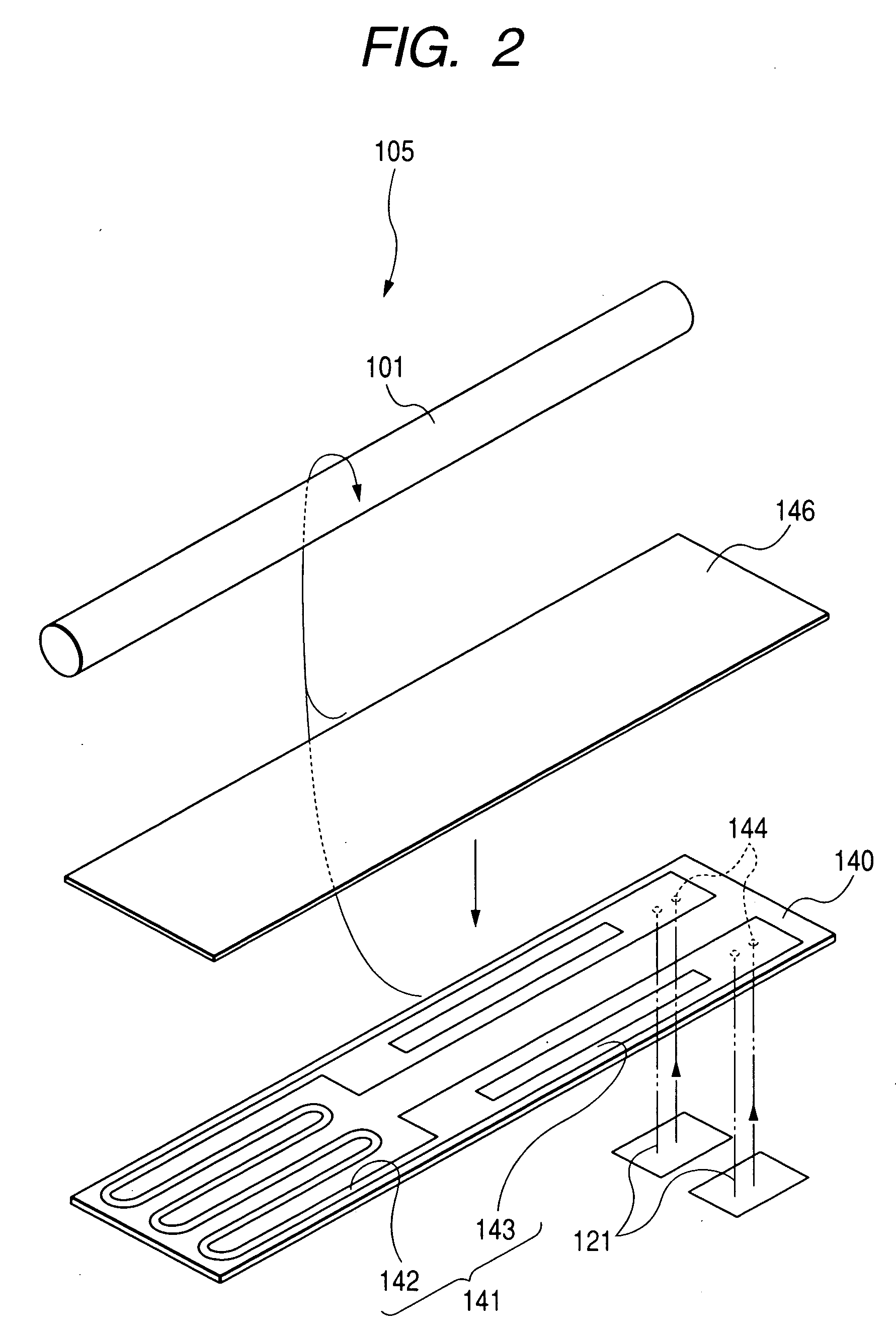

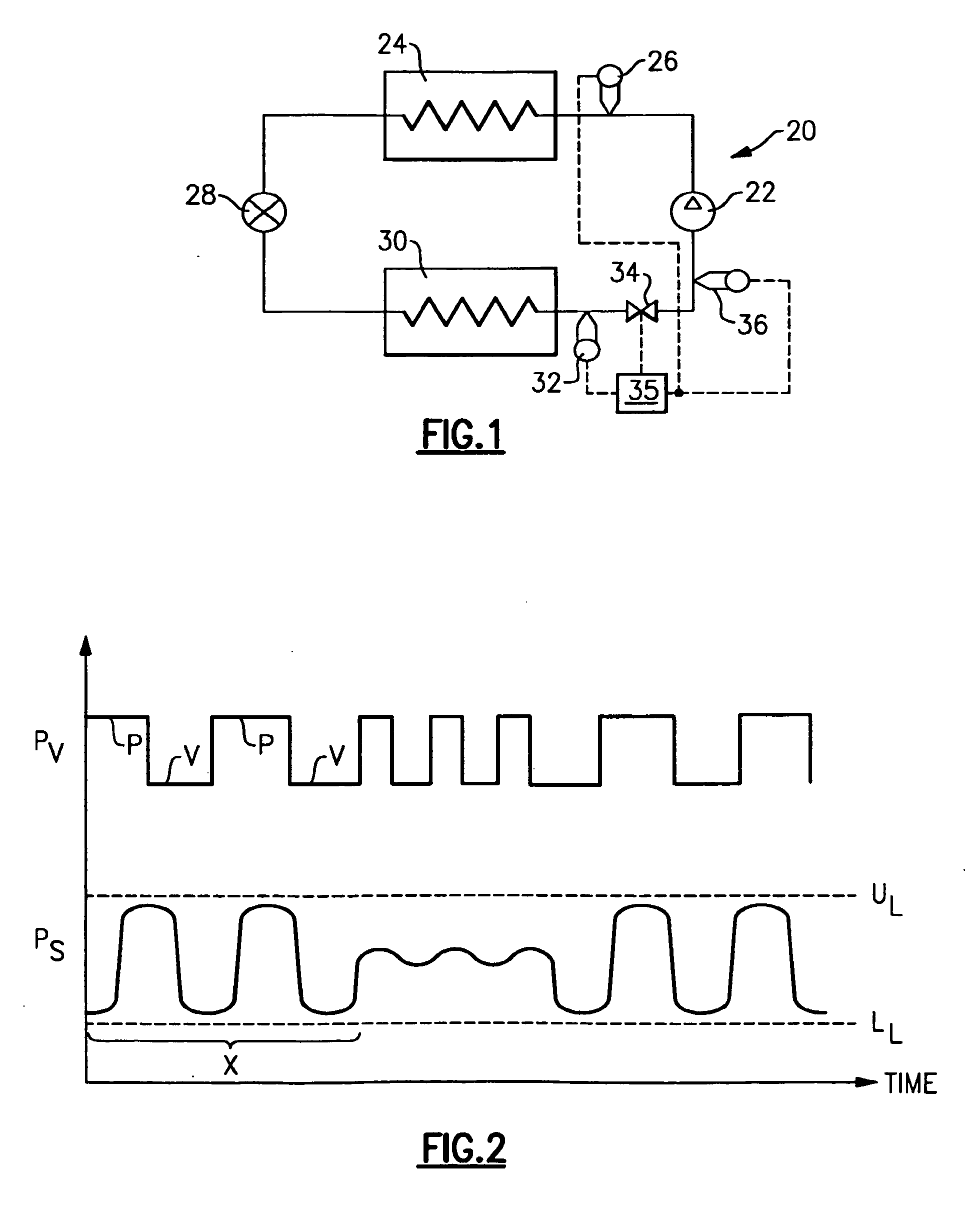

Suction valve pulse width modulation control based on evaporator or condenser pressure

ActiveUS20100058799A1Suppress pressure fluctuationsIncrease cycle rateMechanical apparatusCompression machines with non-reversible cycleSystem pressureRefrigerant

A refrigerant system is provided with a suction pulse width modulation valve, and a pulse width modulation control for controlling this valve. System pressures, such as the pressure on the evaporator and the condenser are monitored. The measured system pressures are maintained within a band of acceptable lower and upper limits. As the pulse width modulation control cycles the valve, the refrigerant pressures in the evaporator and the condenser tend to fluctuate. The control ensures those fluctuations are within the limits by controlling the duty cycle of the valve.

Owner:CARRIER CORP

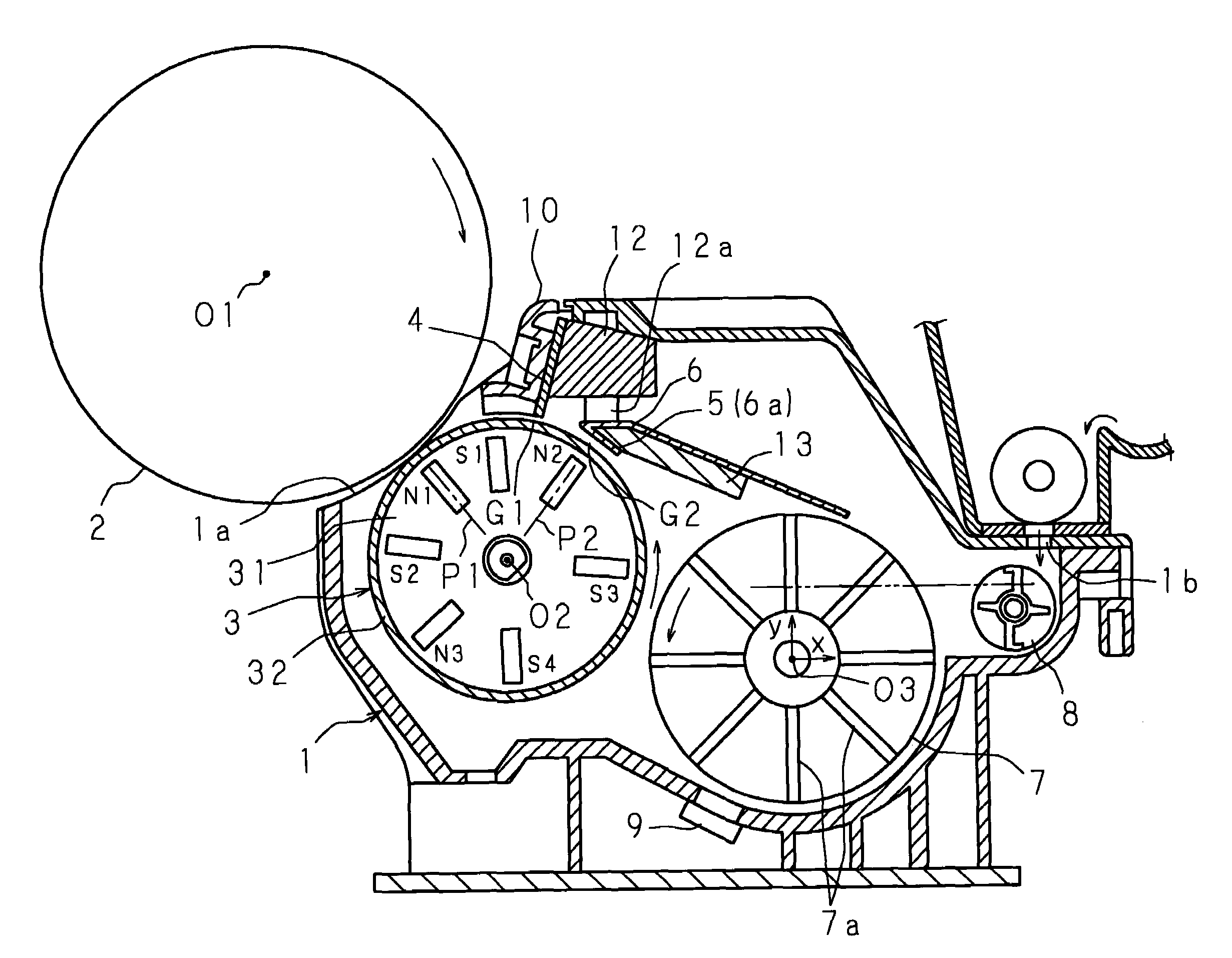

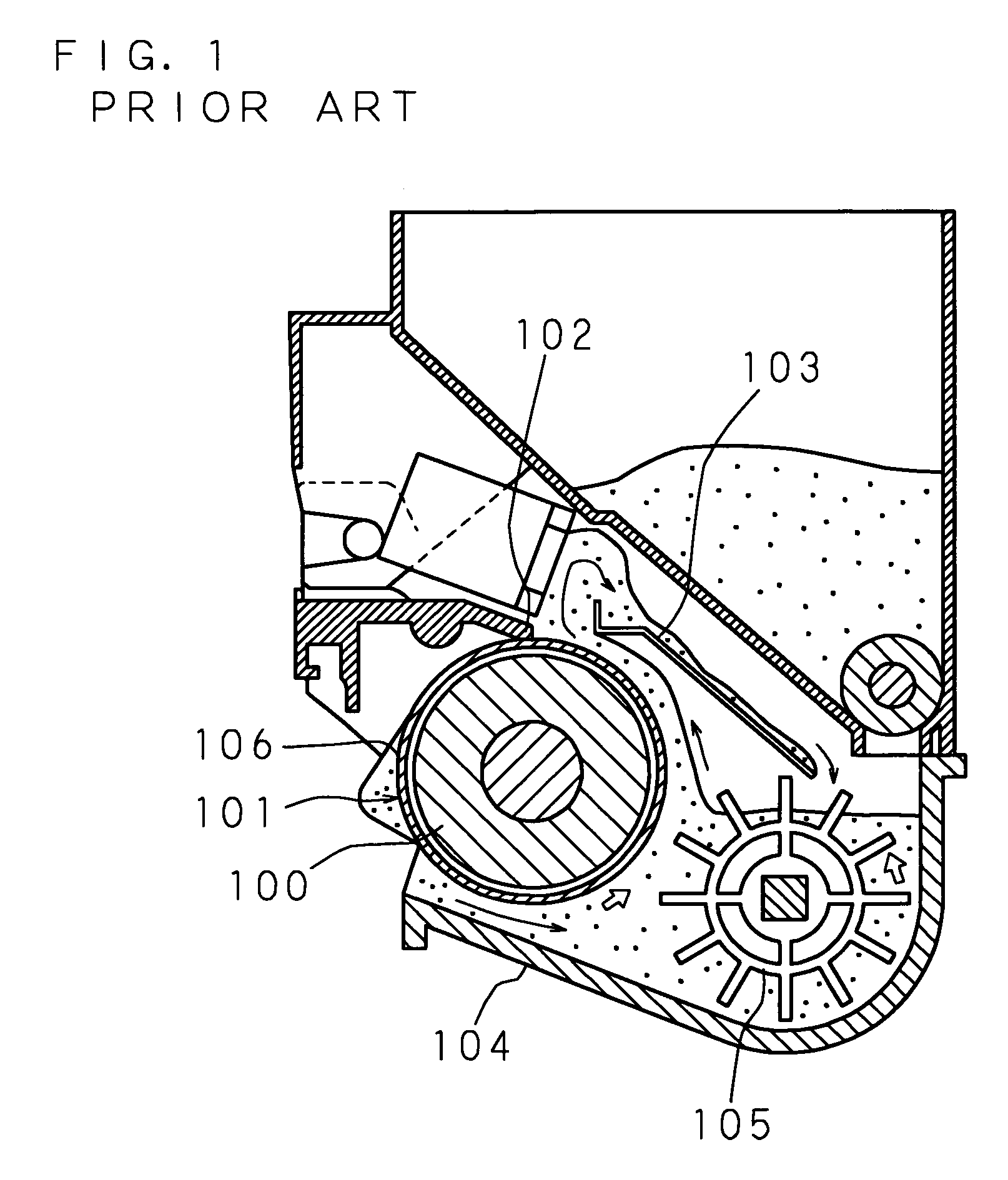

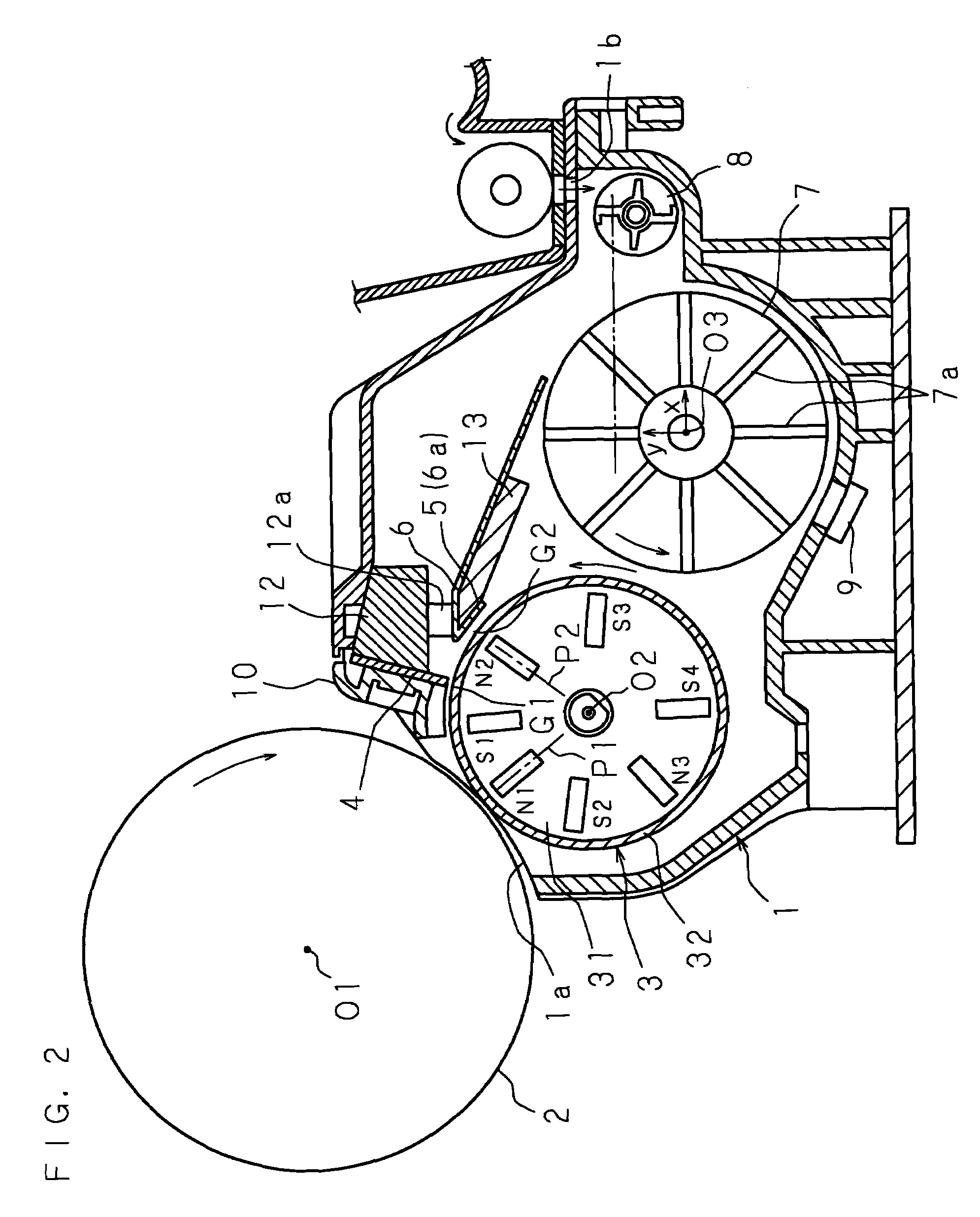

Developing device and image forming device

InactiveUS7620351B2Increase cycle rateImprove image qualityElectrographic process apparatusLatent imageImage formation

A developing device comprises a stirring roller 7 having stirring blades 7a for stirring a developer, a developing roller 3 for transferring the developer to an electrostatic latent image, a control member 4 for controlling the amount of developer transferred from the developing roller 3 to the electrostatic latent image, a reflux plate 6 by which the excess developer resulting from control by the control member 4 is flowed back to the stirring roller 7, one end portion of the reflux plate 6 being disposed in the vicinity of the outer periphery of the stirring roller 7, part of the developer stirred by the stirring roller 7 flying toward the reflux plate 6, wherein said one end portion of the reflux plate 6 is disposed at a position remote from the stirring roller 7 over a distance greater then the maximum fly distance of the developer provided by rotation of the stirring roller 7.

Owner:SHARP KK

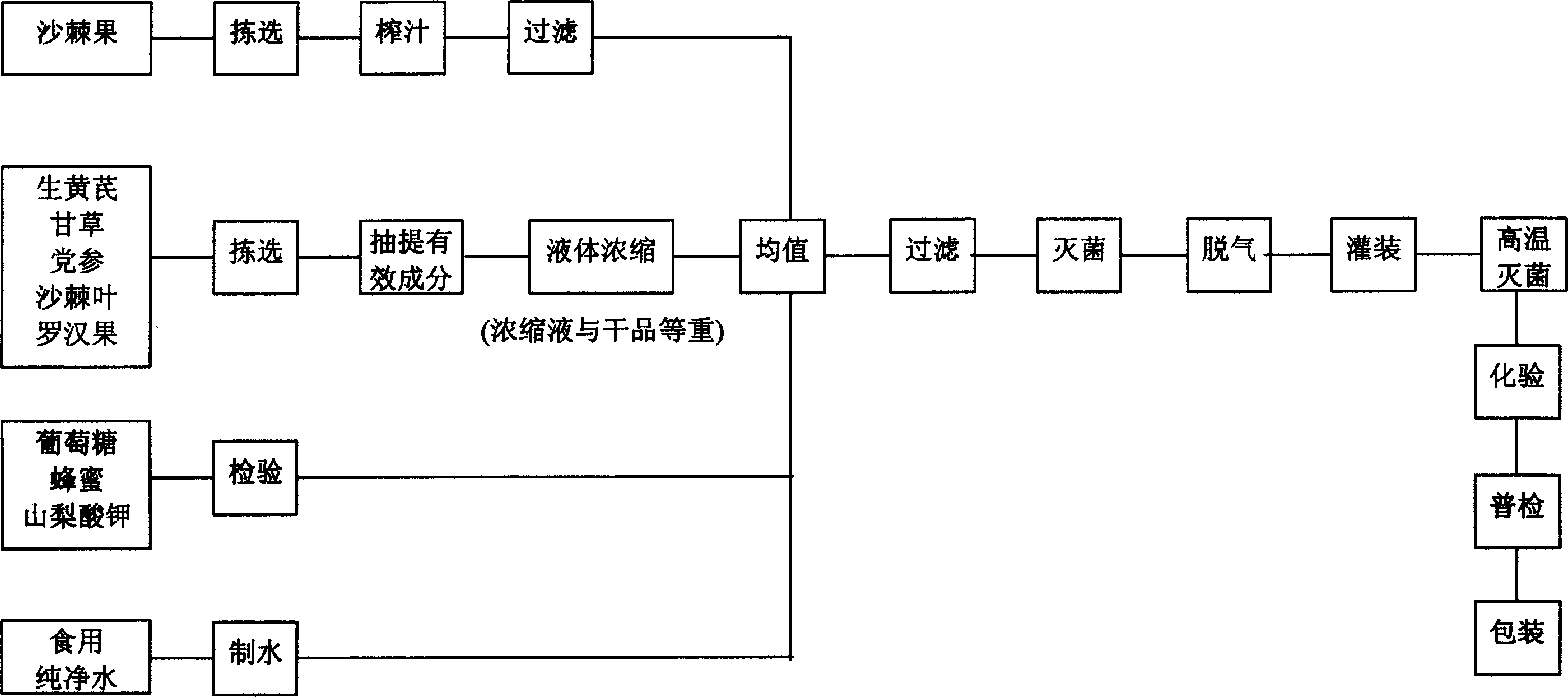

Sea-buckthorn astragalus root beverage

A sea-buckthorn and milk vetch root beverage for preventing SARS, characterized in that the beverage mainly comprises sea-buckthorn fruit juice, raw astragalus root and flavoring agent, wherein the percentage by weight of each constituent are, seabuckthorn fruit juice 0.5-5%, raw astragalus root 0.8-3%, flavoring agent 1-30%, the rest for drinking water. The functional beverage possesses the effect of enhancing human body resistance to diseases, and has good taste.

Owner:任志田

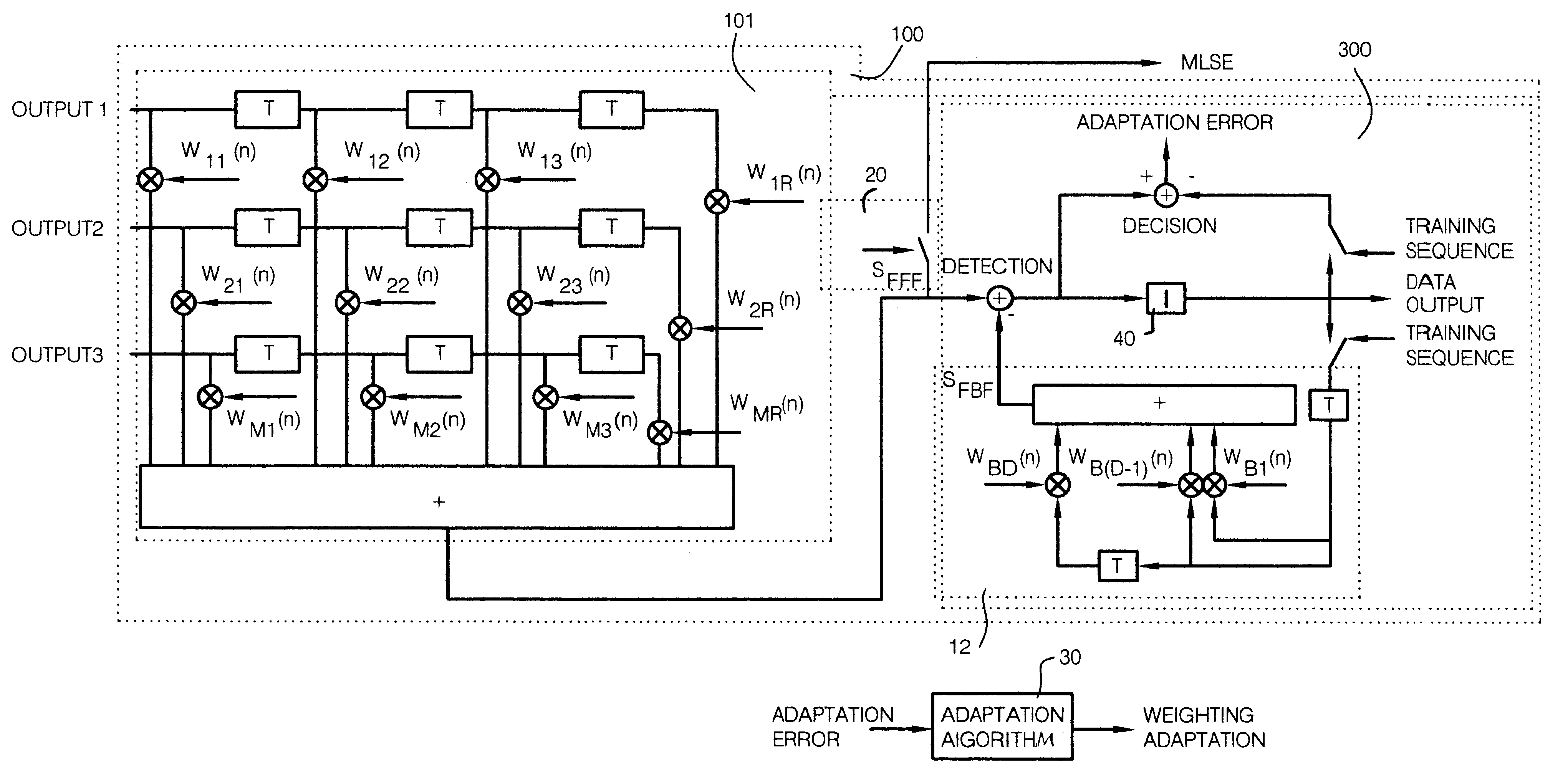

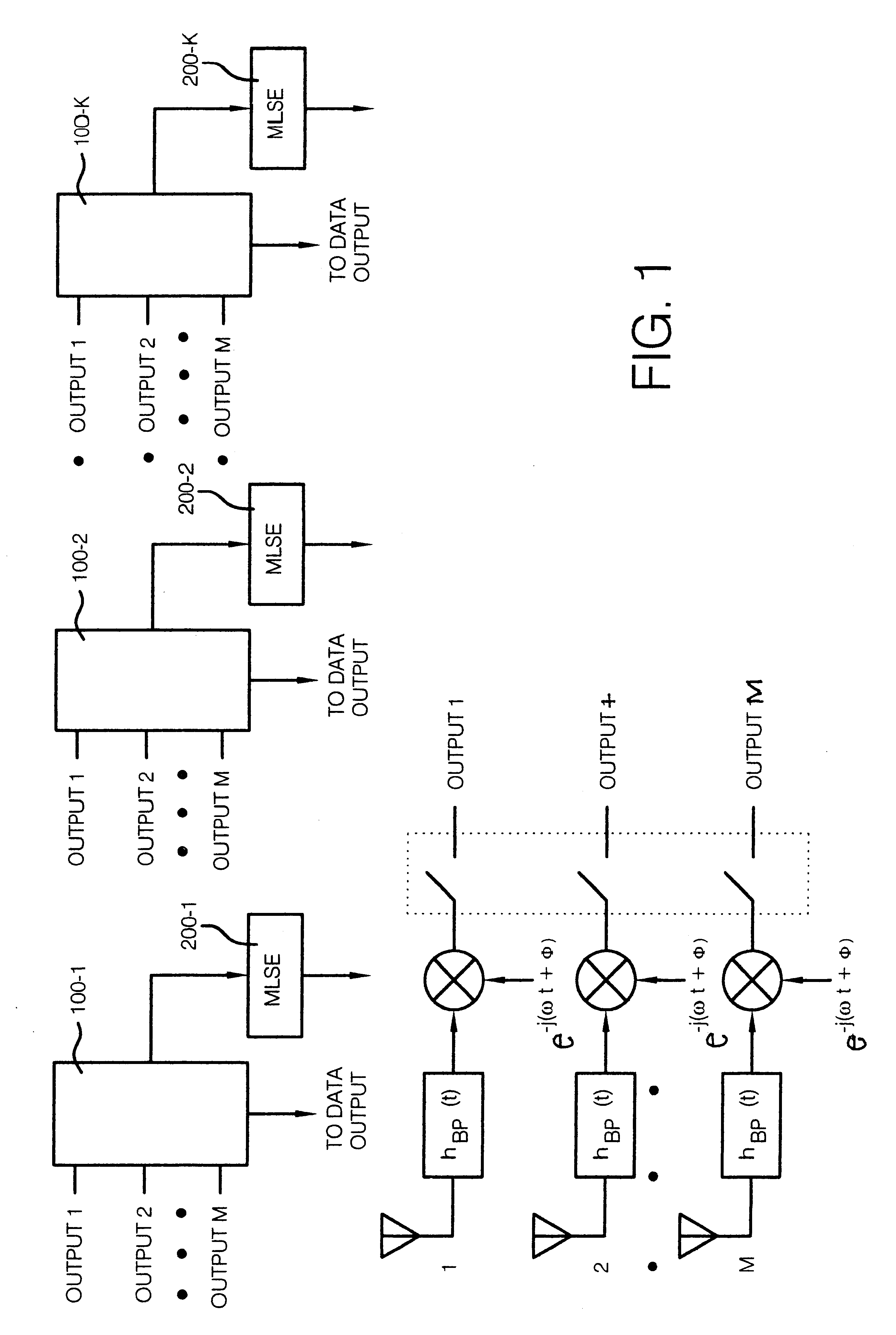

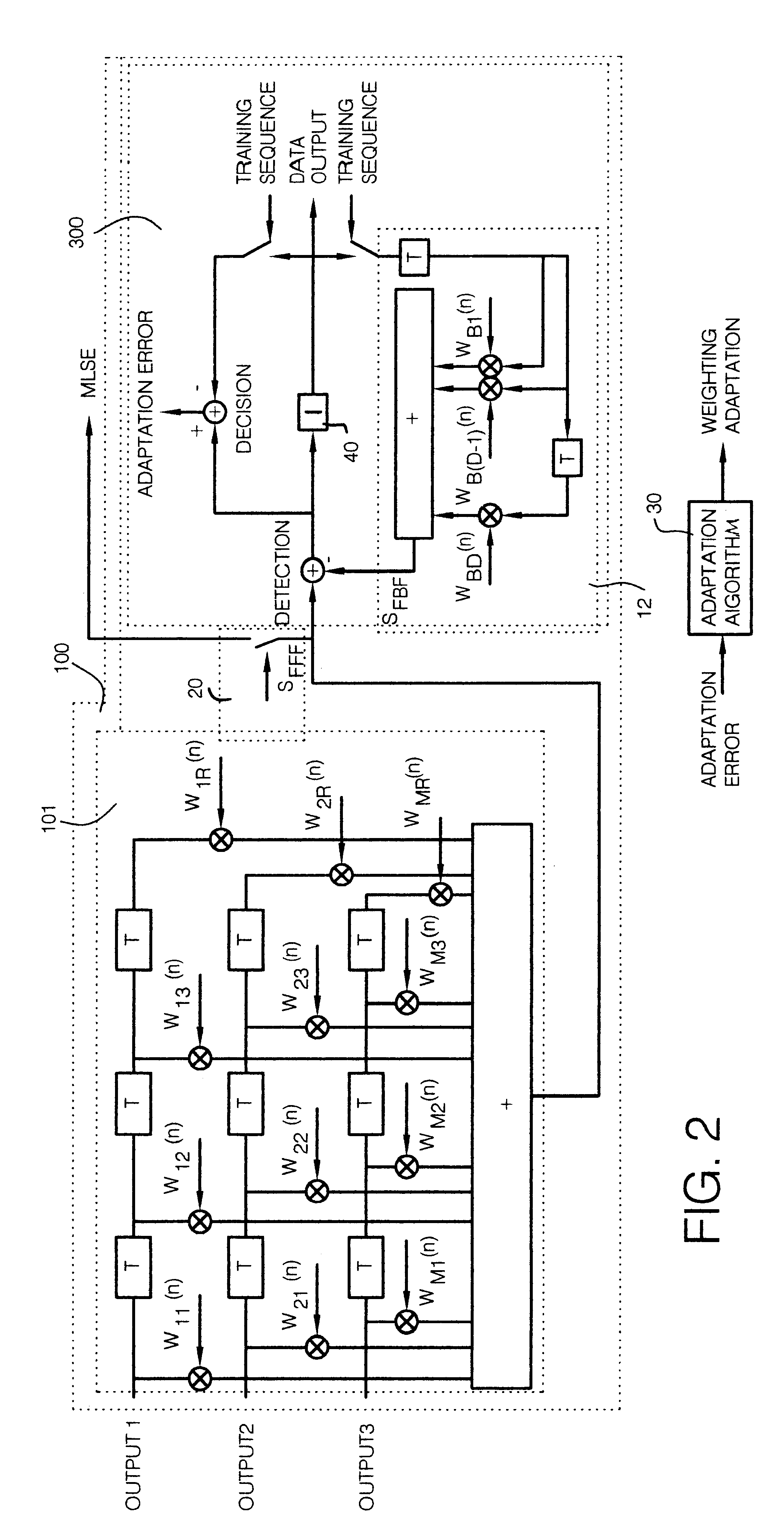

Process and device for the increase of subscriber capacity in a cellular mobile radio network

InactiveUS6345075B1Increase capacityImprove bindingSpatial transmit diversityPolarisation/directional diversityDecision circuitMobile radio

For each K subscriber of a cellular mobile radio network who is supplied with one and the same frequency and one and the same time slot a decision-feedback and therefore non-linear antenna pre-processing facility with a decision-feedback structure is used comprising forward filters backward filters and decision circuits for the adaptation of the antenna weighting factors, wherein the backward filters are adapted to the length of the processing window D of MLSE, and the output signals of the forward filters for the actual data detection are taken to the MLSE of the subscriber concerned, before the subtraction of the feedback component takes place. Each of the receiver structures similar to K can be adapted and operated independently from the other K-1 structures. A common vectorial MLSE for the common data detection of all K subscribers can be employed.

Owner:TELEKOM AUSTRIA

Apparatus for collecting and conveying stacks of sheets

InactiveUS8066468B2Increase cycle rateWithout disturbing and degrading stack quality of stackPile receiversPackagingEngineeringMechanical engineering

The invention relates to collecting and conveying devices for stacks of sheets (3), comprising a collecting station (1) in which a corresponding number of sheet stacks (3) are formed simultaneously from several imbricated flows (2) of sheets which are guided adjacent to each other, a transversal transporter (4) which is arranged at a distance behind the collecting station (1) for transporting the finished stack of sheets (3) in a manner transversal to the direction of transport of the sheets in the collecting station (1) and a transfer device (5) which is used to transport the stack of sheets (3) from the collecting station (1) to the transversal transporter (4). According to the invention, a carriage (9) that can be displaced over a given path in a manner that is synchronous with the transversal support (4) is arranged adjacent thereto. Also, a row of holding down clamps (10) is secured to said carriage and the holding down clamps can be lowered on the stack of sheets (3) located on the transversal transporter (4).

Owner:BIELOMATIK LEUZE GMBH & CO

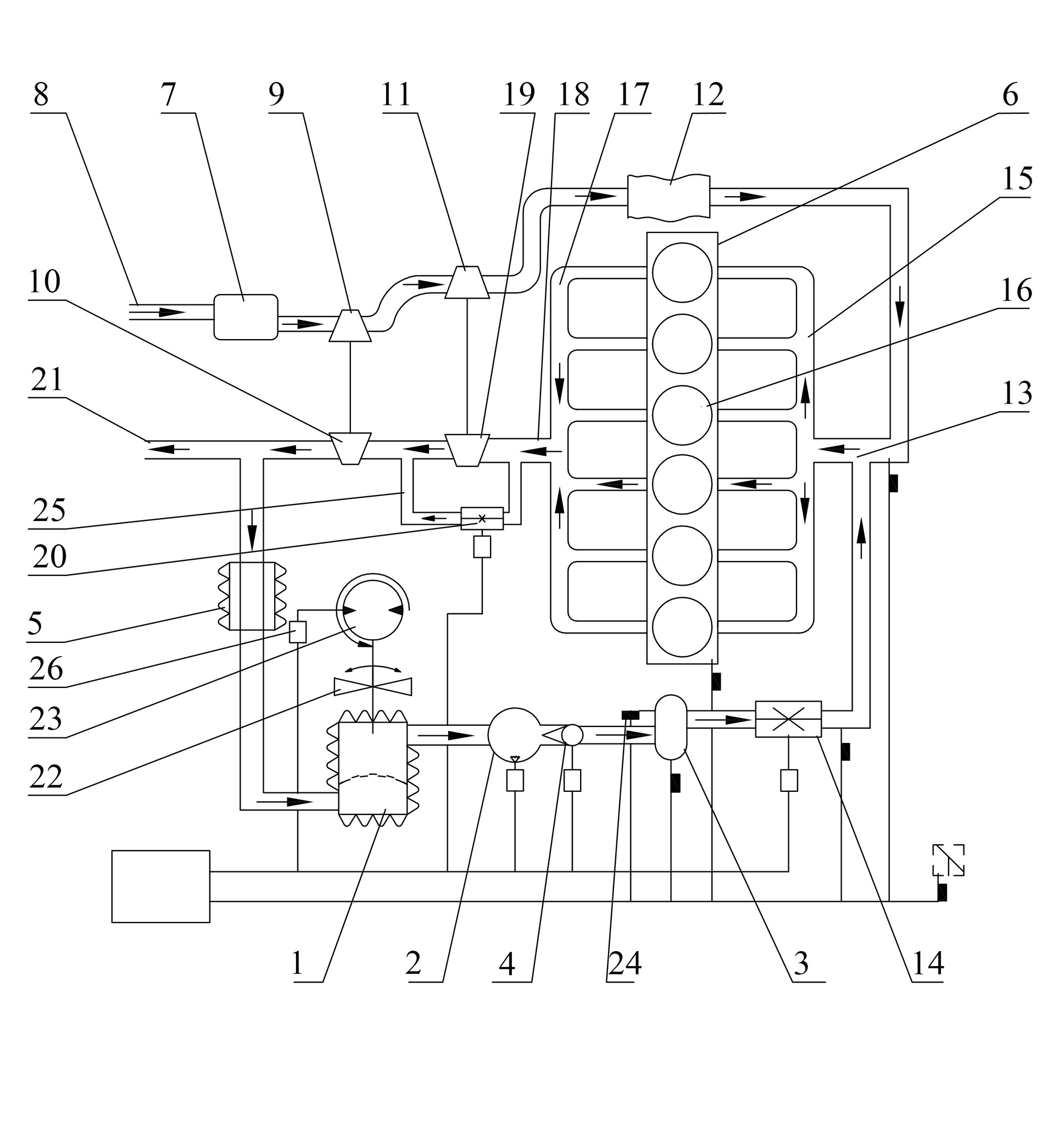

Exhaust gas recirculation system for internal combustion engine

InactiveCN101956633AIncrease EGR rateShorten the lengthNon-fuel substance addition to fuelInternal combustion piston enginesExternal combustion engineInternal combustion engine cooling

The invention discloses an exhaust gas recirculation system for an internal combustion engine. The exhaust gas recirculation system comprises a cooling component, a gas compressor and a gas storage tank which are connected in turn; a gas inlet end of the cooling component is communicated with an exhaust pipe of the internal combustion engine; and a gas outlet end of the gas storage tank is communicated with a gas inlet of the internal combustion engine. The exhaust gas recirculation system has the advantages of simple and compact structure, low cost, stable and reliable work, quick exhaust gas recirculation response, capability of effectively reducing harmful emissions of the internal combustion engine, accurate control on recirculation exhaust gas amount and the like.

Owner:HUNAN UNIV

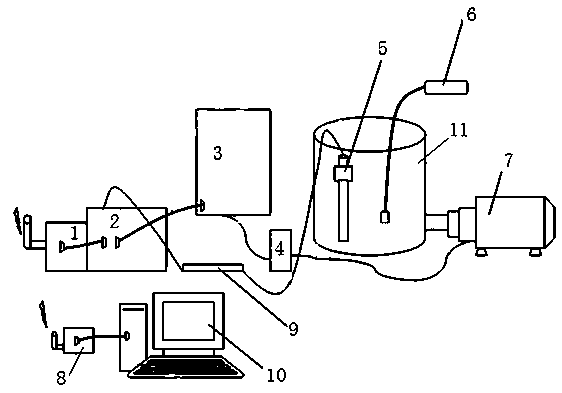

Intelligent variable flow water quality control system for circulating aquaculture

InactiveCN104317241AReduce consumptionRealize monitoringProgramme control in sequence/logic controllersComputer monitoringControl signal

The invention discloses an intelligent variable flow water quality control system for circulating aquaculture. The intelligent variable flow water quality control system comprises a lower computer variable flow control system, a lower computer variable flow executing system and an upper computer monitoring system, wherein the lower computer variable flow control system is formed by a water quality parameter sensor, a transmitter, a controller, a second wireless communication module, a frequency converter and an air switch, the lower computer variable flow executing system is formed by a water pump and an aerator, and the upper computer monitoring system is formed by a monitoring terminal and a first wireless communication module. The lower computer variable flow control system is used for detecting water quality parameters and outputting control signals to the lower computer variable flow executing system, and thus the rotating speed of the water pump is changed to improve the water quality; the upper computer monitoring system and the lower computer variable flow control system display and monitor the water quality parameters through wireless signal transmission, the aerator is controlled to be opened or closed according to the monitoring data, and aeration is selected to be conducted on the water of an aquaculture pool. By means of the intelligent variable flow water quality control system for circulating aquaculture, cost can be greatly saved, and energy consumption can be lowered; in addition, long-distance communication is conducted through the Internet of Things technology based on wireless communication, the water quality is monitored, and higher convenience and higher intelligence are achieved.

Owner:ZHEJIANG UNIV

Pump

ActiveUS20130343882A1Efficient executionPressure in the transported fluidTableware washing/rinsing machine detailsPump componentsImpellerEngineering

An impeller radial pump includes a pump chamber with a central suction and with a pump chamber outlet, wherein an impeller is provided in the pump chamber. Radially outside of the impeller, a circular ring shaped and circumferential pump chamber ring section is provided as a part of the pump chamber, wherein the pump chamber ring section essentially has an extension along the axial direction of the pump from the impeller against the suction direction. The pump chamber ring section has a varying width and is configured to be narrower in a compression region in the circulation direction.

Owner:E G O ELEKTRO GERAETEBAU GMBH

Resin composition for fiber-reinforced composite material, cured product thereof, fiber-reinforced composite material, molding of fiber-reinforced resin, and process for production thereof

InactiveUS8487052B2Improve liquidityHigh strengthSynthetic resin layered productsWood working apparatusMethacrylateAryl

The present invention provides a resin composition for a fiber-reinforced composite material, which has excellent fluidity and impregnation into a fiber base material and which produces a cured product having excellent heat resistance. A resin composition for a fiber-reinforced composite material contains, as essential components, a poly(glycidyloxyaryl) compound (A), a polymerizable monomer (B) which is an unsaturated carboxylic acid or an anhydride thereof and has a molecular weight of 160 or less, an aromatic vinyl compound or a (meth)acrylate (C), and a radical polymerization initiator (D), wherein an equivalent ratio [glycidyloxy group / acid group] of a glycidyloxy group in the component (A) to an acid group in the component (B) is 1 / 1 to 1 / 0.48, and a molar ratio [(B) / (C)] of the component (B) to the component (C) is in the range of 1 / 0.55 to 1 / 2.

Owner:DIC CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com