Preparation method, product and application of ferrous doped Fe-MOFs Fenton-like catalyst

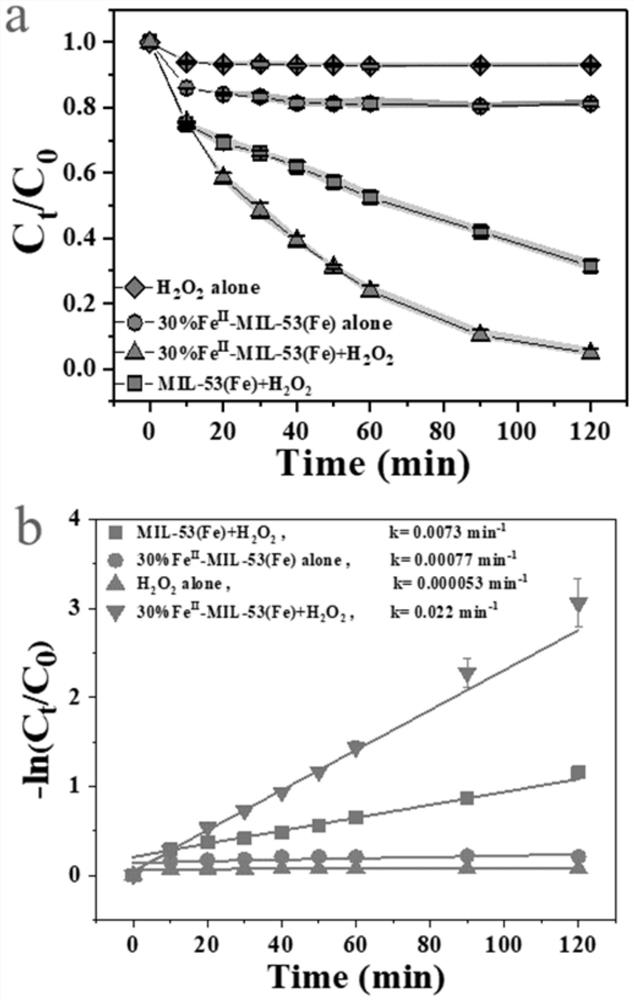

A catalyst, fe-mofs technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of insufficient density of coordinative unsaturated metal centers, organic Contaminant removal and mineralization efficiency is not high, low redox cycle rate and other problems, to achieve the effect of rich pore structure, accelerated cycle, positive redox potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

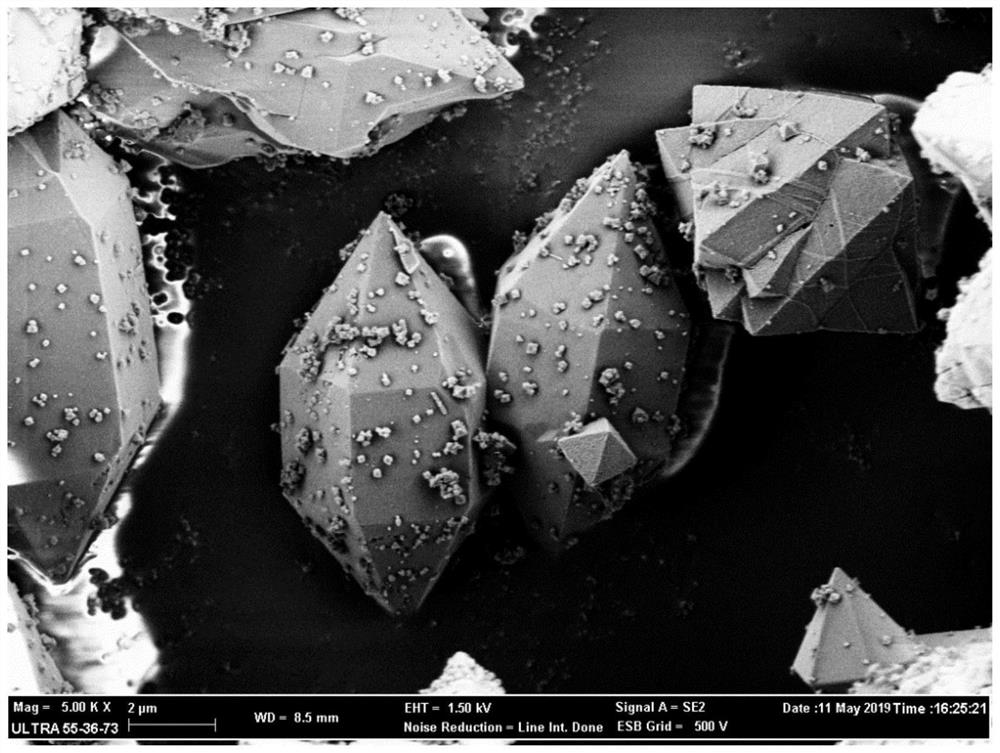

[0044] A preparation method of Fe(II)-doped Fe-MOFs Fenton-like catalyst, which forms a porous Fe(II)-doped Fe-MOFs-Fenton-like catalyst through ferrous ion-doped Fe-MOFs solvothermal self-assembly, according to Follow the steps below:

[0045] (1) Under magnetic stirring, according to the molar ratio of N,N dimethylformamide and organic ligand terephthalic acid is 500:1, add the organic ligand into the N,N dimethylformamide solution and dissolve completely After obtaining the organic ligand terephthalic acid solution;

[0046] (2) Add n(Fe(II)):n(Fe) mixed metal salts (ferrous chloride tetrahydrate and ferric chloride hexahydrate) with a molar ratio of 0.30:0.70 to the organic ligand terephthalic acid solution (wherein the molar ratio of the total molar weight of n(Fe(II)):n(Fe) to terephthalic acid is 1:1), stir evenly to obtain Fe(II) doped Fe-MOFs Fenton-like catalyst precursor Body mixed solution;

[0047] (3) Transfer the mixed solution to a stainless steel reaction k...

Embodiment 2

[0060] A kind of preparation method of Fe (II) doped Fe-MOFs class Fenton catalyst, as follows:

[0061] (1) Under magnetic stirring, according to the molar ratio of N,N-dimethylformamide (DMF) and organic ligand terephthalic acid is 500:1, the organic ligand is added to the DMF solution, and the organic ligand is obtained after dissolution is complete. Ligand terephthalic acid solution;

[0062] (2) Add n(Fe(II)):n(Fe) mixed metal salts (ferrous chloride tetrahydrate and ferric chloride hexahydrate) with a molar ratio of 0.20:0.80 to the organic ligand terephthalic acid solution (wherein the total molar ratio of n(Fe(II)):n(Fe) to terephthalic acid is 1:1), stir well to obtain Fe(II) doped Fe-MOFs Fenton catalyst Precursor mixed solution;

[0063] (3) Transfer the mixed solution to a stainless steel reaction kettle lined with polytetrafluoroethylene. After solvothermal reaction at 150 °C for 3 h, centrifuge, precipitate and wash, and dry at 100 °C for 24 h to obtain porous ...

Embodiment 3

[0066] A kind of preparation method of Fe (II) doped Fe-MOFs class Fenton catalyst, as follows:

[0067] (1) Under magnetic stirring, according to the molar ratio of N,N-dimethylformamide (DMF) and organic ligand terephthalic acid is 500:1, the organic ligand is added to the DMF solution, and the organic ligand is obtained after dissolution is complete. Ligand terephthalic acid solution;

[0068] (2) Add n(Fe(II)):n(Fe) mixed metal salts (ferrous chloride tetrahydrate and ferric chloride hexahydrate) with a molar ratio of 0.10:0.90 to the organic ligand terephthalic acid solution (wherein the molar ratio of the total molar weight of n(Fe(II)):n(Fe) to terephthalic acid is 1:1), stir evenly to obtain Fe(II) doped Fe-MOFs Fenton-like catalyst precursor Body mixed solution;

[0069] (3) Transfer the mixed solution to a stainless steel reaction kettle lined with polytetrafluoroethylene. After solvothermal reaction at 150 °C for 3 h, centrifuge, precipitate and wash, and dry at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com