Exhaust gas recirculation system for internal combustion engine

A technology of recirculation system and internal combustion engine, applied in exhaust gas recirculation, internal combustion piston engine, charging system, etc., can solve problems such as real-time control of EGR under adverse transient conditions, limited working range of exhaust gas circulation, and EGR cannot be circulated at a high proportion. , to solve the problem of supercharger delay, which is conducive to fast response and fast response of exhaust gas circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

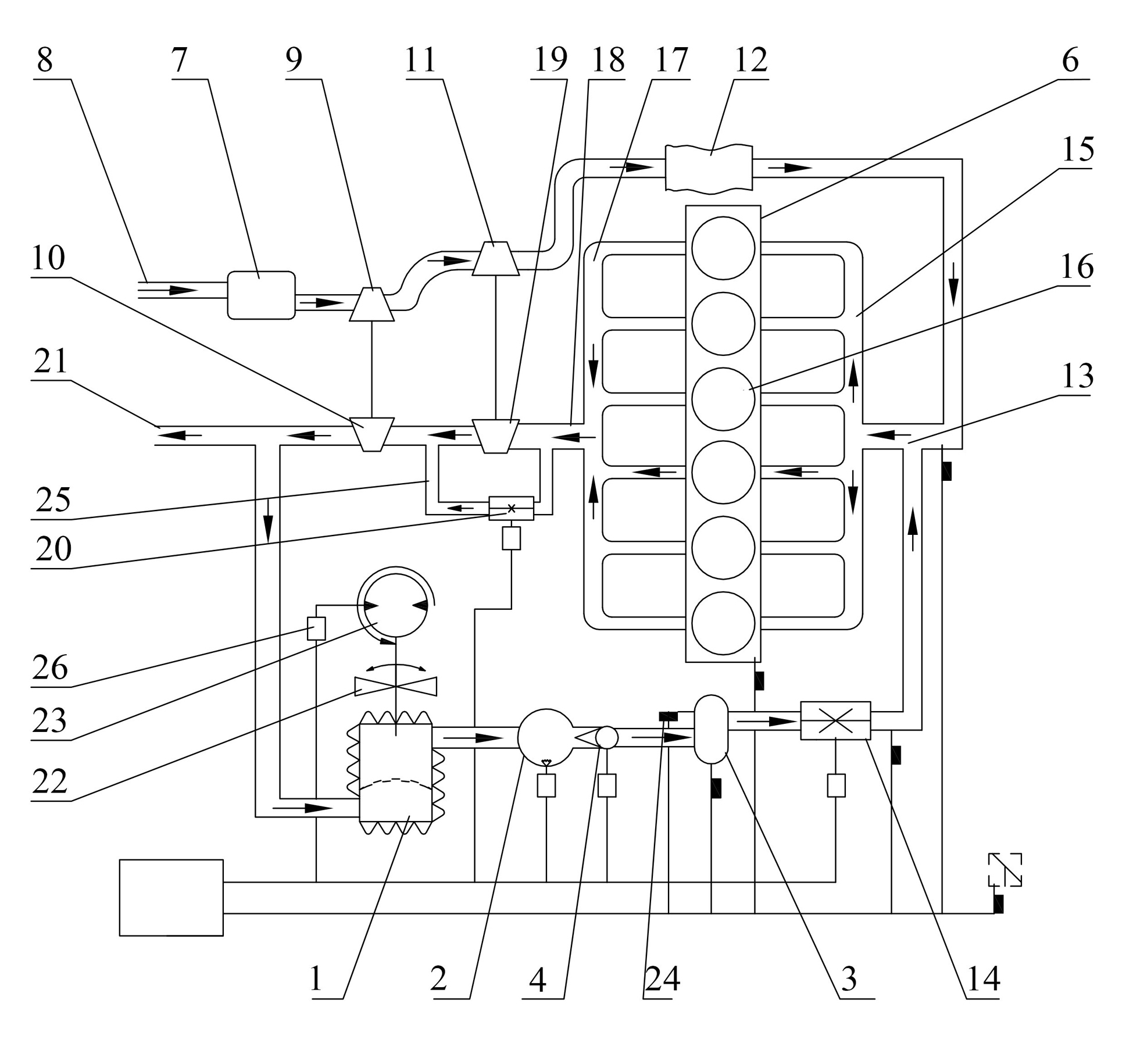

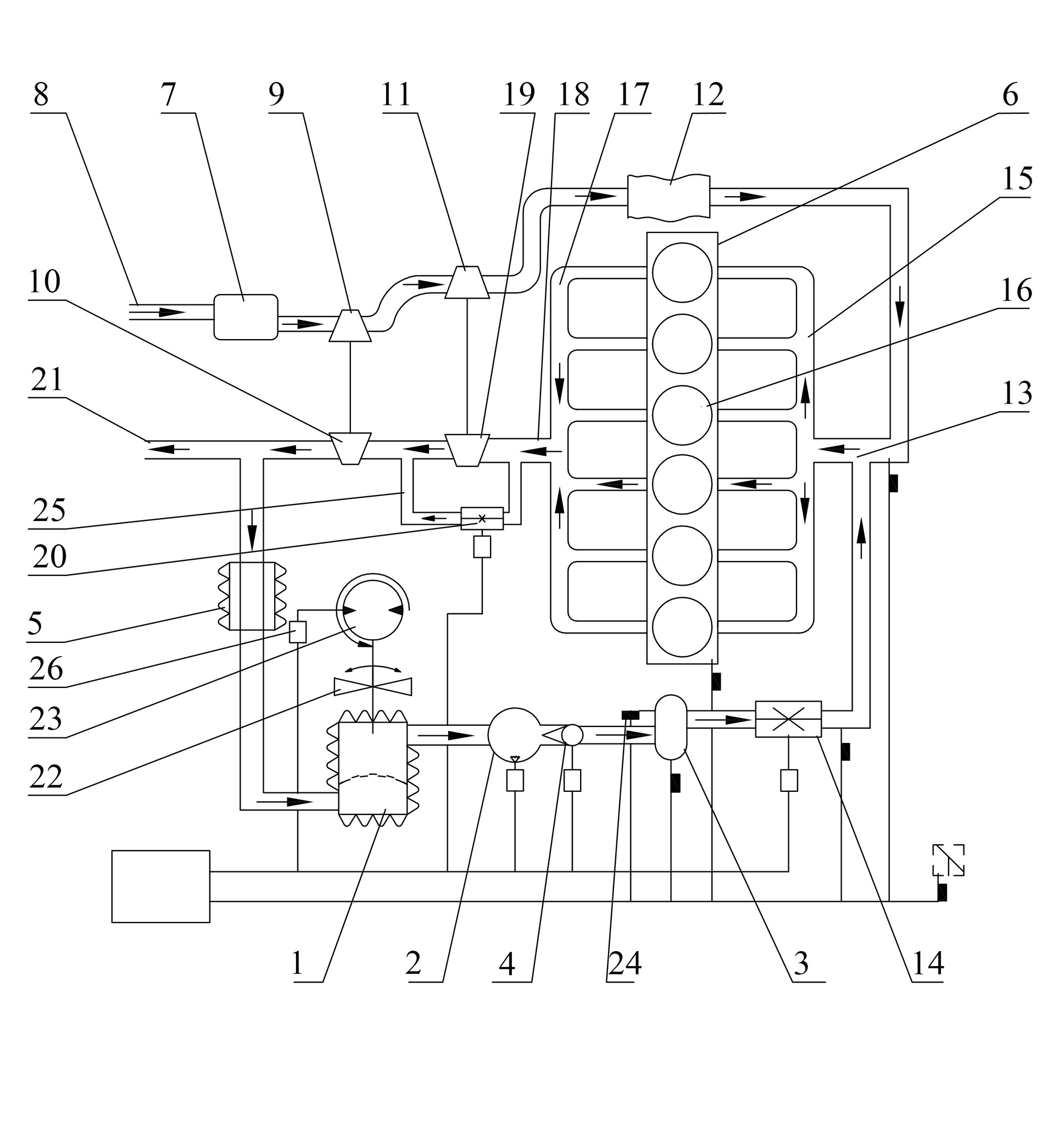

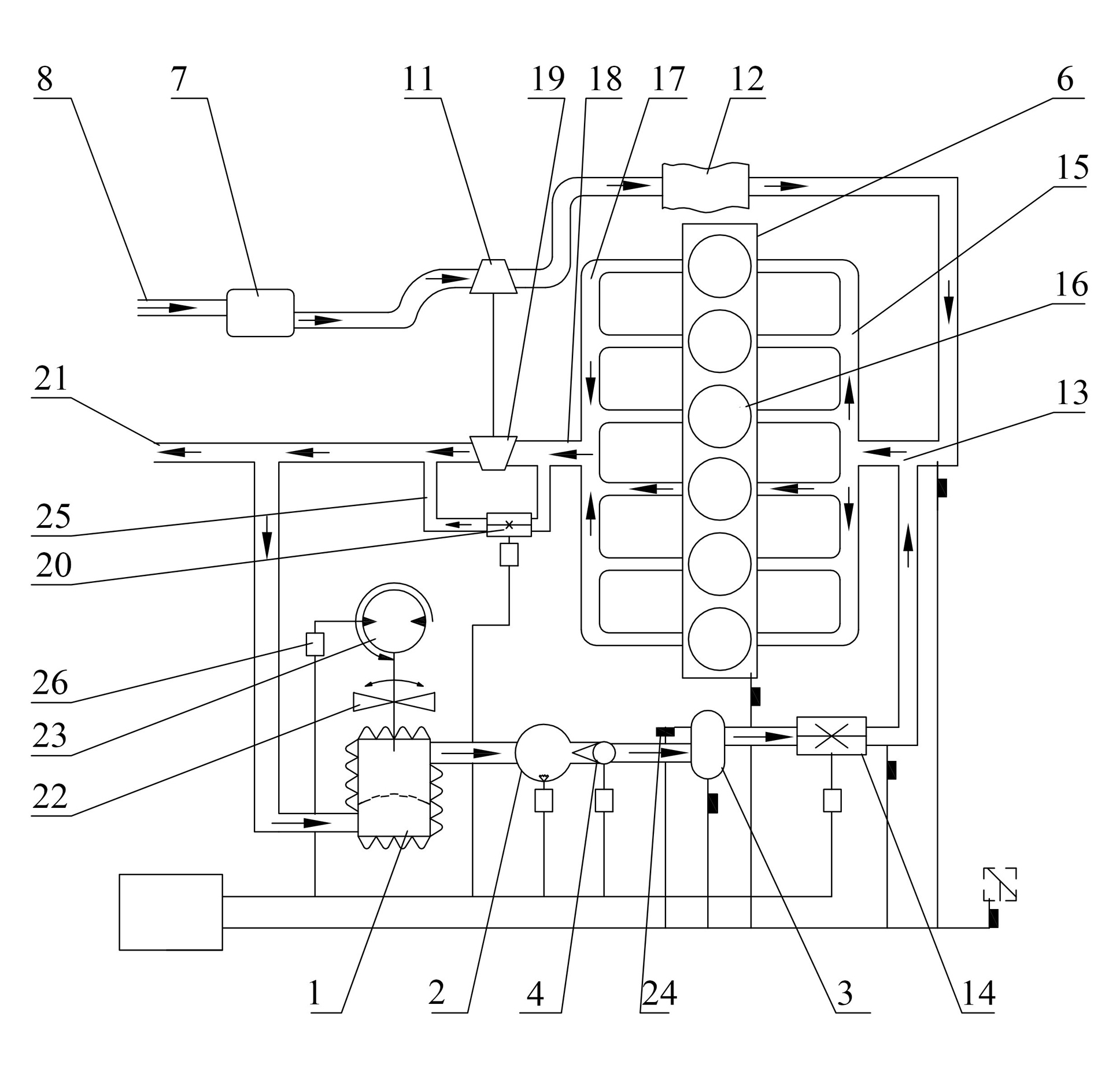

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Such as figure 1 As shown, it is a specific application example 1, the present invention is applied to a two-stage supercharged internal combustion engine. The internal combustion engine 6 takes a diesel engine as an example, and the working process of the diesel engine is divided into four strokes, which are respectively air intake, compression, work, and exhaust. The purpose of the exhaust gas recirculation (EGR) of the present invention is to reduce the combustion temperature in the cylinder (lower than 2000K), suppress the formation of NOx, and reduce the emission of pollutants. In this example, the EGR circulation mode belongs to the low-pressure exhaust gas recirculation system.

[0031] The exhaust gas recirculation system used for internal combustion engines of the present invention comprises a cooling assembly, a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com