Dispensing needle position calibration system and dispensing needle position calibration method

A technology for calibrating systems and dispensing, applied to spraying devices, devices for coating liquid on surfaces, coatings, etc., can solve problems such as wasting production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

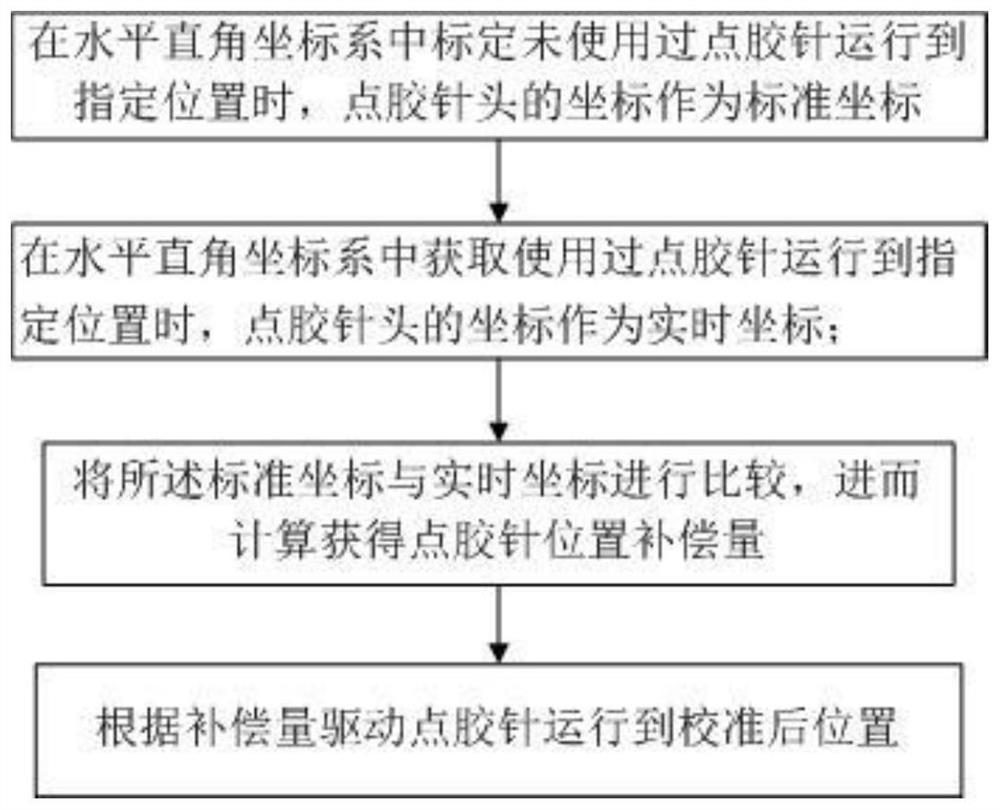

[0054] Such as image 3 As shown, the present invention provides a first embodiment of a dispensing needle position calibration method for dispensing needle position calibration of a dispensing machine, including the following steps:

[0055] 1) When the unused dispensing needle is calibrated to the specified position in the horizontal rectangular coordinate system, the coordinates of the dispensing needle head are taken as the standard coordinates;

[0056] 2) Obtain the coordinates of the dispensing needle as the real-time coordinates when the dispensing needle runs to the specified position in the horizontal rectangular coordinate system;

[0057] 3) Comparing the standard coordinates with the real-time coordinates, and then calculating the position compensation amount of the dispensing needle;

[0058] 4) Drive the dispensing needle to the calibrated position according to the compensation amount.

no. 2 example

[0059] Such as Figure 4 As shown, the present invention provides a second embodiment of a dispensing needle position calibration method for dispensing needle position calibration of a dispensing machine, including the following steps:

[0060] 1) When the unused dispensing needle is calibrated to the specified position in the horizontal rectangular coordinate system, the coordinates of the dispensing needle head are taken as the standard coordinates;

[0061] 2) After performing the dispensing needle removal operation, obtain the coordinates of the dispensing needle when the used dispensing needle runs to the specified position in the horizontal rectangular coordinate system as the real-time coordinates;

[0062] 3) Comparing the standard coordinates with the real-time coordinates, and then calculating the position compensation amount of the dispensing needle;

[0063] 4) Drive the dispensing needle to the calibrated position according to the compensation amount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com