Patents

Literature

36results about How to "Does not affect production takt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

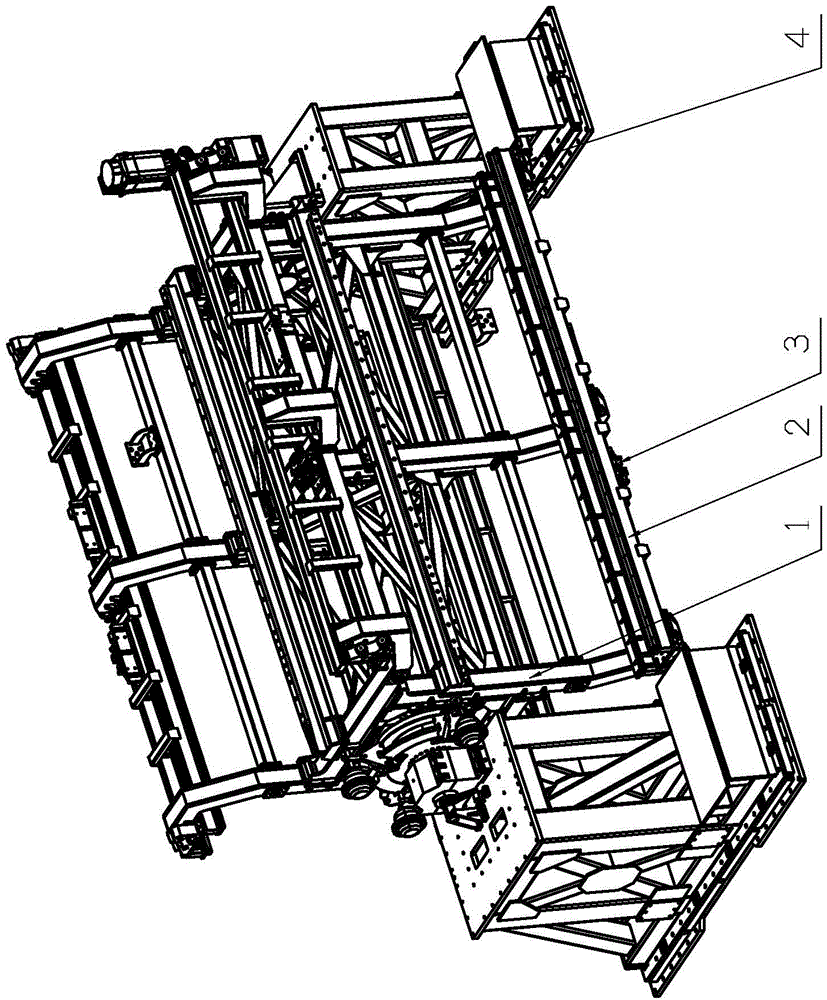

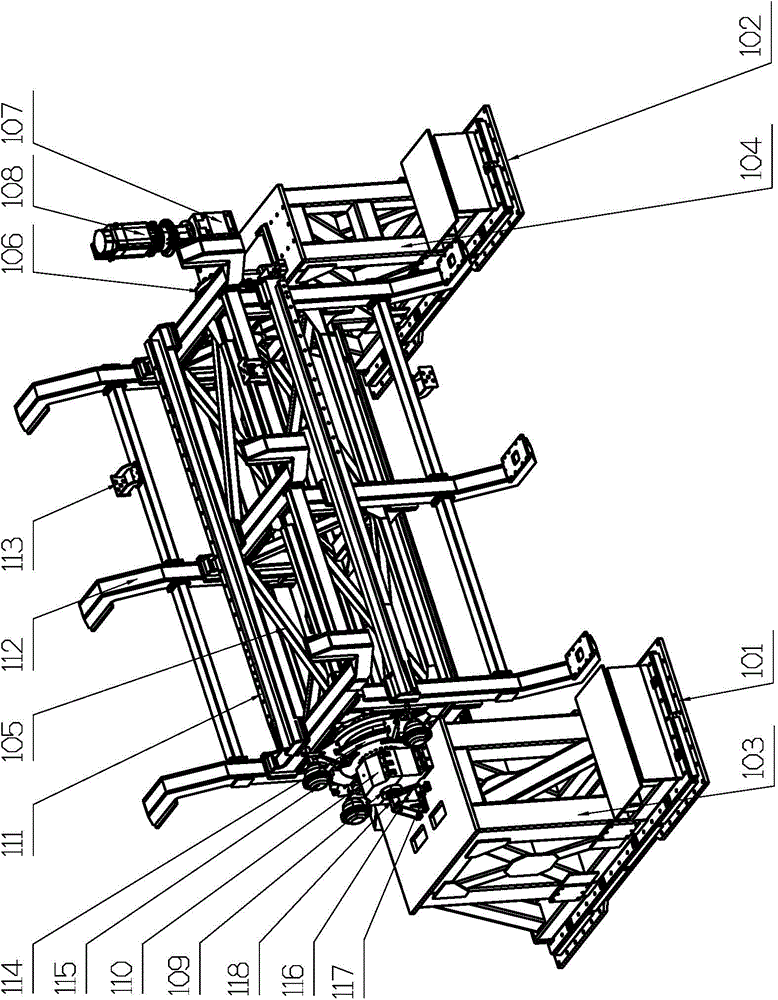

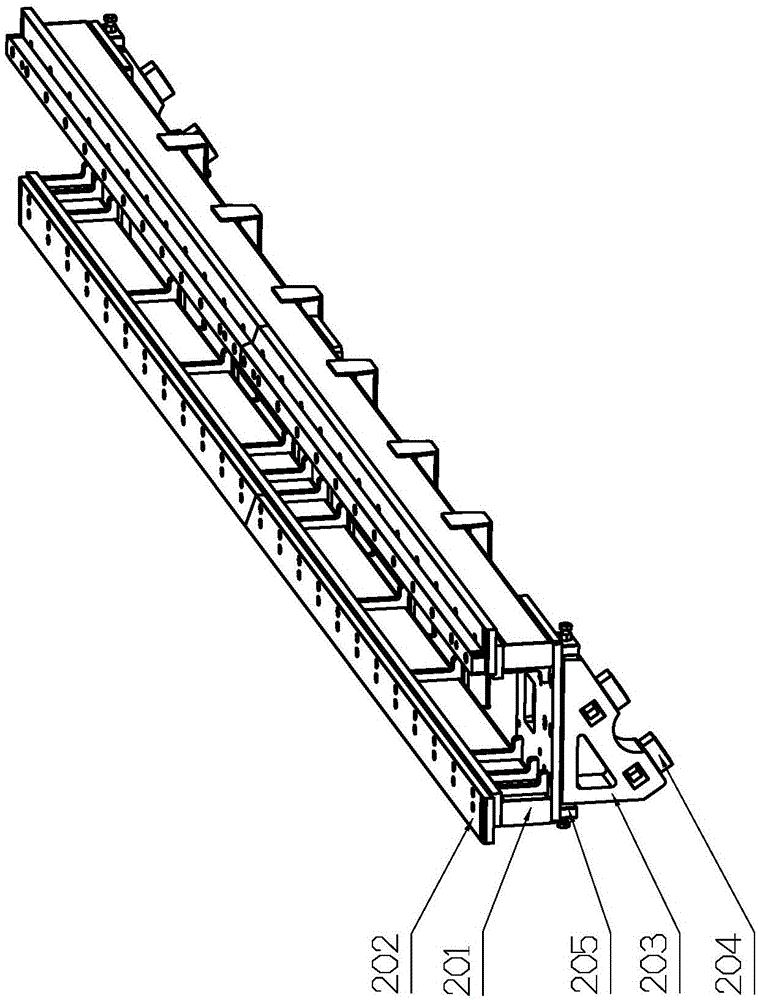

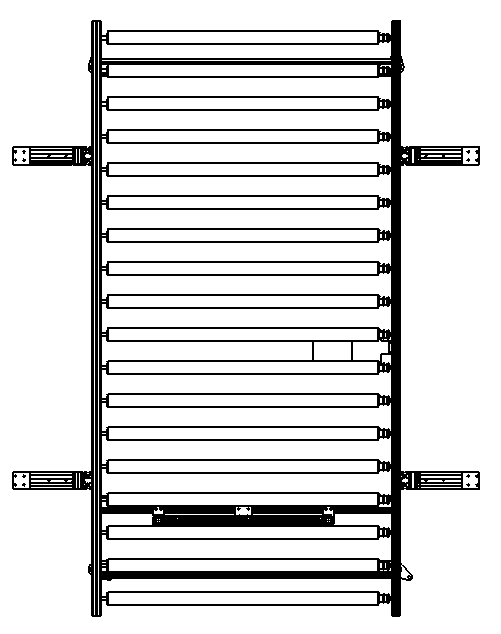

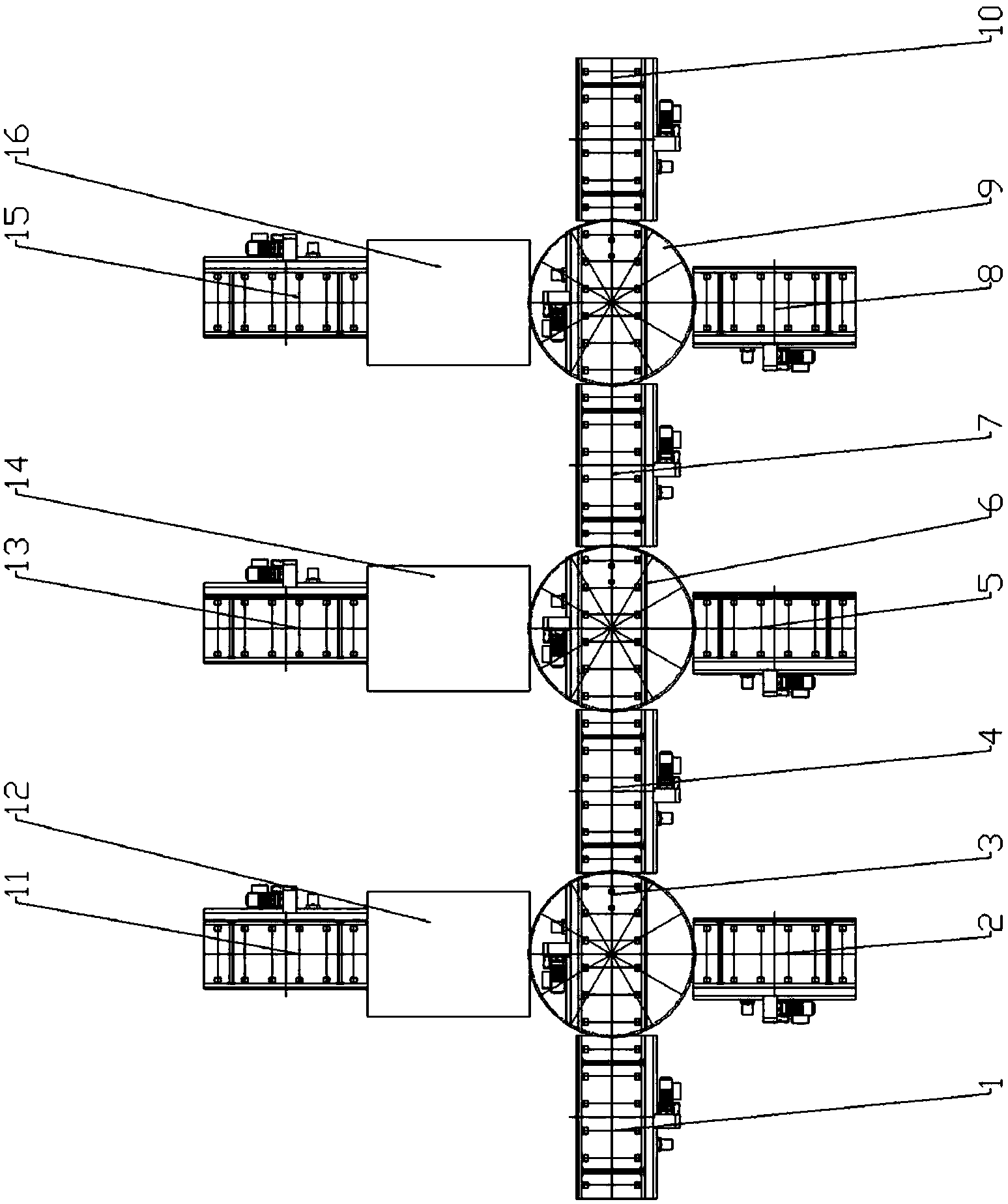

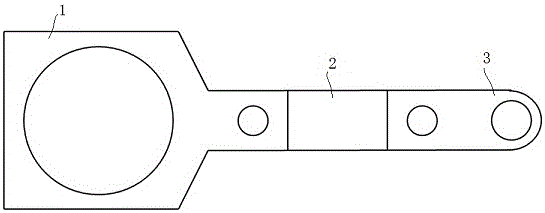

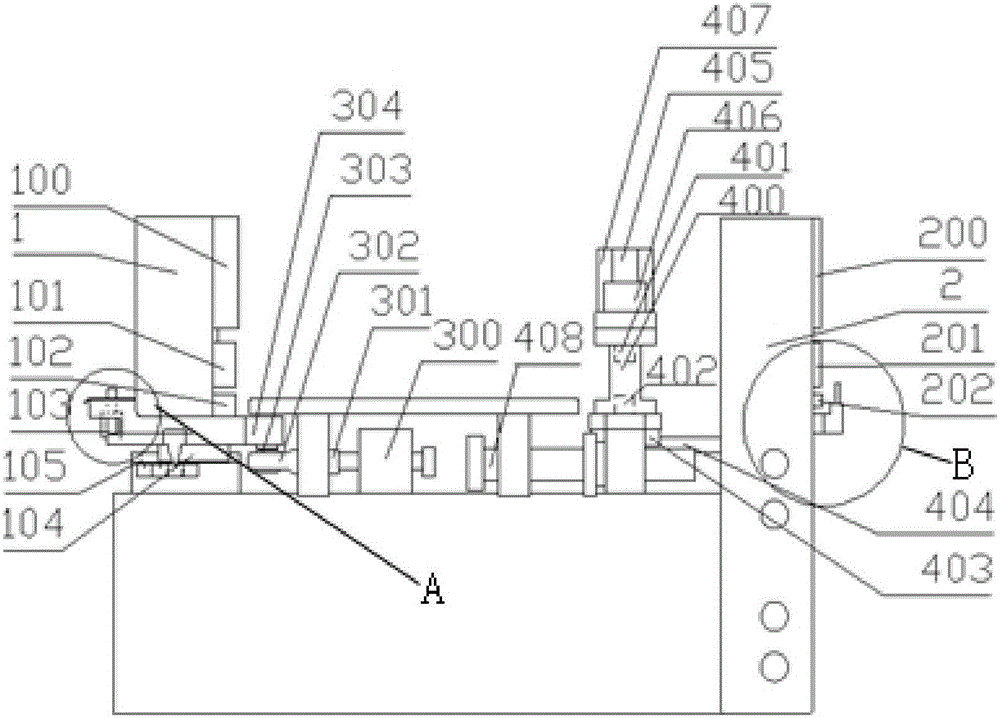

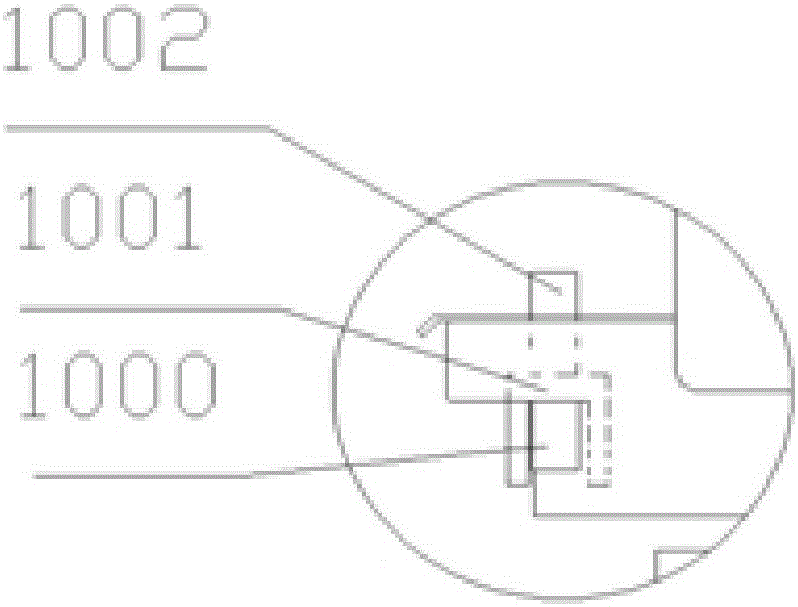

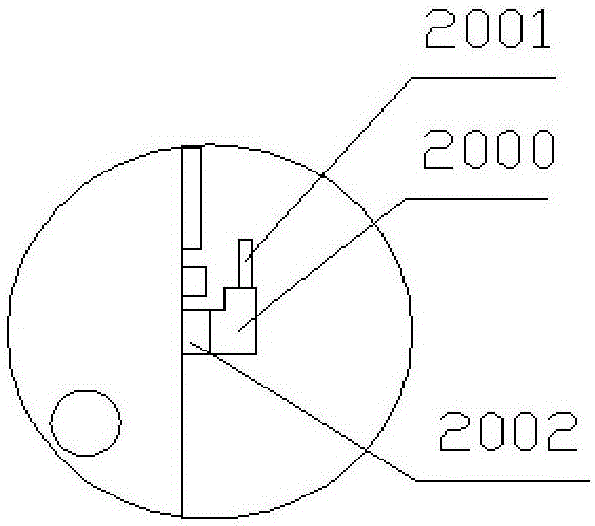

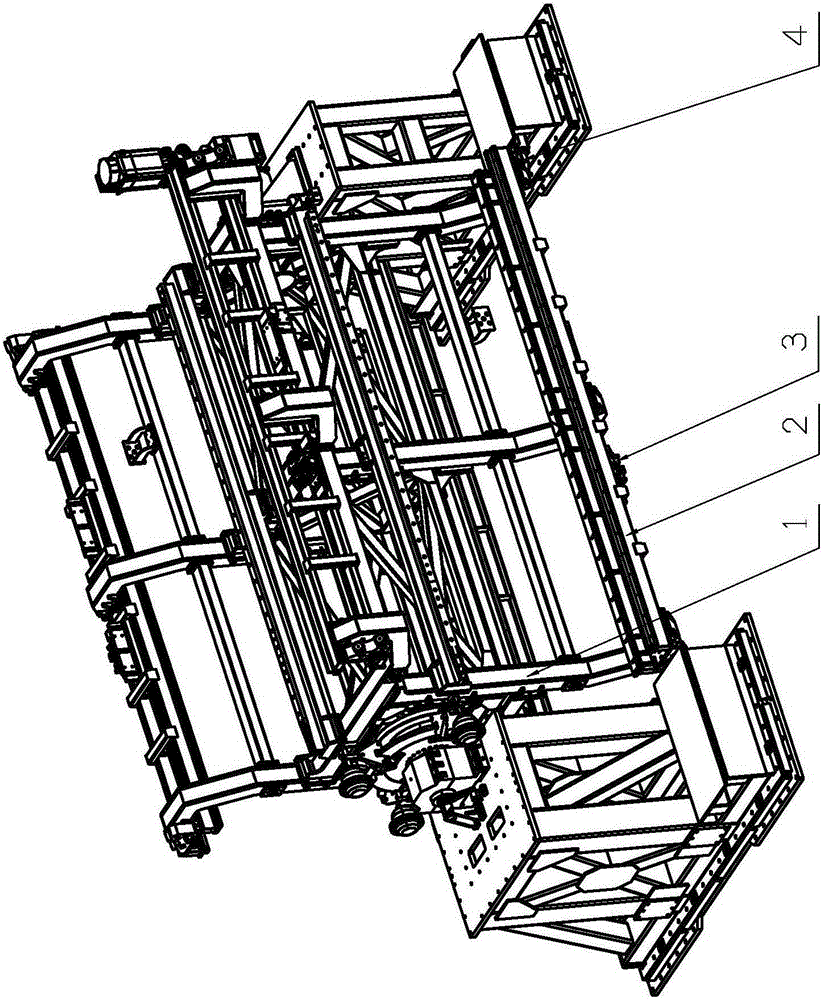

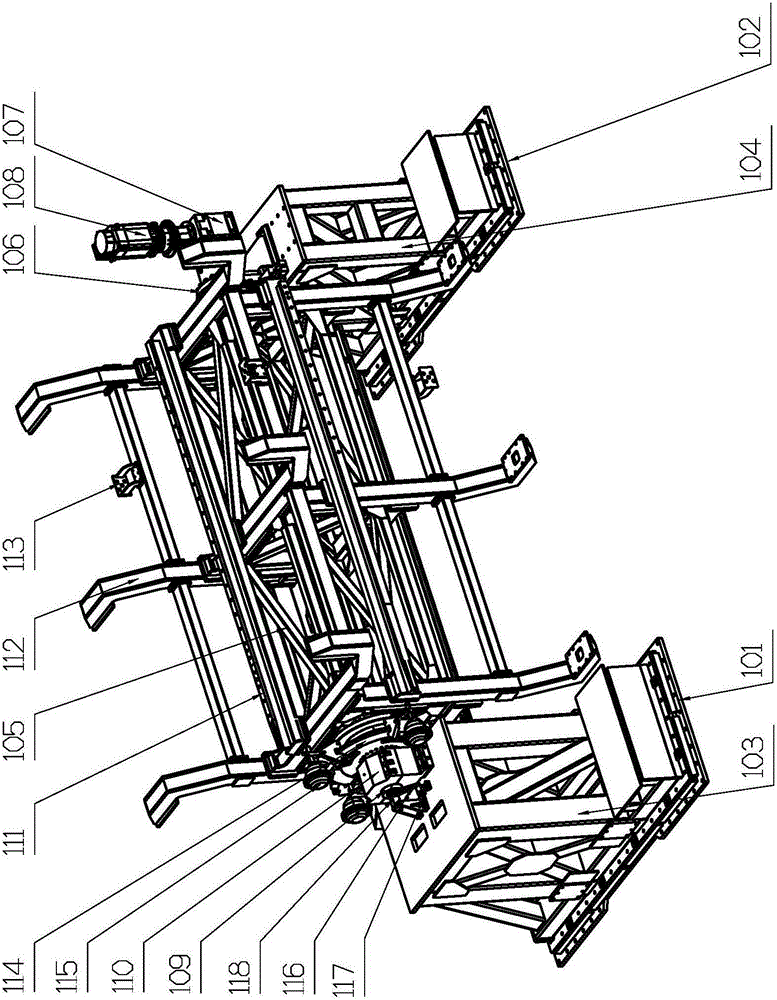

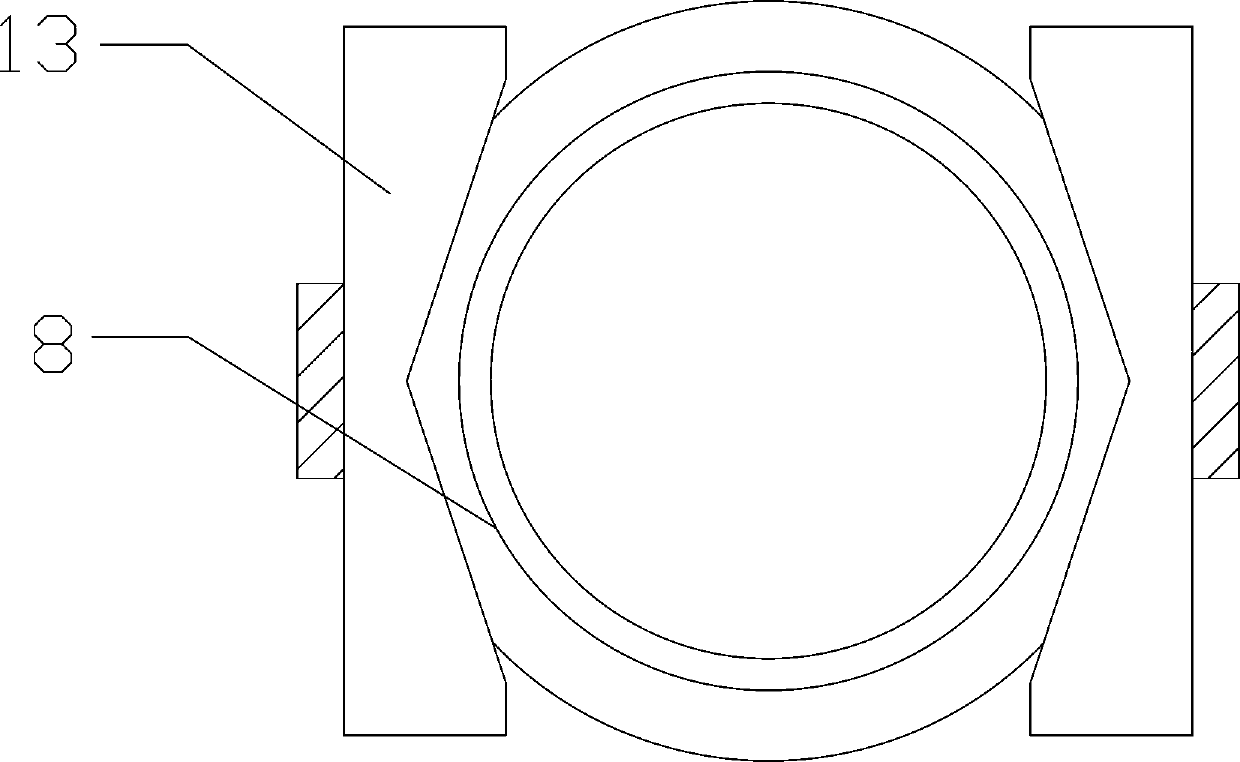

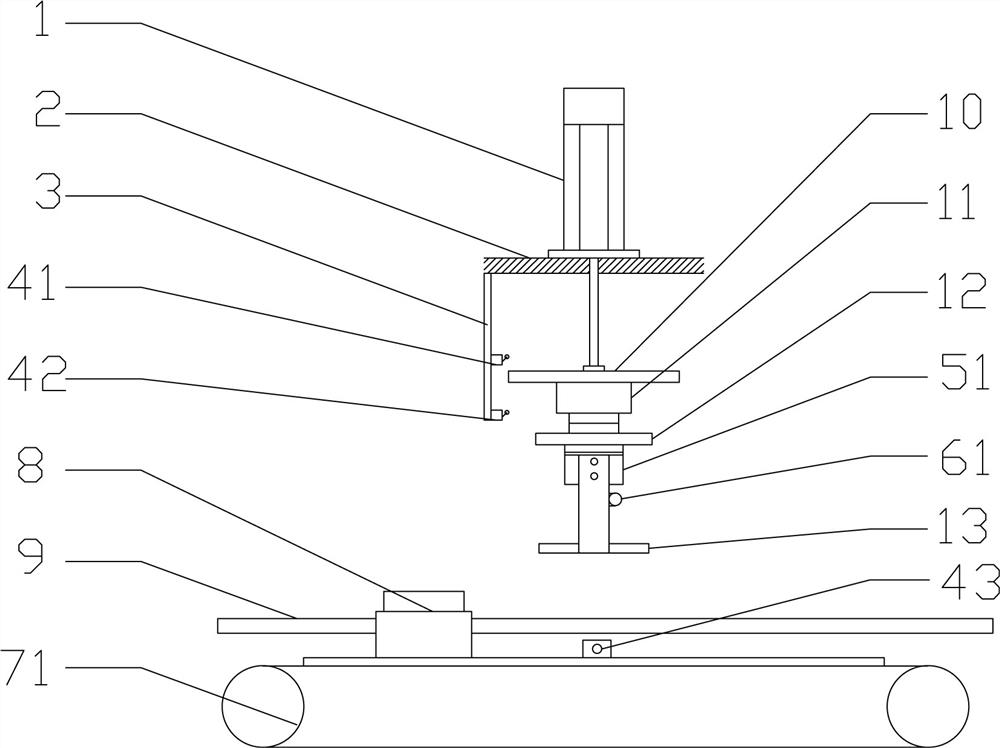

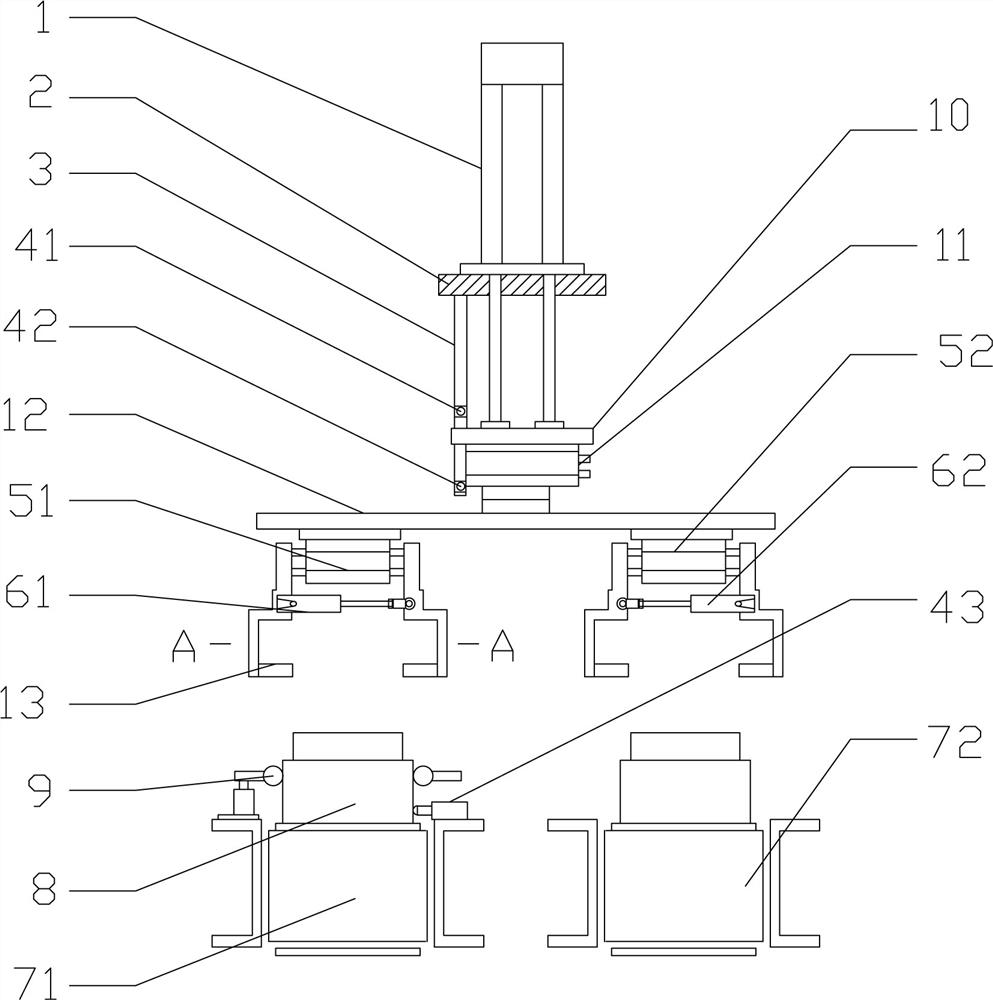

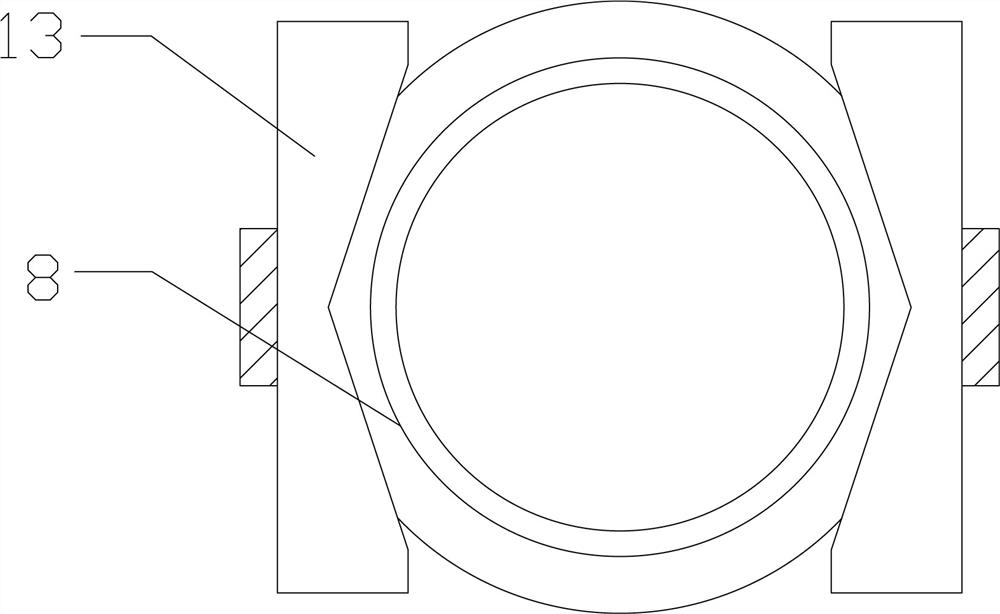

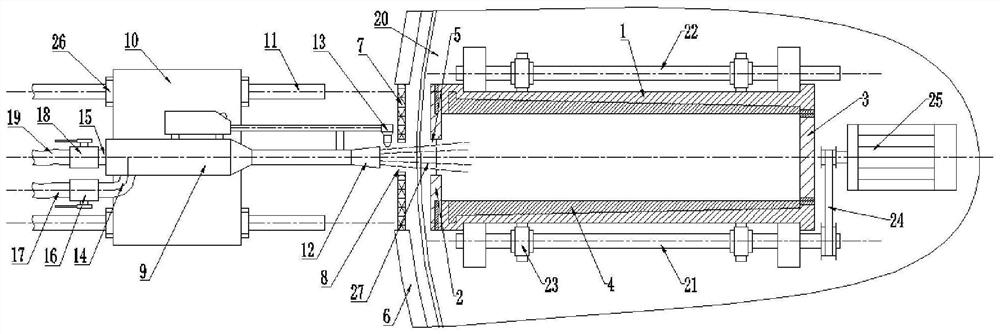

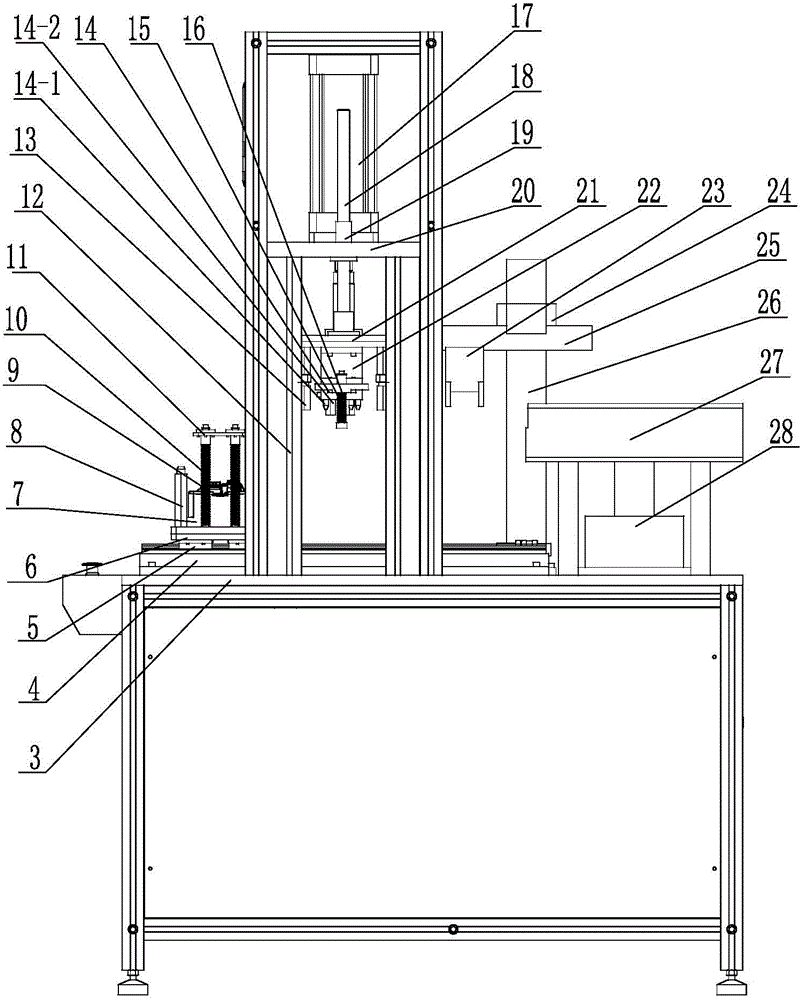

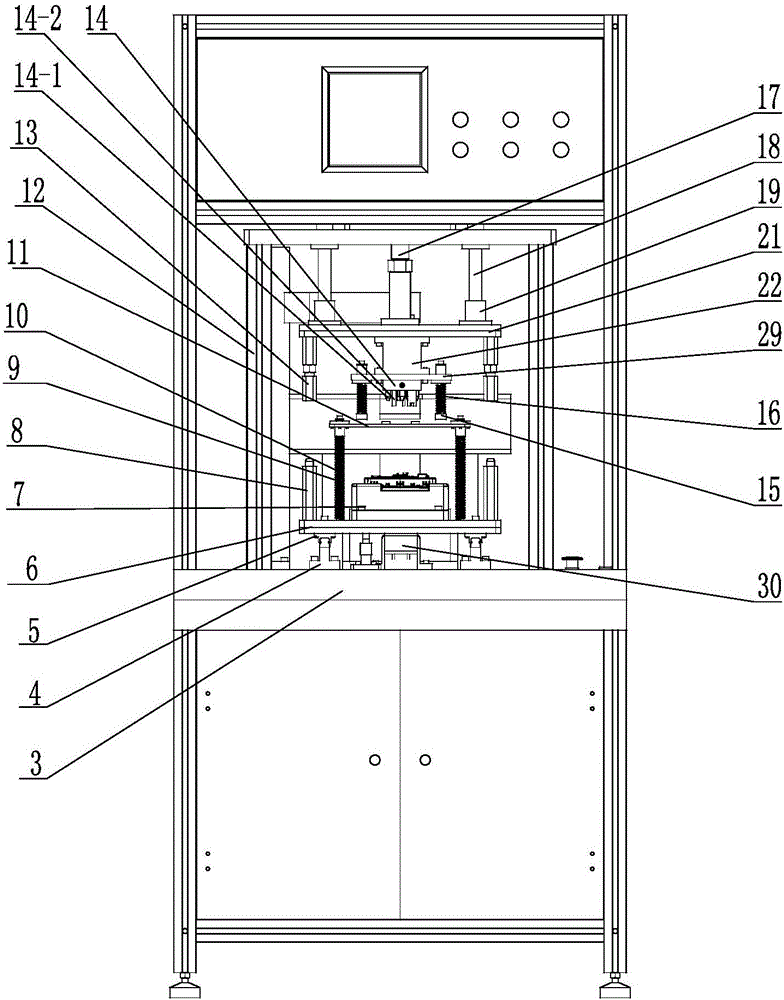

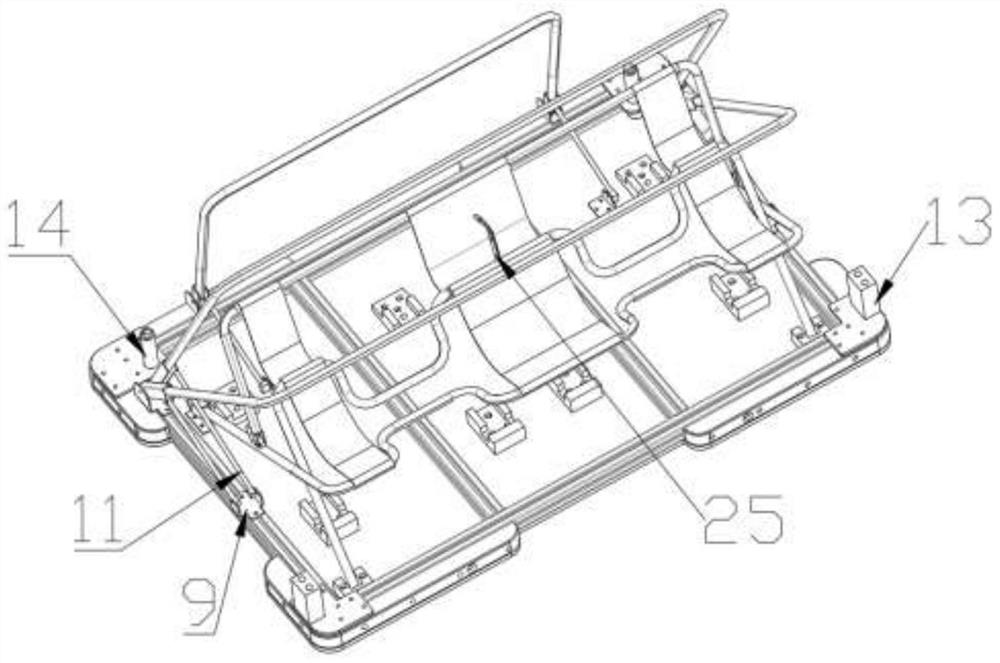

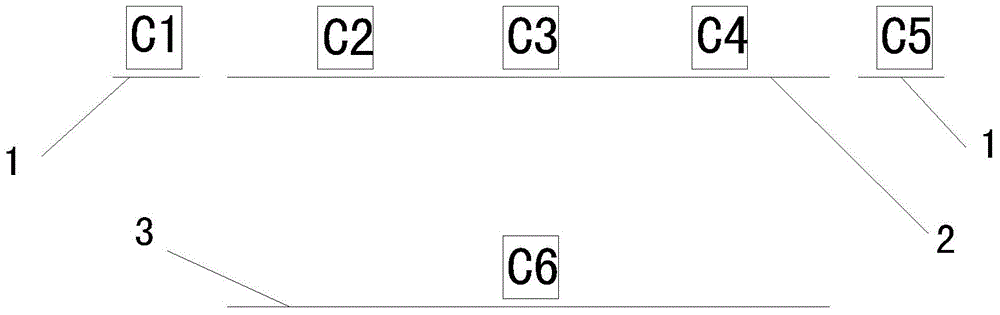

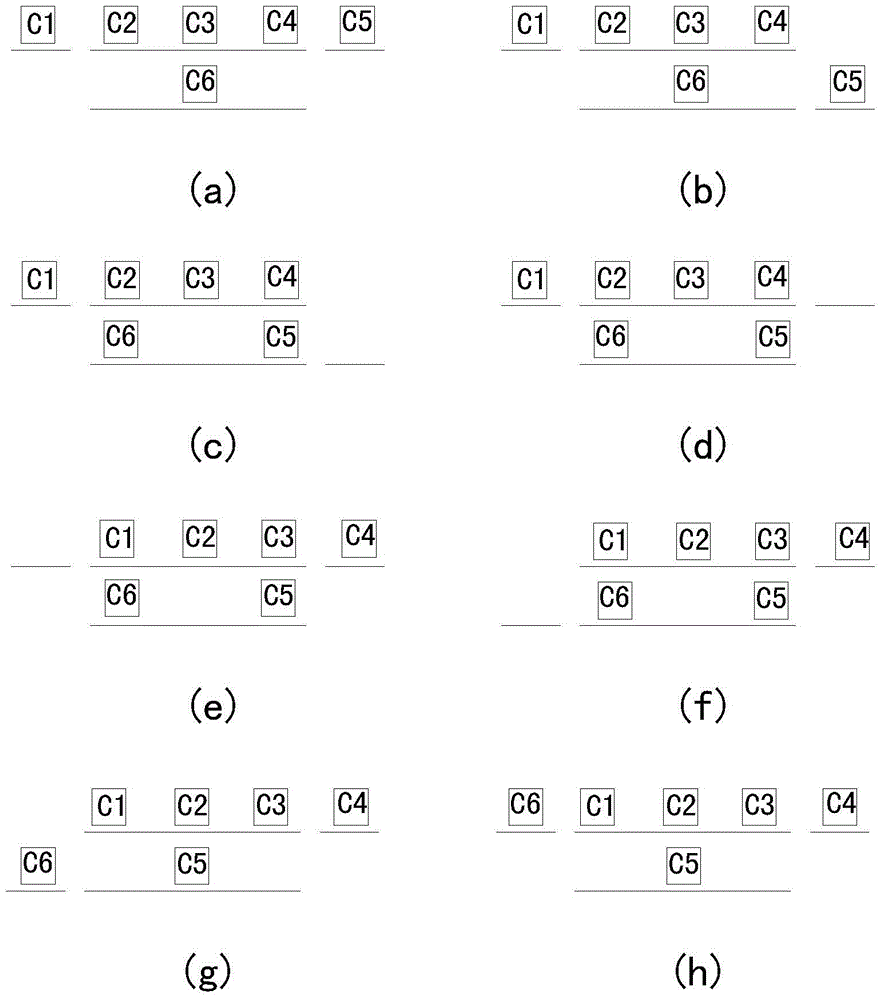

Rotary storing mechanism for body-in-white welding total-splicing clamp

InactiveCN104002076AShort setup times for changeoversDoes not affect production taktWelding/cutting auxillary devicesAuxillary welding devicesBody in whiteSmall footprint

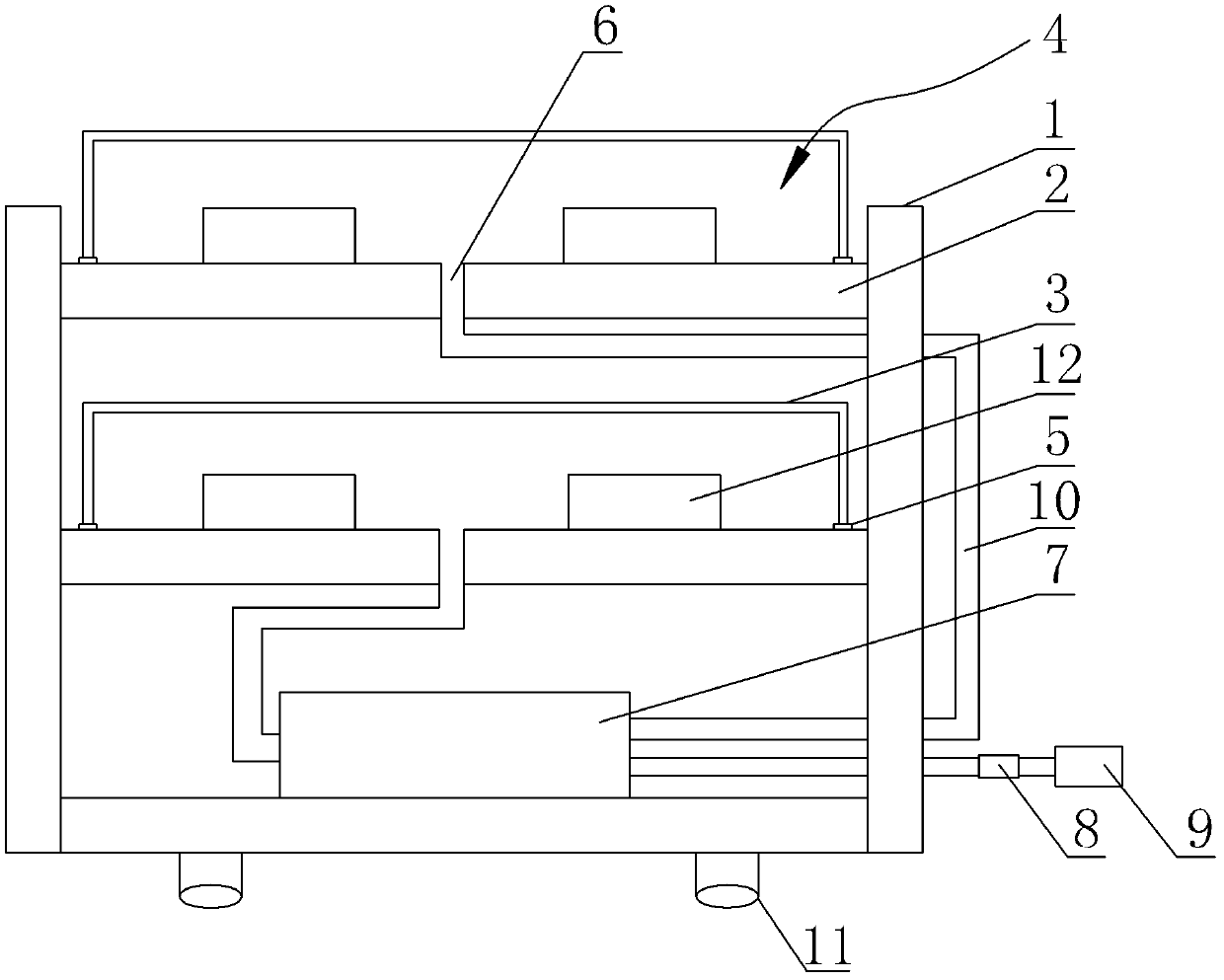

The invention discloses a rotary storing mechanism for a body-in-white welding total-splicing clamp. The rotary storing mechanism comprises a driven end base, a driving end base and a rotary body transversely erected between the driven end base and driving end base, a plurality of clamp containing areas are evenly arranged along the circumference of the rotary body, each clamp containing area is provided with a clamp track, the lower end face of each clamp track is provided with a forked plate mechanism for fixing the clamp on the clamp tracks, and the driven end base and the driving end base are provided with bolt mechanisms capable of limiting rotation of the rotary body respectively. Compared with the prior art, the rotary storing mechanism has the advantages that the remodeling preparation time is short, and the production frequency is not influenced; multi-car-model collineation can be achieved; floor space is small, and a system with the rotary clamp storing mechanism is smallest in floor space compared with an existing multi-car-model collineation flexible total-splicing system side body clamp storage system capable of being switched along with lines.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

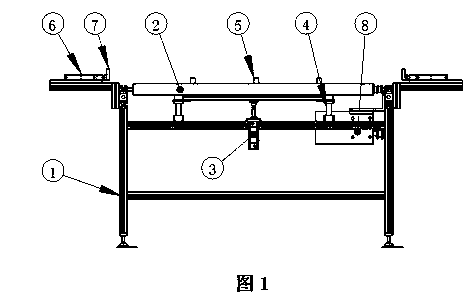

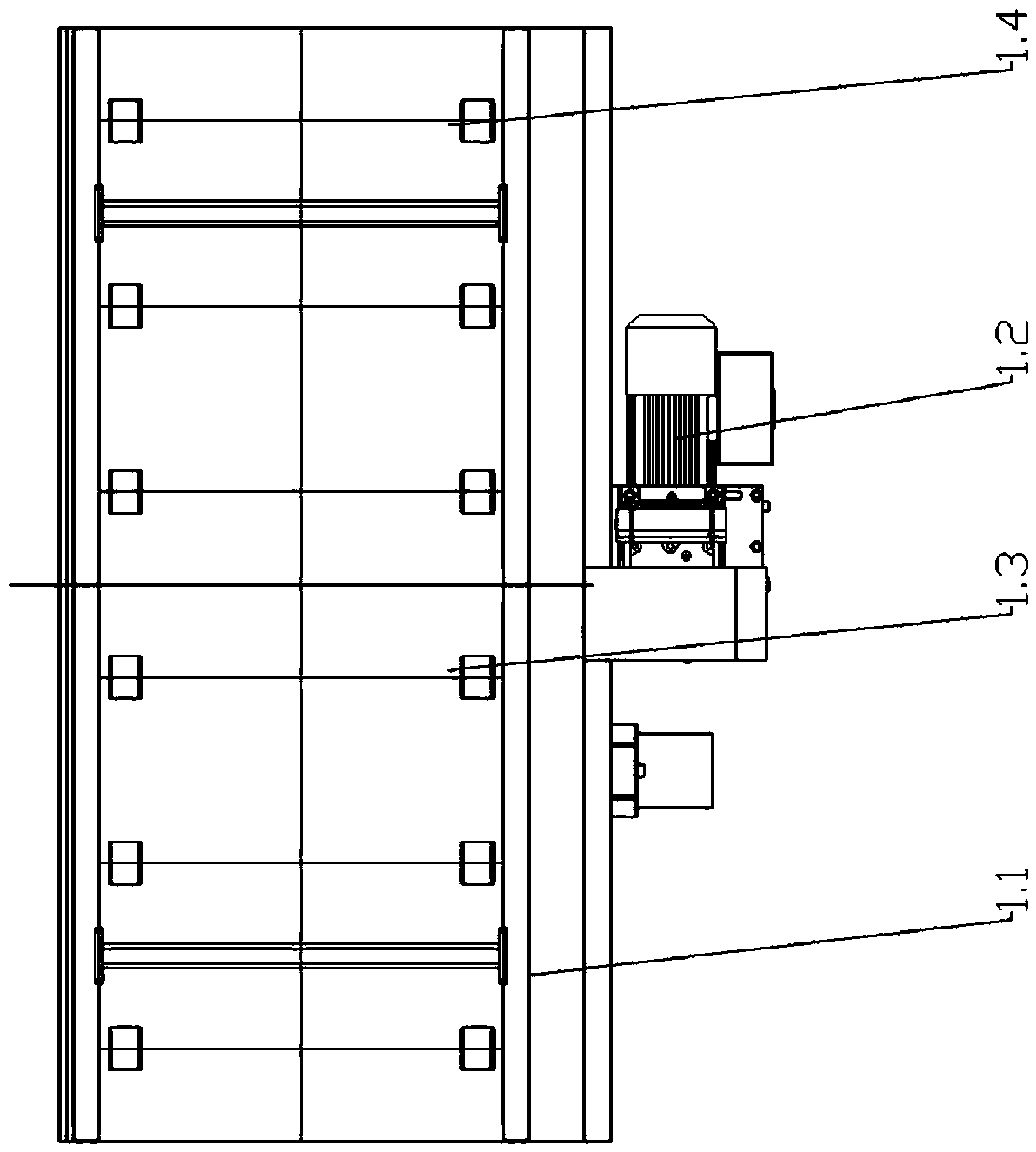

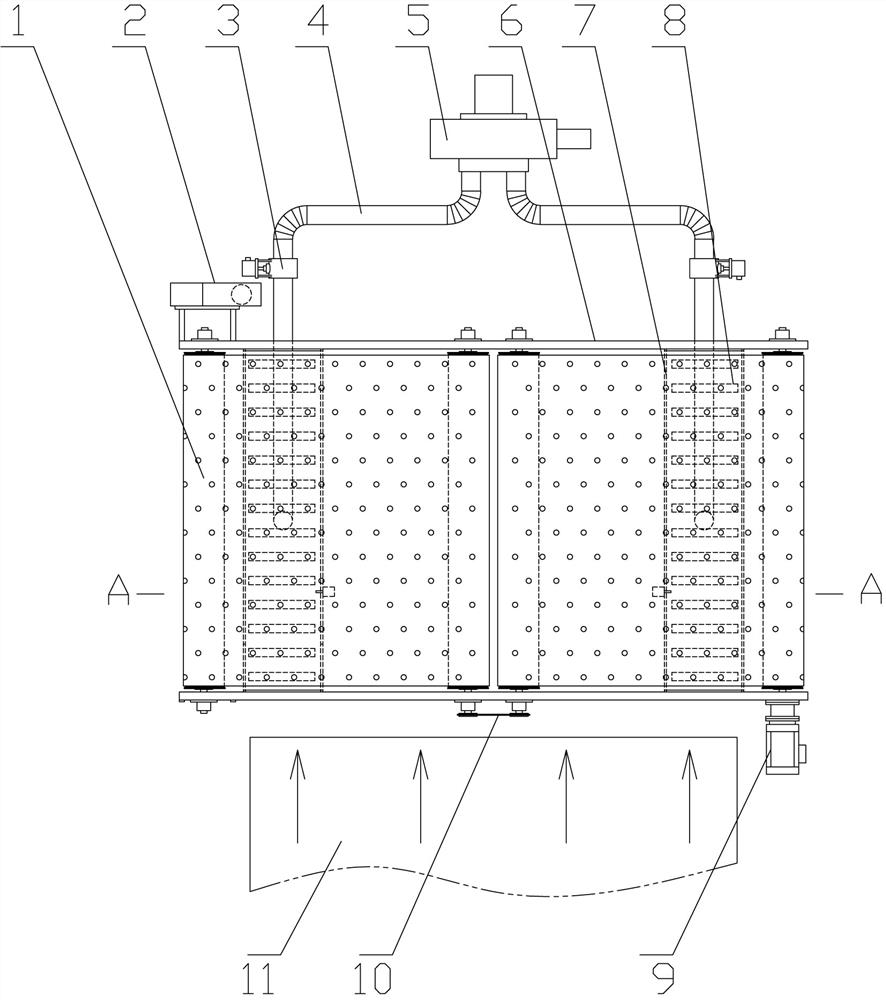

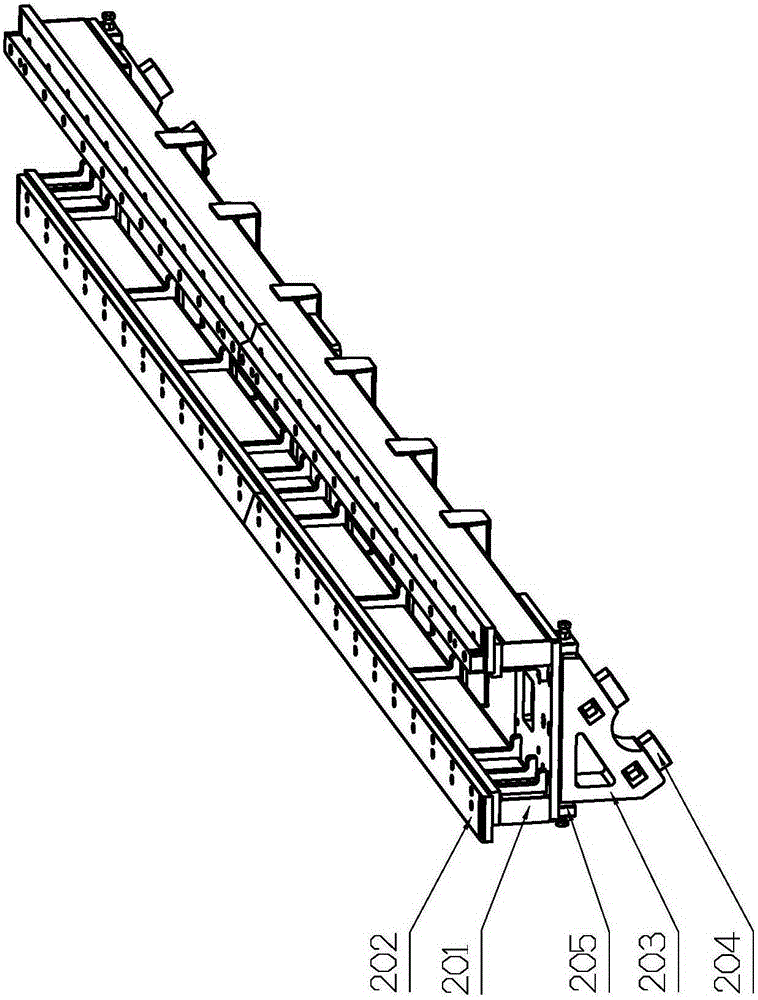

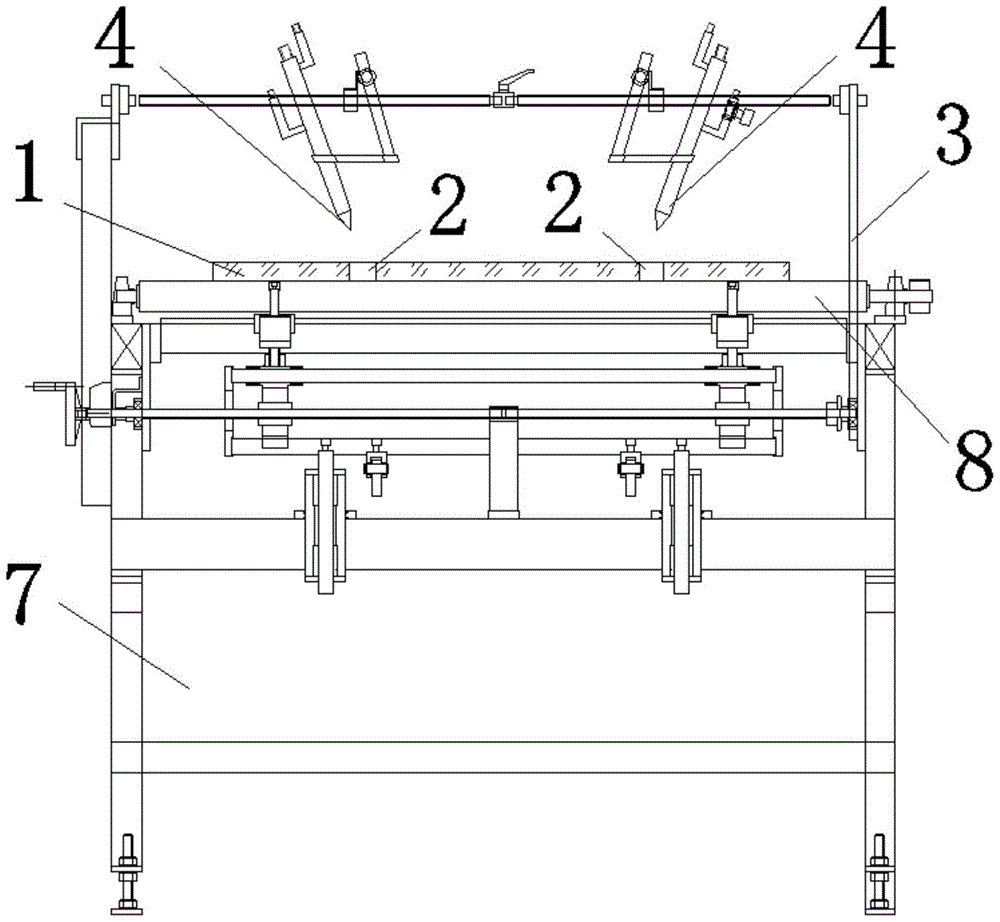

Center positioning system used for roller transmission line

InactiveCN103508184APrecise positioningImprove efficiencyConveyor partsRoller-waysElectric machineryStructural engineering

The invention provides a center positioning system used for a roller transmission line. The center positioning system comprises a rack, rollers, front-and-back positioning cylinders, guide columns, positioning columns, left-and-right positioning cylinders, positioning plates and motors. The rollers are arranged and fixed on the rack in sequence, the motors are fixed below the rollers on one side of the rack and connected with the rollers, the front-and-back positioning cylinders and the guide columns are fixed on the rack, the guide columns are installed on the two sides of the front-and-back positioning cylinders, and the positioning columns are fixed to the front ends of the cylinders. The center positioning system used for the roller transmission line is simple in structure, accurate in positioning and good in stability.

Owner:SUZHOU SUOLIWANG NEW ENERGY TECH CO LTD

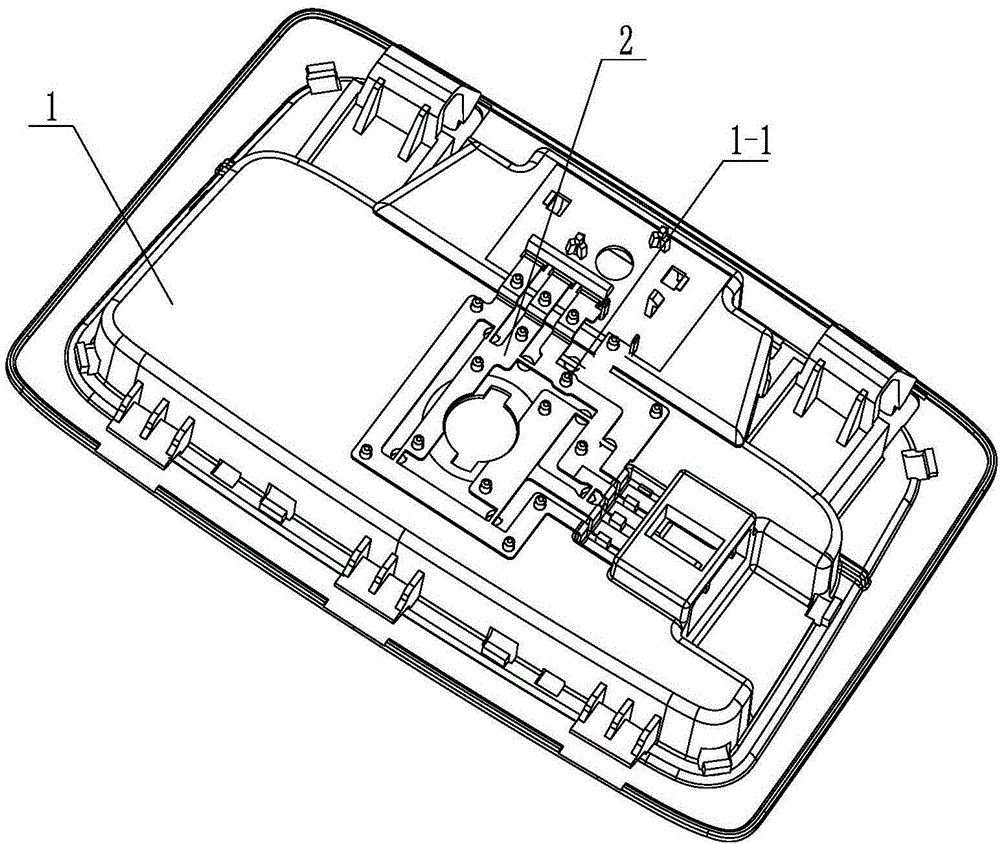

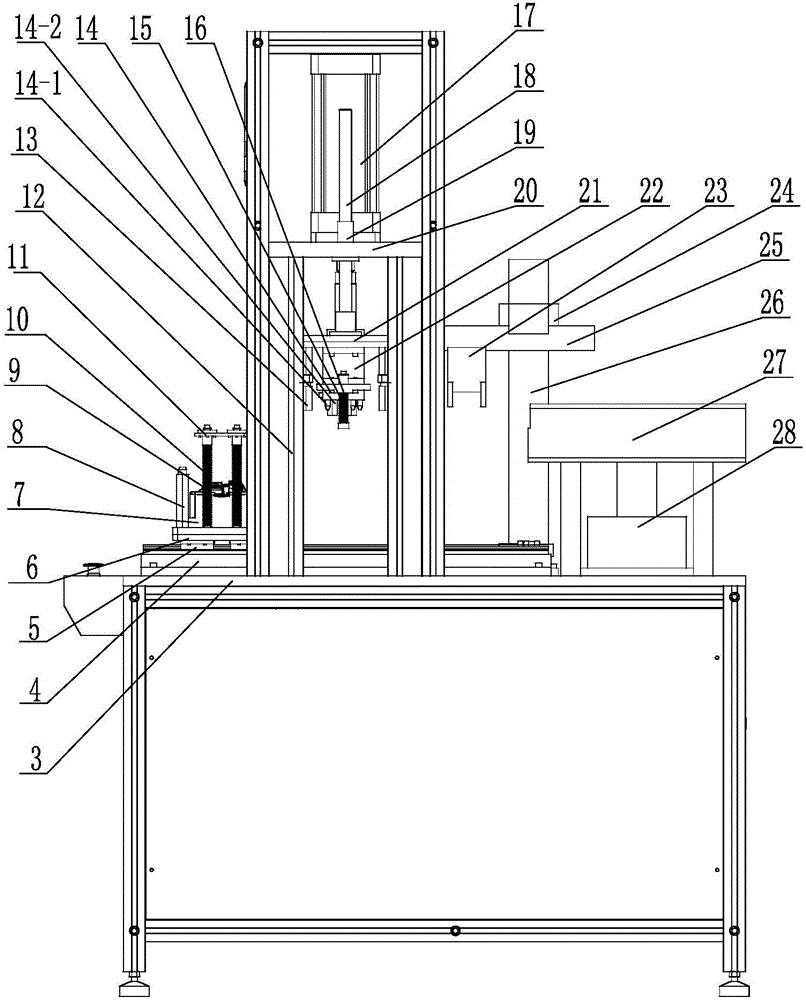

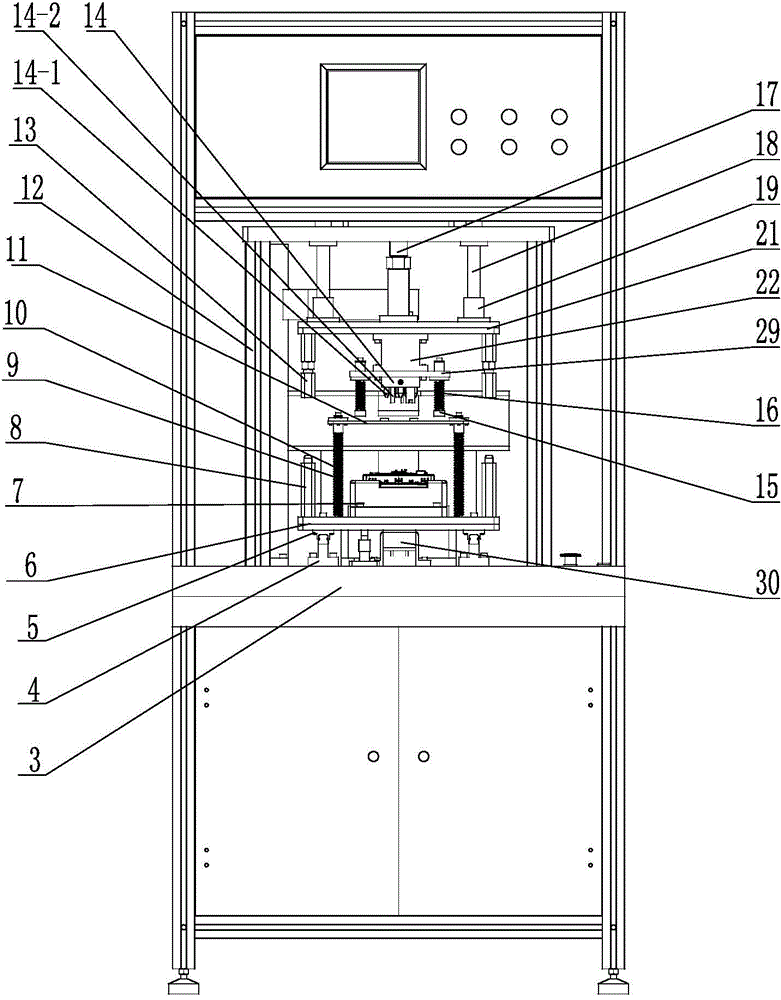

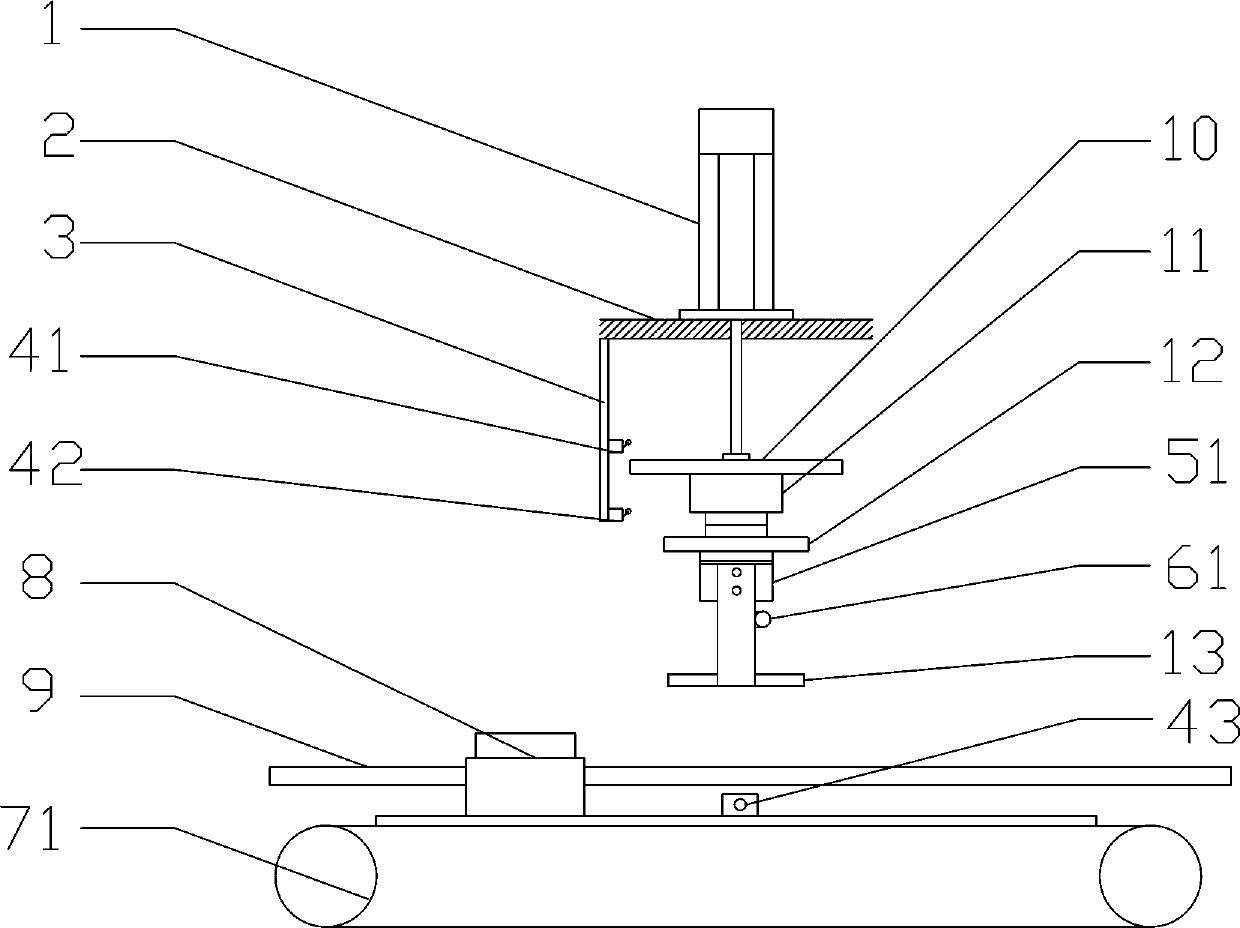

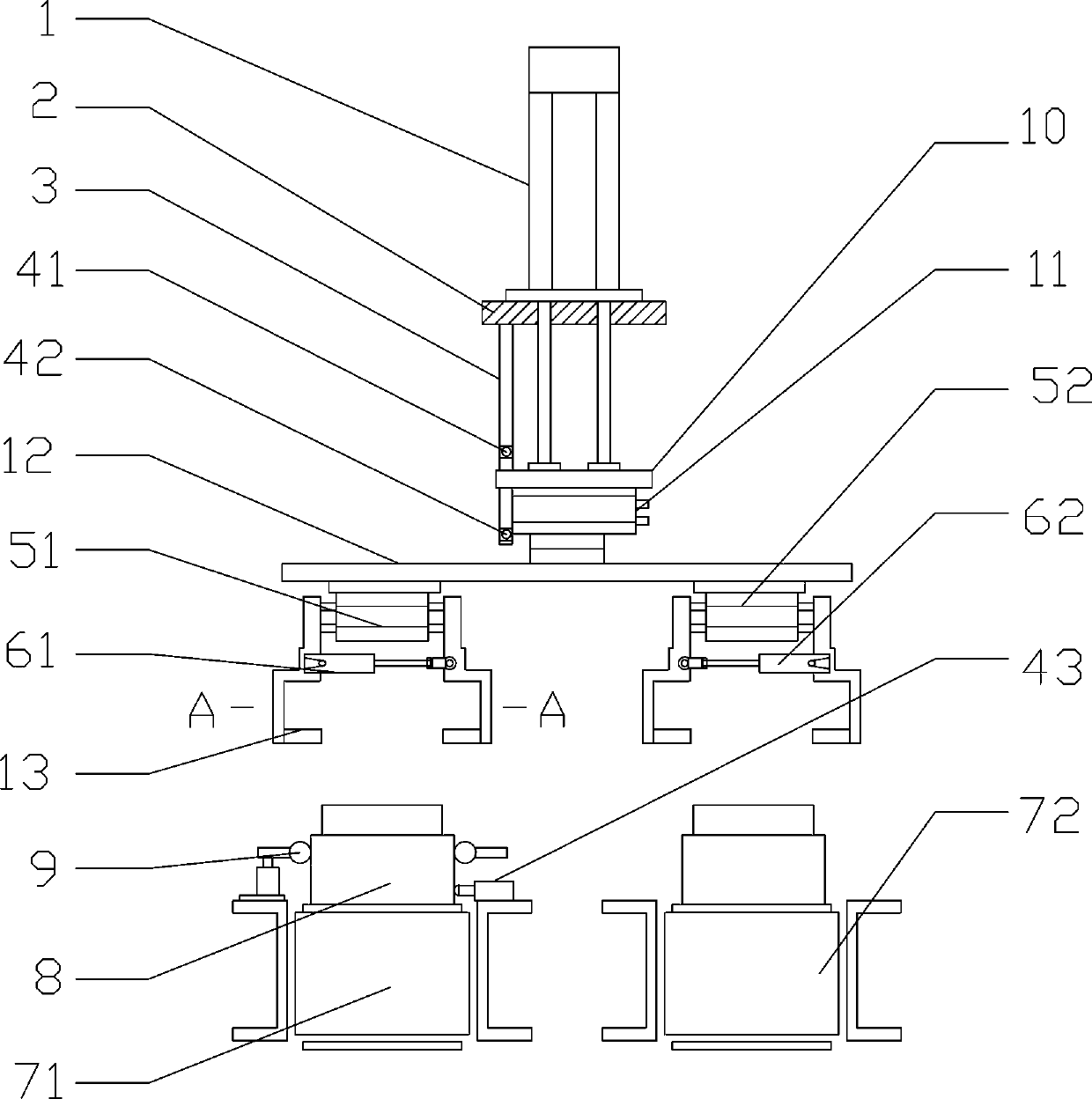

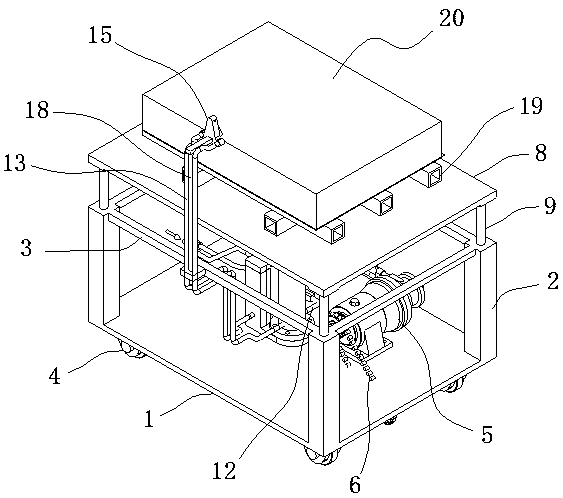

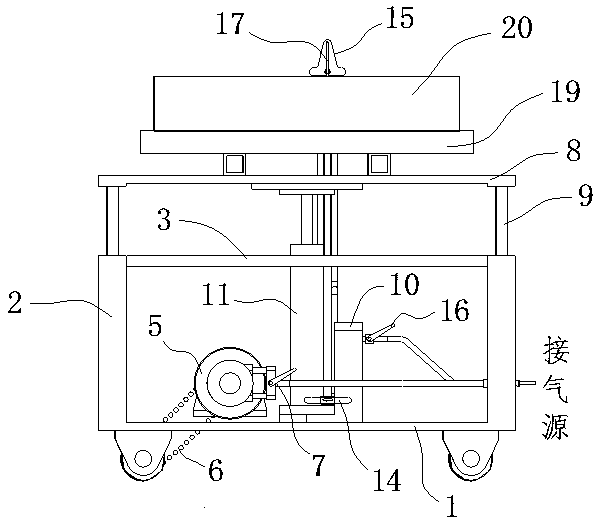

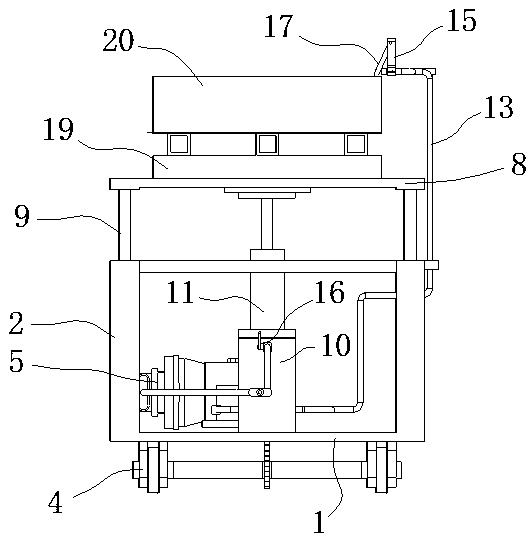

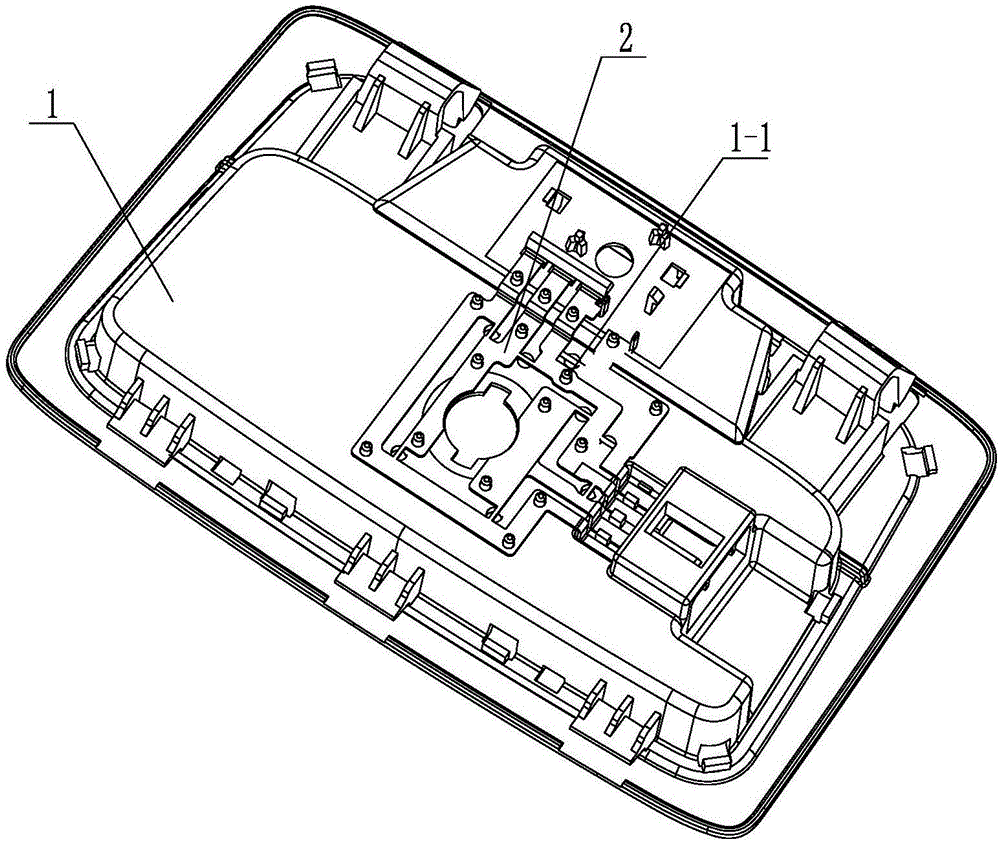

Plastic hot riveting device for automobile lamp

The invention relates to a plastic hot riveting device for an automobile lamp. A workbench is provided with a lamp body positioning mechanism, a press riveting mechanism, a rivet head grabbing mechanism and a heating mechanism. The lamp body positioning mechanism comprises a push air cylinder, a lamp body positioning base and a floating positioning base. The push air cylinder installed on the workbench is connected with the lamp body positioning base. The floating positioning base is connected with the lamp body positioning base and arranged at the upper portion of the lamp body positioning base. A rivet head positioning plate on the floating positioning base is borne on a lower elastic body. The press riveting mechanism comprises a rivet pressing air cylinder, guide columns and a rivet pressing mechanism, wherein the rivet pressing air cylinder is connected with the rivet pressing mechanism. A pressing base of the rivet pressing mechanism is provided with pressing columns and air blowing pipes, and elastic push rods connected to the pressing base are opposite to the rivet head positioning plate. The rivet head grabbing mechanism comprises a support, a lifting rod and a movable rod which are connected. The heating mechanism comprises a heating furnace and a rotary disc, and the heating furnace and the rotary disc are fixed to the workbench. The plastic hot riveting device is reasonable in structure, rapid hot riveting and cooling can be achieved during multi-point riveting, the riveting quality can be ensured, and the riveting efficiency can be improved as well.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

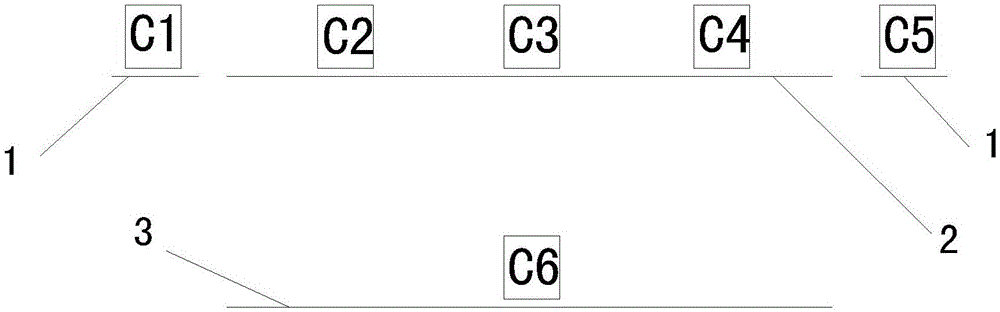

Complete machine leakage detection line for diesel engine

ActiveCN103935717ATimely online repairDoes not affect circulationMechanical conveyorsDiesel engineDiesel fuel

The invention relates to a detection line, in particular to a complete machine leakage detection line for a diesel engine and belongs to the technical field of engine assembly. The complete machine leakage detection line comprises a main line body, wherein a first rotary table, a second rotary table and a third rotary table are arranged on the main line body from left to right in sequence. A first storage section line body is arranged on one side of the first rotary table, and a first leakage detector and a first repair line body are arranged on the other side of the first rotary table. A second storage section line body is arranged on one side of the second rotary table, and a second leakage detector and a second repair line body are arranged on the other side of the second rotary table. A third storage section line body is arranged on one side of the third rotary table, and a third leakage detector and a third repair line body are arranged on the other side of the third rotary table. By means of the complete machine leakage detection line, takt requirements of complete machine leakage detection of the diesel engine can be met, production takt is not affected when online repair of the diesel engine can be performed, offline repair can be performed conveniently, and production efficiency and productivity are increased greatly.

Owner:CHINA FIRST AUTOMOBILE

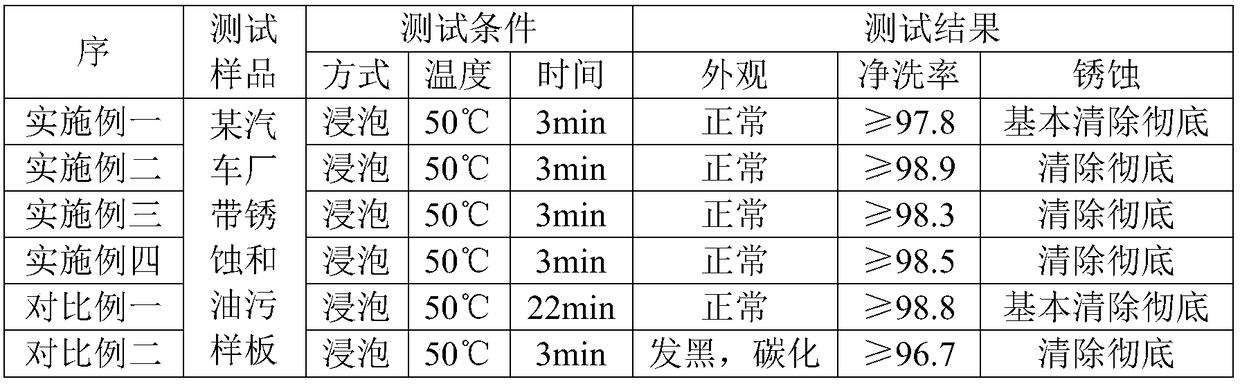

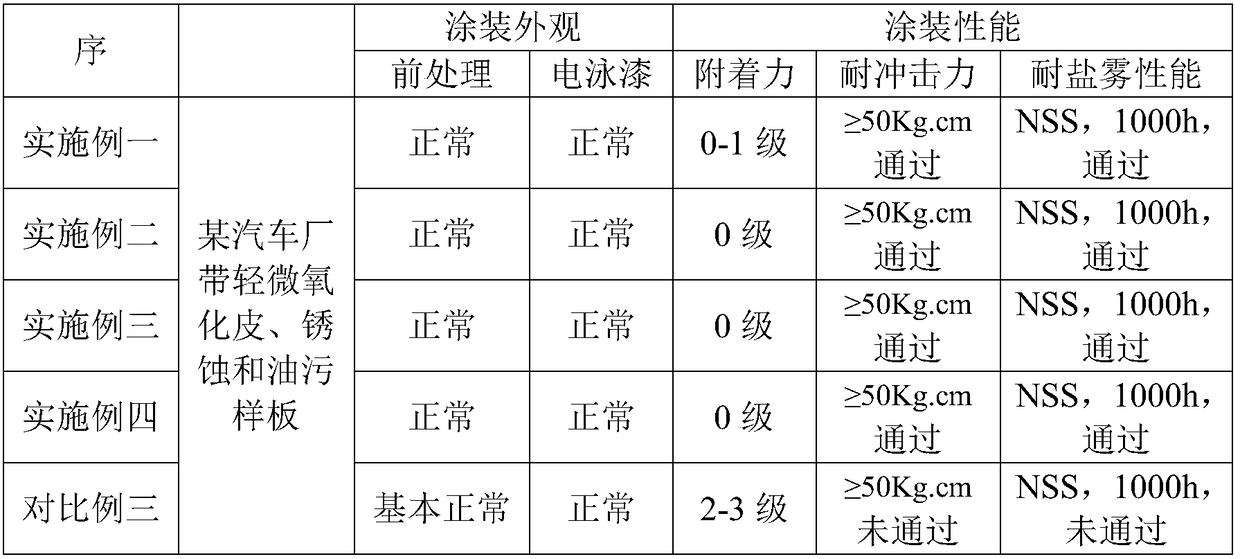

Neutral oil and rust removing detergent used for agreeing with coating pretreatment production takt and preparation method

The invention discloses neutral oil and rust removing detergent used for agreeing with the coating pretreatment production takt and a preparation method and relates to the technical field of metal surface oil and rust removing treatment. The neutral oil and rust removing detergent used for agreeing with the coating pretreatment production takt and the preparation method comprise the following components including, by weight percentage, 5-25% of inorganic salt, 20-40% of organic acid, 5-15% of chelate, 1-5% of surface active agent, 0.5-5% of corrosion inhibitor and the balance water. Accordingto the neutral oil and rust removing detergent, the oil and rust removing speed is high, the existing production takt is not influenced, in the coating application, on the premise of not increasing investment of large equipment or not changing the existing production takt, an original degreasing agent is directly replaced by the neutral oil and rust removing detergent, the existing degreasing working procedure is compatible with the rust removing function, the pretreatment appearance of a metal piece and the appearance of paint films are improved greatly, the adhesive force and the corrosion resisting performance of the paint films are improved remarkably, and the whole coating quality is improved.

Owner:湖北博新材料保护有限公司

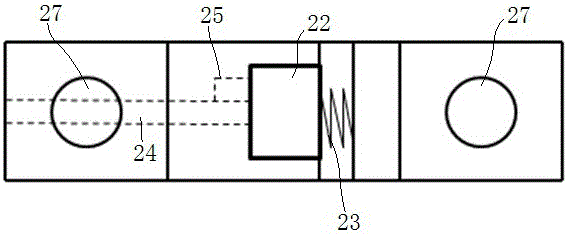

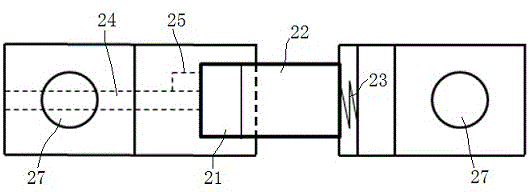

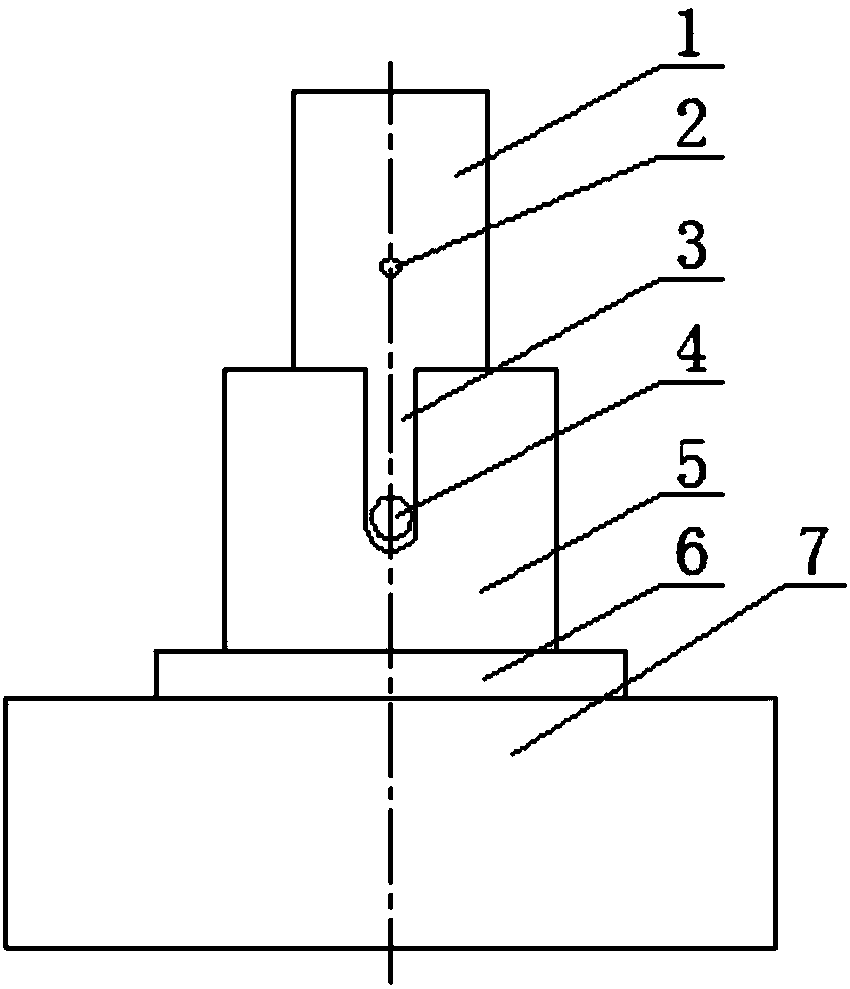

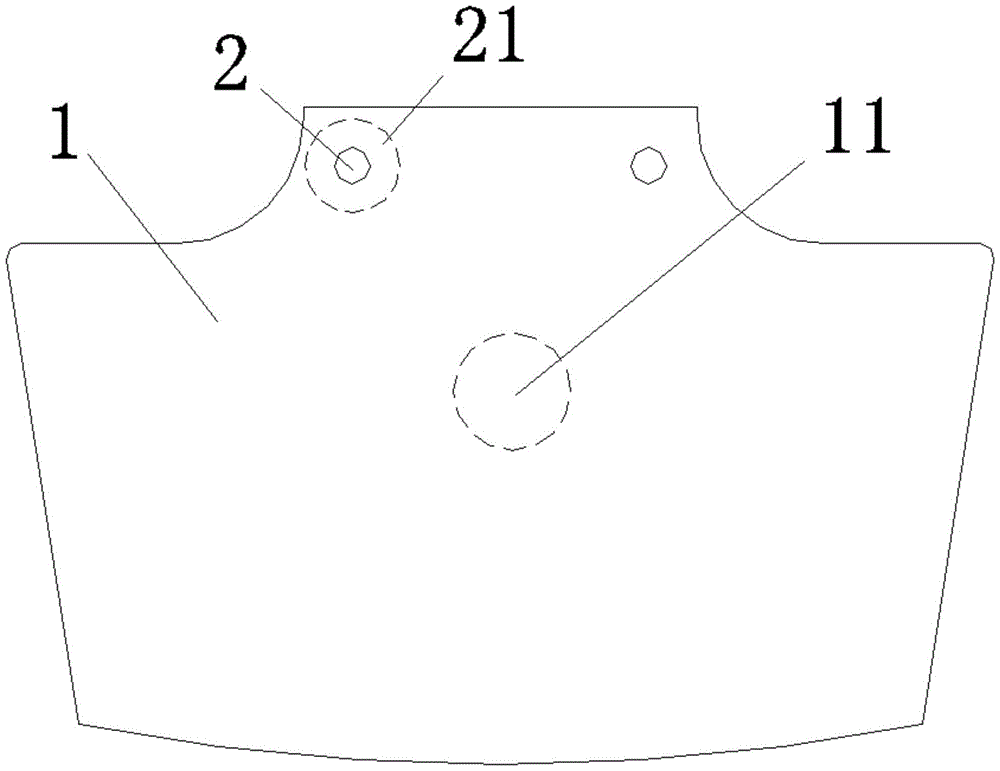

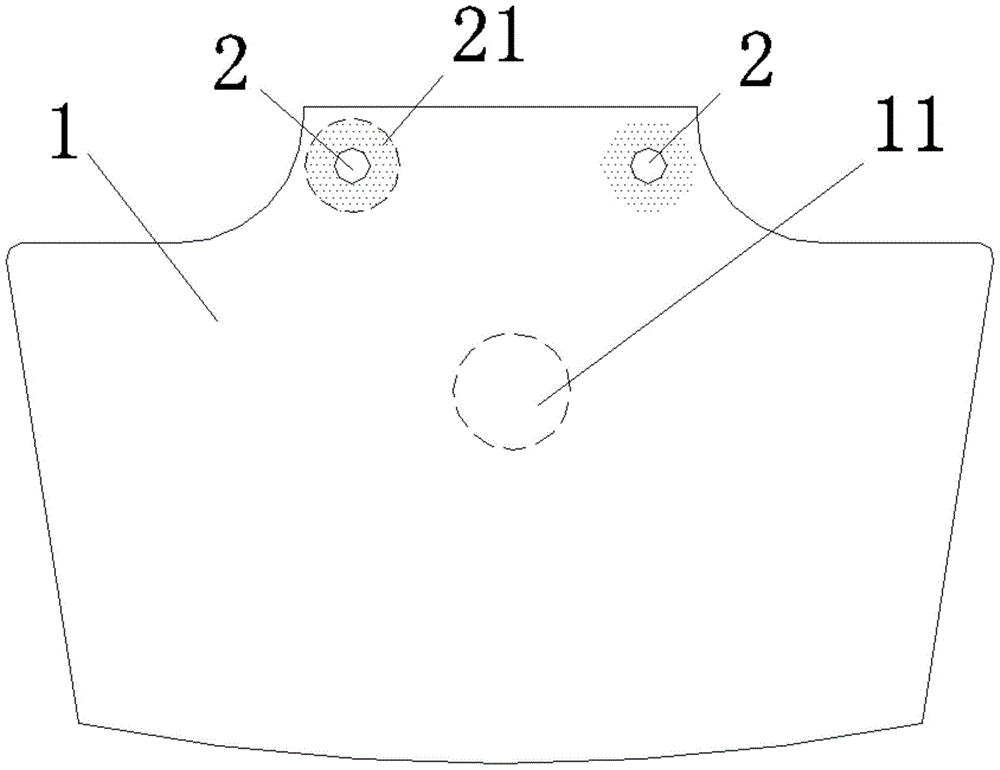

Connecting rod with two-stage-adjustable length

ActiveCN106089978AAdjustable lengthEasy to produceConnecting rodsEngine controllersLocking mechanismSelf locking

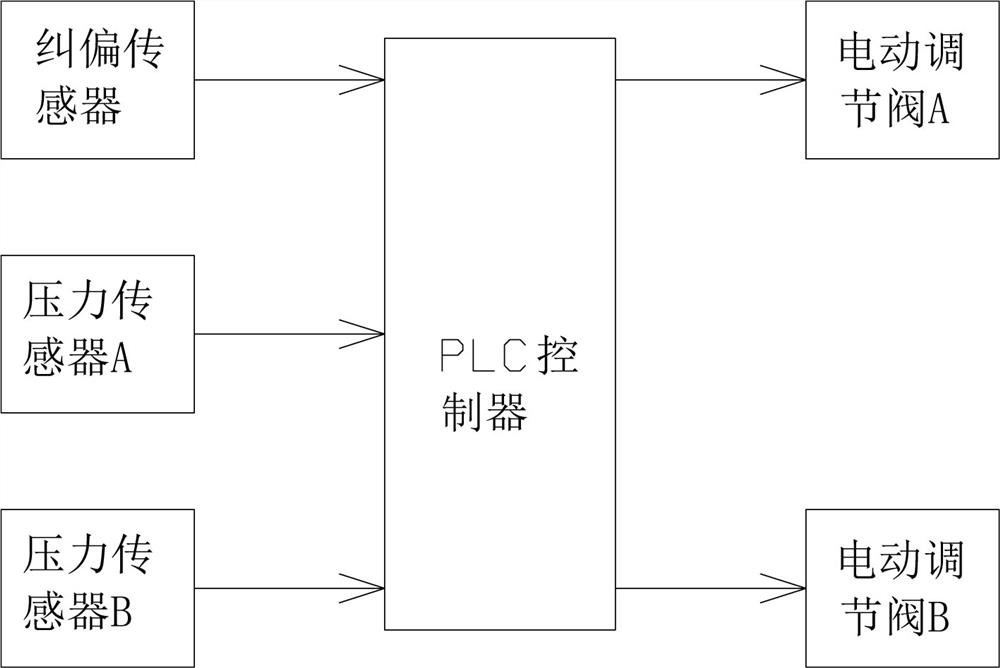

The invention relates to a connecting rod with the two-stage-adjustable length. The connecting rod comprises a large connecting rod head (1) and a small connecting rod head (3) and is characterized by further comprising a variable-length rod body (2), wherein one end of the variable-length rod body (2) is connected with the large connecting rod head (1), and the other end of the variable-length rod body (2) is connected with the small connecting rod head (3); the variable-length rod body (2) comprises a cavity (21) and a valve rod (22) which are connected with each other in an inserted manner, a connecting head at the bottom end of the cavity (21) is connected with one end of the large connecting rod head (1), and the bottom of the cavity (21) communicates with an oil duct hole at a crankshaft connecting hole in the large connecting rod head (1) by the aid of a main oil duct (24); and a connecting head at the other end of the valve rod (22) is connected with the small connecting rod head (3), and a spring (23) is arranged between the valve rod (22) and the connecting head of the valve rod (22). A self-locking mechanism (26) is further arranged between the cavity wall of the cavity (21) and the valve rod (22). Engine oil pressure control is adopted, and two-stage length adjustment of the connecting rod is realized by the aid of different oil pressures.

Owner:CHERY AUTOMOBILE CO LTD

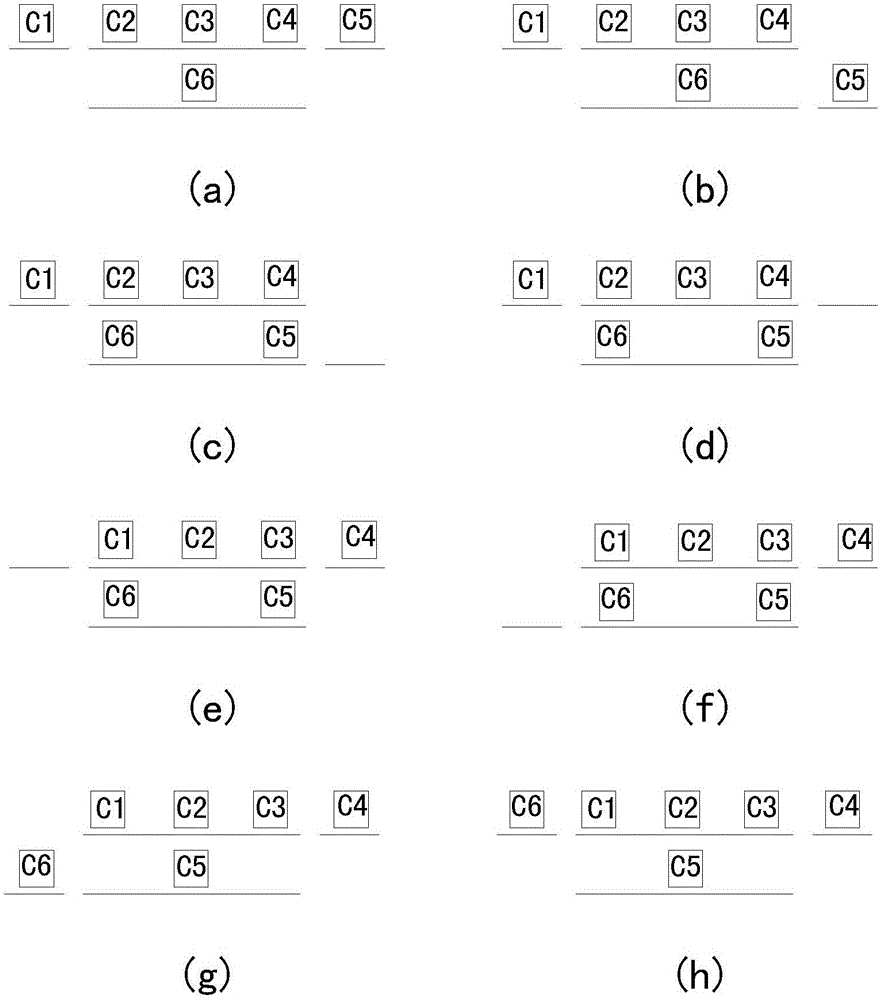

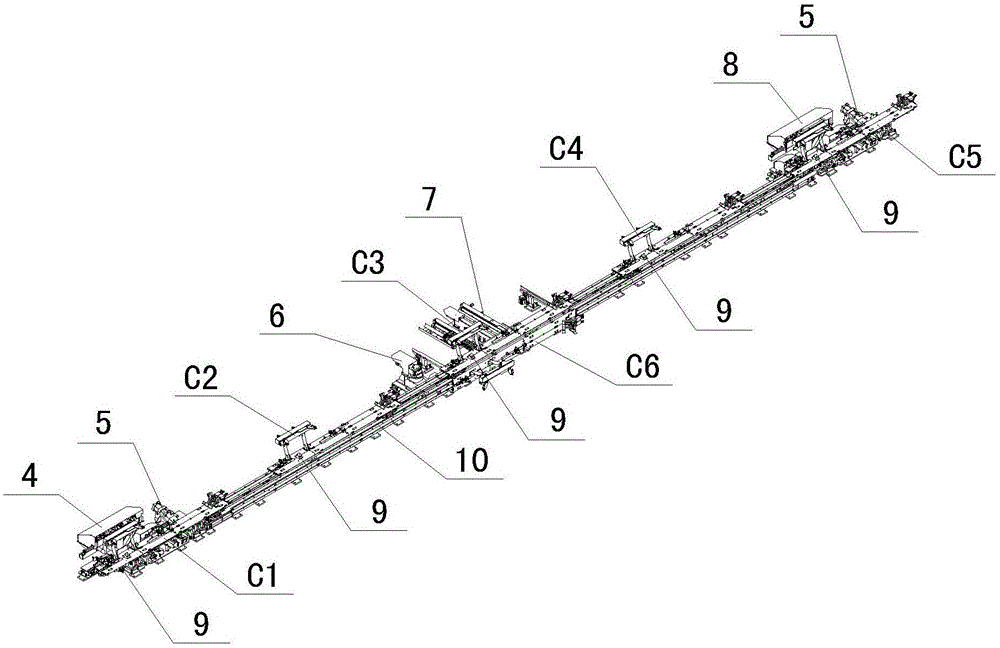

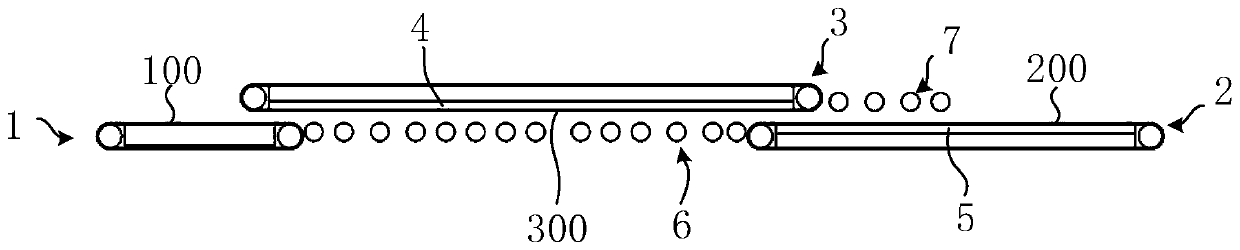

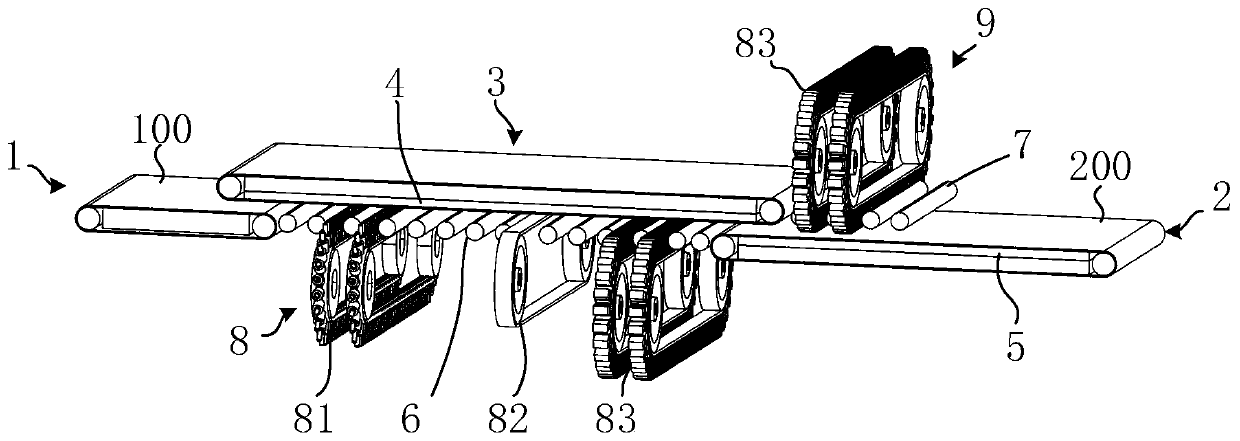

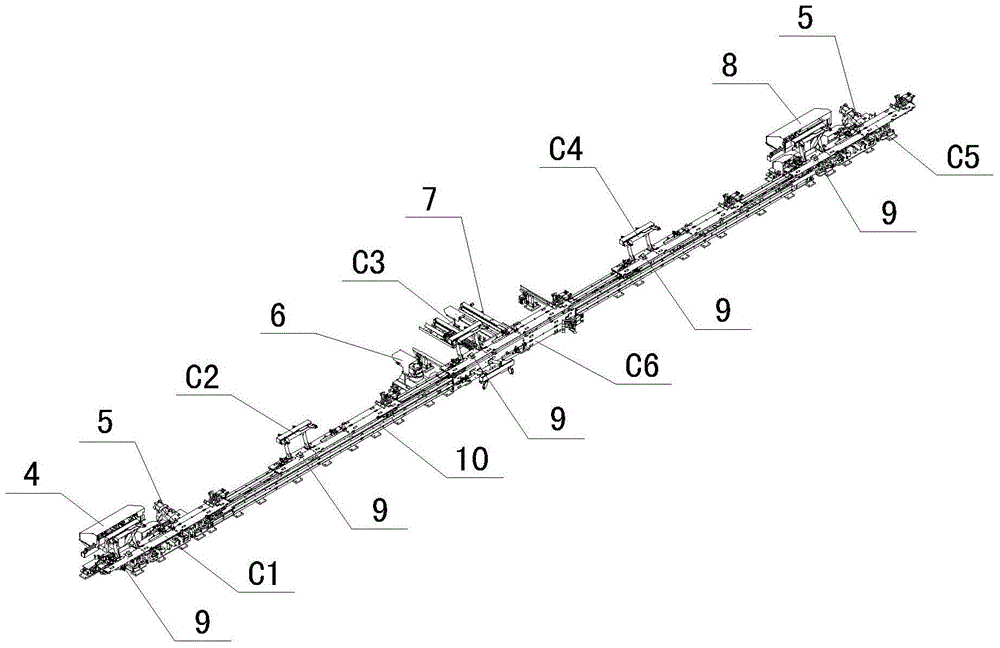

Tackle circulating transporting device and conveying method thereof

ActiveCN105059859AReduce in quantitySolving Ergonomic IssuesMechanical conveyorsProduction lineEngineering

The invention discloses a tackle circulating transporting device and a conveying method thereof. The device comprises a tackle workpiece locking external force device, a tackle workpiece loosening external force device, a tackle transferring-to-clamp switching device, a tackle control mechanism, a tackle movement mechanism, rails and multiple tackles arranged on the rails. The rails comprise the movable rail and the fixed rail. The fixed rail comprises parallel conveying rail bodies and return rail bodies. A movable rail switching device is arranged between the movable rail and the fixed rail. The tackles are distributed on various stations of a production line, the space of a plant is not independently occupied, no lifting mechanism is arranged, the scale space in the height direction is reduced, and the ergonomic problem of an existing reciprocating conveying mechanism is solved. The tackle circulating transporting device can directly work on the tackles without affecting the production takt, the number of the tackles needed for circulating conveying is small, conveyance and return of the tackles can be achieved through the same tackle movement mechanism, and therefore tackle circulation is achieved, and the utilization efficiency of the conveying device is improved.

Owner:四川成焊宝玛焊接装备工程有限公司 +1

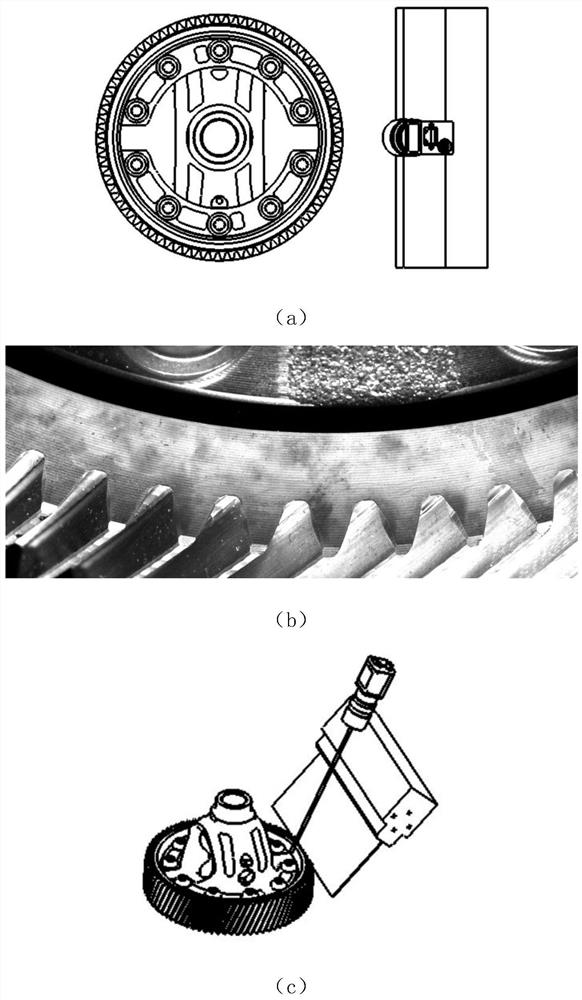

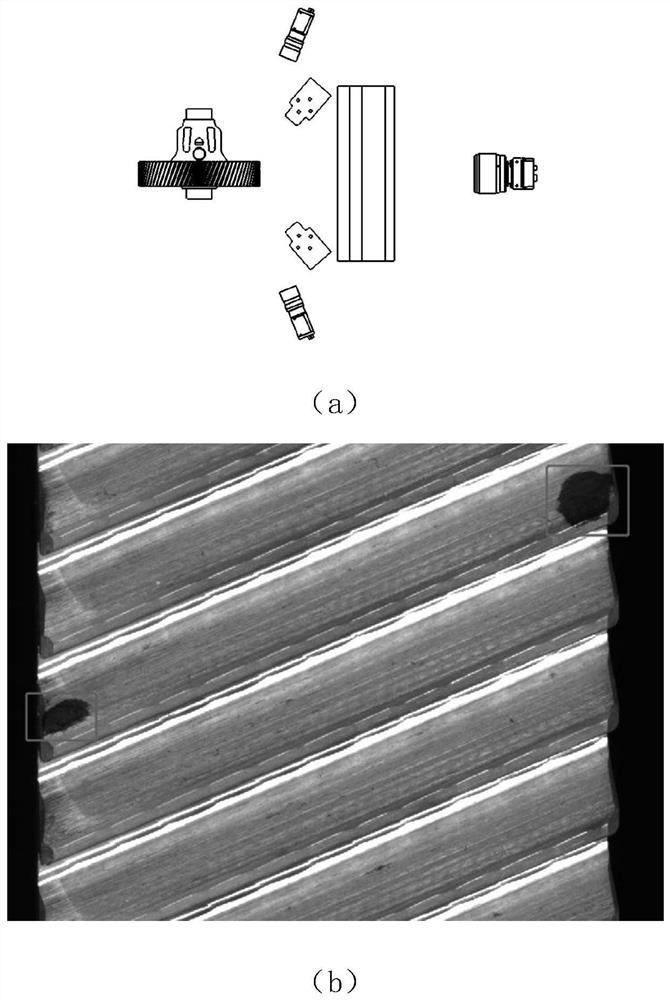

Image acquisition system and method based on gear shaft visual detection, product, equipment and terminal

PendingCN112903693AEfficient collectionIncrease reflectionOptically investigating flaws/contaminationProduction lineGear wheel

The invention discloses an image acquisition system and method based on gear shaft visual detection, a product, equipment and a terminal, and relates to the technical field of gear shaft product defect detection and visual optical design. A shooting station is arranged, the upper and lower end surfaces and the upper and lower tooth surfaces of a gear shaft respectively use a set of independent shooting units which are respectively used for detecting surface defects of the upper and lower end surfaces and the upper and lower tooth surfaces of the gear shaft; end surface shooting units are arranged, the shooting units shooting the upper and lower end surfaces are mirror images of each other along the tooth surfaces, and the upper and lower end surface areas of the gear are shot; tooth surface shooting units are arranged, the shooting units shooting the upper and lower tooth surfaces are mirror images of each other along the axis of the gear, and the upper and lower tooth surface areas are shot. According to the optical design system, the picture information of each surface of the gear shaft is effectively collected, the number of cameras and light sources is reduced, mechanical motion scheme design is facilitated, and potential risks and equipment maintenance cost are reduced. When the optical design system is implemented, an original gear shaft production line does not need to be broken, and shooting can be completed only by stopping on the original production line.

Owner:菲特(天津)检测技术有限公司

Detection device with mistake-proofing function

InactiveCN108246960AEasy to operateOvercome bad problemsMeasurement devicesSurface mountingEngineering

Owner:林德英利(天津)汽车部件有限公司

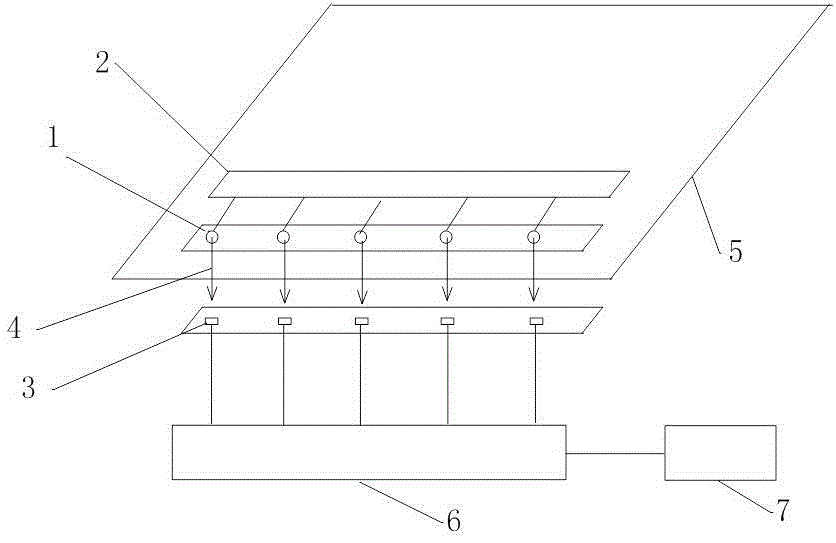

Detection device for liquid crystal display panel of touch screen production technology

InactiveCN105425432ASimple structureDoes not affect production taktUsing optical meansNon-linear opticsLaser transmitterAbnormal thickness

The invention discloses a detection device for the thickness of a liquid crystal panel. The detection device is characterized by comprising a light emitting system composed of a plurality of laser emitters and a laser controller, a light receiving system composed of laser sensors matched with the laser emitters in number, and a light processing device, wherein the laser emitters and the laser sensors are located above and below the liquid crystal panel. The light processing device and the light receiving system are connected in a communication mode. According to the detection device, online liquid crystal panel thickness measurement can be achieved, and the phenomenon that a panel with the abnormal thickness enters vacuum coating equipment, a photoresist coating machine and an exposure machine is avoided.

Owner:范师华

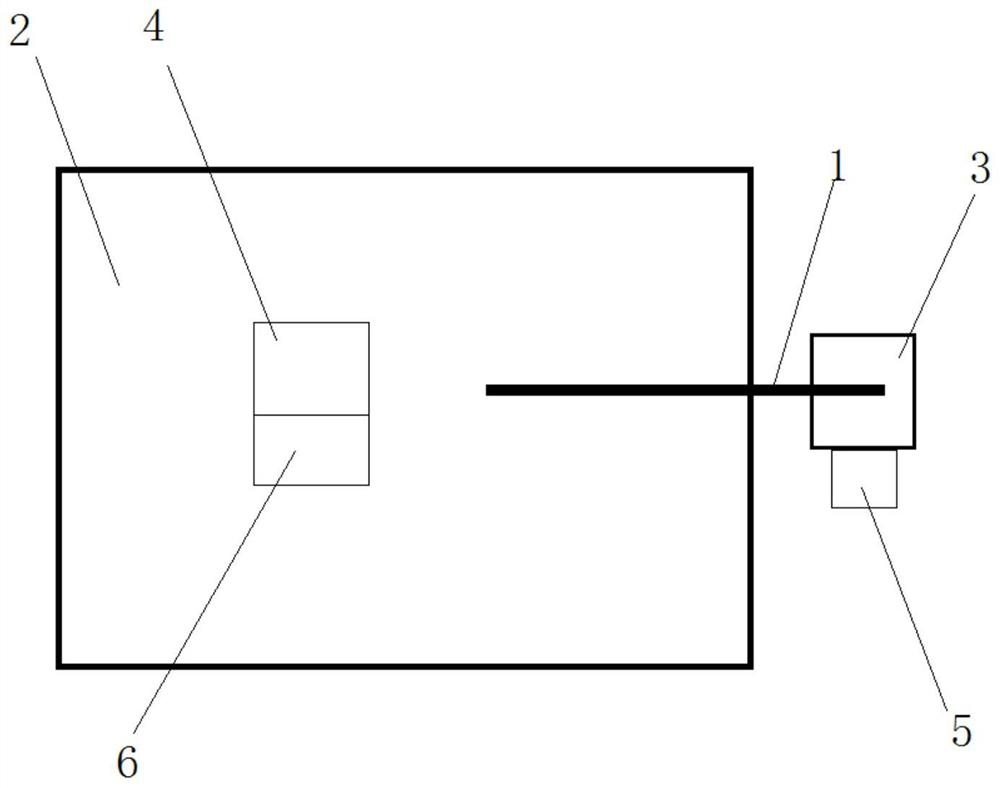

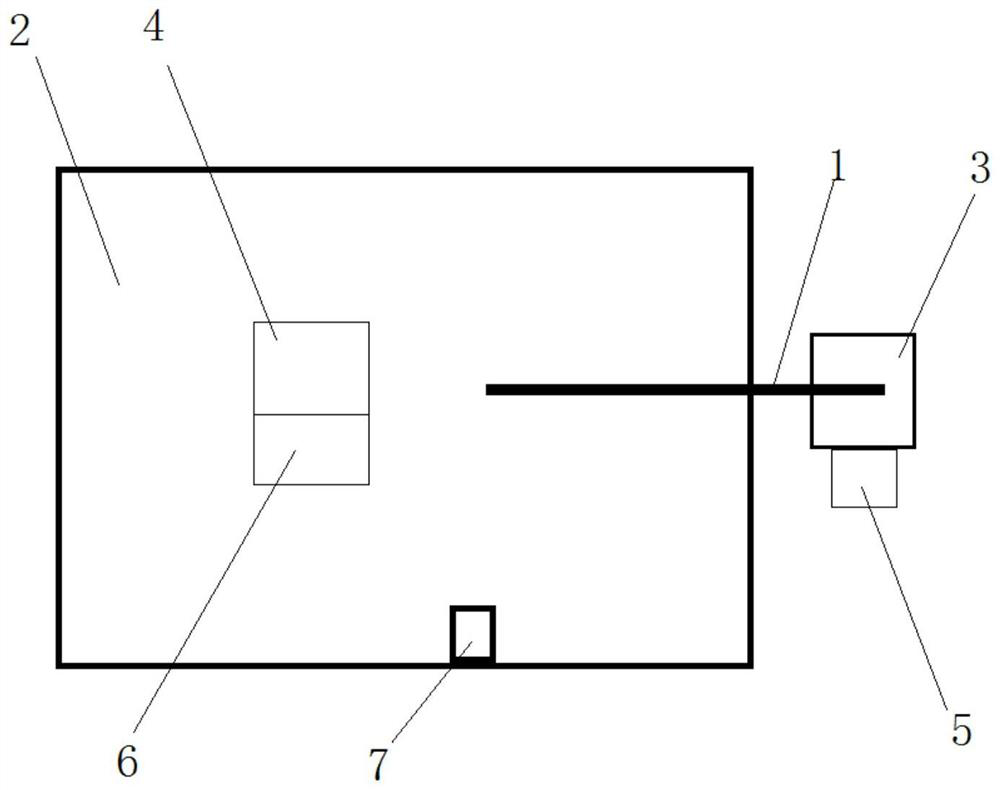

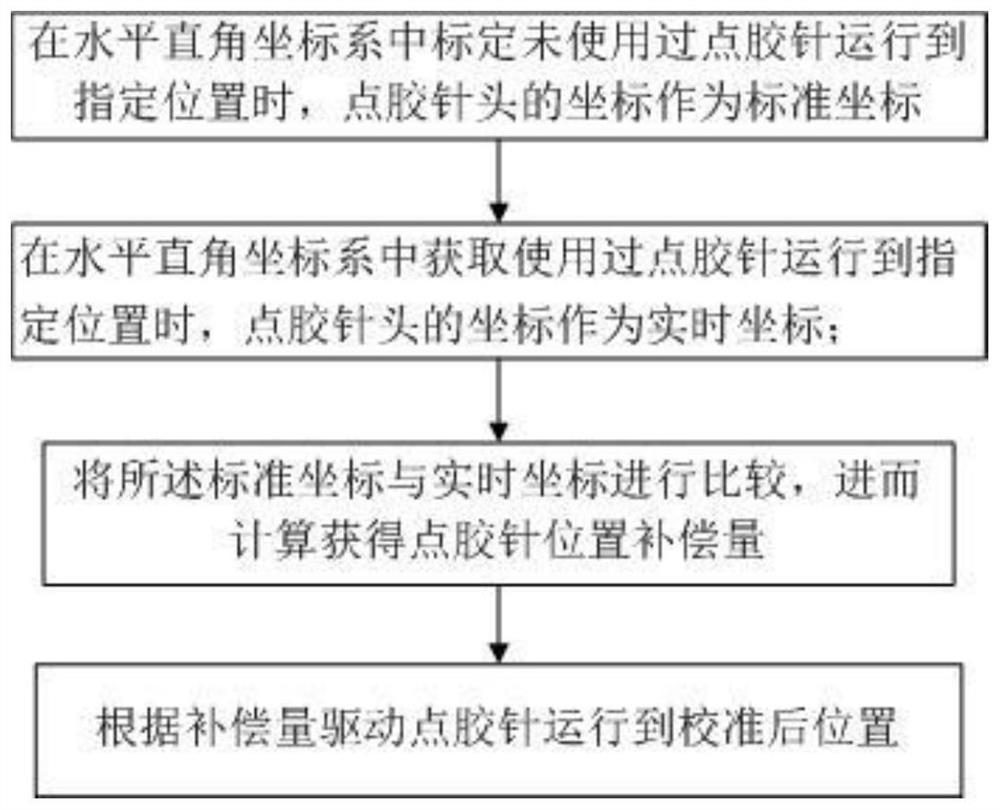

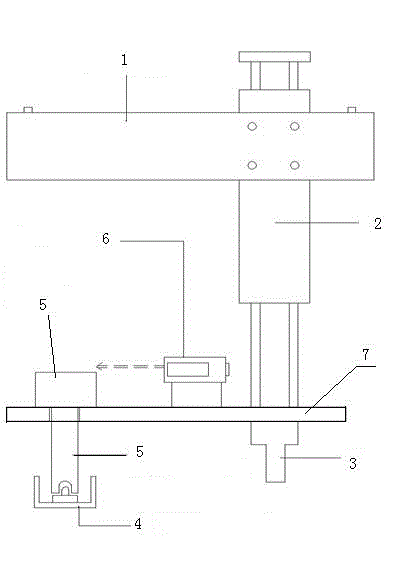

Dispensing needle position calibration system and dispensing needle position calibration method

InactiveCN112756194AAvoid Length EffectsThe result is accurateLiquid surface applicatorsSpraying apparatusMechanical engineeringBiomedical engineering

The invention discloses a dispensing needle position calibration system which is used for position calibration of a dispensing needle of a dispensing machine. The dispensing needle is arranged above a dispensing platform, the dispensing needle is driven by a driving module to move within a specified range above the dispensing platform, and the dispensing needle performs dispensing operation on a product located on the dispensing platform. The dispensing needle position calibration system comprises an acquisition module and a control compensation module; the acquisition module is arranged on the dispensing platform, the control compensation module controls the driving module to drive the dispensing needle to move to a specified position above the acquisition module, the acquisition module acquires preset data for the dispensing needle, the acquisition module sends the acquired preset data to the control compensation module, the control compensation module calculates a compensation amount according to a compensation calculation rule, and the driving module drives the dispensing needle to move to the calibrated position according to the compensation amount sent by the control compensation module. The invention further discloses a dispensing needle position calibration method. According to the device and the method, the position of the dispensing needle can be quickly and accurately calibrated.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Anti-fault detecting device used in automated assembly production devices

ActiveCN102941247AImprove one-time assembly pass rateSimple structureMetal working apparatusRhythmLaser

The invention discloses an anti-fault detecting device used in automated assembly production devices, comprising a set of vacuum adsorption molds which are connected through a mechanical arm and can complete absorb and release assembly parts, the vacuum adsorption molds and a set of detection units for sensing whether the assembly parts exist or not by laser are arranged on a same fixed plate in parallel to each other, the fixed plate is connected up to the mechanical arm, and the center distance between the detection unit and the vacuum adsorption mold is identical to the distance between adjacent two assembly parts in the automated assembly production device. According to the invention, the anti-fault detecting device disclosed herein can accurately sense whether there is a failure of assembling parts or not, thus the primary assembling qualification of the products is significantly raised; the structure is simple, the installation is convenient, and the flexibility and practicality are achieved; there is no influence on the production rhythm, and the primary assembling qualification is significantly raised.

Owner:曲阜天博汽车零部件制造有限公司

Solder strip pre-stretching mechanism

InactiveCN106826020AOperating time close toIncrease production capacityFinal product manufactureWelding/cutting auxillary devicesMechanical engineeringPre stretching

The invention relates to a solder strip pre-stretching mechanism. The solder strip pre-stretching mechanism comprises a support structure and is characterized in that a first pressing mechanism and a second pressing mechanism are arranged on upstream side and downstream side of the support structure; the first pressing mechanism comprises a first pressing plate and a first pressure bearing plate fixedly connected to a first support plate which is arranged horizontally and glidingly in the direction of the upstream side and the downstream side, and the first pressing plate is connected with a first pressing drive device; the second pressing mechanism comprises a second pressing plate and a second pressure bearing plate connected with a second pressing drive device; the first pressing mechanism is connected with a stretching mechanism, the stretching mechanism comprises a stretching drive device and a connecting part, and the stretching drive device is connected with the first support plate through the connecting part to drive the first support plate to move horizontally to stretch a solder strip. The solder strip can be stretched to be straightened, so that quality of a cell string can be improved while the production takt of the whole machine cannot be affected, and capacity of a series welding device is improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

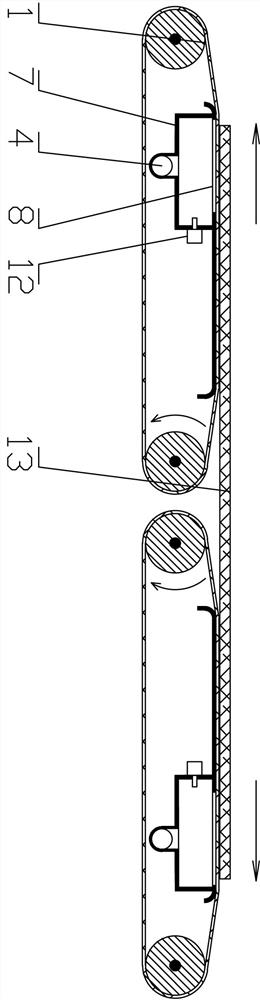

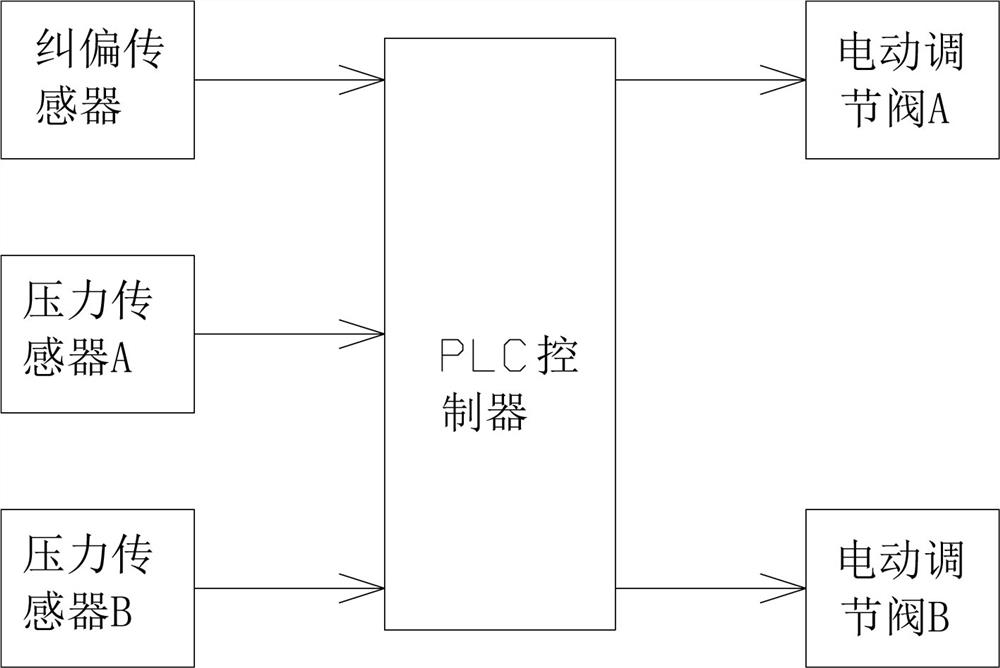

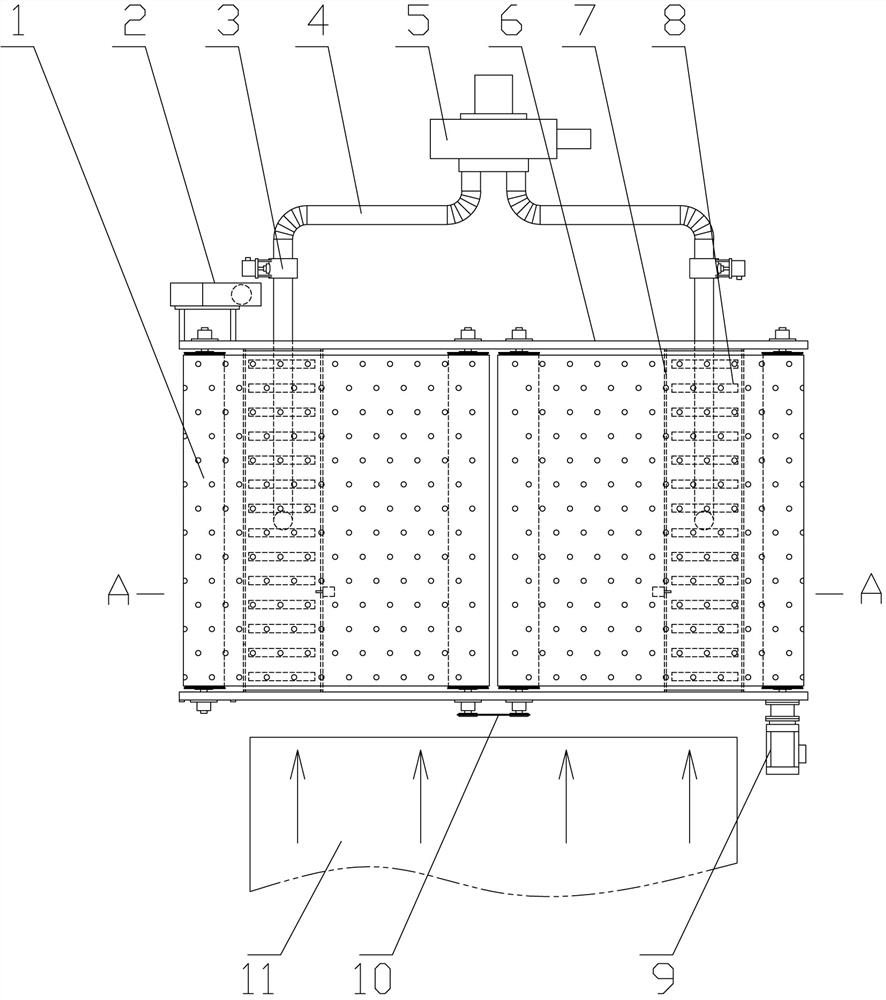

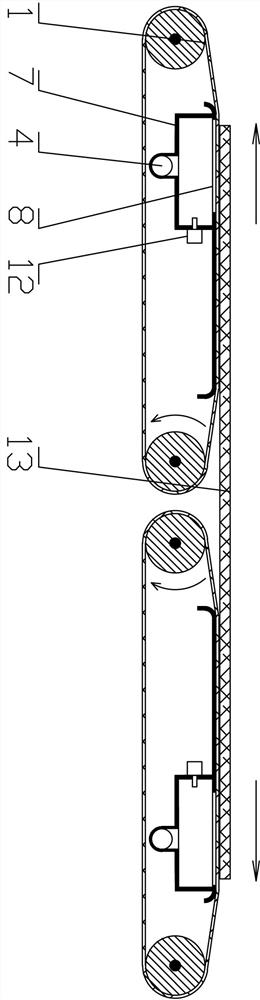

Corrugated paper wrinkle removing device and method

ActiveCN112109386AEliminate Surface WrinklesSmooth and beautiful surfaceMechanical working/deformationStructural engineeringAir pump

The invention discloses a corrugated paper wrinkle removing device and a method. The corrugated paper wrinkle removing device comprises a rack and an air extracting pump, wherein two flat suction mechanisms are arranged in the rack, each flat suction mechanism comprises a perforating belt conveyor assembled in the rack, air extracting boxes are arranged in the perforating belt conveyors, a plurality of air extracting holes are formed in the surfaces of the air extracting boxes, the air extracting pump communicates with the air extracting boxes through air extracting pipes, and the conveying directions of the two perforating belt conveyors in the two flat suction mechanisms are opposite. The corrugated paper wrinkle removing device can flatten corrugated paper.

Owner:HUBEI TAISHENG PACKAGING

A corrugated paper wrinkle removal device and method

ActiveCN112109386BBonding surface is flatThe bonding surface is flat and beautifulMechanical working/deformationAir pumpEngineering

A corrugated paper wrinkle removal device and method, including a frame and an air pump, two sets of suction leveling mechanisms are arranged in the frame, and the suction leveling mechanism includes a perforated belt conveyor assembled in the frame, and the perforated belt conveys There is a suction box inside the machine, and a number of suction holes are opened on the surface of the suction box. The suction pump is connected to the suction box through the suction pipe. The two perforated belt conveyors in the two sets of suction leveling mechanisms have opposite conveying directions. The present invention is capable of leveling corrugated corrugated paper.

Owner:HUBEI TAISHENG PACKAGING

Feeding device, surface treatment equipment and surface treatment method

PendingCN110509061ADoes not affect production taktReduce investmentOther manufacturing equipments/toolsProduction lineEngineering

The invention belongs to the technical field of surface treatment, and discloses a feeding device, surface treatment equipment and a surface treatment method. The feeding device comprises a first conveying mechanism, a second conveying mechanism and a third conveying mechanism which is located between the first conveying mechanism and the second conveying mechanism and has a downward working surface, wherein the third conveying mechanism is configured with a magnetic unit which is capable of sucking workpieces so as to ensure that both the upper and lower surfaces of the workpieces can undergosurface treatment in the process of conveying the workpieces and overturn equipment such as manipulator and the like is not required for overturning, so that the surface treatment equipment can be matched with the production speeds of the upstream and downstream machining lines under the condition of not influencing the surface treatment quality, thereby not influencing the production cycles of the workpiece production lines and decreasing the equipment investment and space occupation.

Owner:LANUSS LNDUSTRIAL EQUIP SUZHOU CO LTD

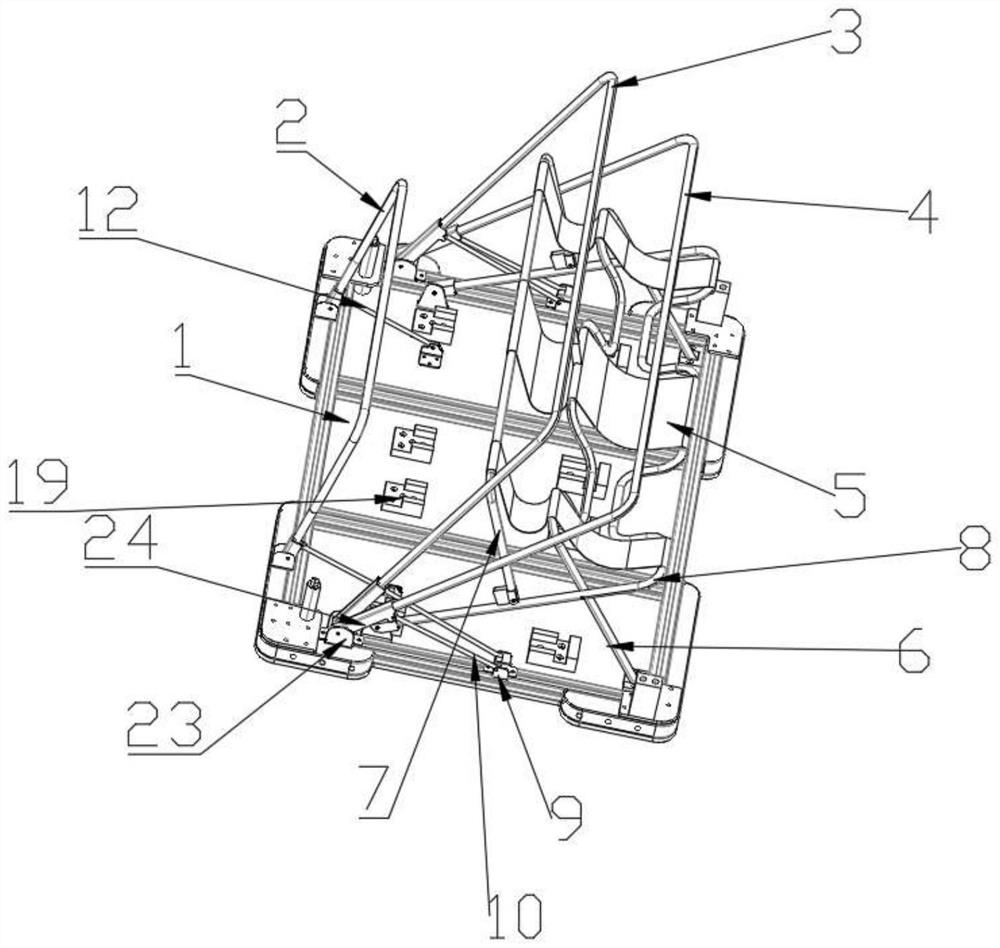

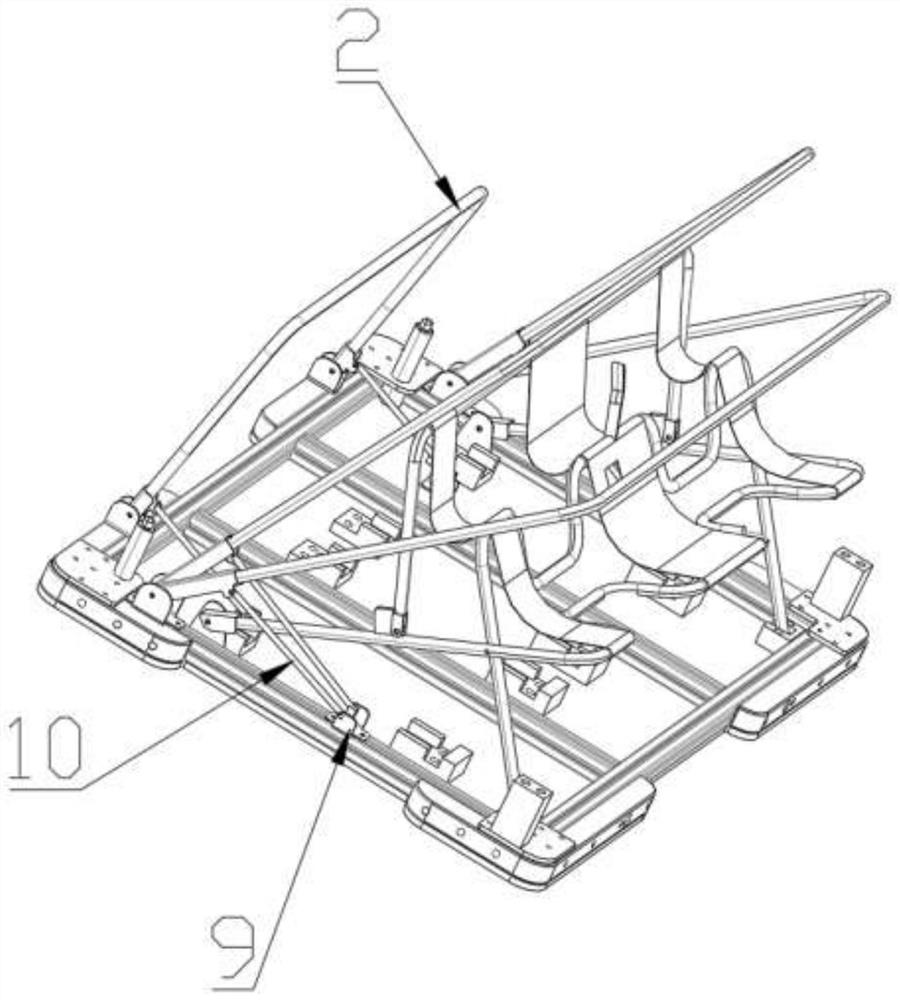

A rotary storage mechanism for body-in-white welding assembly fixture

InactiveCN104002076BShort setup times for changeoversDoes not affect production taktWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall footprint

The invention discloses a rotary storing mechanism for a body-in-white welding total-splicing clamp. The rotary storing mechanism comprises a driven end base, a driving end base and a rotary body transversely erected between the driven end base and driving end base, a plurality of clamp containing areas are evenly arranged along the circumference of the rotary body, each clamp containing area is provided with a clamp track, the lower end face of each clamp track is provided with a forked plate mechanism for fixing the clamp on the clamp tracks, and the driven end base and the driving end base are provided with bolt mechanisms capable of limiting rotation of the rotary body respectively. Compared with the prior art, the rotary storing mechanism has the advantages that the remodeling preparation time is short, and the production frequency is not influenced; multi-car-model collineation can be achieved; floor space is small, and a system with the rotary clamp storing mechanism is smallest in floor space compared with an existing multi-car-model collineation flexible total-splicing system side body clamp storage system capable of being switched along with lines.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

Shaft sleeve detection sorting device and method

ActiveCN111112119ADoes not affect production taktImprove detection and sorting efficiencySortingStructural engineeringPiston rod

The invention discloses a shaft sleeve detection sorting device and method. The shaft sleeve detection sorting device comprises a first belt conveyor, two guiding rods are arranged on a rack of the first belt conveyor, and form a channel in the first belt conveyor in a spacing mode, the first belt conveyor carries shaft sleeves to pass through the interior of the channel, a bracket is arranged onone side of the first belt conveyor, a linear air cylinder is mounted on the bracket, the lower end of a piston rod of the linear air cylinder is connected with a rotating air cylinder through a firstsupporting plate, a second supporting plate is connected to the rotating end of the rotating air cylinder, a first pneumatic clamping claw is mounted at one end of the second supporting plate, clamping plates are fixedly mounted on piston rods at the two ends of the first pneumatic clamping claw correspondingly, and triangular notches are formed in the opposite end faces of the two clamping plates correspondingly. The shaft sleeve detection sorting device and method are used for solving the problems that when the shaft sleeves are manually detected, the efficiency is low, and false detectionor missing detection is prone to occurring.

Owner:CHINA THREE GORGES UNIV

A shaft sleeve detection and sorting device and method

ActiveCN111112119BDoes not affect production taktImprove detection and sorting efficiencySortingStructural engineeringPiston rod

A shaft sleeve detection and sorting device and method, including a first belt conveyor, two guide rods are arranged on the frame of the first belt conveyor, and a passage is formed between the two guide rods on the first belt conveyor, and the first The belt conveyor carries the bushing through the channel. A bracket is installed on the side of the first belt conveyor. A linear cylinder is installed on the bracket. The lower end of the piston rod of the linear cylinder is connected to the rotary cylinder through the first support plate, and the second support plate Connected to the rotary end of the rotary cylinder, the first pneumatic gripper is installed at one end of the second support plate, splints are fixedly installed on the piston rods at both ends of the first pneumatic gripper, and triangles are provided on the opposite ends of the two splints. gap. The invention is used to solve the problems that manual detection of shaft sleeves is inefficient and prone to false detection or missing detection.

Owner:CHINA THREE GORGES UNIV

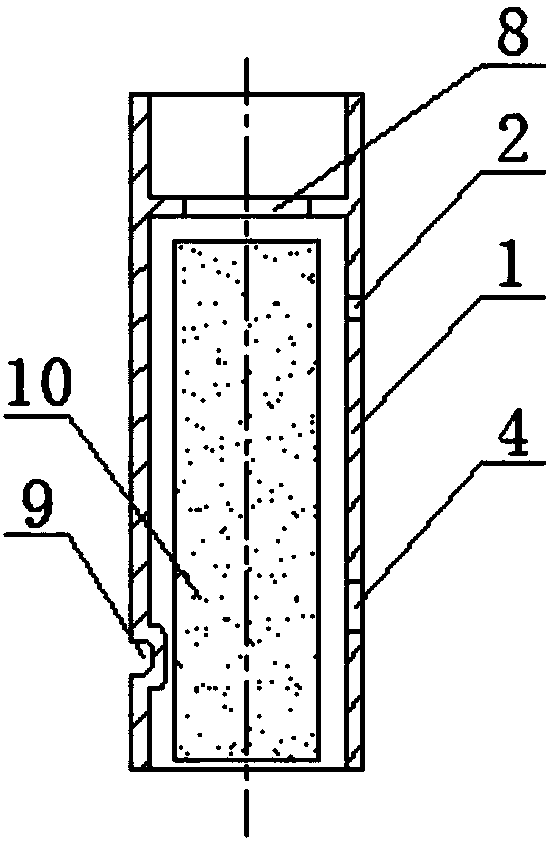

Drying device for centrifugal casting coating layer of cylinder jacket

The invention belongs to the technical field of centrifugal casting, and particularly relates to a drying device for a centrifugal casting coating layer of a cylinder jacket. The drying device comprises a centrifugal casting machine and a metal mold thereof, a front cover plate and a rear bottom plate are arranged at the front end and the rear end of the metal mold respectively, a coating layer is sprayed on the inner wall of the metal mold, a sprue gate is formed in the center of the front cover plate, a flame gun is arranged in front of the sprue gate and erected on a moving trolley, a rail is laid below the moving trolley, the moving trolley can move along the rail, a flame nozzle is arranged on the rear portion, close to the flame penetrating hole, of the flame gun, an ignition gun is arranged on the side of the flame gun, a gas port and a combustion-supporting gas port are formed in the front portion of the flame gun, the gas port is connected with a first gas supply hose through a first gas inlet valve, and the combustion-supporting gas port is connected with a second gas supply hose through a second gas inlet valve. According to the drying device, natural gas is adopted for reverse drying from inside to outside from the metal mold, the coating layer is dried faster and more fully, and casting defects caused by supercooling of a cylinder jacket material are avoided.

Owner:GKN ZHONGYUAN CYLINDER LINER CO LTD

A tempering method and tempering device for glass with holes

ActiveCN105036563BSimple processEasy maintenanceGlass tempering apparatusGlass productionTemperingHydrocotyle bowlesioides

The invention relates to the technical field of glass tempering, in particular to a tempering method for perforated glass. The method includes the following steps: pretreating, placing, heating, forming and cooling, and is characterized in that when a glass sheet is placed on a glass sheet placing section, a fire blowing pipe is used to align the hydrocarbon industrial fuel gas flame to the through hole in the glass sheet for blowing fire, so that the carbon powder can be uniformly adhered to the periphery of the through hole in the glass sheet. The invention further provides a glass tempering device for implementing the method. The glass tempering method and device have the advantages that the process is simple, the device is convenient to maintain, carbon powder blowing is fast, and the original production rhythm is not affected, the yield is high, and no any influence on the appearance or quality of the glass sheet is realized.

Owner:FUYAO GROUP FUJIAN MACHINERY MFG

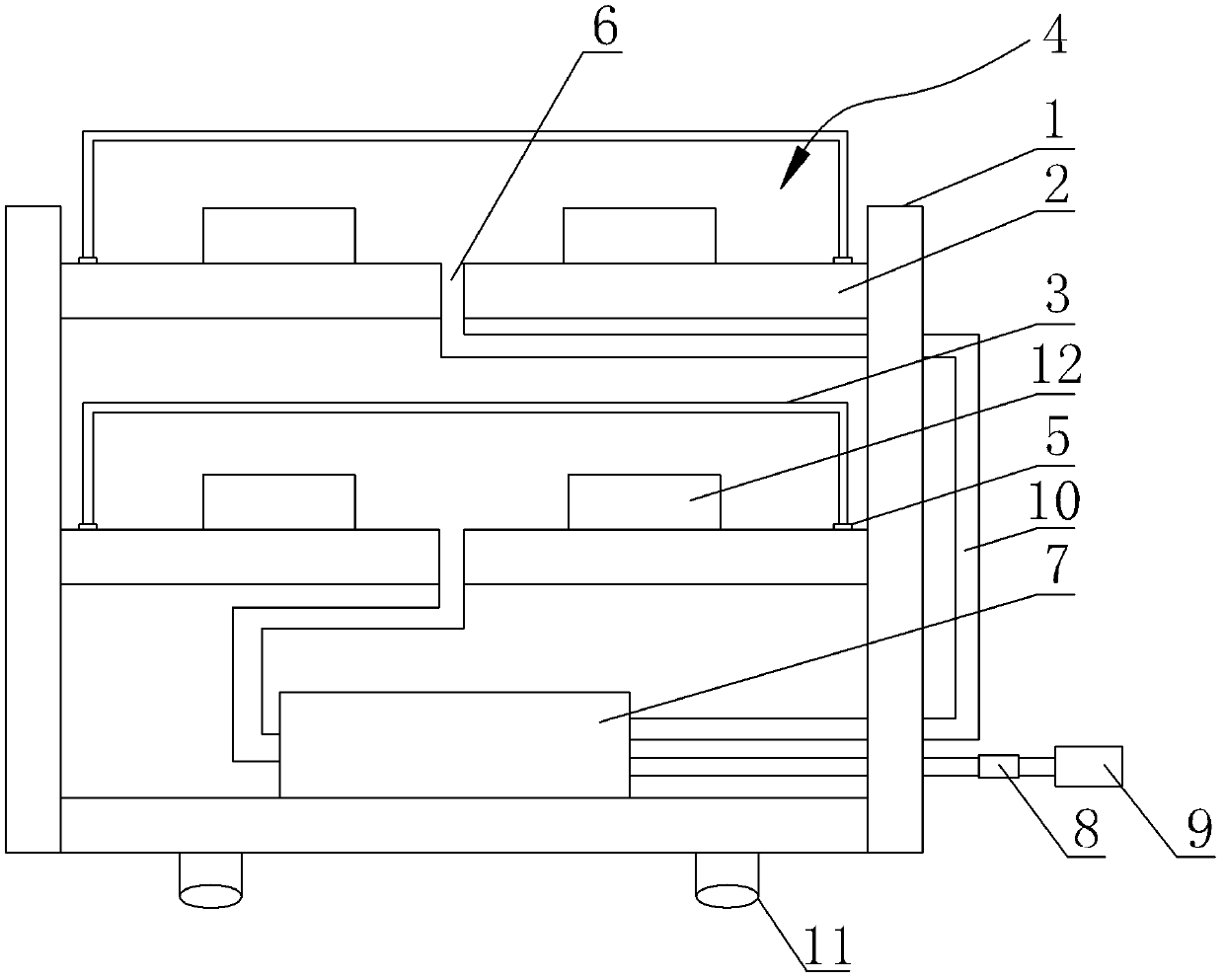

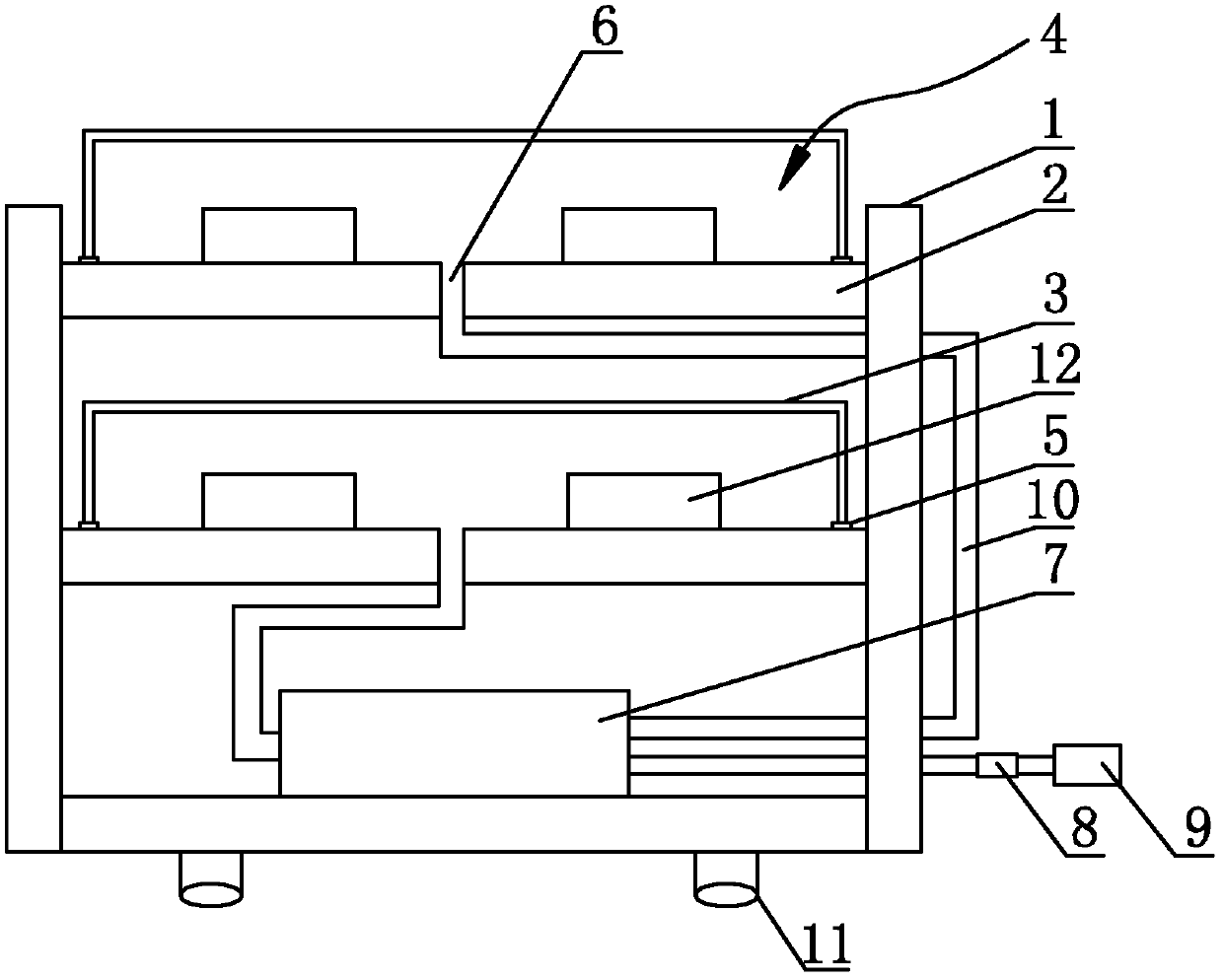

Moisturizing core storing frame

ActiveCN102602604BAvoid Strength LossAvoid breakingLiving organism packagingExternal framesEngineeringStructural engineering

Owner:SUZHOU MINGZHI TECH

Stamping waste collection device

ActiveCN108672584BAchieve liftingRealize regulationMetal-working feeding devicesPositioning devicesWaste collectionEngineering

The object of the present invention is to provide a stamping waste collecting device with a simple structure, convenient control and a high degree of automation. The stamping waste collecting device of the present invention comprises a frame; a traveling mechanism for driving the frame to move; a waste receiving platform mounted on the frame by a lifting mechanism; and a height adjusting mechanismused for reducing the height of the waste receiving platform when the height of waste on the waste receiving platform exceeds a predetermined height. The stamping waste collecting device of the present invention uses the height adjusting mechanism to adjust the height of the waste receiving platform in real time when receiving the waste. Thereby the waste receiving platform is lowered as the height of the waste increases, so that the releasing height of a robot is kept constant, which simplifies the control of the robot and eliminates interference with other components possibly caused by a low releasing height of the robot, thus the safety is improved.

Owner:CHERY AUTOMOBILE CO LTD

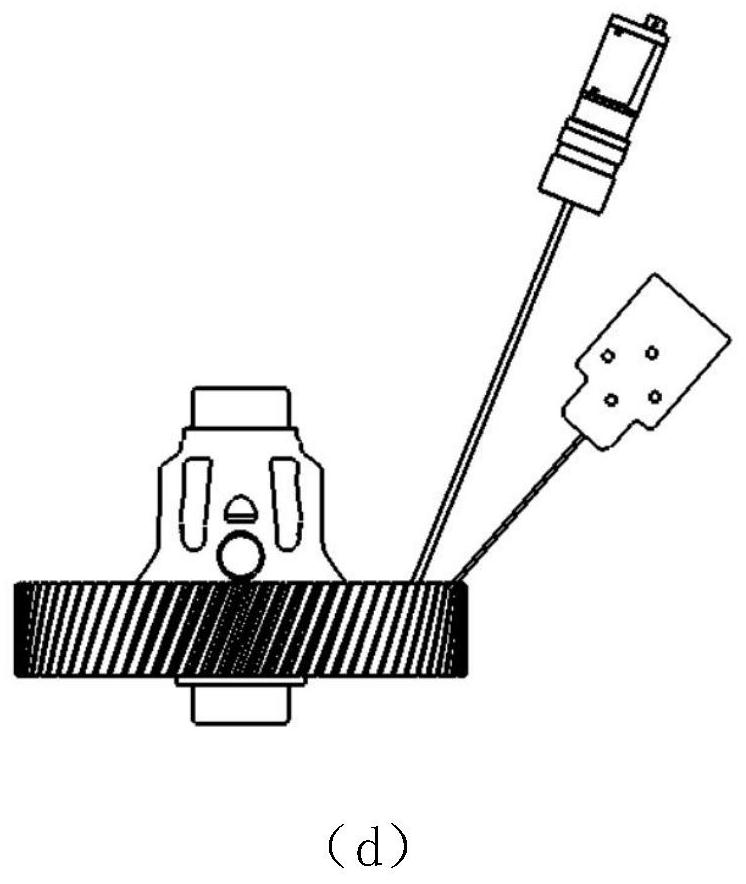

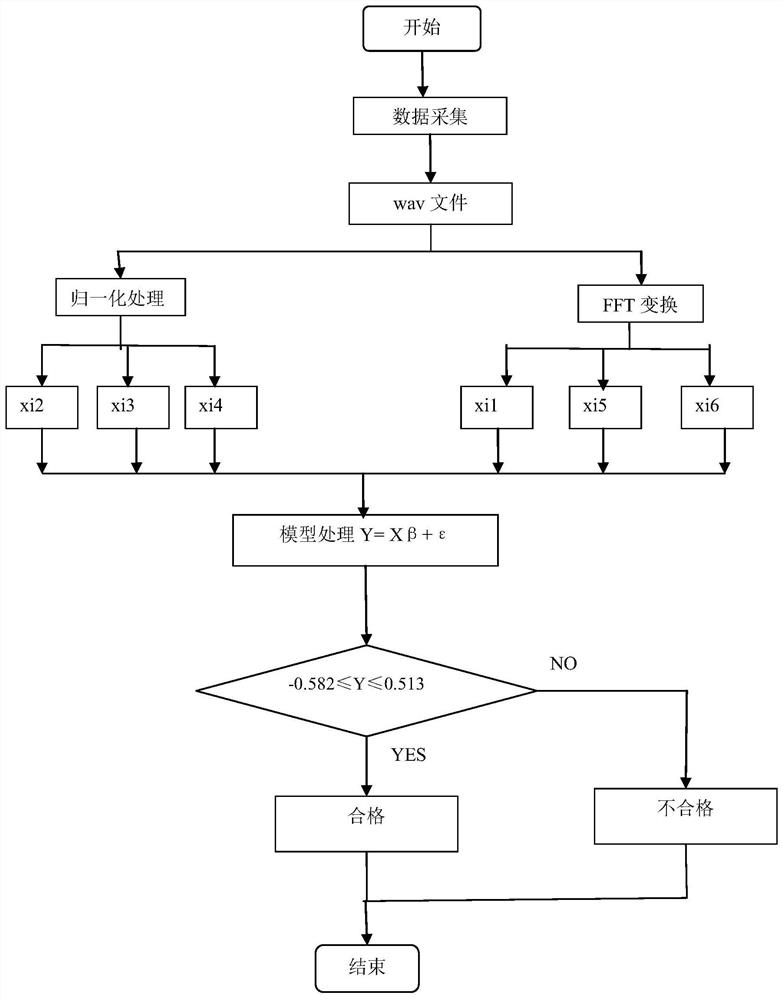

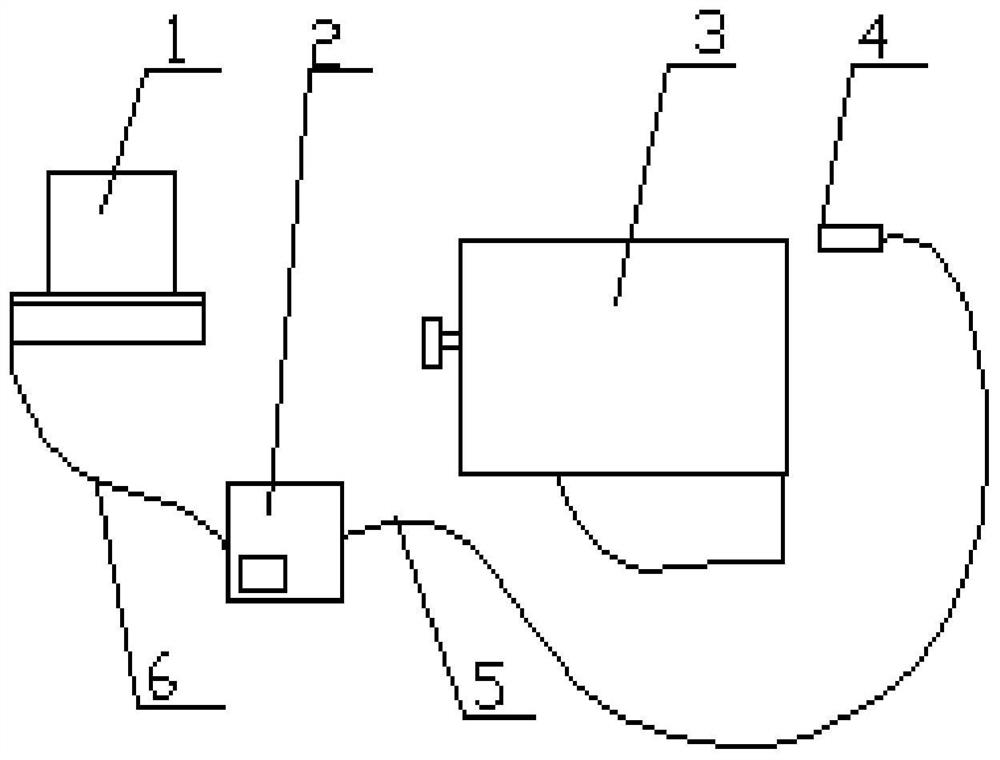

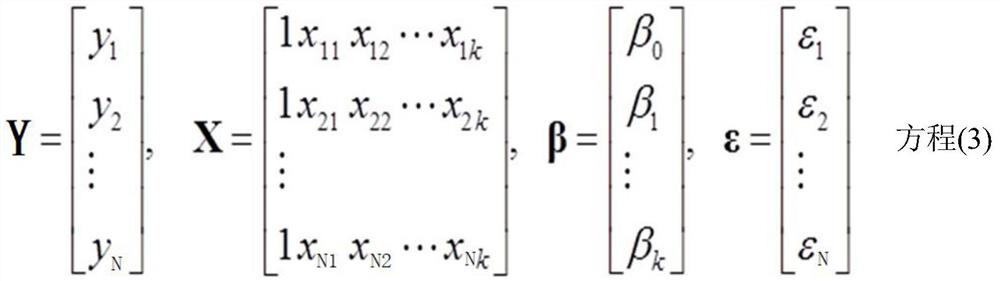

Diesel engine gear abnormal sound identification method based on wav file

PendingCN113609692AImprove accuracyImprove adaptabilityDesign optimisation/simulationComplex mathematical operationsNoiseGear wheel

The invention discloses a diesel engine gear abnormal sound recognition method based on a wav file. The method comprises the following steps step 1, arranging a noise sensor (4) above a diesel engine (3) to collect a wav noise audio file; step 2, transmitting the wav noise audio file to a computer (1) through a signal recorder (2); step 3, collecting wav noise audio files of N diesel engine samples, and recording gear abnormal sound fault states corresponding to the wav noise audio files; step 4, establishing a gear abnormal sound recognition model based on the N wav noise audio files, wherein the input of the gear abnormal sound recognition model is the wav noise audio files, and the output of the gear abnormal sound recognition model is a judgment value Y; and step 5, inputting any wav noise audio file of the diesel engine into the gear abnormal sound recognition model, and judging whether the diesel engine is qualified or not according to the judgment value Y. According to the invention, the on-line product qualification condition can be checked in real time during diesel engine production, the troubleshooting accuracy is high, and the production rate of the diesel engine is not affected.

Owner:上海新动力汽车科技股份有限公司

Plastic heat riveting device for car lights

The invention relates to a plastic hot riveting device for an automobile lamp. A workbench is provided with a lamp body positioning mechanism, a press riveting mechanism, a rivet head grabbing mechanism and a heating mechanism. The lamp body positioning mechanism comprises a push air cylinder, a lamp body positioning base and a floating positioning base. The push air cylinder installed on the workbench is connected with the lamp body positioning base. The floating positioning base is connected with the lamp body positioning base and arranged at the upper portion of the lamp body positioning base. A rivet head positioning plate on the floating positioning base is borne on a lower elastic body. The press riveting mechanism comprises a rivet pressing air cylinder, guide columns and a rivet pressing mechanism, wherein the rivet pressing air cylinder is connected with the rivet pressing mechanism. A pressing base of the rivet pressing mechanism is provided with pressing columns and air blowing pipes, and elastic push rods connected to the pressing base are opposite to the rivet head positioning plate. The rivet head grabbing mechanism comprises a support, a lifting rod and a movable rod which are connected. The heating mechanism comprises a heating furnace and a rotary disc, and the heating furnace and the rotary disc are fixed to the workbench. The plastic hot riveting device is reasonable in structure, rapid hot riveting and cooling can be achieved during multi-point riveting, the riveting quality can be ensured, and the riveting efficiency can be improved as well.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

Moisturizing core storing frame

ActiveCN102602604AAvoid Strength LossAvoid breakingLiving organism packagingExternal framesEngineeringStructural engineering

The invention relates to a moisturizing core storing frame which comprises a core frame which is provided with a layer of core plates or a plurality of layers of core plates for accommodating sand cores; the core plate is provided with a cover body; a storing space which is used for accommodating sand cores is formed between the cover body and the core plate; and the core frame is provided with a vacuum device which is communicated with the storing space. For the sand core with high storing environmental requirements, through the moisturizing core storing frame provided by the invention, the condition that the strength of the sand core is lowered and the sand core is fractured caused by that the sand core absorbs moisture is avoided, so that the production beat can not be influenced, the sand core storing time can be prolonged, and the sand core performance can not be influenced; and through the moisturizing core storing frame, the sand core storage is not limited in a constant-temperature constant-moisture room.

Owner:SUZHOU MINGZHI TECH

Automatic pre-lithiation method for industrial application of lithium battery and preparation method

PendingCN113725495AImprove compatibilitySolve the problem of prerationalizationFinal product manufactureLi-accumulatorsProduction linePhysical chemistry

The invention relates to an automatic pre-lithiation method for industrial application of a lithium battery and a preparation method. A lithium source pre-embedded with lithium is applied to materials in the assembling and packaging stages. Sealing is conducted quickly, then the standing formation time ranges from 24 h to 48 h, high-quality pre-physicochemical can be achieved, and meanwhile the production takt is not affected. The pre-lithiation material and the processing steps are all concentrated to the final assembling and packaging link of the lithium battery in a lithium battery production line, so that the time for the pre-lithiation process to be in contact with water and oxygen in the environment is shortest, meanwhile, the compatibility to the production line is highest, and the influence on the production takt is minimum or completely not influenced. According to the method disclosed by the invention, the lithium source material required by pre-lithiation is not applied to a positive plate, a negative plate and a diaphragm in a previous pulping process and a flaking process of the lithium battery, but is applied to a subsequent assembling and packaging process. When the materials used in the subsequent assembling and packaging process are applied, a lithium source pre-embedded with lithium can be stabilized.

Owner:慈溪斯昂尼电池有限公司

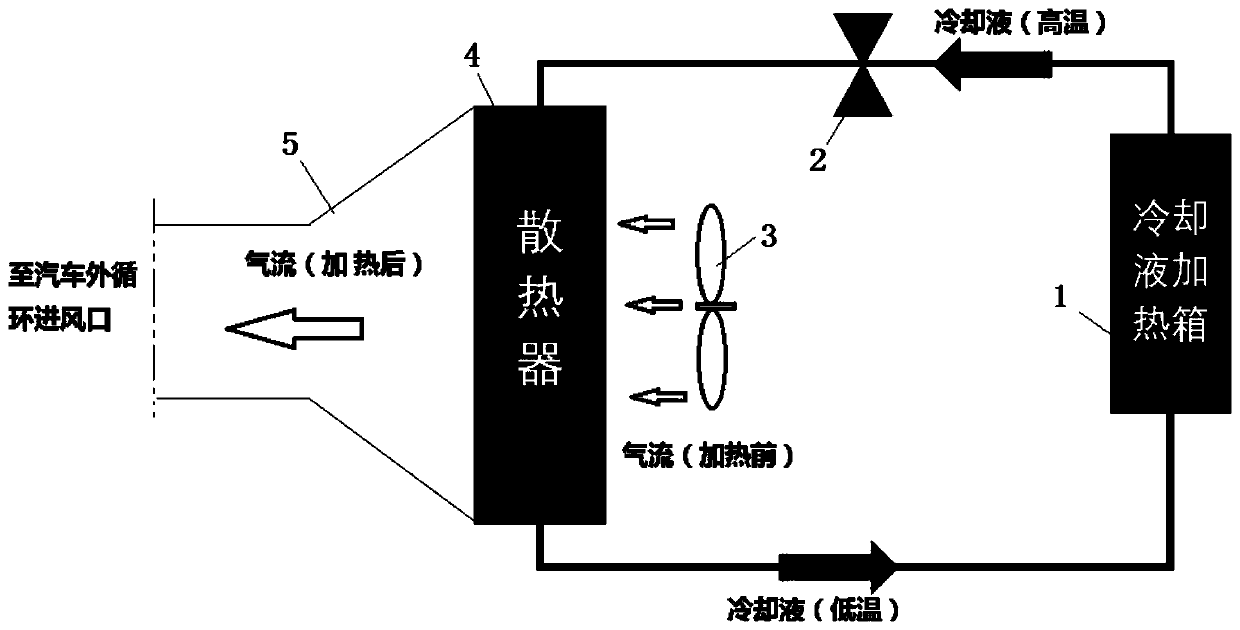

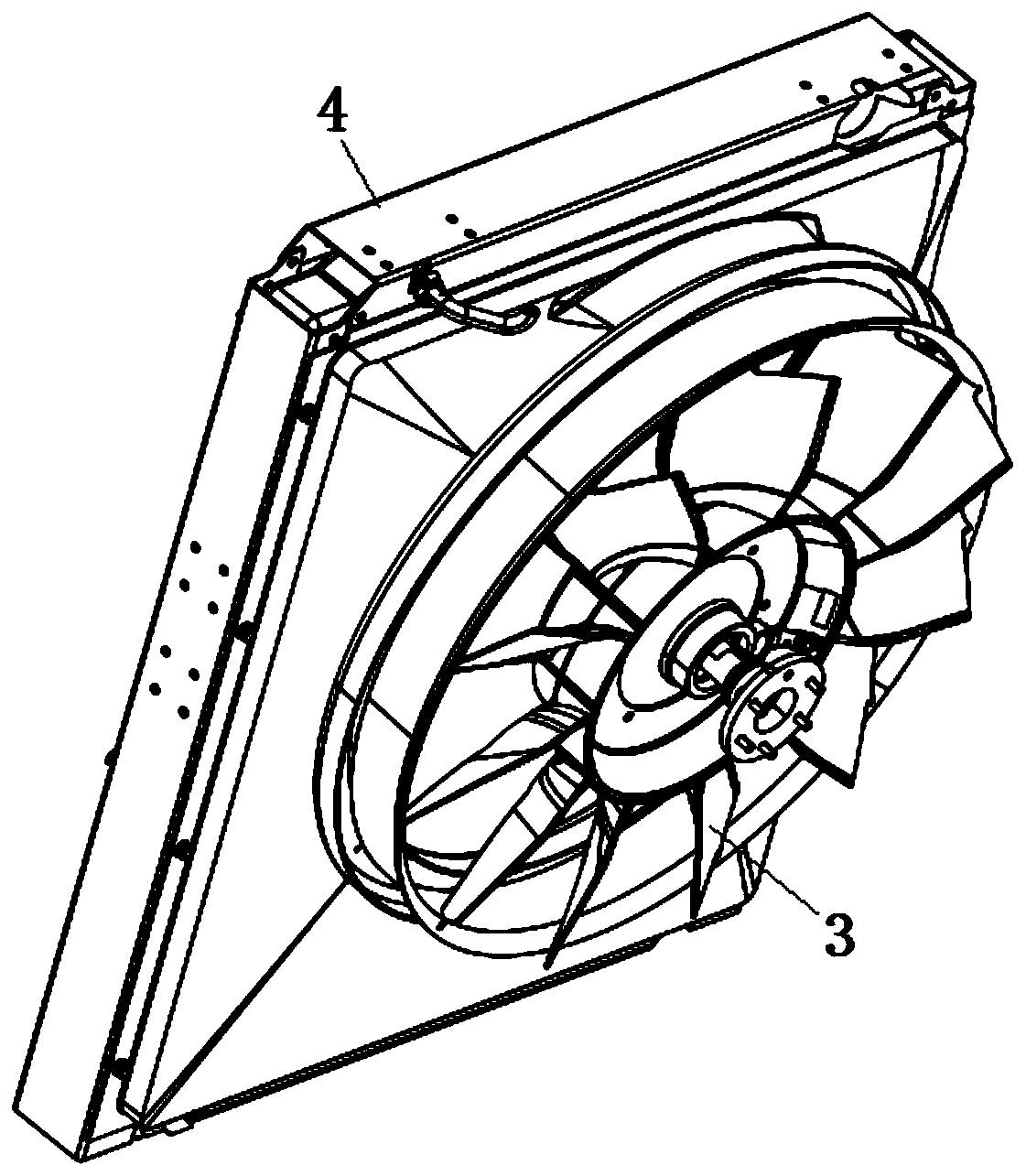

Device and method for detecting automobile air-conditioning system in low-temperature environment

PendingCN111422029ASmall footprintQuick and easy detectionAir-treating devicesVehicle heating/cooling devicesAutomotive engineeringMechanical engineering

The invention relates to a device and method for detecting an automobile air conditioning system in a low-temperature environment. The device comprises an external hot air source, wherein the externalhot air source is connected with an automobile air conditioner external circulation air inlet through an air duct, and hot air of the external hot air source is introduced into the automobile air conditioner external circulation air inlet through the air duct to provide hot air for an automobile air conditioner. The external hot air source is connected with the external circulation air inlet of the automobile air conditioner through the air duct and provides hot air for the automobile air conditioner, and it is guaranteed that the automobile air conditioner system can be started in a low-temperature environment to detect functions of the system. The occupied space is small, detection is convenient and rapid, and the production takt is not influenced.

Owner:DONGFENG COMML VEHICLE CO LTD

General assembly tray for improving loading efficiency of whole vehicle seat and method thereof

PendingCN113859396AIntegrity and aesthetics guaranteedImprove convenienceVehiclesAutomotive engineeringMechanical engineering

The invention discloses a general assembly tray for improving the loading efficiency of a whole vehicle seat. The final assembly tray comprises a tray bottom plate, and a first blocking pipe, a second blocking pipe, a third blocking pipe, a fourth blocking pipe, a fifth blocking pipe and a sixth blocking pipe are rotatably installed on one side of the tray bottom plate; the general assembly tray further comprises canvas; the horizontal pipes of the fourth blocking pipe, the fifth blocking pipe and the sixth blocking pipe penetrate through the canvas; the longitudinal pipes of the first baffle pipe, the second baffle pipe and the third baffle pipe are respectively connected with a first gas spring, a second gas spring and a third gas spring; the general assembly tray can be used for carrying whole vehicle seats (including driver seats and passenger seats), backrests (rear-row split type backrests or rear-row integrated backrests), rear-row seat cushions and the like in a classified mode, and the problems of indentation, damage and the like caused by mutual scraping, collision and the like in the transportation process can be avoided; the appearance integrity and attractiveness are ensured, the production takt of workers is not affected, and meanwhile operation convenience is improved.

Owner:王志伟

A kind of trolley circulation conveying equipment and conveying method thereof

ActiveCN105059859BReduce in quantitySolving Ergonomic IssuesMechanical conveyorsEngineeringErgonomics in Canada

The invention discloses a tackle circulating transporting device and a conveying method thereof. The device comprises a tackle workpiece locking external force device, a tackle workpiece loosening external force device, a tackle transferring-to-clamp switching device, a tackle control mechanism, a tackle movement mechanism, rails and multiple tackles arranged on the rails. The rails comprise the movable rail and the fixed rail. The fixed rail comprises parallel conveying rail bodies and return rail bodies. A movable rail switching device is arranged between the movable rail and the fixed rail. The tackles are distributed on various stations of a production line, the space of a plant is not independently occupied, no lifting mechanism is arranged, the scale space in the height direction is reduced, and the ergonomic problem of an existing reciprocating conveying mechanism is solved. The tackle circulating transporting device can directly work on the tackles without affecting the production takt, the number of the tackles needed for circulating conveying is small, conveyance and return of the tackles can be achieved through the same tackle movement mechanism, and therefore tackle circulation is achieved, and the utilization efficiency of the conveying device is improved.

Owner:四川成焊宝玛焊接装备工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com