Detection device with mistake-proofing function

A detection device and functional technology, applied in the field of detection devices with error-proof function, can solve the problems of failure to fully guarantee the quality of the workpiece output, the degree of fatigue and the weakening of concentration, and the impact on the overall performance of the car, so as to avoid The effect of unqualified products flowing into the market, concentration relief, and detection of fatigue relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

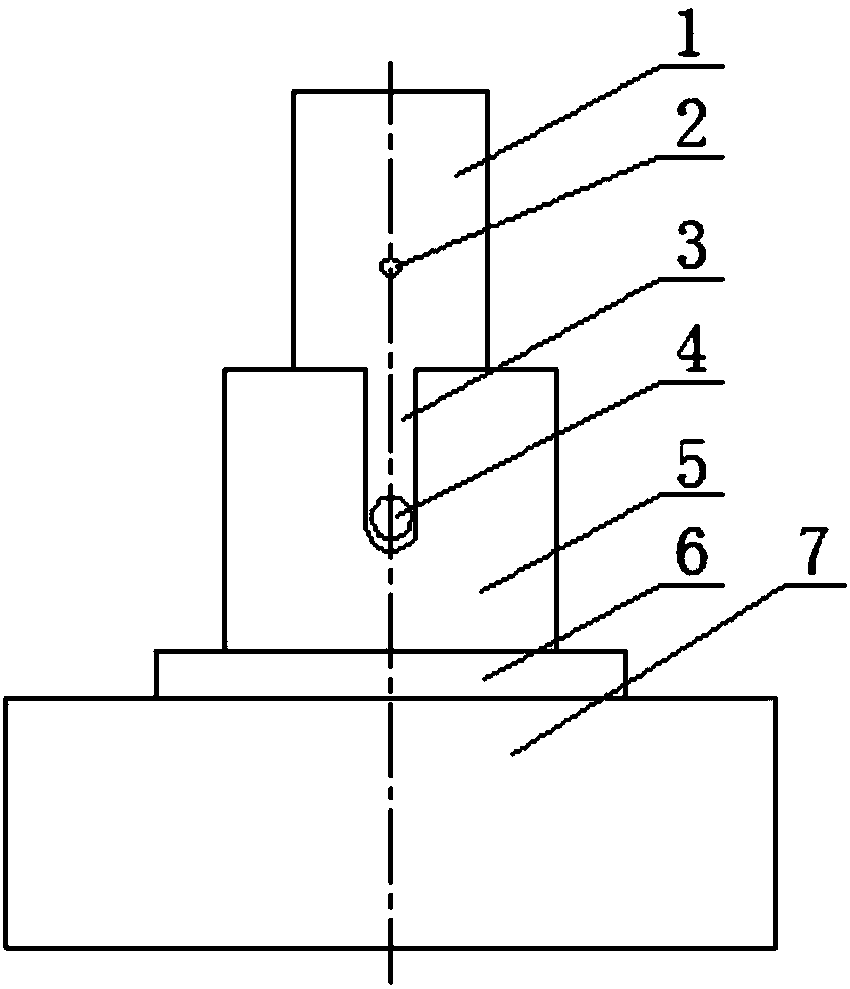

[0018] A detection device with an error-proof function, comprising a lower mold mounting platform 7, a riveting mold base 5, a riveting mold core 1 and an optical sensor 10, a riveting mold base is installed on the upper surface of the lower mold mounting platform, and a riveting mold base is installed on the lower mold mounting platform and the riveting mold The gasket 6 is coaxially inserted between the mold seats.

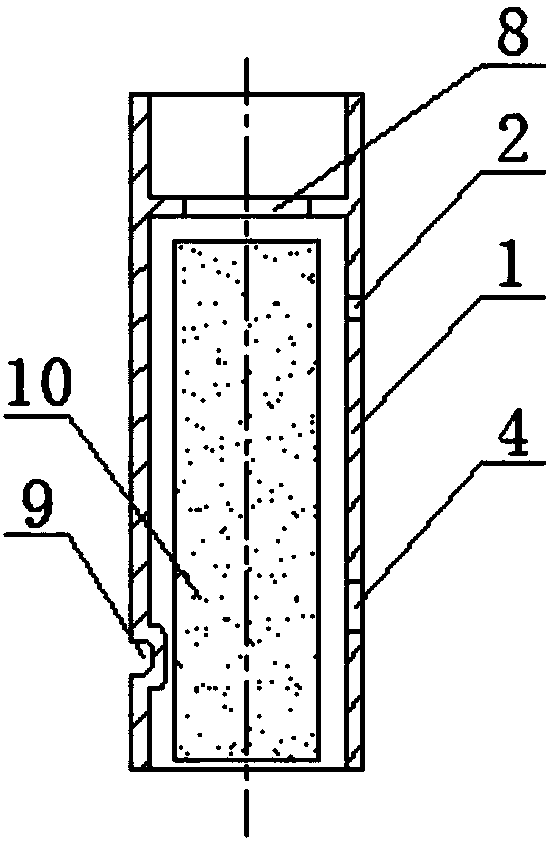

[0019] A riveting mold core is coaxially inserted in the riveting mold base, and a mounting slot 9 is formed at the bottom of the riveting mold core, through which the riveting mold core is stuck in the riveting mold base. A coaxial stepped hole 8 is made inside the riveting mold core, the upper h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com