Anti-fault detecting device used in automated assembly production devices

A detection device and production equipment technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., to achieve the effect of improving the pass rate of one assembly, not affecting the production cycle, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

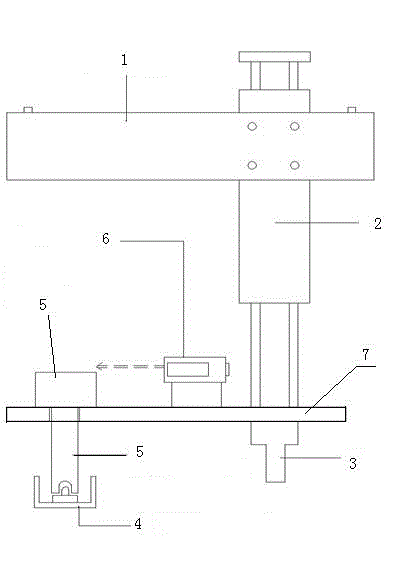

[0013] An error-proof detection device applied in automatic assembly production equipment, the front end of a horizontal cylinder 1 is connected downwards with a vertical cylinder 2, and the vertical cylinder 2 is connected with a fixed plate 7, a vacuum suction mold 3 and a set of laser sensor The detection device for measuring the presence or absence of assembly parts is installed on the fixed plate 7 in parallel, and the fixed plate 7 is connected to the vertical cylinder 2 upwards. The distance between the assembled workpieces is equal; the detection device is as follows: there is a hole at one end of the fixed plate 7, and a T-shaped pin 5 is inserted in the hole, and the lower end of the T-shaped pin 5 can go deep into the position of the assembly, and the There is a laser sensing sensor 6 above which can sense the height 6 of the T-shaped pin;

[0014] working principle:

[0015] It can be seen from the accompanying drawings that the detection device and the vacuum suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com