A filter assembly air tightness automatic detecting device

An automatic detection and filter technology, applied in the direction of detecting the appearance of fluid at the leak point, using the liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of affecting the life of the engine, cumbersome manual operation, and easy to leak detection. , to achieve the effect of improving the qualification rate of one-time assembly, reducing workload and labor intensity, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

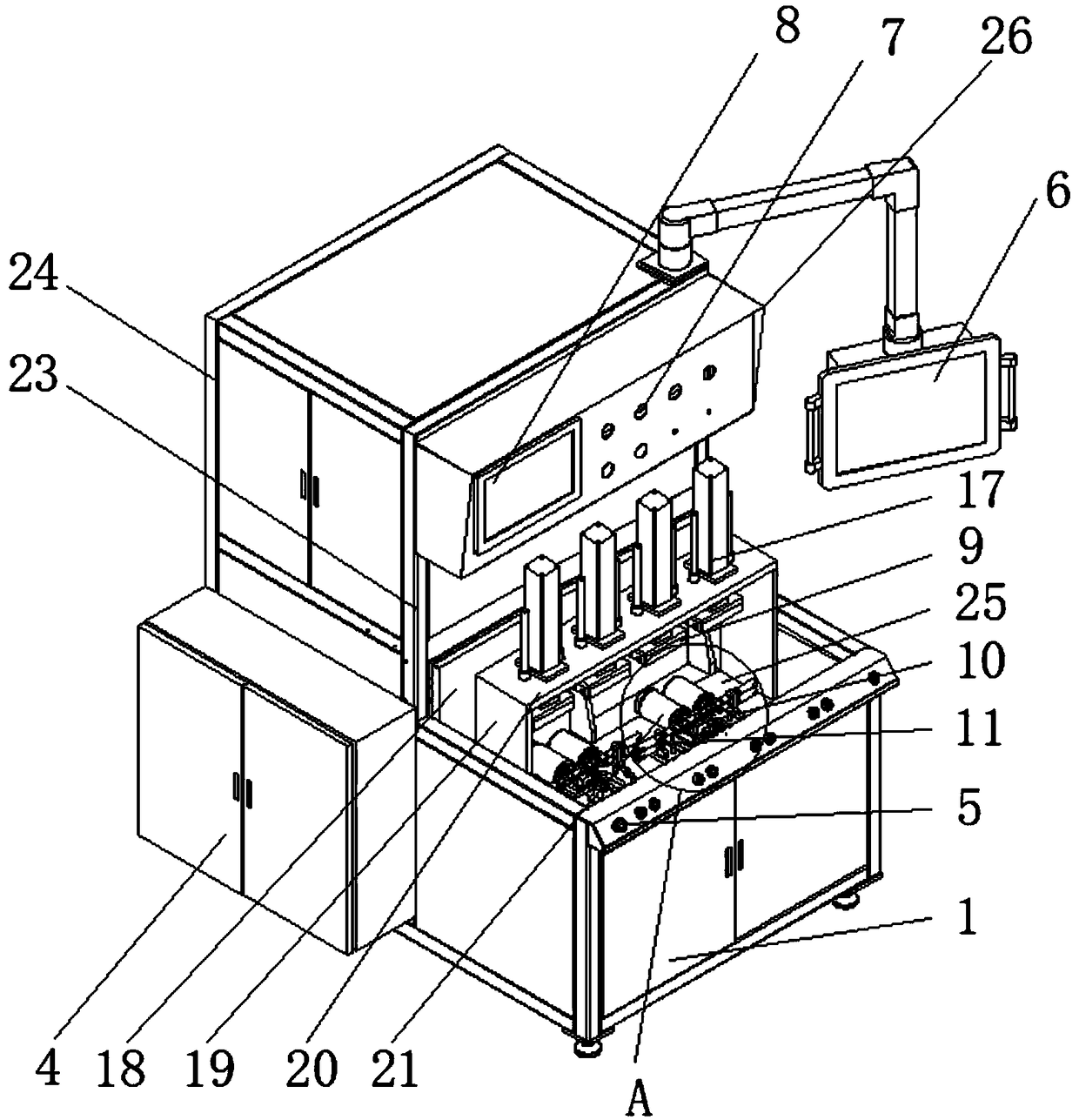

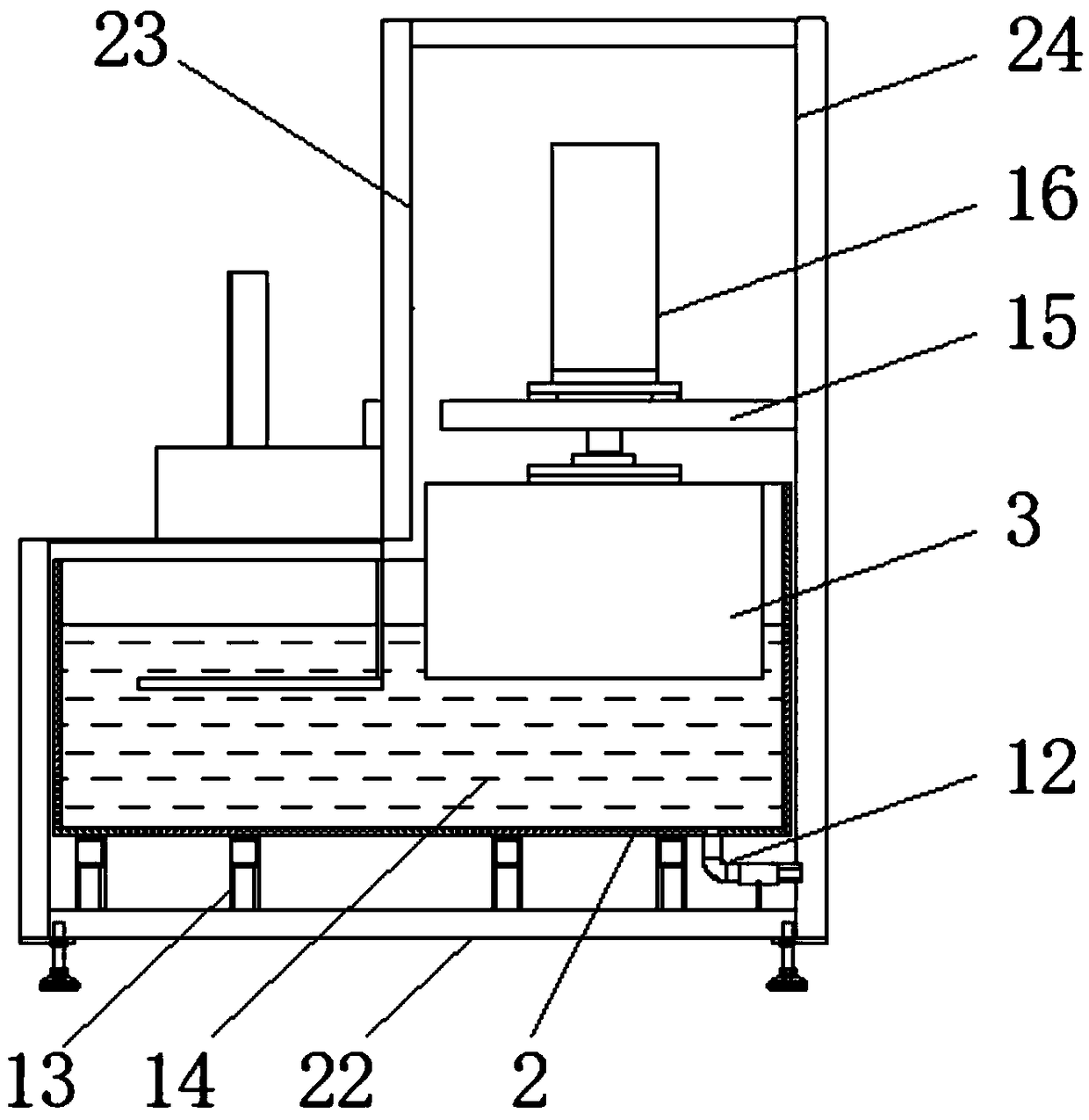

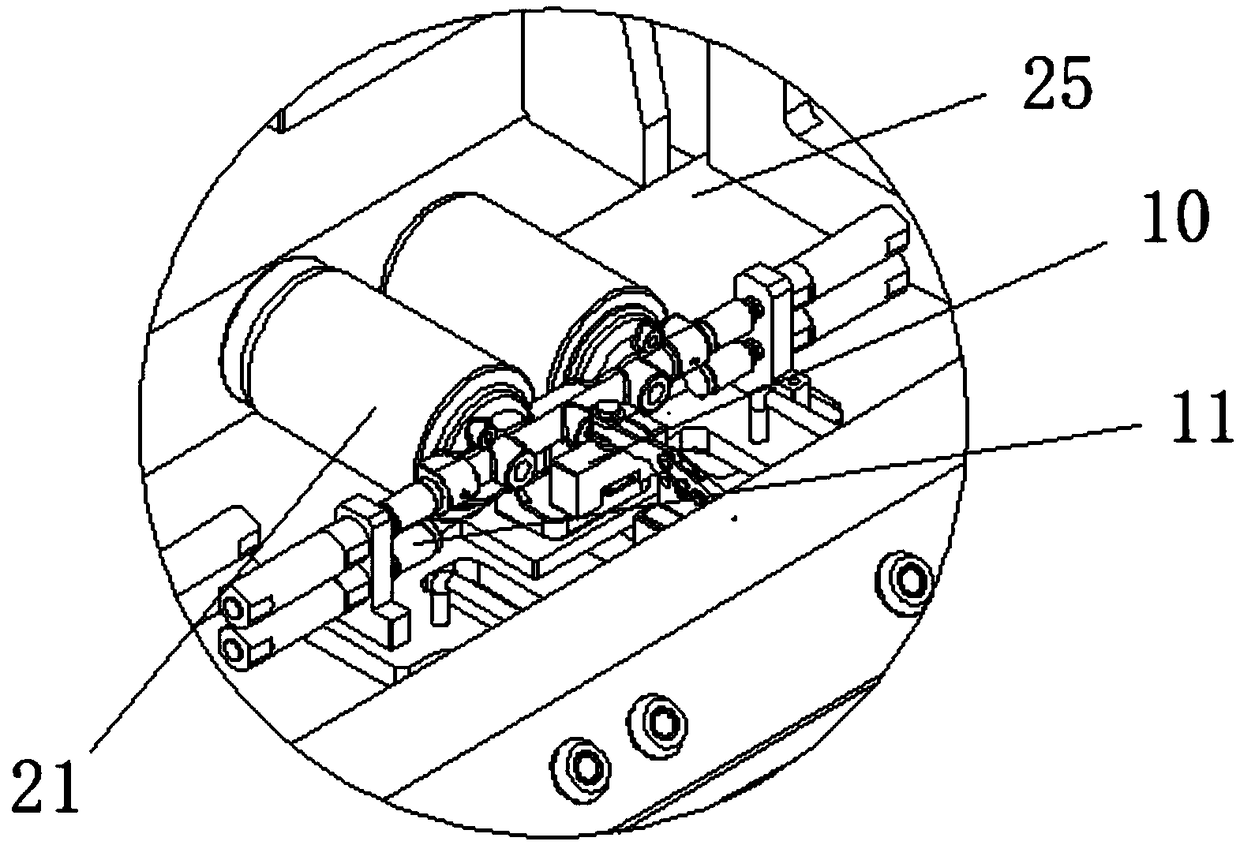

[0017] according to Figure 1-3 A filter assembly airtight automatic detection equipment shown in the figure includes a frame 1 and a filter assembly 21, one end of the frame 1 is bolted to a bottom plate 22, and one side of the bottom plate 22 is welded and fixed with a plurality of support blocks 13. A large water tank 2 is placed on one end of the support block 13, a first bracket 23 is welded and fixed on one side of the bottom plate 22, a fixing plate 18 is fixed on one side of the first bracket 23, and a reinforcing plate is fixed on one side of the fixing plate 18. plate 19, one end of the reinforcing plate 19 is bolted with the first cylinder fixing plate 20, the other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com